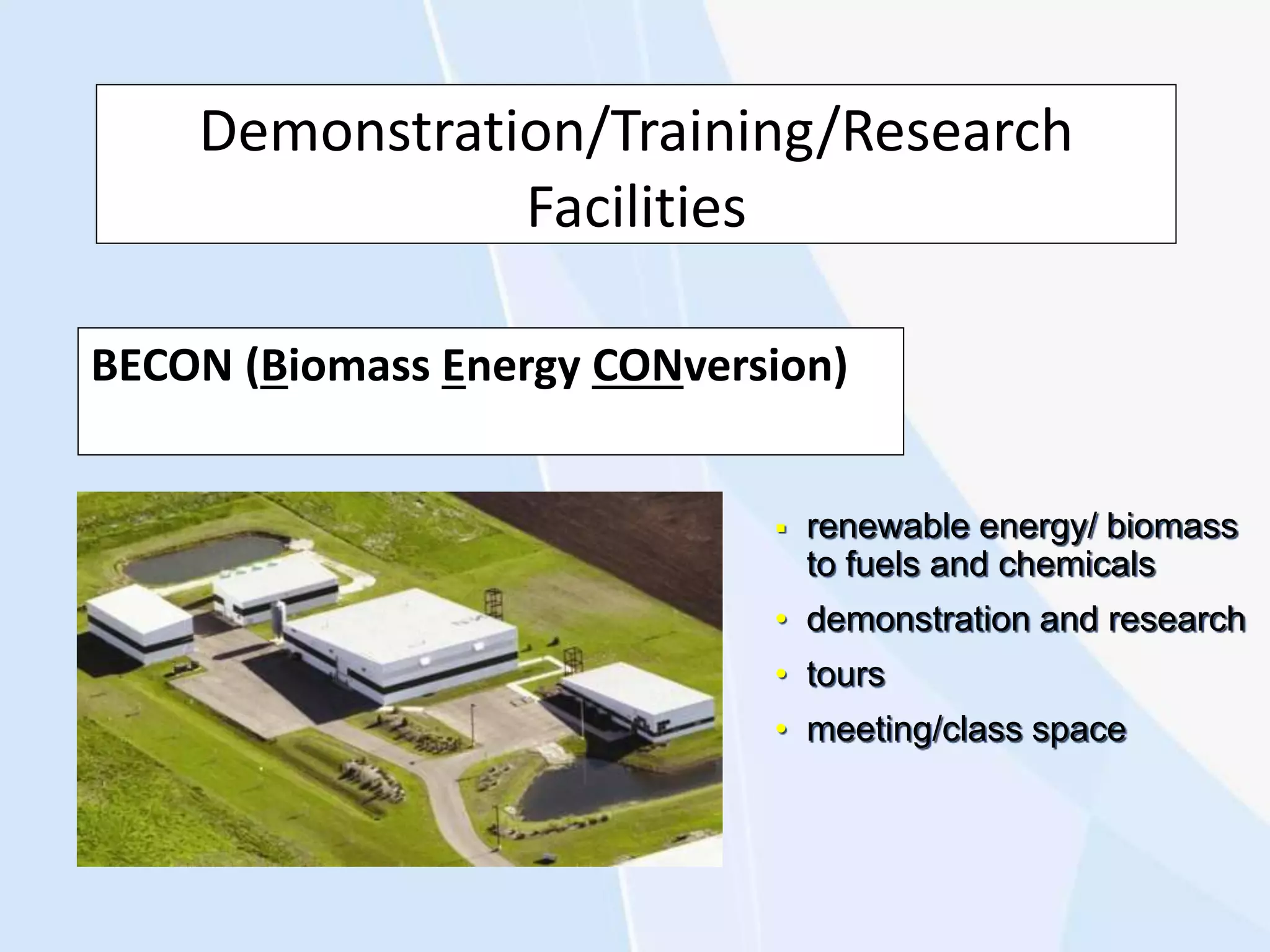

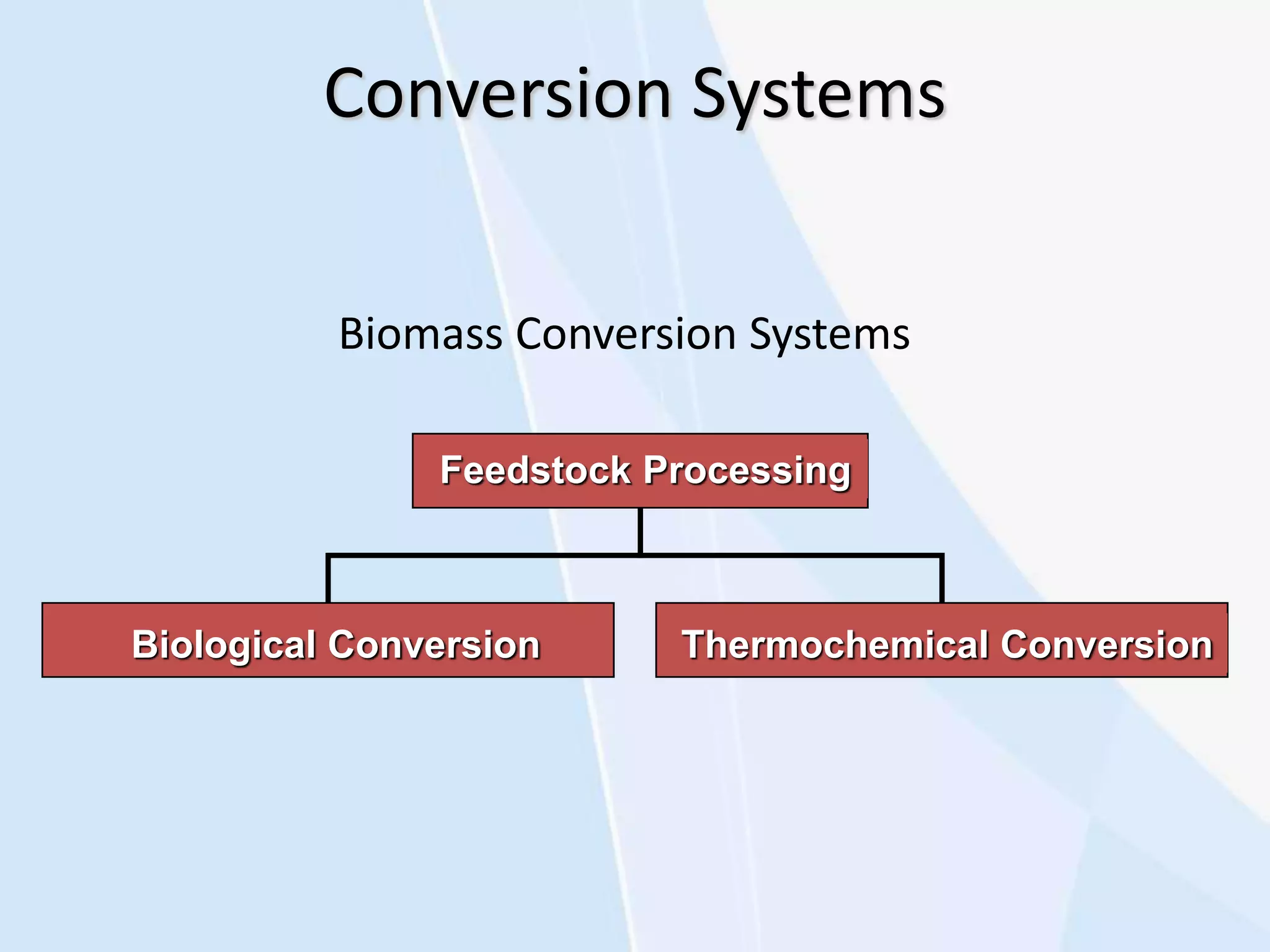

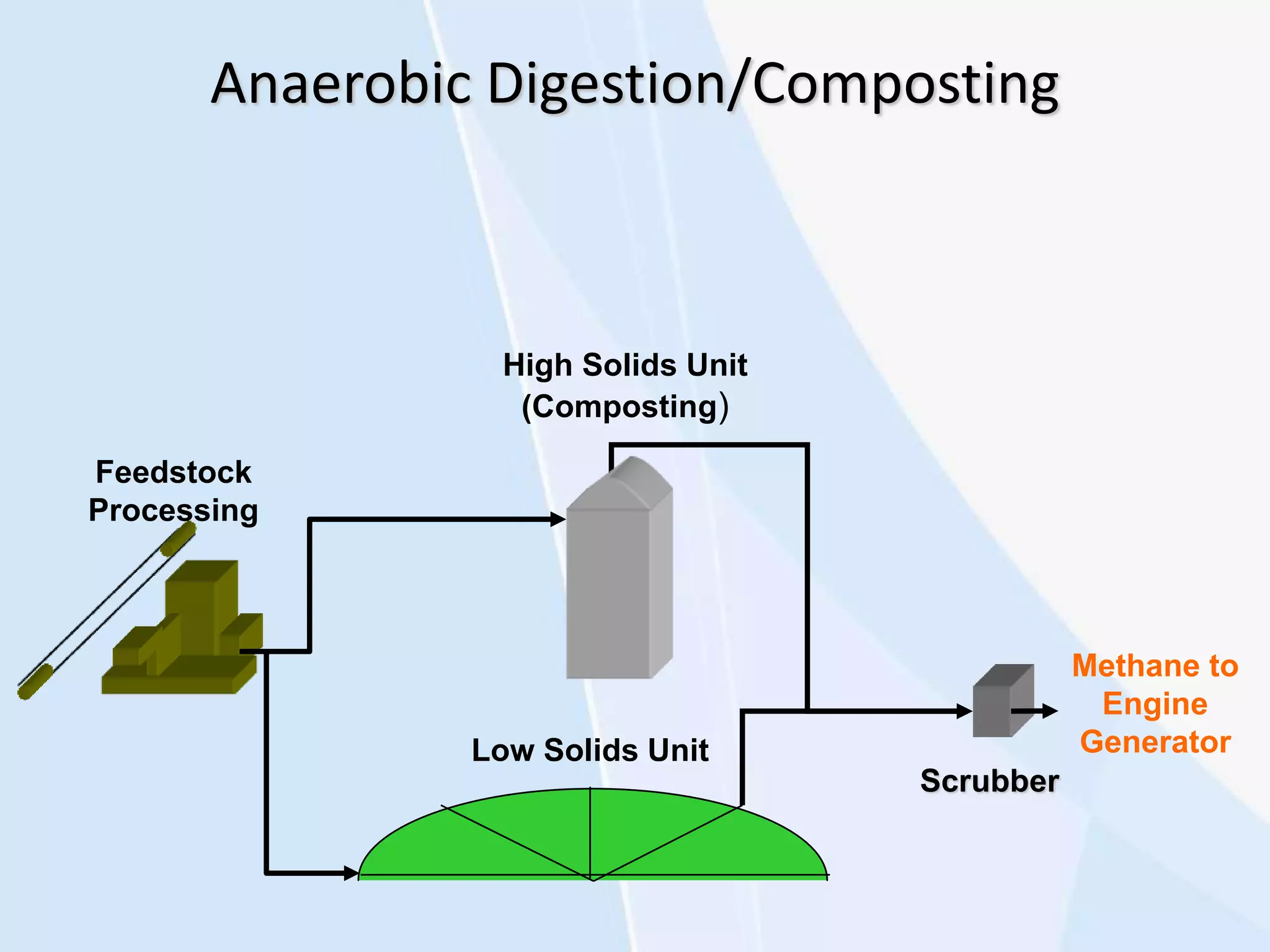

