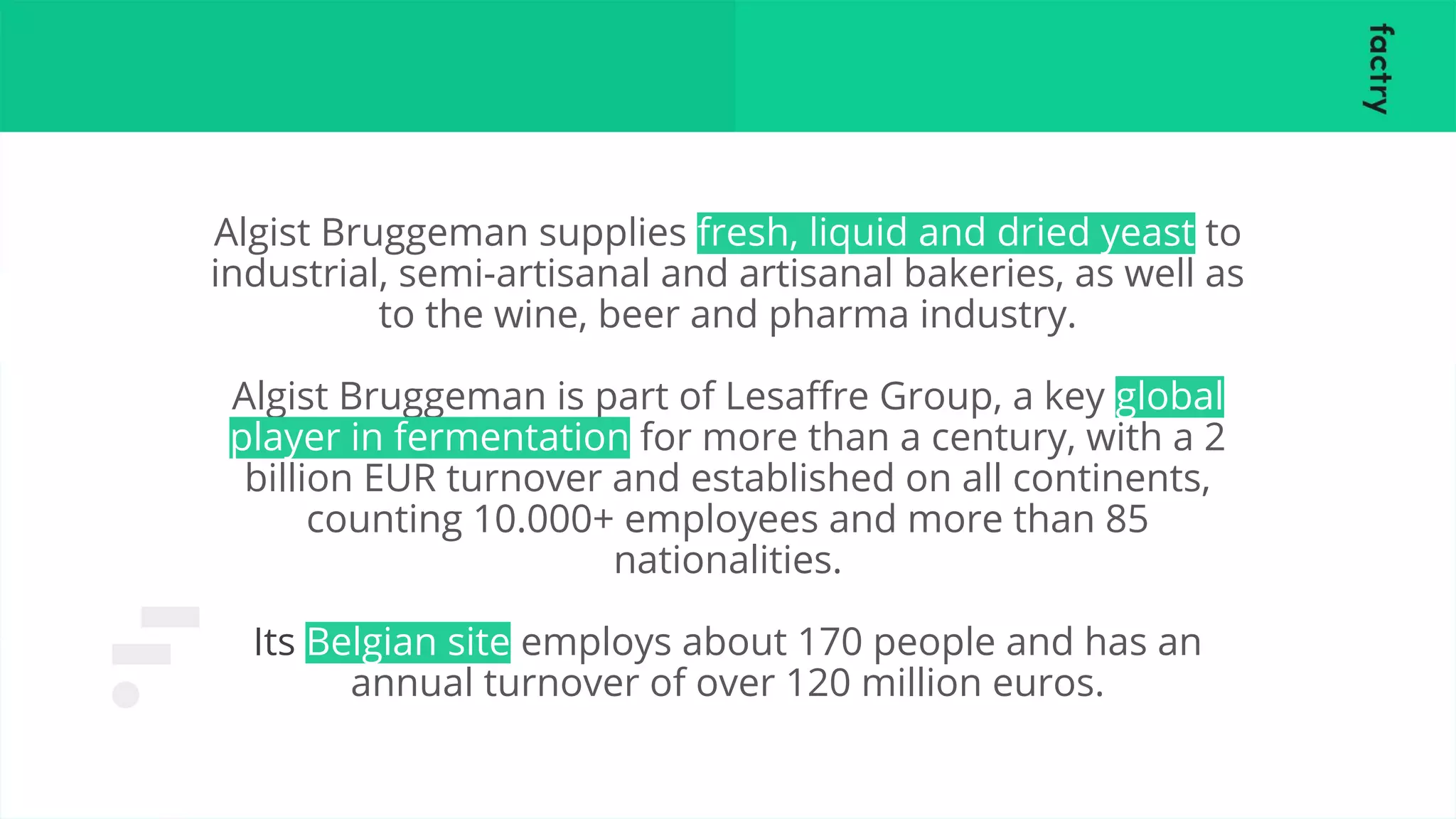

