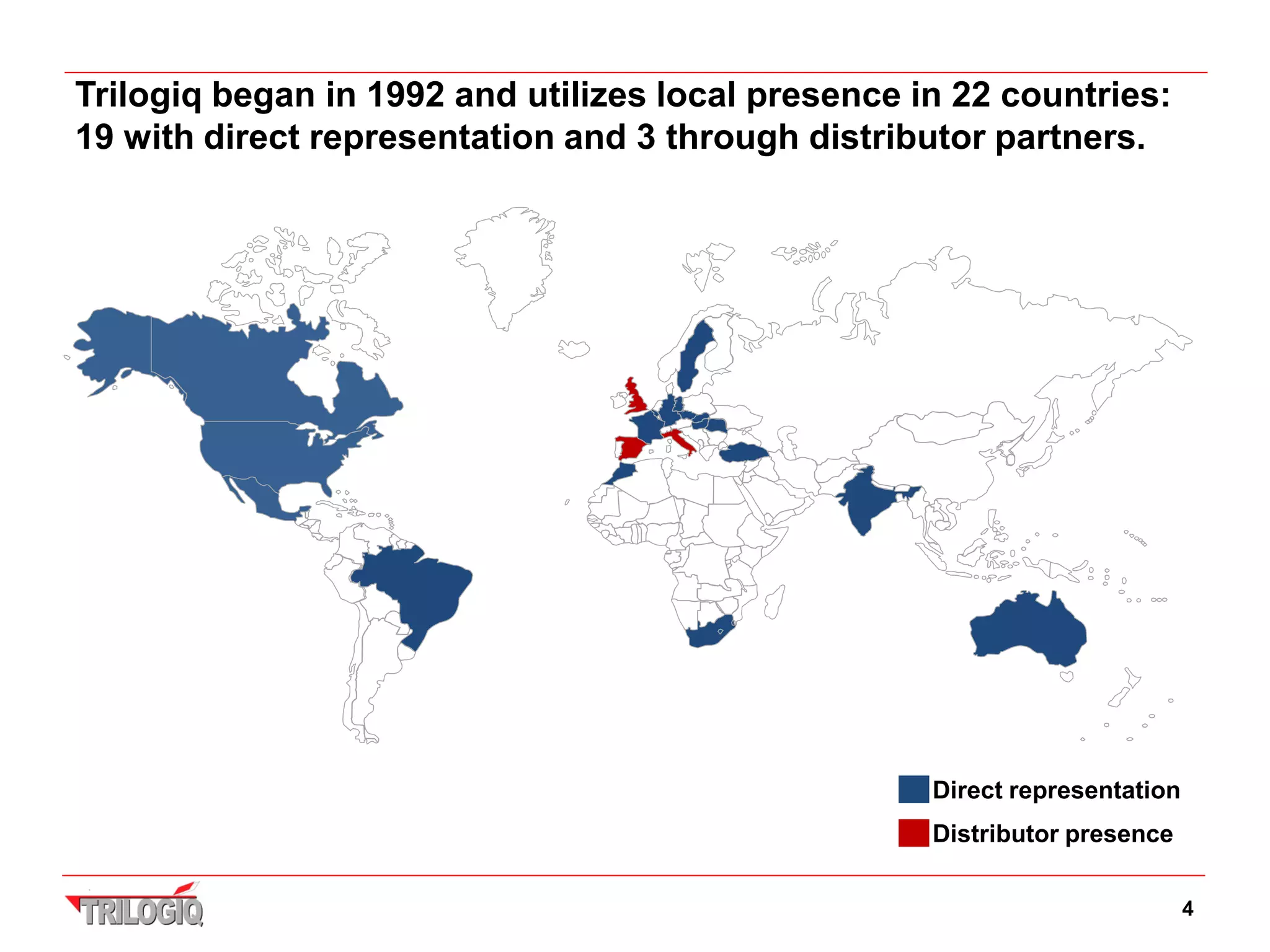

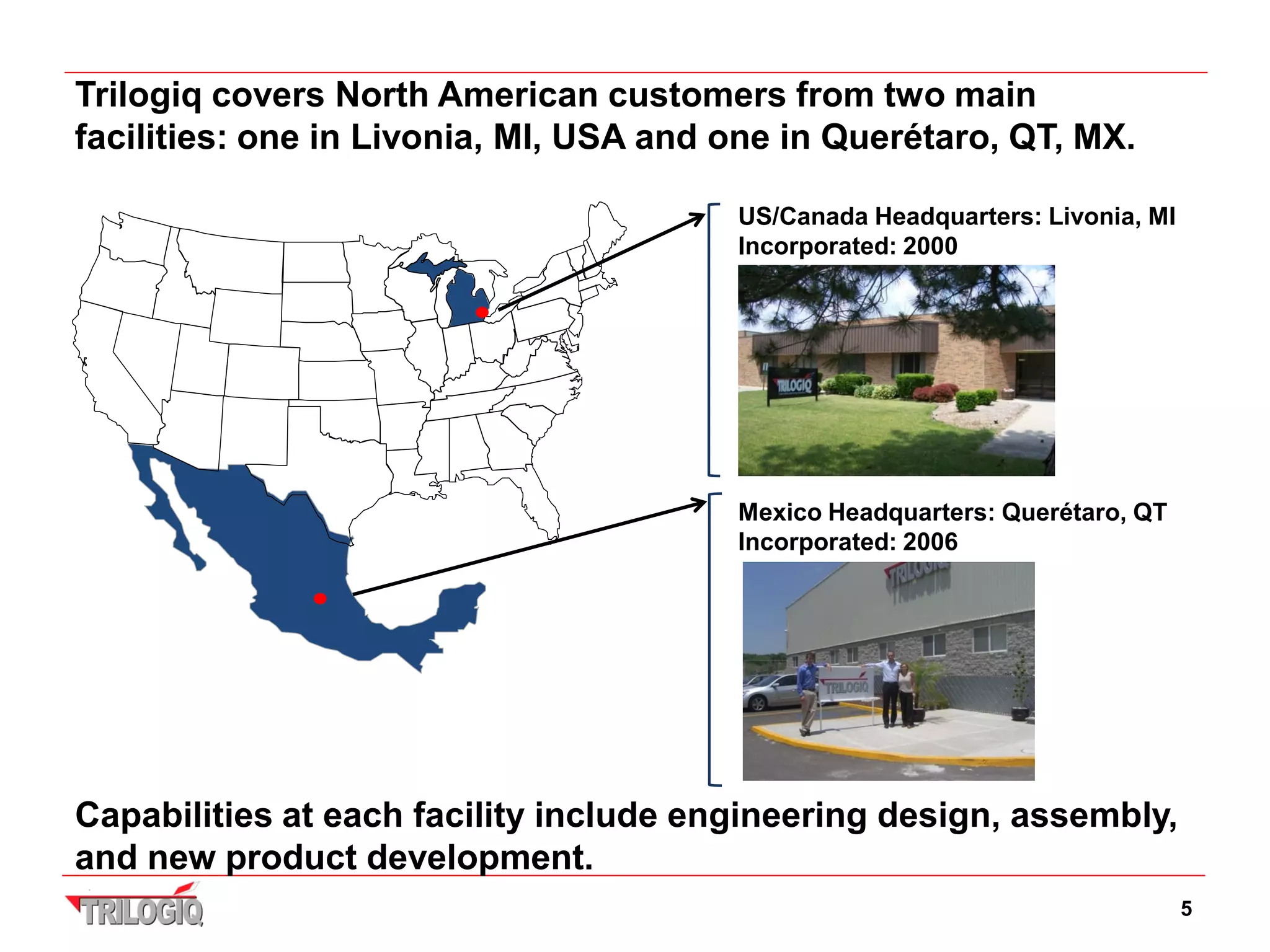

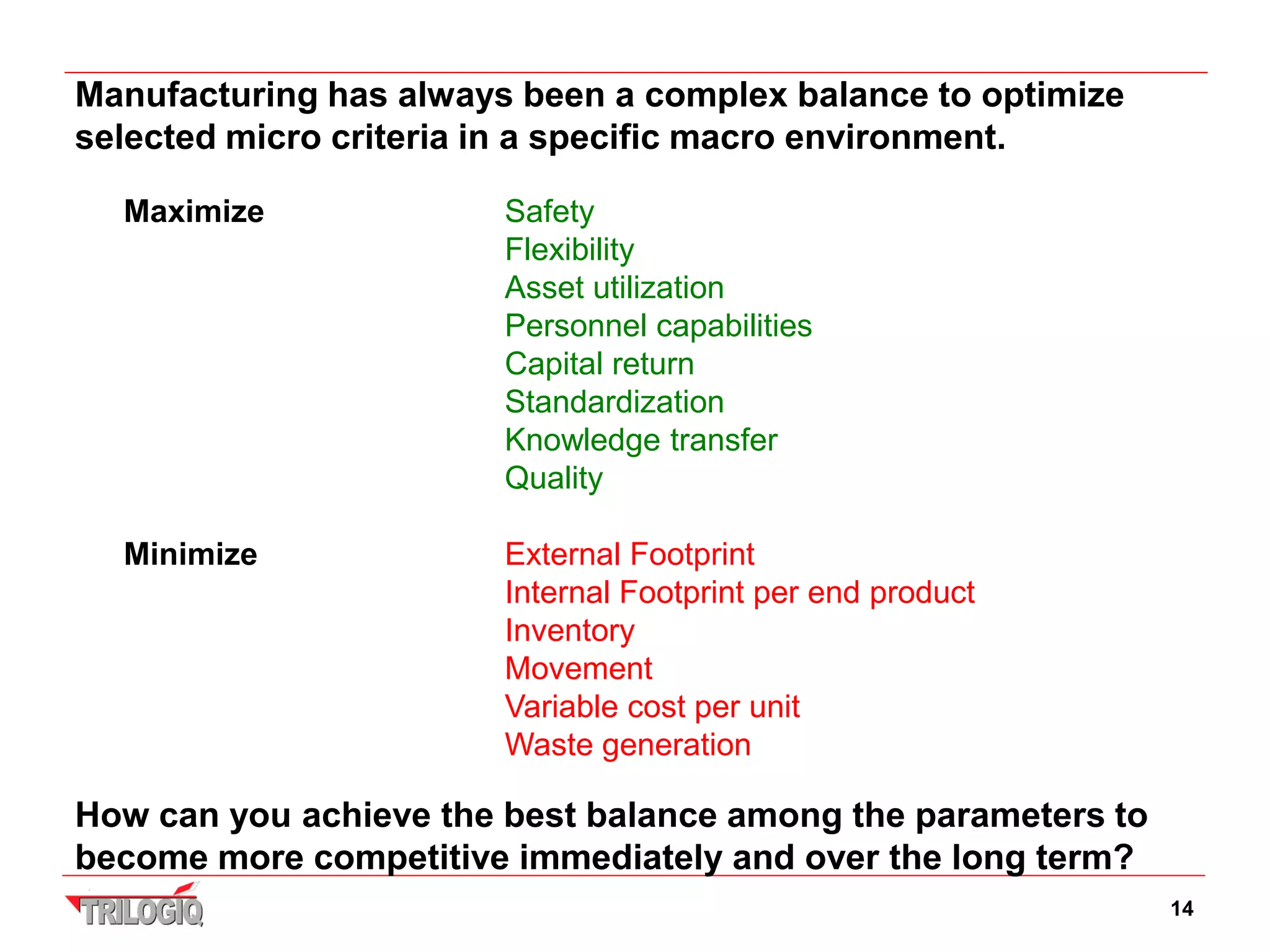

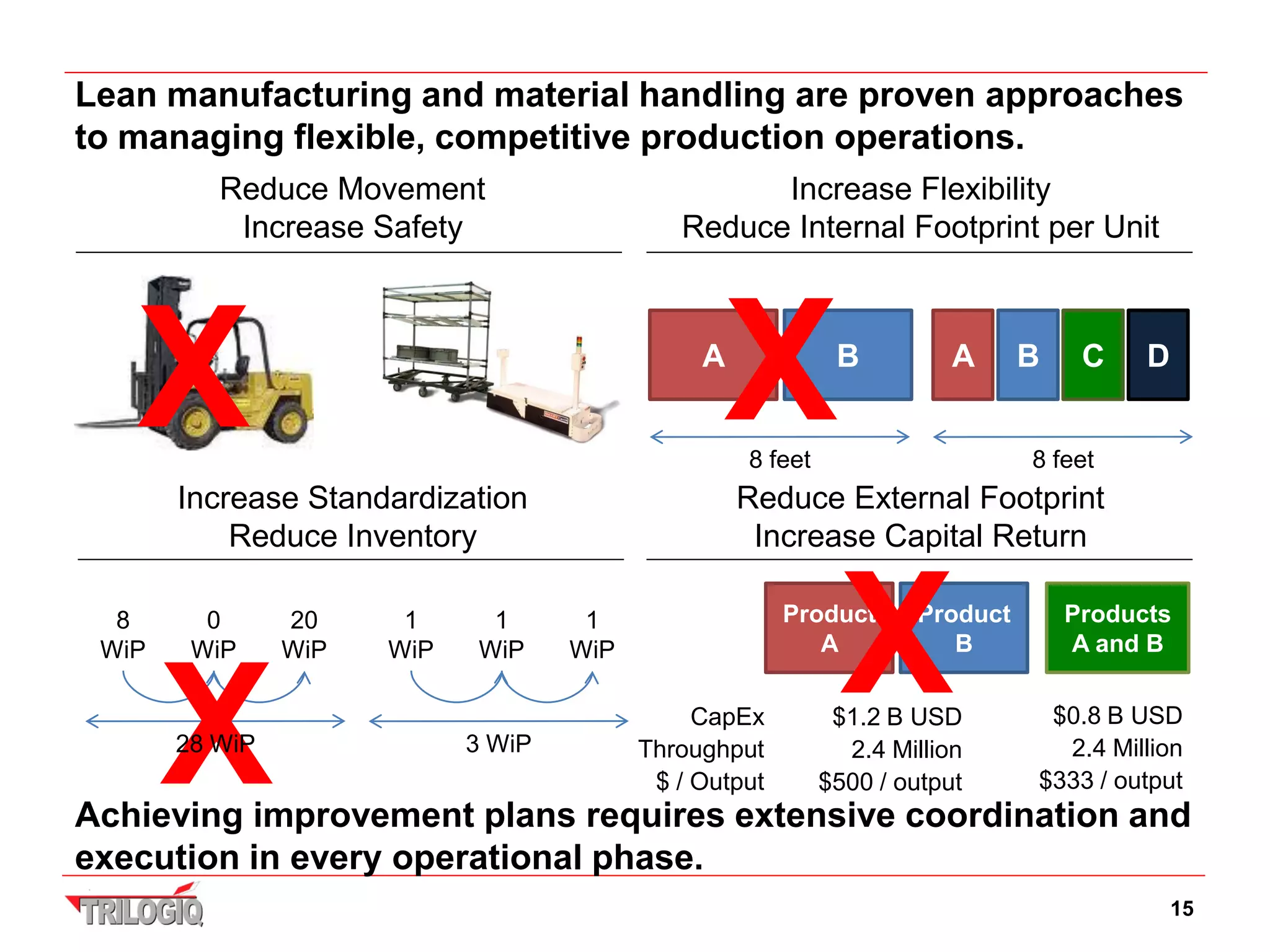