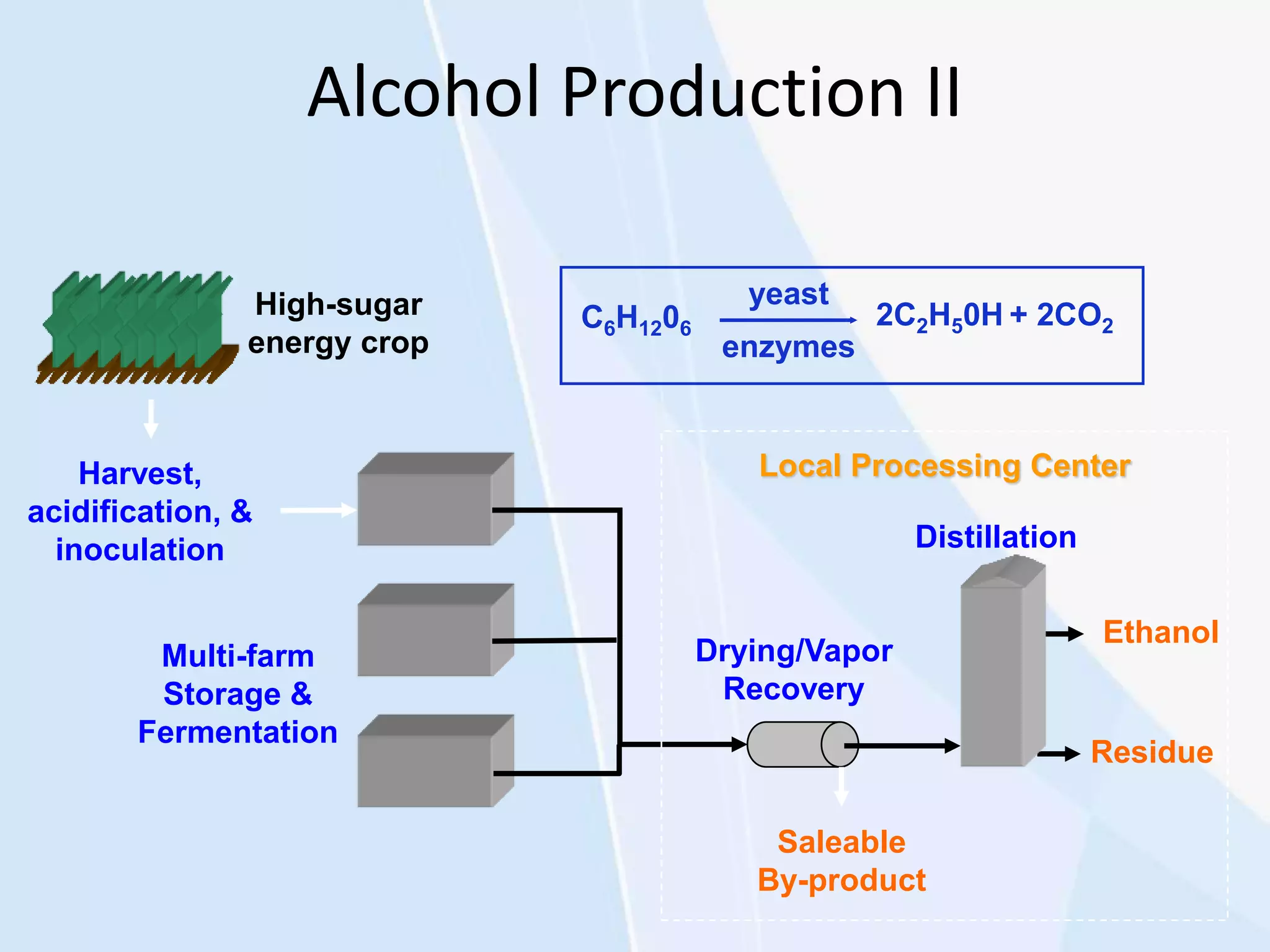

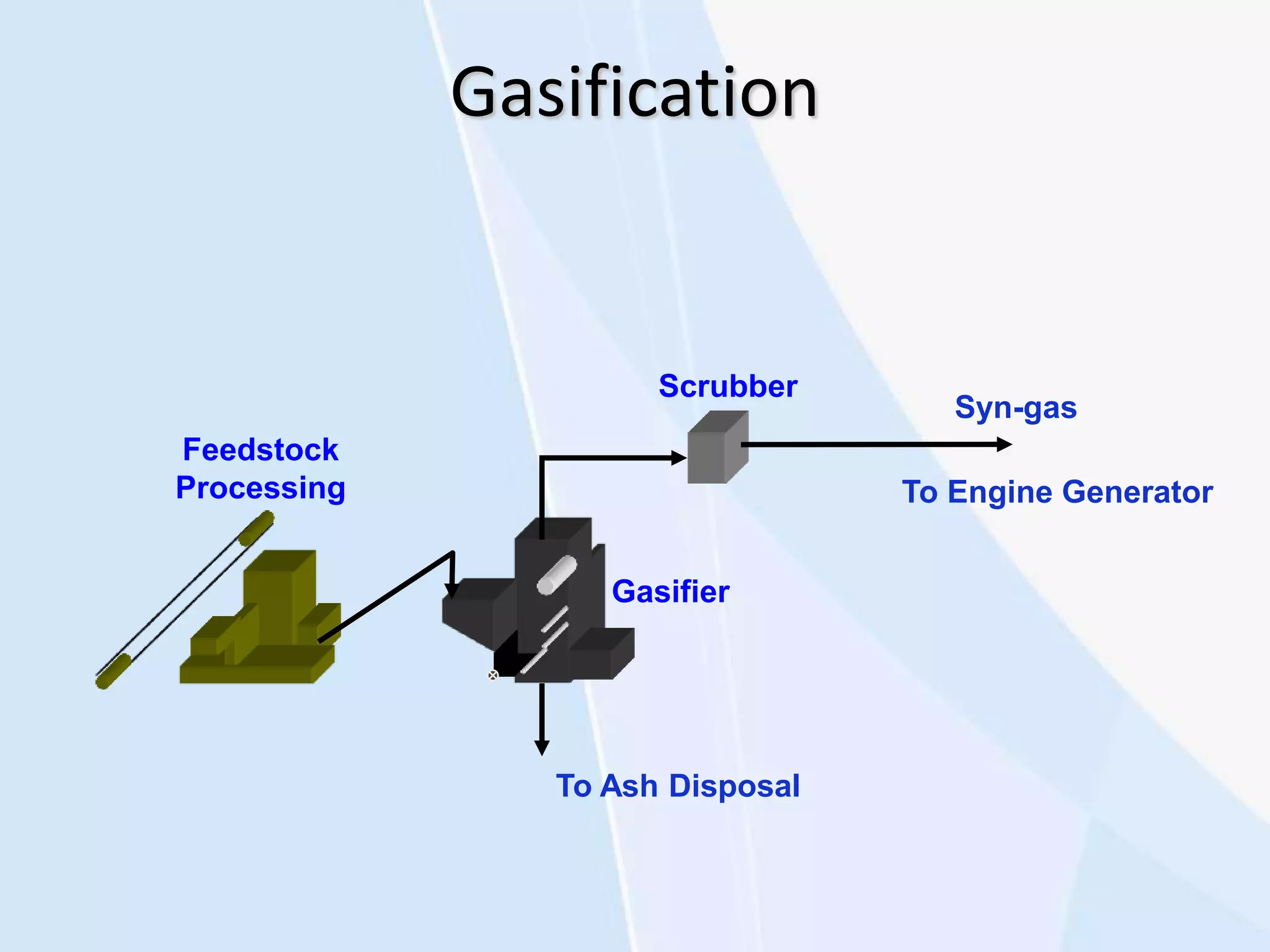

