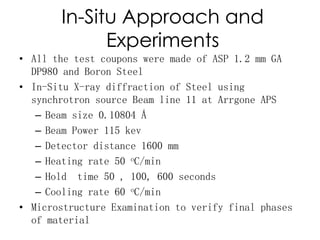

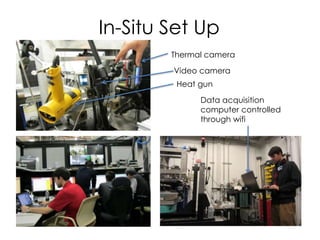

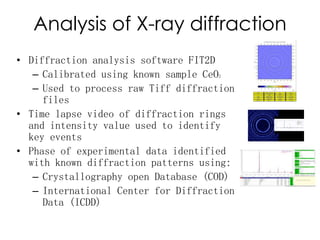

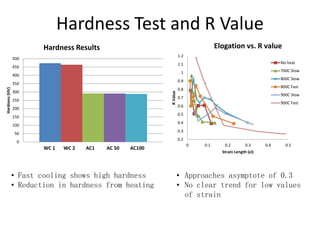

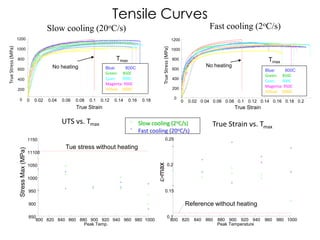

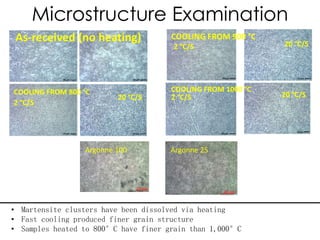

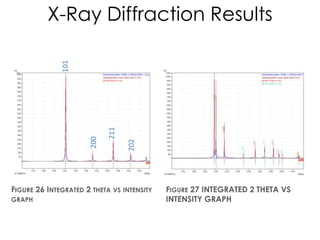

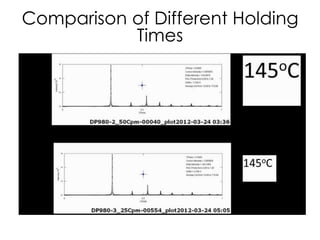

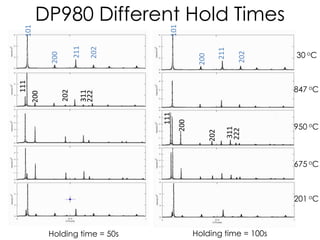

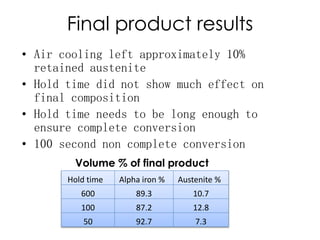

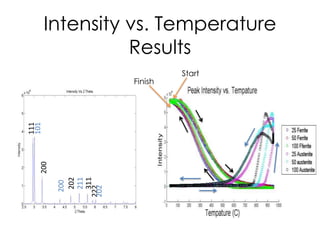

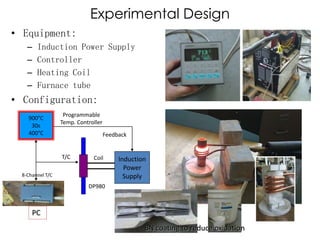

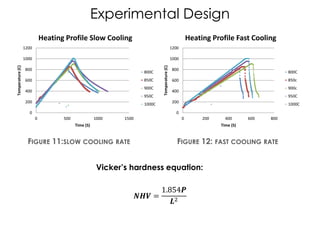

This document summarizes Jorge Cisneros' master's thesis on investigating the phase transformation of DP980 dual phase steel during heating and cooling using in-situ synchrotron X-ray diffraction. The objectives were to determine the phase transmission curve for different heating profiles and holding times. Experiments involved heating tensile test coupons to various peak temperatures using induction heating and characterizing the phase changes using X-ray diffraction and microscopy. Results showed that peak temperature and cooling rate most impacted the final phases, with fast cooling producing finer grains. Holding time had little effect on the final composition above 50 seconds.

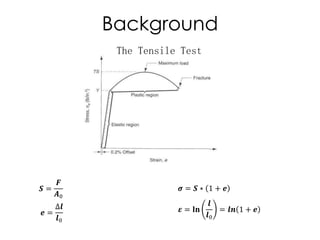

![Tensile Test

• Measure w & t with two extensometers, or w & R

where R from interrupt test;

R = ew/et = ln(w/wo)/ln(t/to)

• True strain el :

el = (ew + et) = ew (1+ 1/R) = (1+ 1/R) ln(w/w0)

• True stress,

from t/t0=(w/w0)1/R

sl = F/(wt)=F/[wt0(w/wo)1/R]](https://image.slidesharecdn.com/2cbcb08e-b3c2-4fae-8b0f-824fe1c62d59-151011174508-lva1-app6892/85/ResearchSummary-10-320.jpg)