Steel 4140Left MiddleRight AVGHardness (HRA)42.7.docx

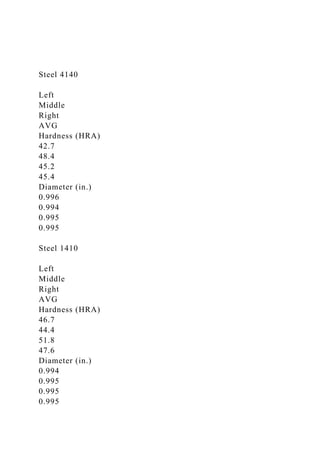

- 1. Steel 4140 Left Middle Right AVG Hardness (HRA) 42.7 48.4 45.2 45.4 Diameter (in.) 0.996 0.994 0.995 0.995 Steel 1410 Left Middle Right AVG Hardness (HRA) 46.7 44.4 51.8 47.6 Diameter (in.) 0.994 0.995 0.995 0.995

- 2. Steel 1410 Rockwell A (HRA) Measurements Every 1/16 inch for 1 inch Every 1/8 inch for 1 inch Every 1/4 inch for 2 inches 1 23.0 45.9 41.9 2 45.7 47.1 42.0 3 47.8 46.6 40.9 4 46.0 44.9 29.5 5 46.0 46.7 32.7 6 45.1 47.5 42.5 7 47.1 45.3 43.0 8 46.9

- 4. Steel 4140 Rockwell A (HRA) Measurements Every 1/16 inch for 1 inch Every 1/8 inch for 1 inch Every 1/4 inch for 2 inches 1 69.8 60.3 57.5 2 73.2 61.4 55.4 3 72.2 59.4 51.2 4 72.4 60.1 57.7 5 72.0 58.1 53.2 6 73.2 58.3 72.5 7

- 6. 63.2 EXPERIMENT 6 HEAT TREATMENT OF STEEL Purpose The purposes of this experiment are to: Background To understand heat treatment of steels requires an ability to understand the Fe-C phase diagram shown in Figure 6-1. Steel with a 0.78 wt% C is said to be a eutectoid steel. Steel with carbon content less than 0.78 wt% C is hypoeutectoid and greater than 0.78 wt% C is hypereutectoid. The region marked austenite is face-centered- cubic (FCC) and ferrite is

- 7. body-centered-cubic (BCC). There are also regions that have two phases. If one cools a hypoeutectoid steel from a point in the austenite region, reaching the A3 line, ferrite will form from the austenite. This ferrite is called proeutectoid ferrite. When A1 is reached, a mixture of ferrite and iron carbide (cementite) forms from the remaining austenite. The microstructure of a hypoeutectoid steel upon cooling would contain proeutectoid ferrite plus pearlite The size, type and distribution of phases present can be altered by not waiting for thermodynamic equilibrium. Steels are often cooled so rapidly that metastable phases appear. One such phase is martensite, which is a body-centered tetragonal (BCT) phase and forms only by very rapid cooling. Much of the information on non-equilibrium distribution, size and type of phases has come from experiments. The results are presented in a time- temperature-transformation (TTT)

- 8. diagram shown in Figure 6-2. As a sample is cooled, the temperature will decrease as shown in curve #1. At point A, pearlite (a mixture of ferrite and cementite) will start to form from austenite. At the time and temperature associated with point B, the austenite will have completely transformed to pearlite. There are many possible paths through the pearlite regions. Slower cooling causes coarse Pearlite, while fast cooling causes fine pearlite to form. Cooling can produce other phases. If a specimen were cooled at a rate corresponding to curve #2 in Figure 6-3, martensite, instead of Pearlite, would begin to form at Ms temperature (point C), and the pearlite would be completely transformed to martensite at temperature Ms. Martensite causes increased hardness in steels.