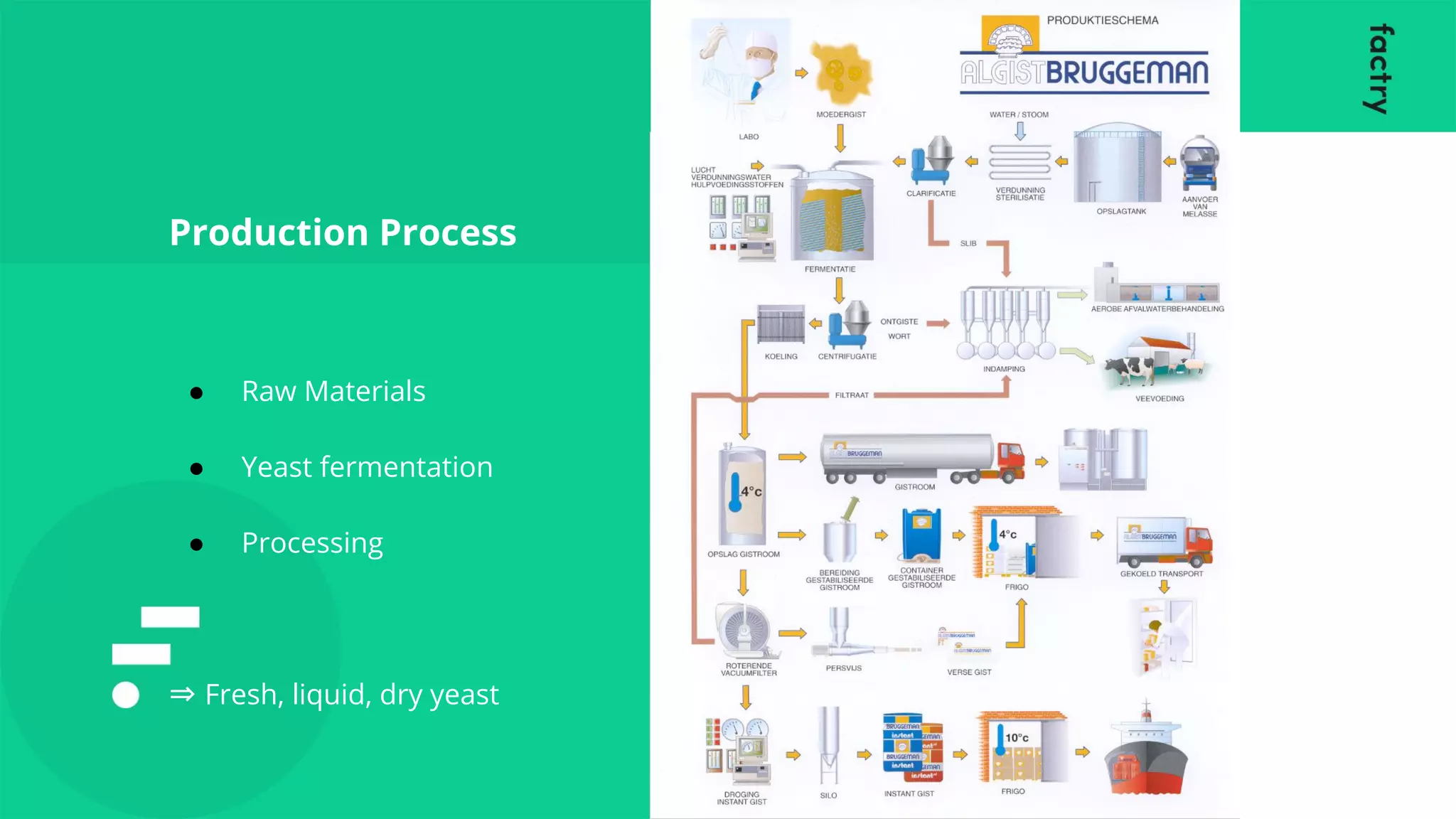

