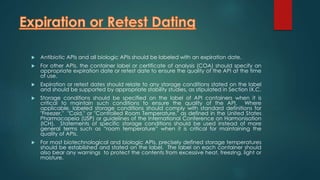

The document discusses guidelines for packaging and labeling of active pharmaceutical ingredients (APIs). It outlines requirements for packaging materials, labeling, storage conditions, and expiration dating to ensure quality. Proper documentation of material specifications, examination and testing is required. Labels must include accurate information and be stored securely to prevent mix-ups. APIs should be packaged and labeled in a way that protects against deterioration and contamination during transport and storage.