- 9. Unfortunately, hardness in steels also produces brittleness. The brittleness is usually associated with low impact energy and low toughness. To restore some of the toughness and impact properties it is frequently necessary to "temper" or "draw" the steels. This is accomplished by heating the steel to a temperature between 500ºF (260ºC) and 1000ºF (540ºC). Tempering removes some of the internal stresses and introduces recovery processes in the steel without a large decrease in hardness or strength. To obtain the desired mechanical properties it is necessary to cool steel from the proper temperature at the proper rates and temper them at the proper temperature and time. Isothermal transformation diagrams for SAE 1045 steel are shown in Figure 6-4. Heat Treatment of Steels

- 10. Common steels, which are really solid solutions of carbon in iron, are body-centered-cubic. However, the carbon has a low solubility in bcc iron and precipitates as iron carbide when steel is cooled from 1600ºF (870ºC). The processes of precipitation can be altered by adjusting the cooling rate. This changes the distribution and size of the carbide which forms a laminar structure called pearlite during slow cooling processes. If a steel is quenched into water or oil from 1600ºF (870ºC) a metastable phase called martensite forms, which is body-centered-tetragonal. This phase sets up large internal stresses and prevents carbide from forming. The internal stresses produce a high hardness and unfortunately, low toughness. After cooling, to restore toughness, steels are tempered by reheating them to a lower temperature around 800ºF (426ºC) and cooling. The tempering relieves the internal stresses and also allows some iron carbide to form. It also restores ductility.

- 11. Procedure You are provided with 6 specimens of SAE 1045 steel for your study. Measure the hardness of all specimens using the RA scale. 1. Heat four specimens in one furnace at 1600 + 25ºF (870 + 15ºC) for 1/2 hour. 2. Put the other 2 specimens in a separate furnace at the same temperature for 1/2 hour. 3. Remove one specimen from the furnace with 2 specimens and cool it in air on a brick. 4. Turn off the furnace with the one remaining specimen. Allow the sample to remain in the furnace for one hour. The air-cooled and furnace-cooled specimens can be cooled in water after one hour. Why? (Answer this in your write up). 5. Remove the four specimens and quickly drop them into water; the transfer should take less than one second. A little rehearsal could help. Be careful not to touch the specimens before they are cooled in water.

- 12. 6. Measure Rockwell hardness of the quenched specimens before the next step. 7. Temper 1 each of the quenched specimens for 30 minutes at 600ºF (315ºC), 800ºF (430ºC), and 1000ºF (540ºC). After tempering, the specimens can be cooled in water. 8. Measure hardness of all 6 samples using the Brinell (3000 kg) and Rockwell A or C scales. Data Analysis 1. If more than one impression is made per sample, average the Brinell diameters for each specimen. 2. Compute the Brinell hardness numbers and compare with the numbers read from a conversion chart for Rockwell A or C to Brinell. 3. Graph BHN (x-axis) versus Rockwell Hardness numbers (y- axis). 4. Graph Rockwell A or C hardness vs. tempering temperature (oC). 5. Compute the ultimate tensile strength (psi) of all specimens from the average BHN for

- 13. each specimen using: Write Up Prepare a single memo report in conjunction with experiment #7 (Hardenability of Steels). The report should combine both experiments in one report. Do not write this up as a two part report. (The hardness and hardenability concepts from the experiments are related). Within this report you should discuss the data referenced in the "Data Analysis" as well as the following: 1. What is the purpose of quenching and tempering steel? 2. Discuss the sources of error for the various hardness testers, the relative ease with which they may be used, and the comparative consistency of test results. 3. What factors probably contributed to the scatter in the hardness data? 4. Which hardness test appears to be most accurate? 5. Using the inverse lever law, estimate the amount of carbide (Fe3C) present at 1338

- 14. oF (just below the eutectoid temperature) for SAE 1045. 6. What are (or should be) the differences in the microstructure for each heat treatment process and how do these differences correlate with hardness? 7. Discuss errors in this experiment and their sources. MSE 227L Name ________________________ Heat Treatment of steel & Hardenability Poor Fair Average Good Excellent Memorandum Format Used 1 2 3 4 5 Spelling, grammar & punctuation correct 1 2 3 4 5 Report includes: Poor Fair Average Good Excellent Discuss why the air-cooled and furnace-cooled specimens can be quenched in water after one hour. 1 2 3 4 5 Compare Brinell numbers (BHN) found from measured diameters with a conversion chart for Rockwell A or C