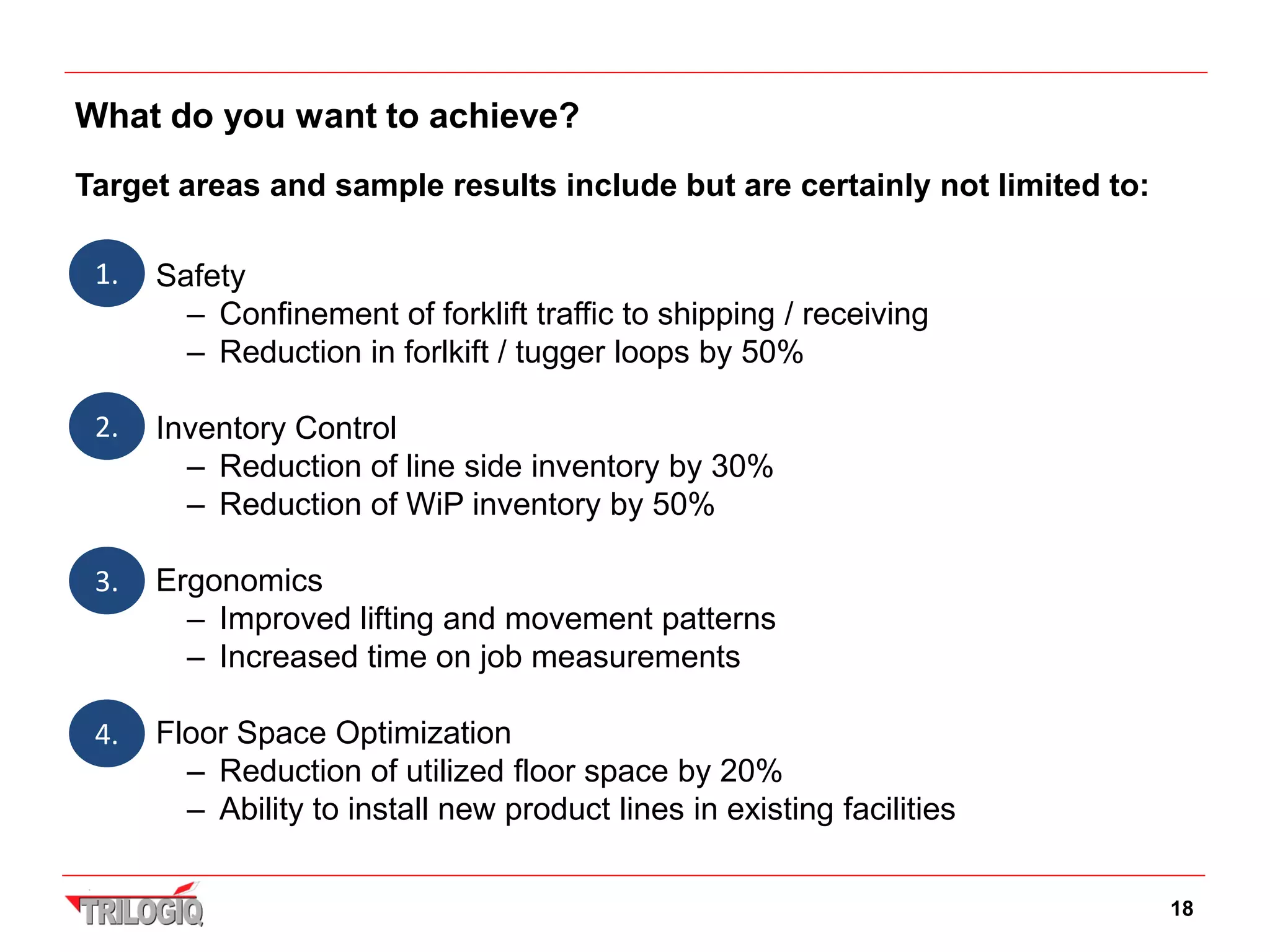

Trilogiq is a global material handling solutions provider founded in 1992 with facilities in North America and representation in 22 countries. They provide custom solutions to enable lean manufacturing and continuous improvement goals. Their solutions draw from various partners and cover industries like automotive, aerospace, electronics, and appliances. Trilogiq aims to help customers balance optimization criteria like safety, flexibility, and costs through proven lean approaches. They work as a bridge between customers' manufacturing concepts and successful implementation on the shop floor.