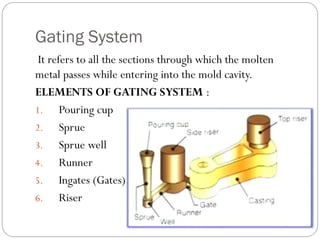

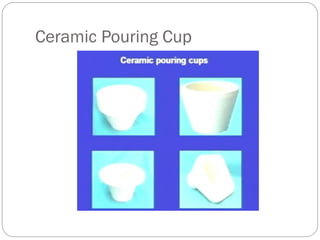

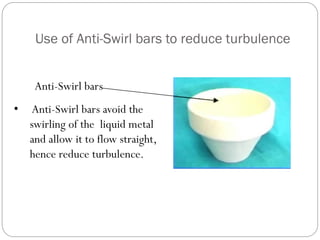

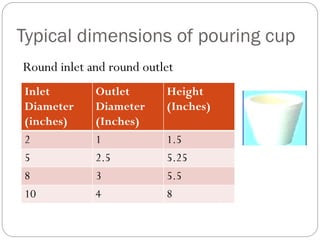

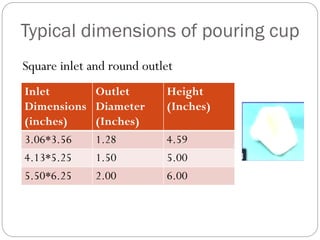

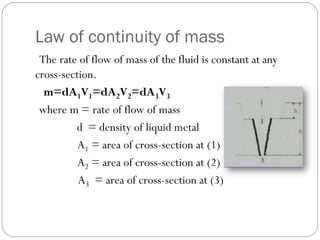

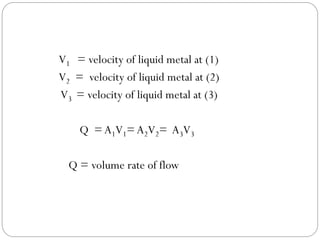

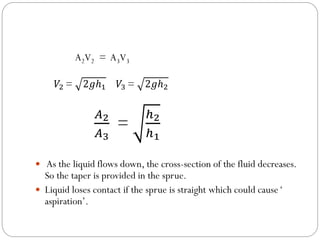

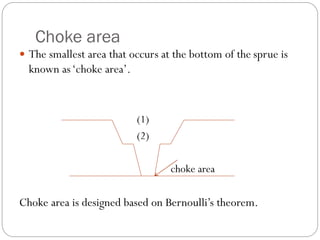

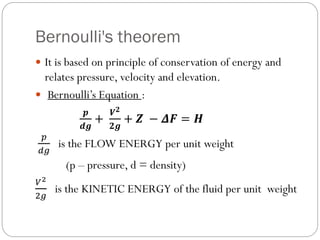

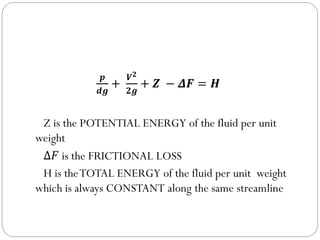

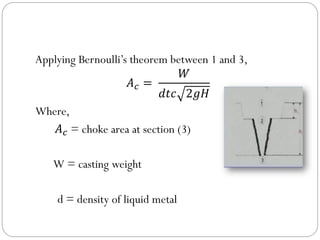

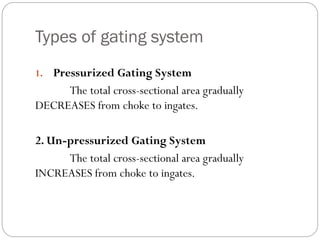

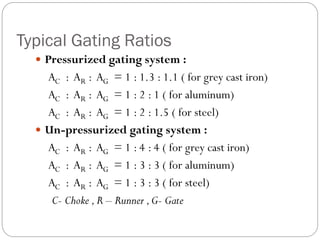

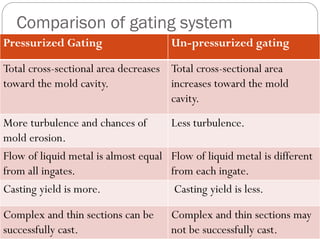

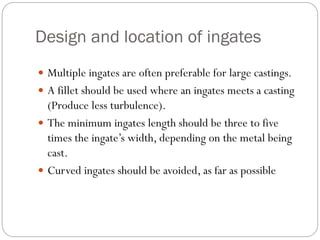

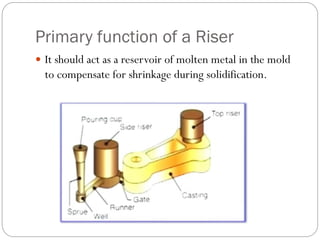

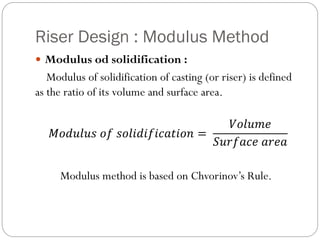

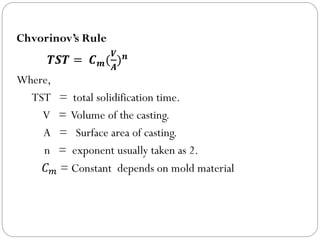

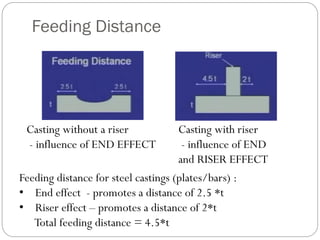

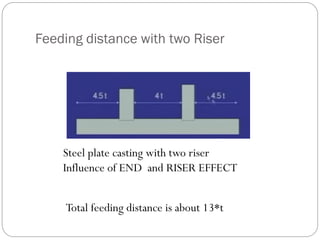

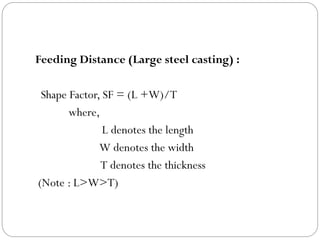