- 15. (6 specimens). Go to website or reference book to find this information; include this data in your tables. 1 2 3 4 5 Include tables (results and data measured) for BHN and RA. Be sure to include measured values from computer. 1 2 3 4 5 Graph BHN (x-axis) vs. Rockwell A or C (y-axis). 2 4 6 8 10 Graph Rockwell A or C (y-axis) hardness vs. tempering temp. 2 4 6 8 10 pecimens from the average BHN for each specimen. 1 2 3 4 5 Discuss the purpose of quenching and tempering steel. 1 2 3 4 5 Discuss the sources of error for the various hardness testers; compare consistency of test results and accuracy (Rockwell vs Brinell). 1 2 3 4 5 Discuss factors that probably contributed to the scatter in

- 16. the hardness data and errors in the experiment (their sources) 1 2 3 4 5 Calculate amount of carbide (Fe3C) present at 1338 o F for SAE 1045. Use the phase diagram included in the lab description and show calculations. 1 2 3 4 5 Discuss the expected microstructure for each heat treatment process (specifically for the 6 samples). 1 2 3 4 5 Discuss the correlation between microstructure and hardness. 1 2 3 4 5 Graph hardness as a function of distance from the quenched end (show both alloys on the same graph). 3 6 9 12 15 Discuss the effects of alloying on hardenability and the shift in the TTT curve due to alloying. 1 2 3 4 5

- 17. Poor Fair Average Good Excellent Overall level of effort apparent 1 2 3 4 5 Quality of graphs 1 2 3 4 5 Quality of Abstract 1 2 3 4 5 Quality of work description 1 2 3 4 5 Quality of conclusions 1 2 3 4 5 Glossary of Terms Understanding the following terms will aid in understanding this experiment. Austenite. Face- Austenitizing. Temperature where homogeneous austenite can form. Austenitizing is the first step in most of the heat treatments for steel and cast irons. Annealing (steel). A heat treatment used to produce a soft,

- 18. coarse pearlite in a steel by austenitizing, then furnace cooling. Bainite. A two-phase micro-constituent, containing a fine needle-like microstructure of ferrite and cementite that forms in steels that are isothermally transformed at relatively low temperatures. Body-centered cubic. Common atomic arrangement for metals consisting of eight atoms sitting on the corners of a cube and a ninth atom at the cubes center. Cementite. The hard brittle intermetallic compound Fe3C that when properly dispersed provides the strengthening in steels. Eutectoid. A three-phase reaction in which one solid phase transforms to two different solid phases. Face-centered cubic. Common atomic arrangement for metals consisting of eight atoms sitting on the corners of a cube and six additional atoms sitting in the center of each face of the cube. Ferrite. Ferrous alloy based on the bcc structure of pure iron at

- 19. room temperature. Hypereutectoid. Composition greater than that of the eutectoid. Hypoeutectoid. Composition less than that of the eutectoid. Martensite. The metastable iron-carbon solid solution phase with an acicular, or needle like, microstructure produced by a diffusionless transformation associated with the quenching of austenite. Normalizing. A simple heat treatment obtained by austenitizing and air cooling to produce a fine pearlite structure. Pearlite. A two-phase lamellar micro-constituent, containing ferrite and cementite, that forms in steels that are cooled in a normal fashion or are isothermally transformed at relatively high temperatures. Tempered martensite. The mixture of ferrite and cementite formed when martensite is tempered. Tempering. A low-temperature heat treatment used to reduce the hardness of martensite by permitting

- 20. the martensite to begin to decompose to the equilibrium phases. References D. Callister Jr, Fundamentals of Materials Science and Engineering, J. Wiley & Sons, NY, 3rd Ed. 2008, Flinn and Trojan, Engineering Materials and Their Applications, Chapter 6 Deiter, Mechanical Metallurgy ASM Handbook on Heat Treatment, Vol. 2 MAE 2165: Materials Science Lab Spring 2017 ENGR 116 Prerequisites: MAE 2160 (may be take concurrently) Textbook: Required: Lab Instructions; The theoretical foundation for the lab will be covered in MAE 2160 text. Course Fee: $50 (Course fee used to purchase materials, supplies, equipment, and fund teaching assistants) Professor: Jackson Graham