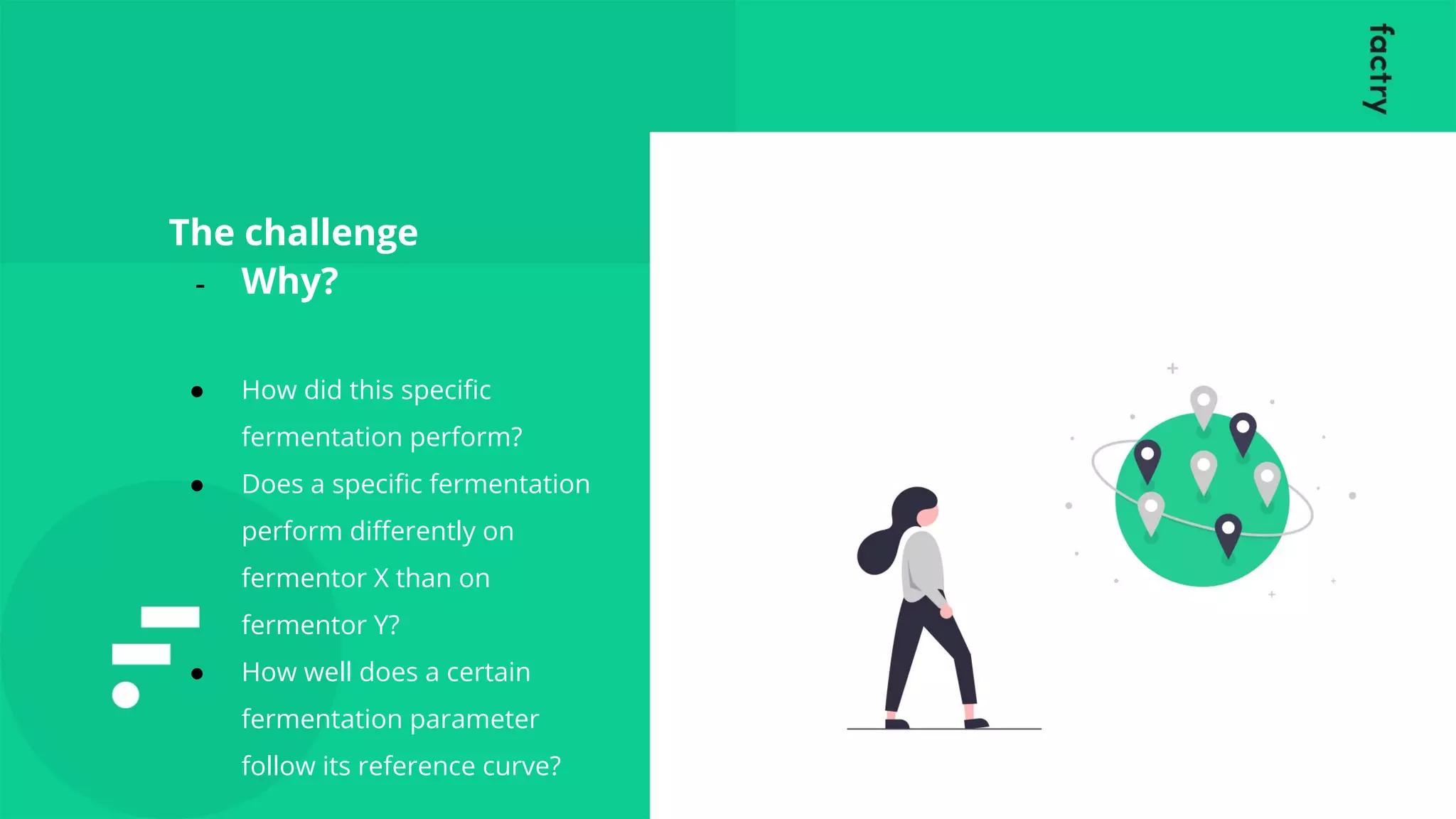

