The document provides information about Kurt workholding products including:

- The new SideWinder vise that mounts vertically to the back of 6" Kurt vises for secondary operations.

- The new PinLock mounting system for quickly and accurately positioning fixture plates with locators and receiver bushings.

- Specifications and details for the PinLock locators and receiver bushings.

- An application chart showing Kurt workholding solutions for different machine types and operations.

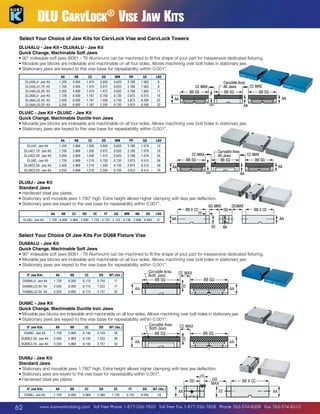

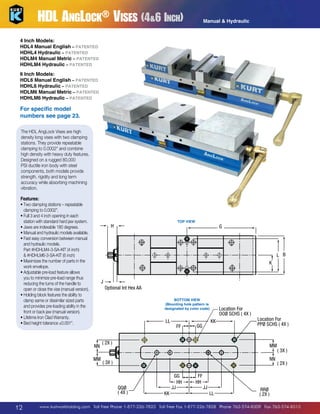

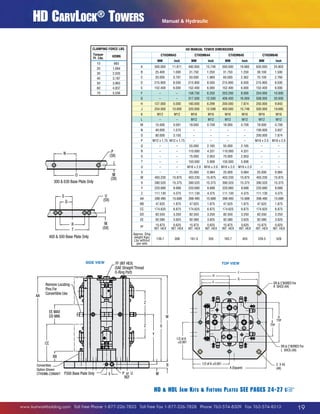

![HD CarvLock® Towers

CTHDHL64 Hydraulic Tower – English

CTHDHLM64 Hydraulic Tower – Metric

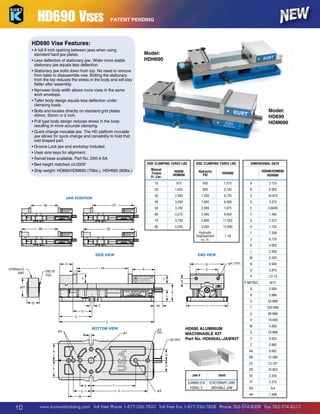

This hydraulically operated eight station tower

features all-new design for fast loading of parts.

All internalized hydraulic piston/nut saves

valuable space. Includes all original KURT

AngLock precision clamping and iron clad rigid

construction for damping vibration.

Features:

• ydraulically operated eight station

H

CTHDHLM64 Cluster Tower.

• tilizes an all internal hydraulic piston nut to

U

12.500 (SQUARE)

conserve space. Pressure is maintained until

6.250

1.97 X 45° (4X)

released by operator or triggering device.

Easy disconnect for pallet shuttle.

R

• epeatable clamping to 0.0002. Each station

DR C'BORED

delivers up to 7,100 lbs. of clamping force at FOR 5/8 SHCS

(4X)

4,500 PSI.

6.299

[160mm] face is controlled separately for

•

Each

convenient part loading and removal.

J

12.598• aw opening is 4 per station.

[320mm] ach face has a maximum total stroke of 1/4

•E

(SQUARE)

.984 [25mm]

(1/8 per station).

DR

J

• aw options available: Hard jaws, machinable C'BORED

FOR

aluminum. machinable ductile iron. See pg.27 1/2 SHCS

(4X)

B

• ase sizes available: 400mm, 500mm, 630mm.

• ifetime Iron Clad Warranty

L

(shown with optional hard jaws)

7.874 [200mm]

15.748 [400mm] (SQUARE)

SIDE VIEW

TOP VIEW

12.500 (SQUARE)

6.250

1.75

24.61

1.97 X 45° (4X)

DR C'BORED

FOR 5/8 SHCS

(4X)

6.299

[160mm]

20.85

12.598

[320mm]

(SQUARE)

.984 [25mm]

DR C'BORED

FOR 1/2 SHCS

(4X)

9.492

7.874 [200mm]

15.748 [400mm] (SQUARE)

18mm 55mm (2X)

(5X)

75mm (2X)

M16 x 2

(5X)

1.250

HD HDL J aw K its F ixture P lates SEE PAGES 24-27

www.kurtworkholding.com | Toll Free Phone 1-877-226-7823 | Toll Free Fax 1-877-226-7828 | Phone 763-574-8309 | Fax 763-574-8313

+

21](https://image.slidesharecdn.com/kurtcatalog2014-140115101915-phpapp02/85/Kurt-Catalog-2014-21-320.jpg)