- 21. Office: EL 286 Office Hours: W 11:00 AM – 12:00 PM or by appointment E-mail: [email protected] Course Description: This lab will allow engineering students to study the mechanical and thermal properties of metals, polymers, ceramics, and composite materials. Emphasis is upon laboratory technique, presentation of experimental results, evaluation of experimental results, and observation of the physical phenomena. Course Objectives: Upon completion of this course, students should be able to: 1. Execute laboratory techniques and procedures 2. Evaluate experimental results, and 3. Professionally present experimental results. Topics Covered: 1. General Lab Safety 2. Computational Material Science 3. Tensile Testing 4. Glass Fracture 5. Phase Diagrams

- 22. 6. Age-Hardening of Aluminum 7. Hardenability of Steels 8. Mechanical Properties of Polymeric Materials 9. Composites Attendance and Communication Policy: Attendance is required during the assigned lab period. You are responsible for any and all information contained in or communicated through Canvas. You are expected to ensure that you will receive any communications sent to you though Canvas in a timely manner. To make up an assignment, or exam, a student will need a physicians’s note attesting to the illness. No other excuses will be accepted for making up late work (i.e. vacation, leisure, community service, oversleeping, forgot to come to class, getting married, car broke down, research, work, family time, etc…). Pre-Labs and Lab Reports: You are required to read the lab and complete the prelab material PRIOR to the lab period. Lab reports, including text, figures, tables, and any other elements, are to be completed INDIVIDUALLY. Lab reports are required for each lab session. The lab reports will be turned in at the beginning of the following lab session or via Canvas prior to the start of the following lab session. Lab reports will be graded based on the guidelines specified for the lab and any rubrics provided. A 25% reduction in credit will be given for assignments up to 24 hours late. No credit will be given for home works and projects that are more than 24 hours late. You may receive help from others when doing in-class assignments and homework but you must only turn in your own work. All work will be completed or

- 23. submitted on Canvas. Grading: The lab reports will be graded according to the requirements included with each lab. Each lab report will be due at the time of your arrival to complete the next lab experiment. Grades will be assigned based on the quality of your work. NOT the effort you put into it. All requests for regrading assignments must be made within 7 calendar days mailto:[email protected] of the return of the assignment. The following grading scale will be used in this course: 100 to 94 A < 94 to 90 A- < 90 to 87 B+ < 87 to 84 B < 84 to 80 B- < 80 to 77 C+ < 77 to 74 C < 74 to 70 C- < 70 to 67 D+

- 24. < 67 to 64 D < 64 to 61 D- < 61 to 0 F Academic Standards: Cheating and plagiarism are serious academic offences and will be handled by following the University policy. At a minimum, a grade of zero will be assign for the entire assignment or exam. A description of the USU academic honor system can be found at the following website: https://studentconduct.usu.edu/studentcode/article6 The College of Engineering has an Engineering Tutoring Center. Tutoring services are available free of charge to all College of Engineering students. You can find help for any engineering required course, i.e. math, chemistry, physics, and all engineering classes. The Tutoring Center is located in ENGR 322 and 324. Hours are Monday through Friday 8:00 AM to 5:00 PM with extended hours on Tuesday and Thursday until 7:00 PM. https://studentconduct.usu.edu/studentcode/article6

- 25. Tentative Schedule: The weekly experiments are subject to change based on the availability of equipment and materials. After the microscopy lab, each lab time will be split into two groups (“A” and “B”). These two groups will alternate weeks as shown for the remainder of the semester. As a reminder, lab reports are due at the beginning of the next session assigned to your section AND group. Lab Week/Dates Group(s) Prelab Lab Assignment Report Due 1: Safety 1: Jan 9 - 13 All Safety N/A N/A 2: Computational Materials 2: Jan 16 - 20 All N/A Computational Materials N/A 3: Microscopy 3: Jan 23 - 27 All Microscopy Microscopy Computational Materials 4: Tensile Test and Torsion Fatigue 4: Jan 30 - Feb 3 A Tensile Test and Torsion Fatigue Tensile Test and Torsion Fatigue N/A 4: Tensile Test and Torsion Fatigue 5: Feb 6 - 10 B Tensile Test and Torsion Fatigue Tensile Test and Torsion Fatigue N/A 5: Phase Transformation 6: Feb 13 - 17 A Phase Transformation Phase Transformation Tensile Test and Torsion Fatigue No Lab 7: Feb 20 - 24 All N/A N/A N/A 5: Phase Transformation 8: Feb 27 - Mar 3 B Phase Transformation Phase Transformation Tensile Test and Torsion Fatigue Spring Break 9: Mar 6 - 10 All N/A N/A N/A 6: Hardenability and Composite Fabrication 10: Mar 13 - 17 A