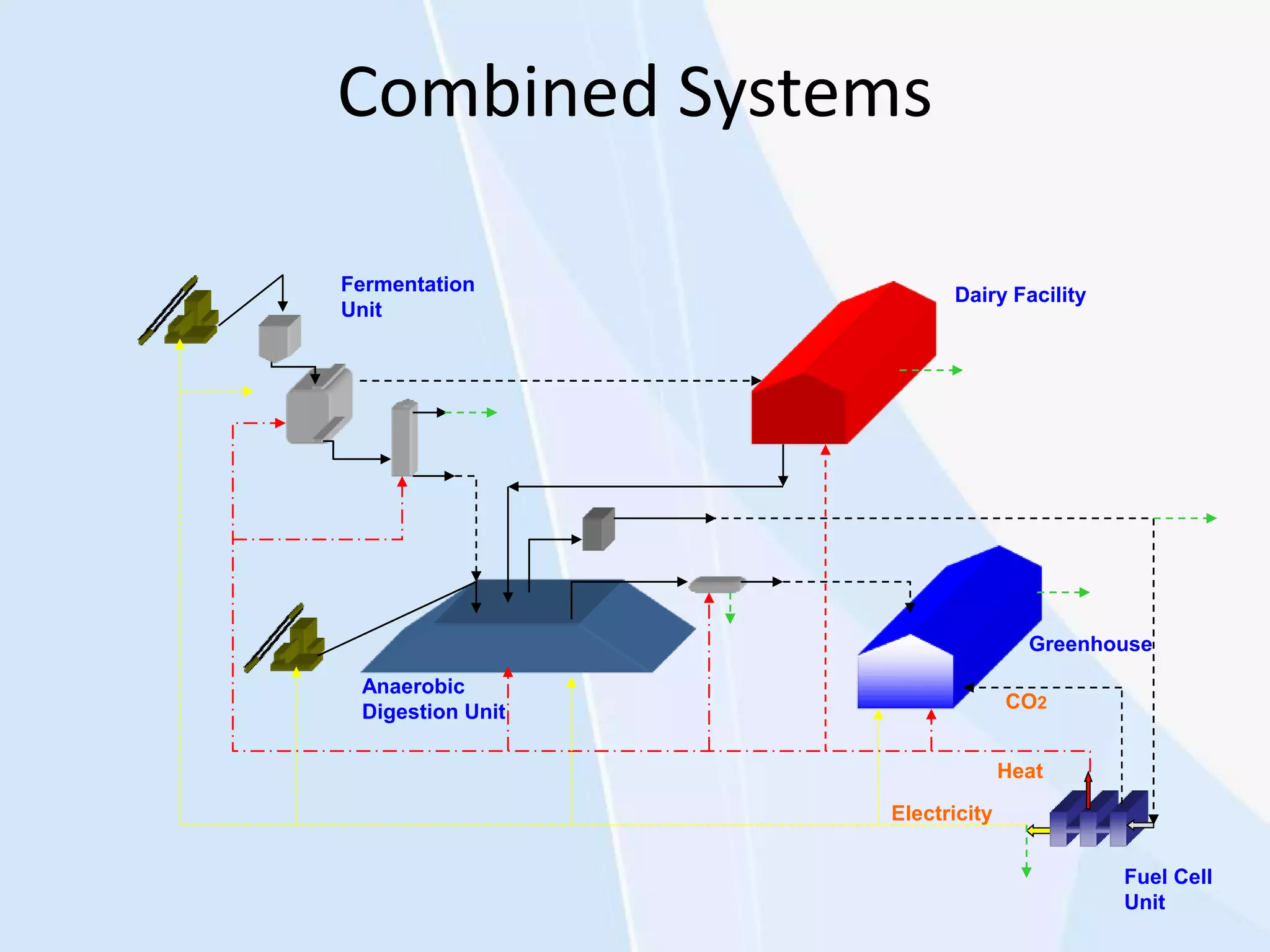

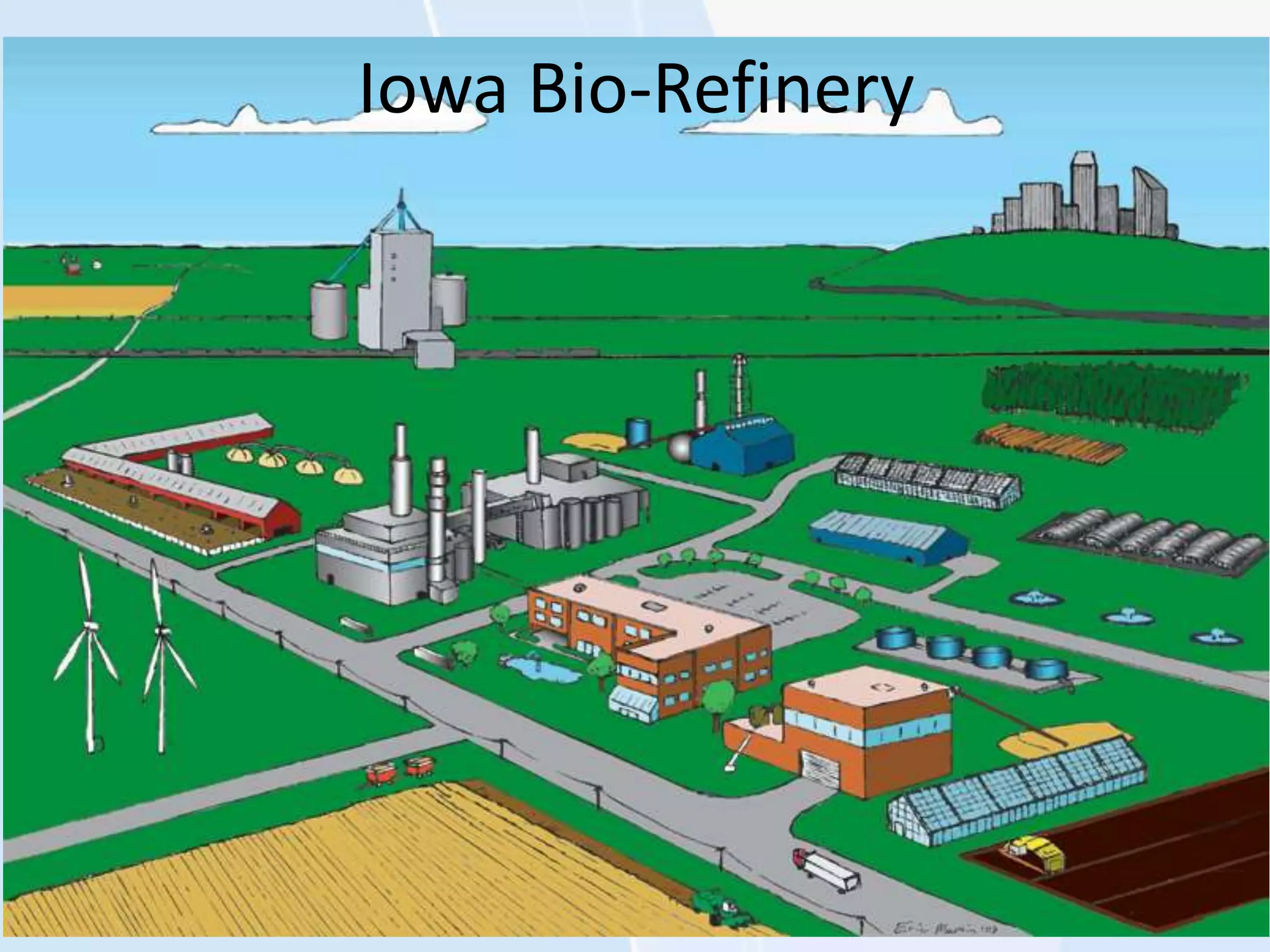

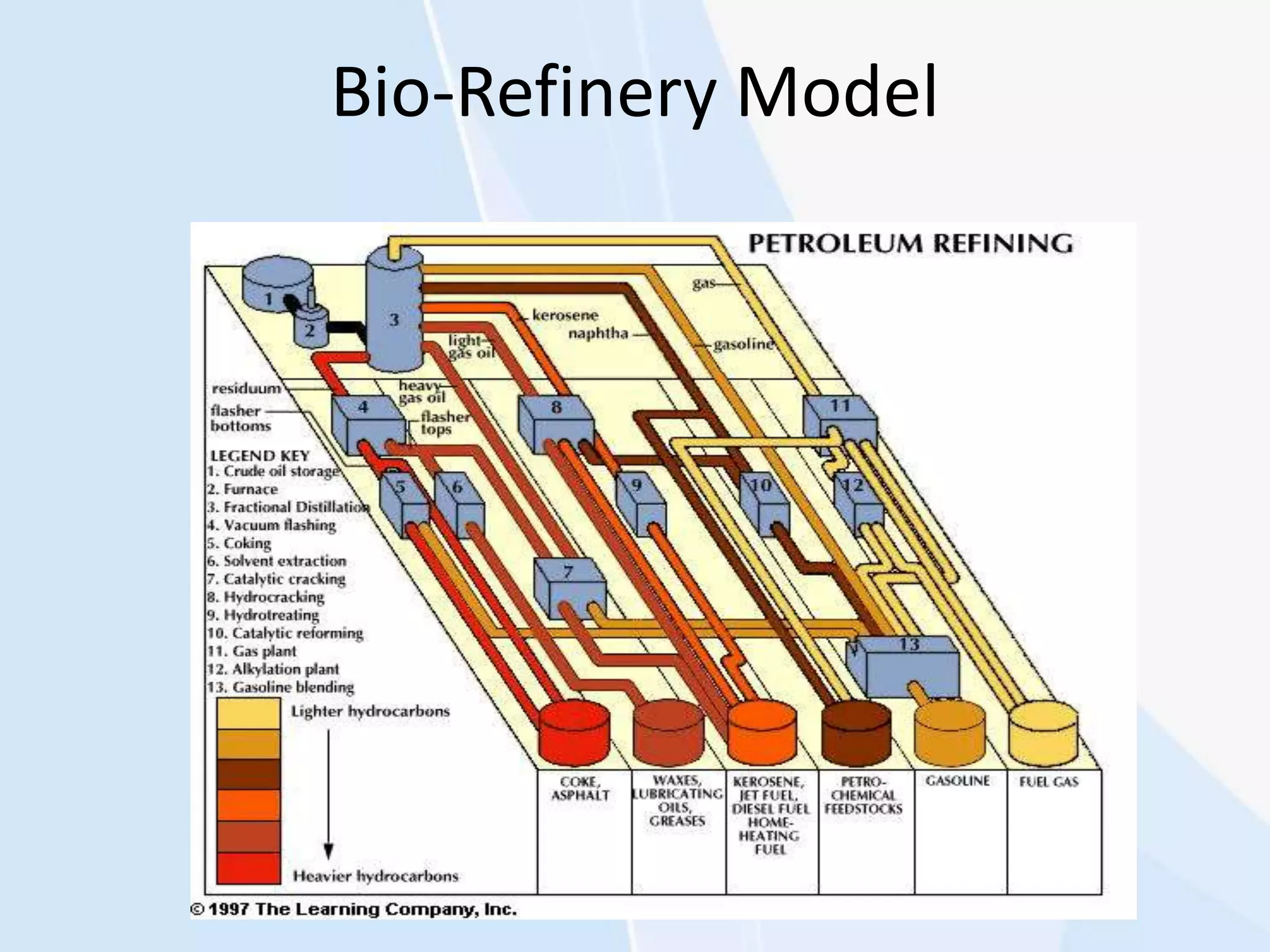