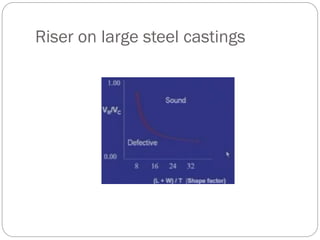

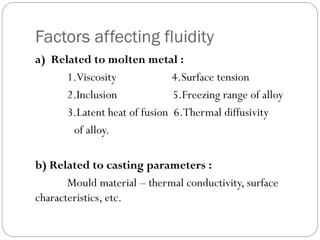

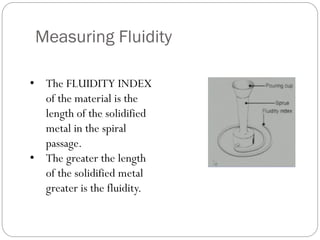

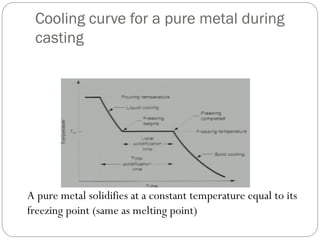

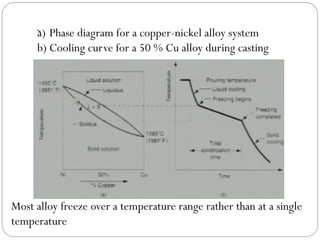

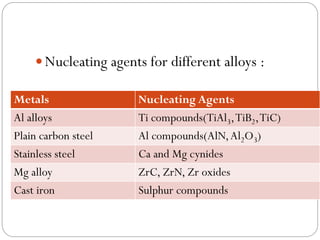

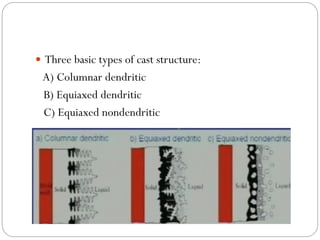

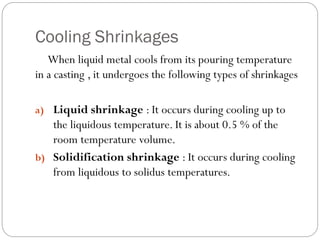

The document discusses the key elements of a gating system for metal casting, including the pouring cup, sprue, runner, ingates, choke, and riser. It explains the functions of each element in filling the mold cavity and regulating metal flow. Design considerations for elements like the pouring cup, sprue, choke, runner, and riser are provided based on principles like Bernoulli's theorem and the law of continuity of mass. Factors that influence metal fluidity and the solidification process like nucleation, grain structure, and shrinkage are also summarized.