- 26. Hardenability and Composite Fabrication Hardenability and Composite Fabrication Phase Transformation 6: Hardenability and Composite Fabrication 11: Mar 20 - 24 B Hardenability and Composite Fabrication Hardenability and Composite Fabrication Phase Transformation 7: Age Hardening and Glass Fracture 12: Mar 27 - 31 A Age Hardening and Glass Fracture Age Hardening and Glass Fracture Hardenability and Composite Fabrication 7: Age Hardening and Glass Fracture

- 27. 13: Apr 3 - 7 B Age Hardening and Glass Fracture Age Hardening and Glass Fracture Hardenability and Composite Fabrication 8: Polymers and Composite Testing 14: Apr 10 - 14 A N/A Polymers and Composite Testing Age Hardening and Glass Fracture 8: Polymers and Composite Testing 15: Apr 17 - 21 B N/A Polymers and Composite Testing Age Hardening and Glass Fracture 16: Apr 24 - 28 All N/A N/A Polymers and Composite Testing The Memorandum Report 1. Name Lab Time: (for example, Tuesday or Wednesday 2:00 PM) Lab Group (1-4) MSE 227 Lab # (2, 4, 6 & 7, 8, 9) – Title of report 2. Abstract Similar to a summary, helps a busy reader decide whether to

- 28. read the whole report. Since the abstract gives a thumbnail sketch of the report, an abstract of a memo- report should run no longer than half a page; frequently one paragraph describing the entire report (100 words or less) will suffice. Also the abstract should indicate the conclusions (results) of the work so that the reader will be able to evaluate the relevance of the work. 3. Description of Work (Procedure) A brief description of the actual work performed to explain where and how the data in the report was obtained. Do not copy the manual word for word; you should remember what you did in lab. 4. Results and Discussion May include answers to specific questions and outcome of lab in this section. If required, should include the data (preferably in a tabulated form) and graphs Tables always referred to in the results and discussion section. Figures axis (abscissa) while the vertical axis is only used for the dependent variables.

- 29. a convenient scale on each axis in such a way that the plot will fill roughly half the page. more than one plot is included in the figure. bottom. in Excel. Sample calculations Include a sample calculation for each nontrivial type of calculation. Additional info 1. Typewritten, single spaced on 8 ½ x 11 paper. 2. Attach appropriate rubric to front of Memo report. 3. Reference sources only if they are used The following is an example of a memorandum report. Hardness and tensile strength of a cartridge brass sample were measured as a function of percent cold work (0-60%CW). Both properties increased with the increased percentage of cold work. Recovery, recrystallization, and grain growth characteristics of a 50%CW

- 30. brass was also investigated by measuring Rockwell Hardness (B Scale) of specimens annealed for 1/2 hour in the temperature range of 200- 700°C. A typical curve with the three distinct regions was obtained. The grain size was also determined for the three highest annealing temperatures and a dramatic increase in the average grain size with temperature was observed. Procedure The initial hardness and tensile strength of 70/30 cartridge brass were measured using the Rockwell hardness tester (B scale) and the Instron machine, respectively. The thickness of the samples was successively reduced by rolling up to 60%, while hardness and ultimate tensile strength (UTS) measurements were determined at the different stages of cold work. A 50% CW brass strip was then cut into eight pieces, each was annealed at 200, 250, 300, 350, 400, 500, 600, and 700 °C for 1/2 hr, followed by water quench. The hardness of each sample was finally measured using the Rockwell tester. Samples for the metallographic observation were polished, etched and observed in a light optical microscope at magnification x 100. The ASTM grain size number, n was determined by comparing the microstructure with a standard ASTM grid, and consequently the average grain size was computed. Results and Discussion The data on hardness and tensile strength as a function of the degree of cold work are shown in Table 1. Figures 1 and 2 show the reduction in hardness in terms of inches and percentage of original thickness. The hardness has increased from about 15 to 78 on the Rockwell

