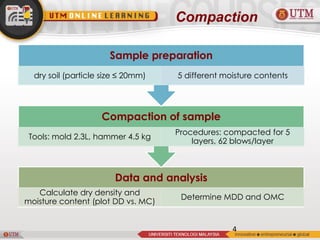

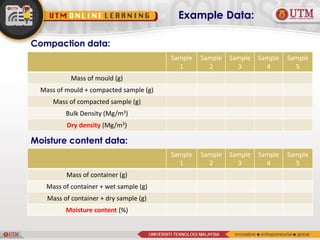

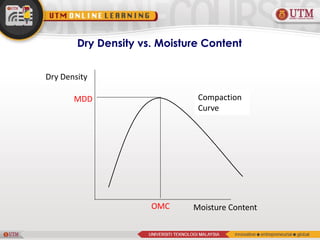

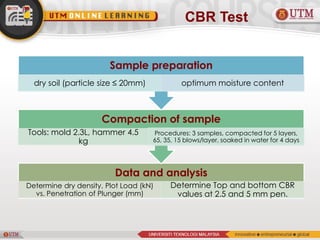

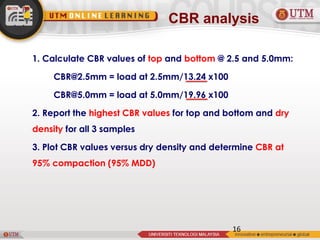

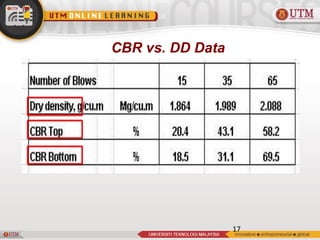

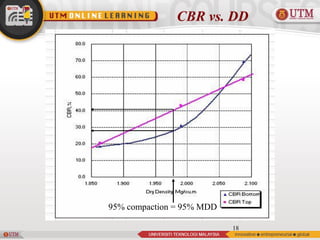

This document discusses procedures for compaction and California Bearing Ratio (CBR) tests to determine the strength and bearing capacity of soils. It describes the compaction test process to find maximum dry density and optimum moisture content by compacting soil samples at different moisture contents. The CBR test process is also outlined, which involves compacting 3 samples at different densities and soaking them in water before measuring penetration resistance to calculate CBR values. Graphs of dry density versus moisture content and CBR versus dry density are used to analyze the results and determine CBR at 95% compaction.