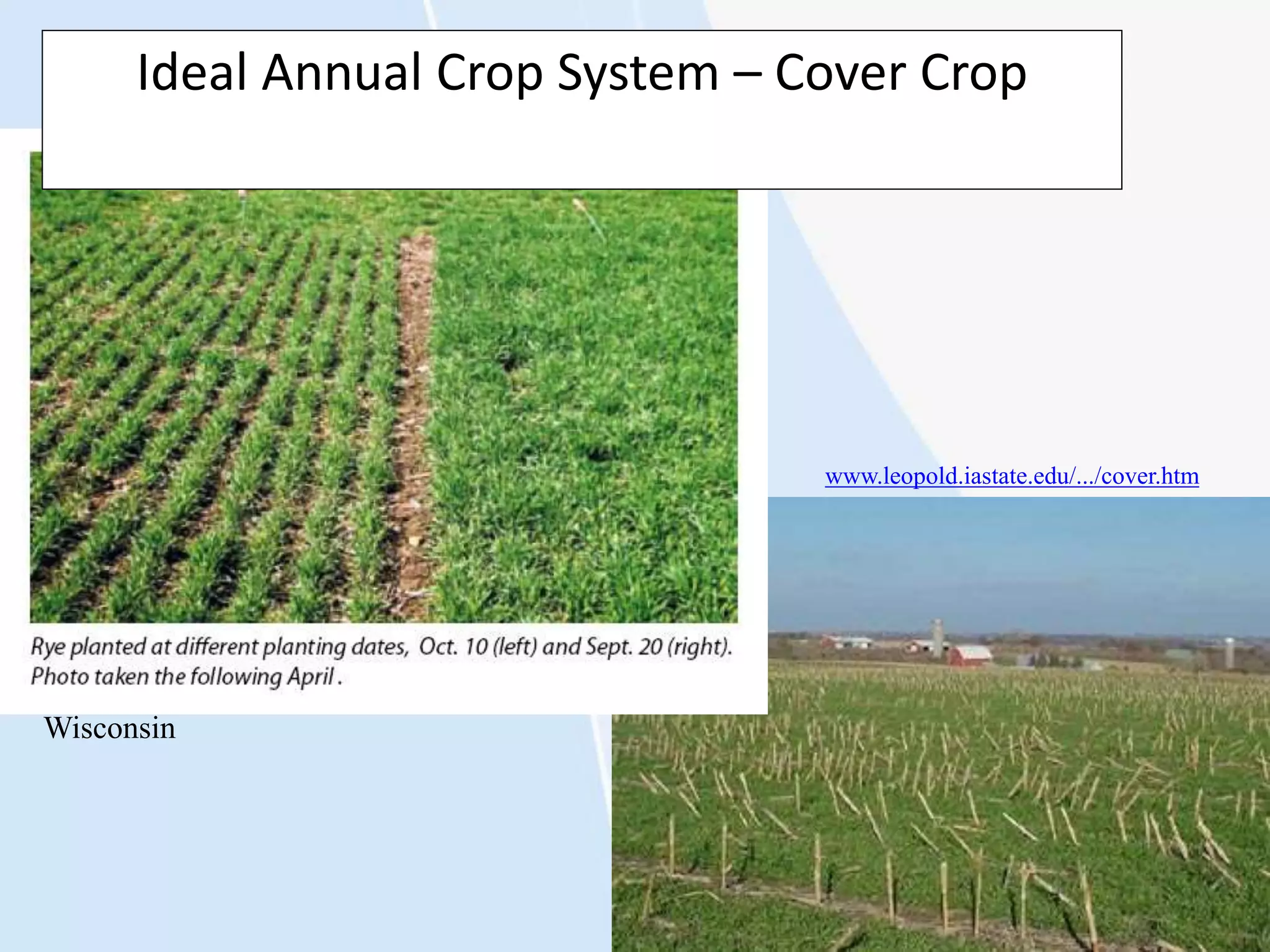

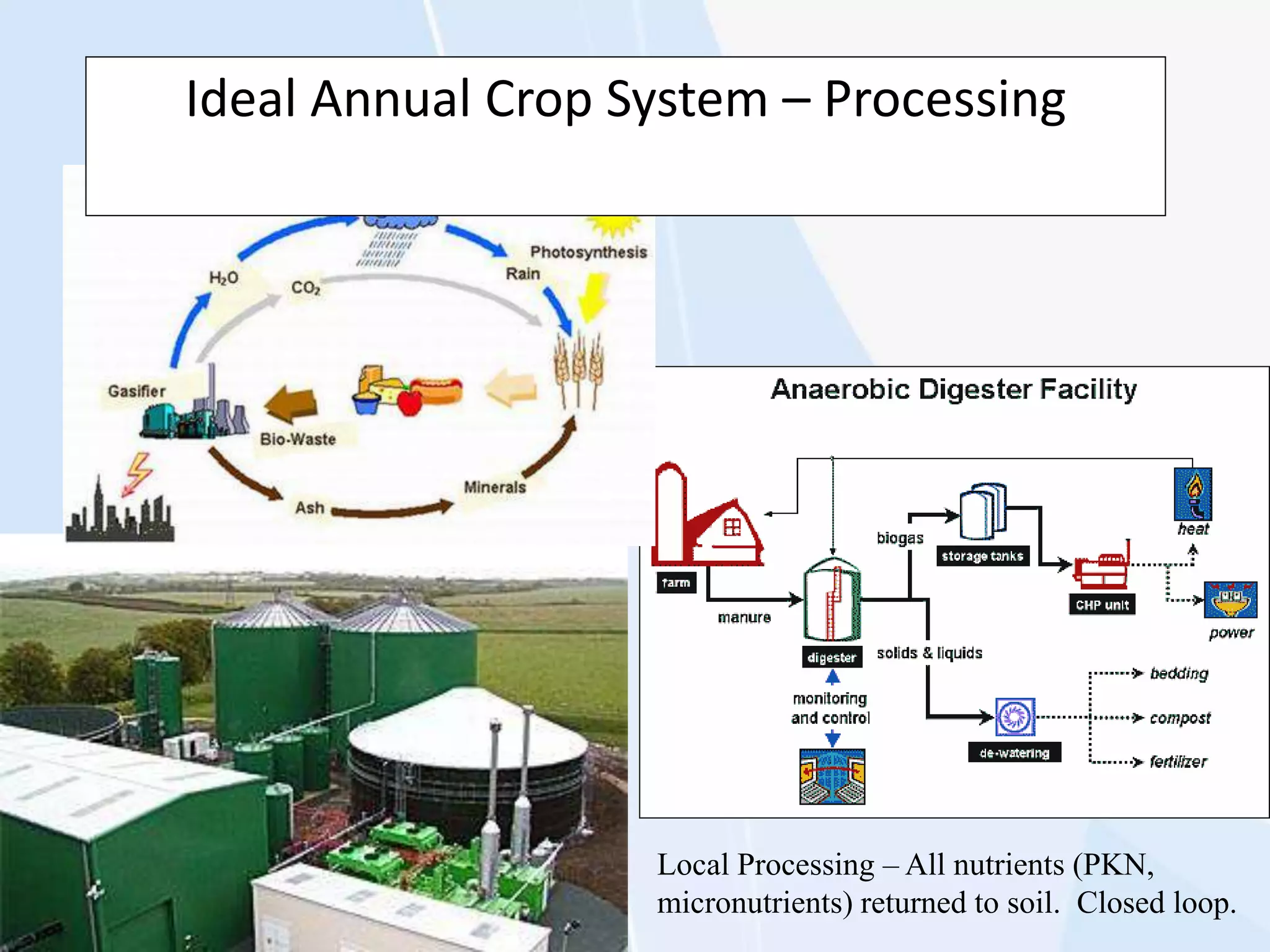

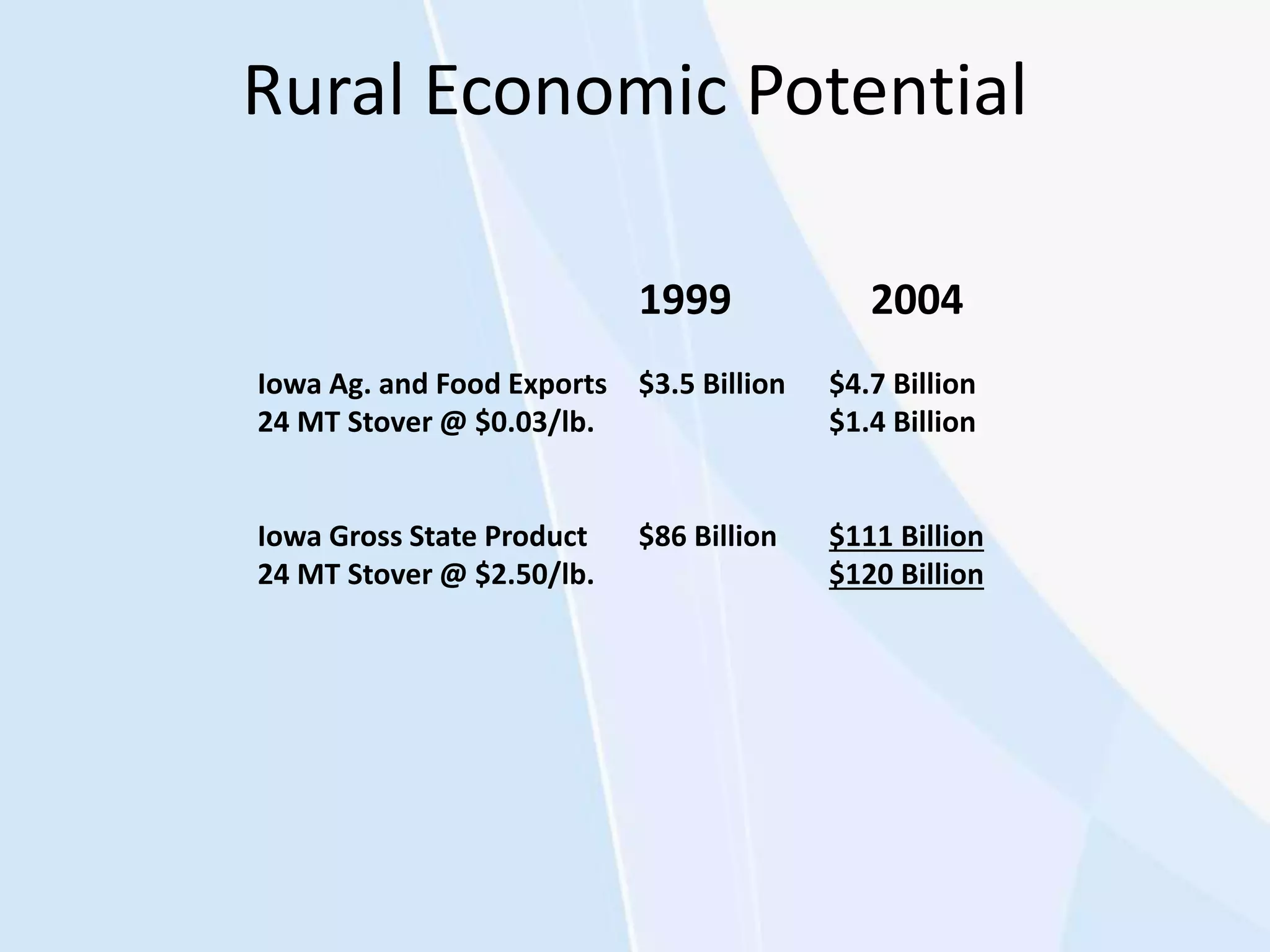

The document summarizes the work of the Iowa Energy Center's Biomass Energy Conversion (BECON) facility. BECON demonstrates and researches converting biomass into fuels and chemicals. It has hosted over 14,000 visitors since 1999 and aims to spur rural economic development through adding value to agricultural products. The ideal is to create integrated biomass systems that improve soils and produce multiple products locally while reducing fossil fuel use.