- 31. B scale as a result of 60% CW. The tensile strength has also varied in a similar trend with the increased amount of cold work. The scatter of the data is very small since both properties were taken as the average of several readings under the same test conditions. Furthermore, the data obtained was in rather good agreement with those published in the literature. Process annealing of the cold worked samples below 250 °C reduced the hardness very slightly. An abrupt decrease in hardness was observed in the temperature range 250-500°C. Above 500°C the hardness continued to decrease at a very small rate until 700oC has been reached. The three stages of the annealing process, namely recovery, recrystallization, and grain growth, have been established accordingly. This is shown clearly by plotting the data in Table 2. The hardness values at high temperatures exhibited greater scatter as is expected when approaching the lower limit of the B scale on the hardness tester. Minor scatter in the values is observed as a result of the statistical errors involved in such measurements. However, the results in general are in good agreement with the literature. Table 1: Rockwell Hardness and Tensile Strength of Cartridge Brass at Different Percentages of Cold Work % CW RB* UTSx10 -7 (N/m2) 0 10 20 30

- 32. 40 50 60 15 50 65 70 73 75 78 34 38 43 48 54 60 65 * Average of four hardness readings on Rockwell B scale. Table 2: Hardness and Grain Size of 50% CW Cartridge Brass as a Function of Annealing Temperature. Temperature oC <RB>* Grain size (mm) 25 200 250 300

- 33. 350 400 500 600 700 75 73 71 52 40 25 17 18 10 0.010 0.041 0.060 0.154 * Average of four hardness readings. C old Working 0.0 20.0 40.0 60.0 80.0

- 34. 100.0 0.1000 0.1200 0.1400 0.1600 0.1800 0.2000 0.2200 0.2400 0.2600 Thickness, inches H a rd n e s s , R B brass Figure 1: Cold Worked Brass showing reduction in thickness versus RB hardness. C old Working 0.0 10.0 20.0 30.0 40.0 50.0

- 35. 60.0 70.0 80.0 90.0 100.0 0 0.1 0.2 0.3 0.4 0.5 0.6 P ercentage reduction in thickness H a rd n e s s , R B Figure 2: Cold worked brass percent reduction in thickness versus RB hardness. References 1. L. H. Van V lack, "Elements of Materials Science and Engineering," Addison Wesley, Inc., 1975. 2. R. A. and P. K. Trojan, "Engineering Materials and Their Applications," Houghton Mifflin Co., 1975. 3. A. G. Guy, “Introduction to Materials Science,” McGraw Hill Book Co., 1972. 4. Metals Handbook, ASM, edited by T. Lyman, 1948.

- 36. EXPERIMENT 7 HARDENABILITY OF STEELS Purpose This experiment is aimed at understanding the effect of cooling rate on the hardness of two steels. The experiment also shows why adding alloying elements other than carbon enables a part to be heat-treated more uniformly and to a greater depth. Background The background for Experiment #6 describes why the rate of cooling affects hardness but it does not explain why some parts that are heat-treated do not reach a high hardness. This problem, which is very real, is not well understood by the average engineer. In a practical sense it is not possible to heat-treat all parts to the same degree. The difference is due to the thickness or volume effect. Basically, when a part is quenched in water or some other fluid, the heat must be conducted out through the surface. This leads to a temperature gradient dt/dx between the surface and the center of the part being heat-treated. The temperature gradient varies with time. The temperature gradient is less steep between the center and the edge at later times. Therefore, the temperature of the center lags in time behind the temperature of the surface. If we were to plot a time profile of the center and the edge temperatures as shown in Figure 7-1,

