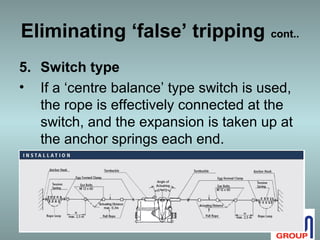

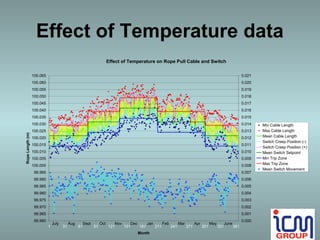

The document outlines a proposal for replacing existing rope switches at the Paraburdoo conveyor to eliminate nuisance trips and ensure compliance with safety standards. It details the impact of temperature on rope length and the challenges posed by current switch tolerances, while evaluating solutions such as switch type modification and materials with lower expansion coefficients. The proposed approach includes installing Kiepe centre balance switches and necessary components without causing downtime.

![Eliminating ‘false’ tripping cont..

4. Eliminating Rope expansion

• Reducing or eliminating rope expansion is an

obvious factor to look at

• Polymers, resins, kevlars etc have very low

expansion co-efficients (say less than 0.0001

compared to 0.013 for steel) but have high

elasticity and creep (stress relaxation) when

compared to steel.

• Phillystran [modified polyester] quoted up to 7%

length variation at 10% of rated load. Their

10mm rope at 230n (AS pullout limit) would be

approx. 7% loaded.](https://image.slidesharecdn.com/ropeswitchreplacement-121211193012-phpapp01/85/Reliable-Rope-Switches-Presentation-12-320.jpg)