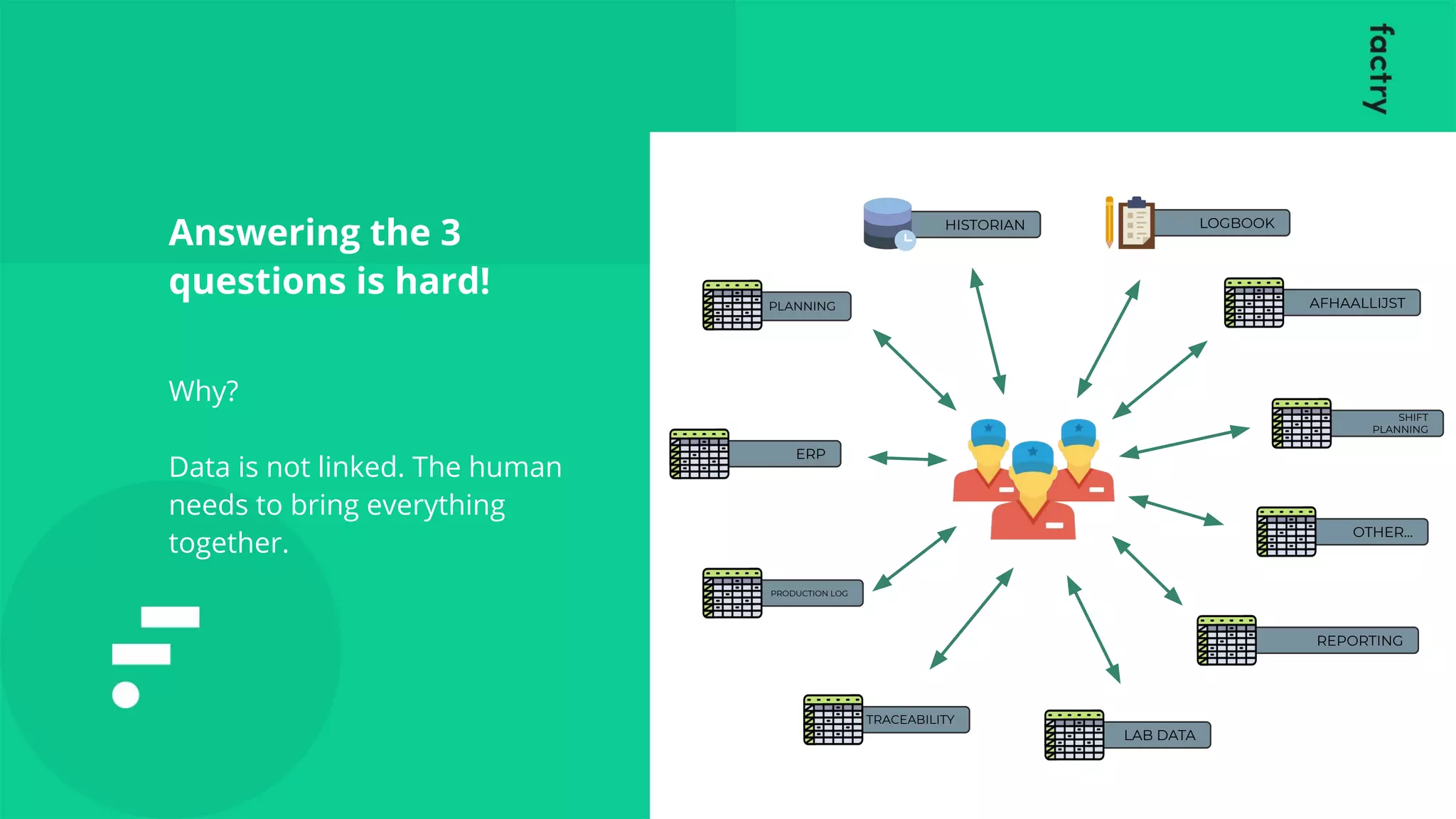

