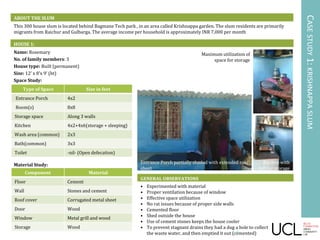

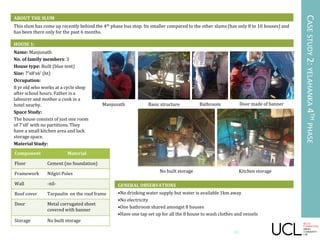

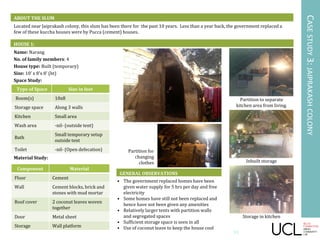

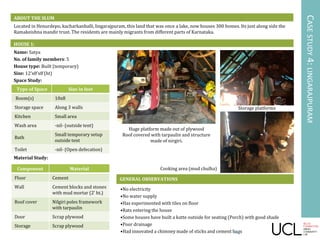

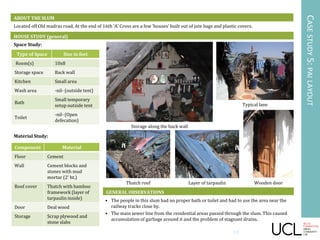

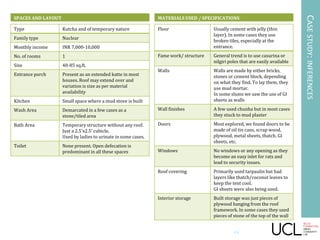

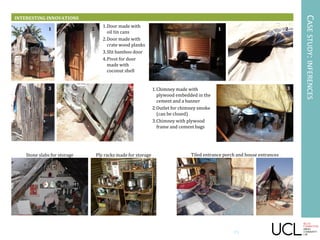

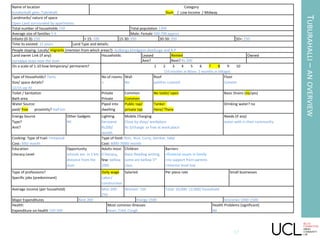

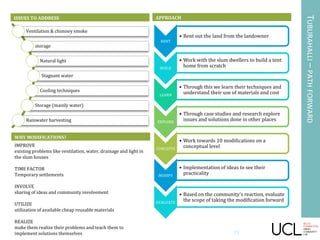

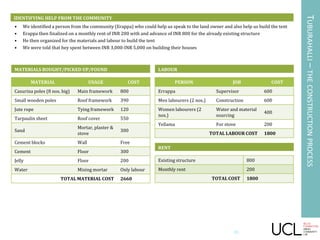

The document provides an overview of slum housing in India and Bangalore, with a focus on conducting case studies of specific slums to understand living conditions, construction techniques, and potential improvements. It describes 5 case studies of slums in Bangalore, including Krishnappa slum, Yelahanka 4th Phase slum, Jaiprakash colony slum, Lingarajpuram slum, and Pai Layout slum. For each case study, it examines the general observations about housing structure, materials used, amenities available, and innovations tried by residents to improve living conditions within their limited means.

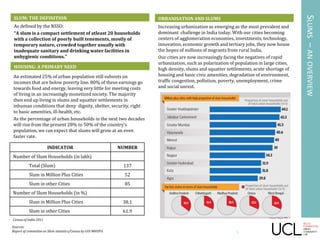

![SLUMS IN BANGALORE

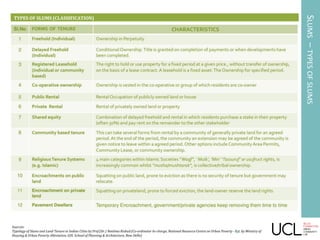

According to a 2012 report submitted to the World Bank by

Karnataka Slum Clearance Board, Bangalore has 862 slums

from total of around 2000 slums in Karnataka. It is estimated

that about 20% of Bangalore population reside in urban slums.

The families living in the slum are not ready to move into the

temporary shelters. 42% of the households migrated from

different parts of India and 43% of the households had

remained in the slums for over 10 years. The Karnataka

Municipality, works to shift 300 families annually to newly

constructed buildings. One third of these slum clearance

projects lack basic service connections, 60% of slum dwellers

lack complete water supply lines and share BWSSB water

supply.

FOCUS:BENGALURU

Source:

• "Major Slum Areas in Top Ten Cities of India". WalkThroughIndia. 13 July 2010.

Retrieved 22 October 2012.

• Teja, Bhanu. "Slum dwellers rehoused Bangalore – The SoftCopy". Iijnm.org. Retrieved

22 October 2012.

• "Water India Slums". India Sanitation Portal. Retrieved 22 October 2012.

• "Slum Dwellers Illegally Tap Board of Water Supply Bangalore's Supply".

Youthkiawaaz.com. 19 February 2011. Retrieved 22 October 2012.

• "All India figures at a glance" (PDF). Department of Economics and Statistics,

Government of Karnataka. Retrieved 1 November 2010.[dead

link]http://www.webcitation.org/5hhoB0jVy

SLUM POPULATION IN BANGALORE (10%)

OWNERSHIP OF NOTIFIED SLUMS

DISTRIBUTION OF RECOGNIZED SLUMS IN BANGALORE

SUBURB

NO. OF

SLUMS

NO. OF

HUTS

POPULATION

Gandhinagar 12 1901 9925

Chikkapete 6 1343 6956

Binnypete 13 1533 9105

Chamarajpete 22 5034 26439

Shantinagar 6 1233 6795

Basavanagadi 7 1276 5985

Yelahanka 13 3297 18696

Jayamahal 16 2096 13111

Malleswaram 24 4401 25233

Bharatinagar 20 1794 11166

Shivajinagar 1 60 350

Jayanagar 24 7302 42426

Rajajinagar 10 1866 13677

Varthur 23 5916 24468

Uttarahalli 34 14758 83020

TOTAL 231 53810 297352

10% (847,497 persons) of

Bangalore's population live

in Slums.

Karnataka Slum Clearance Board, 2008

7](https://image.slidesharecdn.com/a29ea150-da10-4252-948c-240670feb065-151006182757-lva1-app6892/85/06UCL_NeedAssessment_SlumHomes-7-320.jpg)