00.222 - TSHD_HAM_310_jumboising.PDF

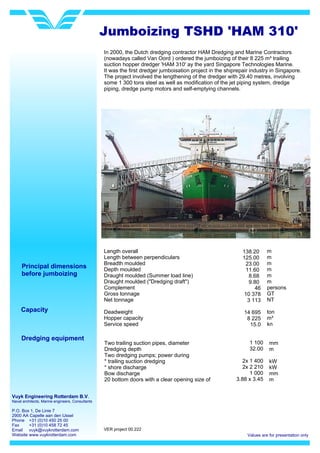

- 1. Vuyk Engineering Rotterdam B.V. Naval architects, Marine engineers, Consultants P.O. Box 1, De Linie 7 2900 AA Capelle aan den IJssel Phone +31 (0)10 450 25 00 Fax +31 (0)10 458 72 45 Email vuyk@vuykrotterdam.com Website www.vuykrotterdam.com Values are for presentation only Principal dimensions before jumboizing Jumboizing TSHD 'HAM 310' m m m m m m persons GT NT ton m³ kn Capacity Length overall Length between perpendiculars Breadth moulded Depth moulded Draught moulded (Summer load line) Draught moulded ("Dredging draft") Complement Gross tonnage Net tonnage Deadweight Hopper capacity Service speed In 2000, the Dutch dredging contractor HAM Dredging and Marine Contractors (nowadays called Van Oord ) ordered the jumboizing of their 8 225 m³ trailing suction hopper dredger 'HAM 310' ay the yard Singapore Technologies Marine. It was the first dredger jumboisation project in the shiprepair industry in Singapore. The project involved the lengthening of the dredger with 29.40 metres, involving some 1 300 tons steel as well as modification of the jet piping system, dredge piping, dredge pump motors and self-emptying channels. 138.20 125.00 23.00 11.60 8.68 9.80 46 10 378 3 113 14 695 8 225 15.0 Two trailing suction pipes, diameter Dredging depth Two dredging pumps; power during * trailing suction dredging * shore discharge Bow discharge 20 bottom doors with a clear opening size of Dredging equipment 1 100 32.00 2x 1 400 2x 2 210 1 000 3.88 x 3.45 mm m kW kW mm m VER project 00.222

- 2. Vuyk Engineering Rotterdam B.V. Naval architects, Marine engineers, Consultants P.O. Box 1, De Linie 7 2900 AA Capelle aan den IJssel Phone +31 (0)10 450 25 00 Fax +31 (0)10 458 72 45 Email vuyk@vuykrotterdam.com Website www.vuykrotterdam.com Values are for presentation only Principal dimensions after conversion Jumboizing TSHD 'HAM 310' 167.60 154.31 23.00 11.60 8.70 10.00 46 13 456 4 036 20 059 12 535 15.1 m m m m m m persons GT NT ton m³ kn Capacity Length overall Length between perpendiculars Breadth moulded Depth moulded Draught moulded (Summer load line) Draught at reduced freeboard Complement Gross tonnage Net tonnage Deadweight Hopper capacity Service speed Dredging equipment VER scope of work First of all VER made a feasibility study on the optimal length for lengthening of the dredger, which resulted in a length of 29.40 metres, taking into account longitudinal strength and stability. In close cooperation with the HAM's technical department, VER worked out a complete tender package, including technical specification, detail engineering and strength calculations of the lengthened vessel. The construction drawings of the mid-body section and coaming extension, the new jet water system, the new hopper discharge system and the renewal of dredge and jet pump drives were carried out as well. An additional 2 000 kW generator set was required for ship's operations. Two trailing suction pipes; diameter Dredging depth: * nominal * maximum Two dredging pump, power during: * trailing suction dredging * shore discharging Two jet water pumps Bow discharge Bottom doors 1 100 35.00 48.00 2x 2 400 2x 2 400 2x 828 900 24 mm m m kW kW kW mm VER project 00.222