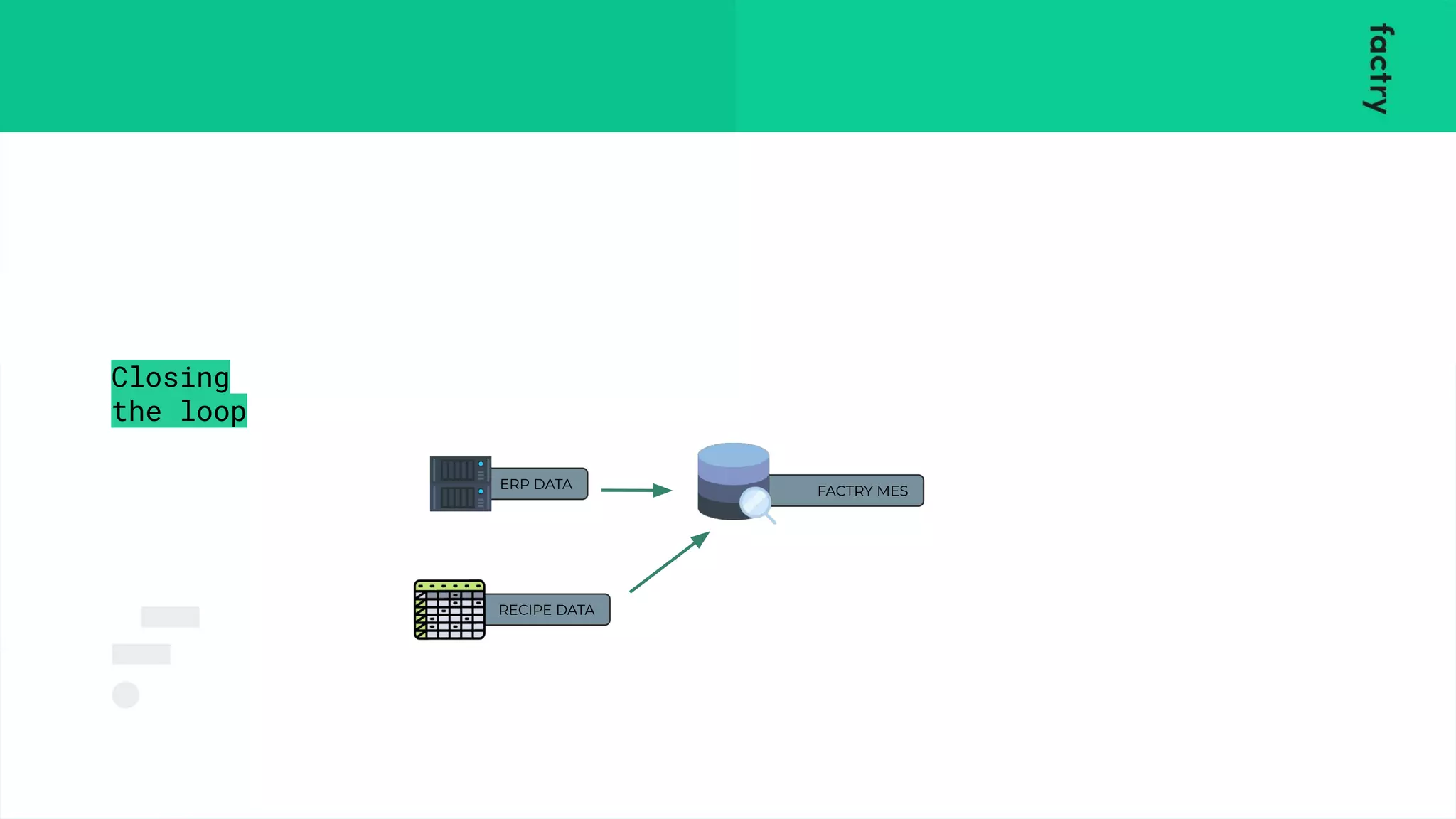

