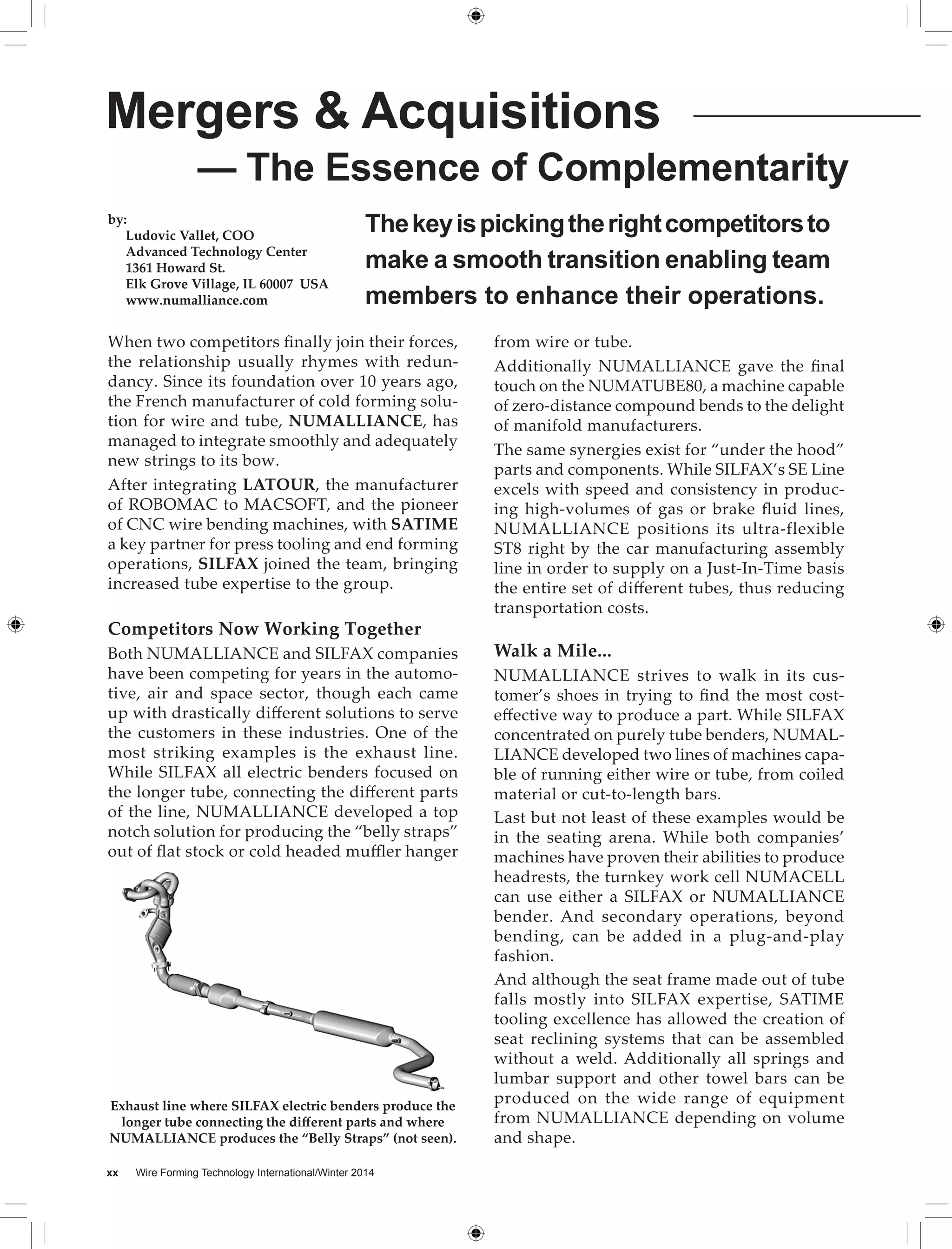

NUMALLIANCE has successfully integrated new companies over the past 10 years to expand its capabilities in cold forming solutions for wire and tube. It recently merged with its competitor SILFAX, bringing increased tube expertise. While the companies previously competed in automotive and aerospace, they take different approaches that are now complementary within NUMALLIANCE. For example, SILFAX focuses on longer tube production while NUMALLIANCE develops solutions for other parts. The key to a successful merger is identifying the right competitors to combine capabilities while allowing team members to enhance operations rather than causing redundancy.