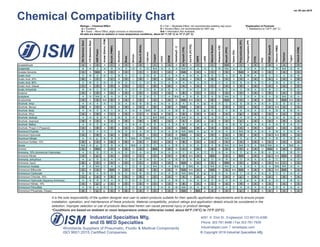

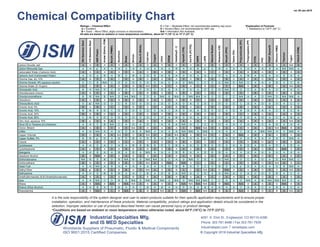

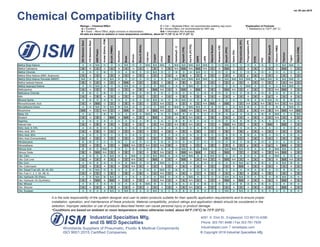

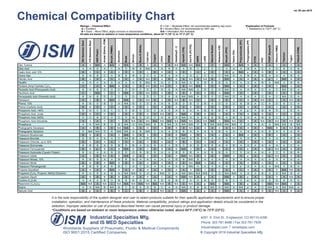

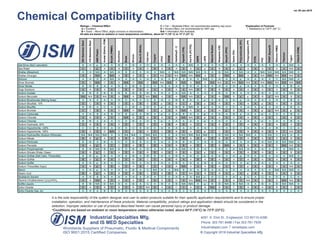

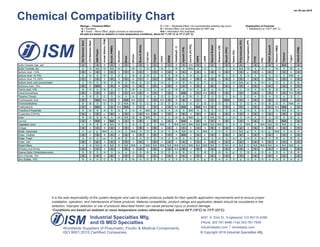

The document is a chemical compatibility chart that provides ratings on a scale of A to D for the compatibility of various chemicals with different materials, with A being excellent compatibility and D being a severe effect and not recommended. It lists various chemicals down the left column and various materials across the top row, and indicates the compatibility of each chemical with each material. Additional information is provided on the ratings and conditions on which they are based at the bottom of the chart.