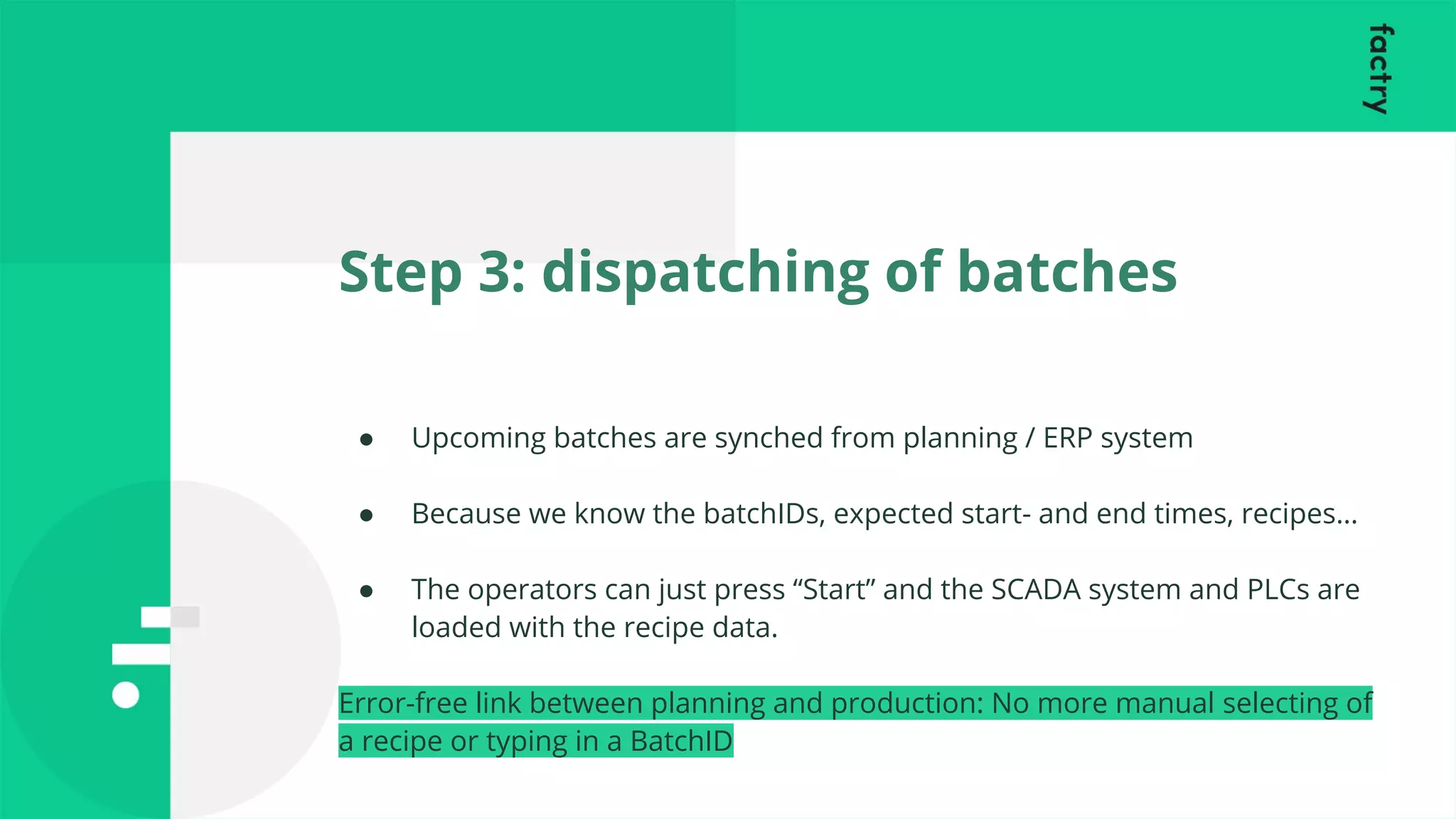