- 37. the time to reach a given temperature T2 is definitely longer in the center than at the edge. This means that cooling rate varies as a function of depth. The greater the depth the slower the cooling rate. The situation with respect to the cooling rate can lead to a different hardness in the center than at the edge. The edge could transform to martensite and the center to pearlite or bainite. In selecting a steel, the ability to cool the center depends upon the thickness of the part. The thicker the part, the slower the cooling rate at the center. For a given thickness, one must select a steel that can be hardened in the center if that is desired. The cooling rate in this case is fixed. The center part of steel can be hardened by shifting the time-temperature- transformation diagram through alloying. Figure 7-2 shows that alloying elements added to plain carbon steel can shift the nose of the TTT curve to longer times and raise the Ms temperature. This means a slower cooling rate can be used to reach the martensitic state. A slower cooling rate means a thicker part can be heat-treated.

- 38. To obtain standardized data on the hardness of steels as functions of cooling rates, the Jominy End Quench test was developed. In the test, water is sprayed on one end of a bar of steel while it is hot. This leads to a one dimensional heat transfer cooling. Except near the surface of the bar the temperature is controlled by heat flow along the length of the bar (like thickness in the part). Moving axially away from the quenched end of the bar, the temperature and the rate of change of temperature are changing. The temperature is higher and the cooling rate is lower. If surface hardness is measured as a function of distance from the end, a hardness profile can be obtained which applies to any part made from the same steel, as shown in Figure 7-3. Procedure You will be given two steels: (type 1045) and a low-alloy steel (type 4143). Before heating the specimens, practice mounting the specimens in the rack and adjusting the water flow to spray the end of the specimens. Stamp each specimen for identification and measure the hardness on the Rockwell A scale. Check to make sure the fork is secure and put the specimen in the furnace at 1600 + 25oF (870 + 45oC) for 45 minutes. While you are waiting for the specimens, examine the microstructure of the alloy steel and carbon steel specimens provided by your instructor. At

- 39. the end of the austenitizing treatment above remove one specimen and carefully, but rapidly, place the specimen in the holder with the water turned on. Methods of Test The standard method for the Jominy test is ASTM - A255. The test consists of austenitizing at 50°F (90°C) above the solvus line on the Fe-C phase diagram that separates γ from γ + α. The specimen is then removed from the furnace and is placed in the cooling tower. The time spent transferring the specimen from the furnace to the fixture should not be more than 5 sec. The fixture is constructed so that the specimen is held 1/2 inch above the water opening with the column of water directed only at the bottom of the bar. The water opening is 1/2 inch in diameter and the flow adjusted to cause the column to rise 2-1/2 inches without the specimen in place. The test piece is held in the fixture for 10 minutes before quenching in cold water. After cooling, one flat surface 0.025 inches deep is ground along the length of the bar. Rockwell A hardness measurements are taken every 1/16 inch for the first inch and every 1/8 for the next inch and 1/4 for the next 2 inches. After hardness measurements are completed, the results should be compared to the New Metals Handbook (Vol. 1)

- 40. Glossary of Terms Understanding the following terms will aid in understanding this experiment. Hardenability. The ease with which a steel can be quenched to form martensite. Steels with high hardenability form martensite even on slow cooling. Hardenability curves. Graphs showing the effect of cooling rate on the hardness of a steel. Jominy test. The test used to evaluate hardenability. An austenitized steel bar is quenched at one end only, thus producing a range of cooling rates along the bar. Quenching. Rapidly cooling a material to some lower temperature by immersion in a liquid bath or gaseous stream. For example quenching steel in a pail of water. Temperature gradient. A difference in temperature across some distance, for example between one end of the Jominy bar and the other. Write Up Prepare a memo report, in conjunction with Experiment #6 (Heat treatment of steels). Plot the hardness as a function of distance from the quenched end with plots for both samples on the same graph. Discuss the effects of alloying on hardenability. Discuss the shift in the TTT curve due to alloying.

- 41. References ASM Vol. 1, Properties of Iron and Steel, 1977. D. Callister Jr, Fundamentals of Materials Science and Engineering, J. Wiley & Sons, NY, 2nd Ed. 2005, Chapter 5 Flinn and Trojan, Engineering Materials and Their Applications, Chapter 6