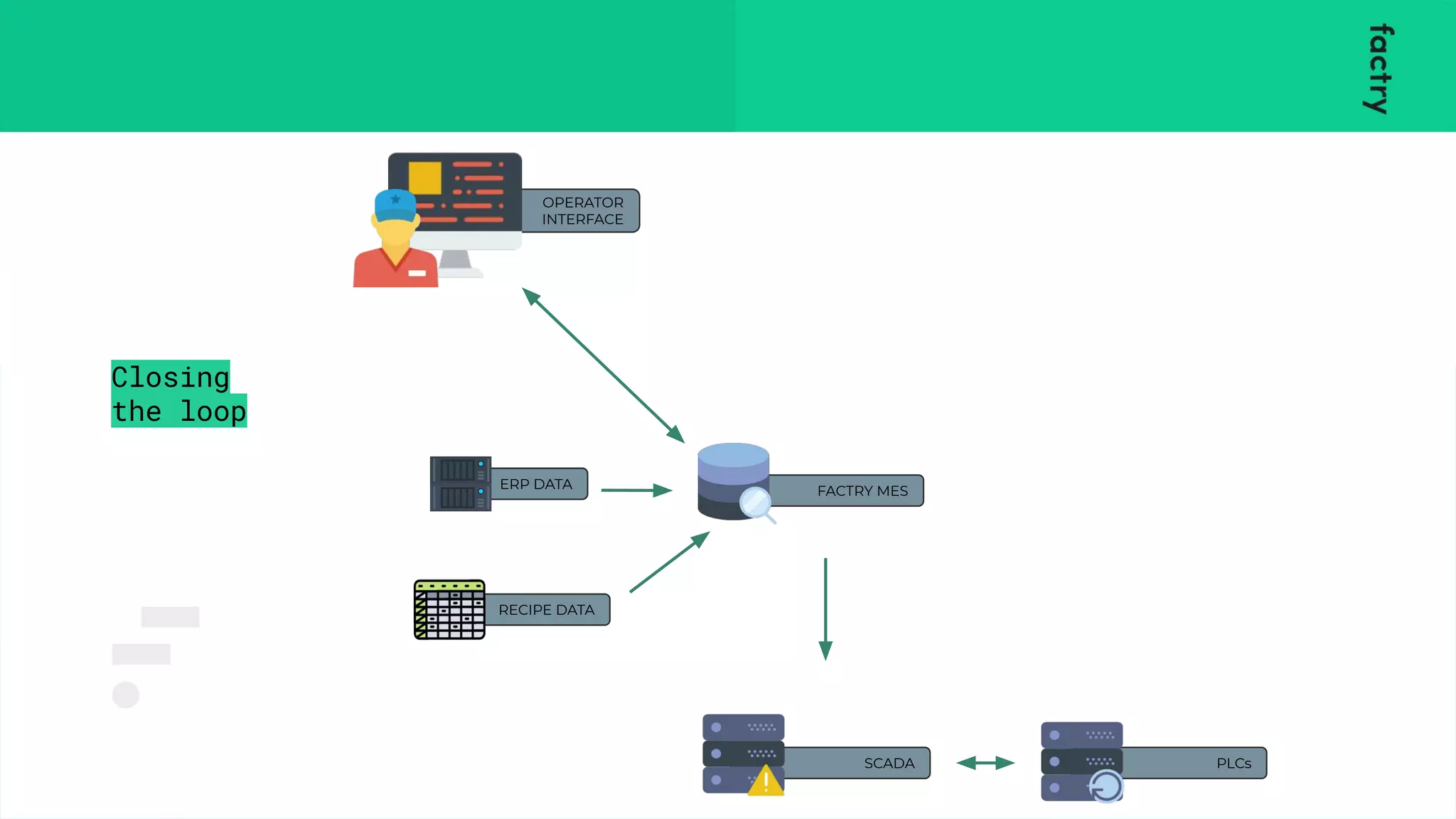

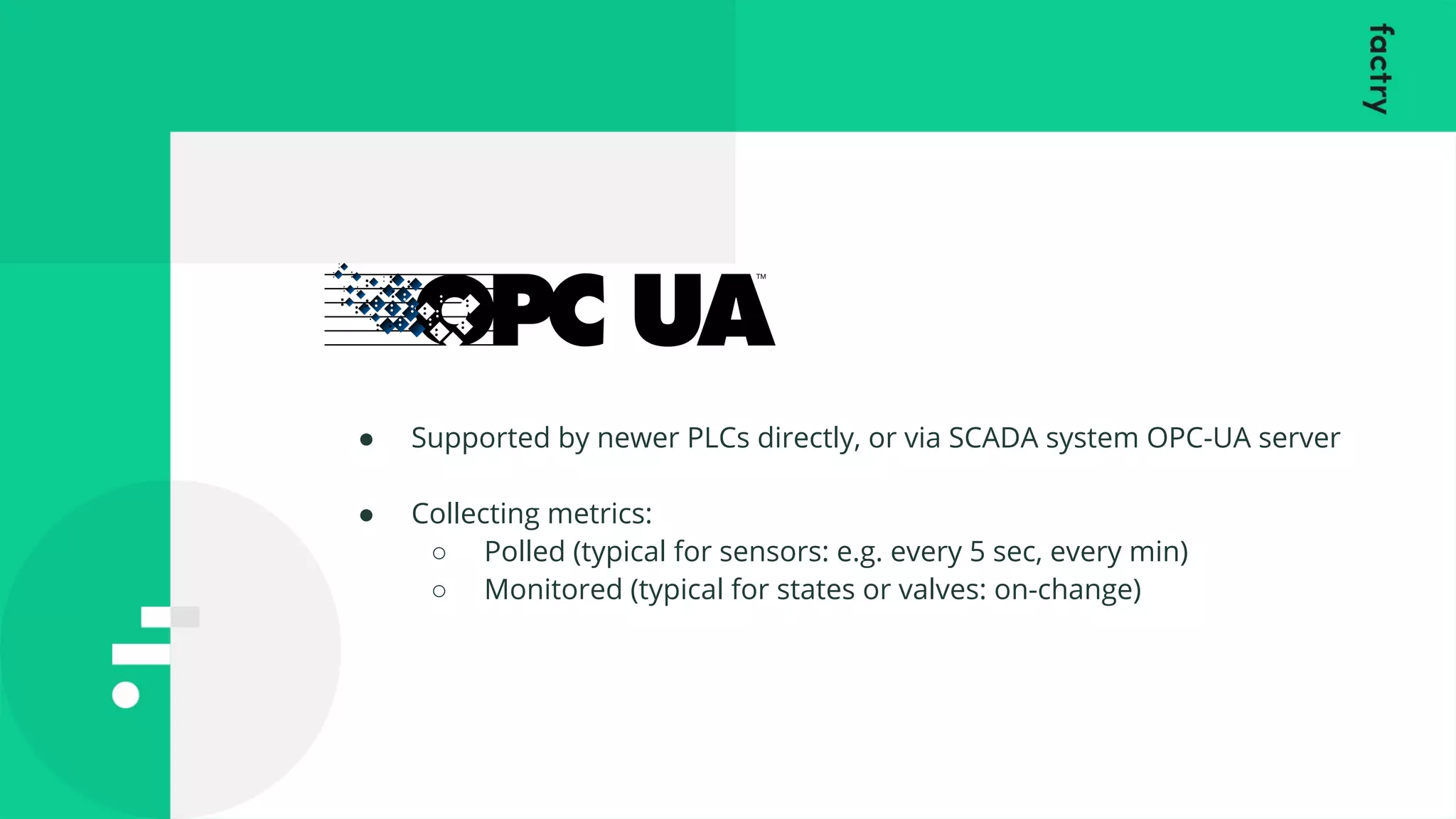

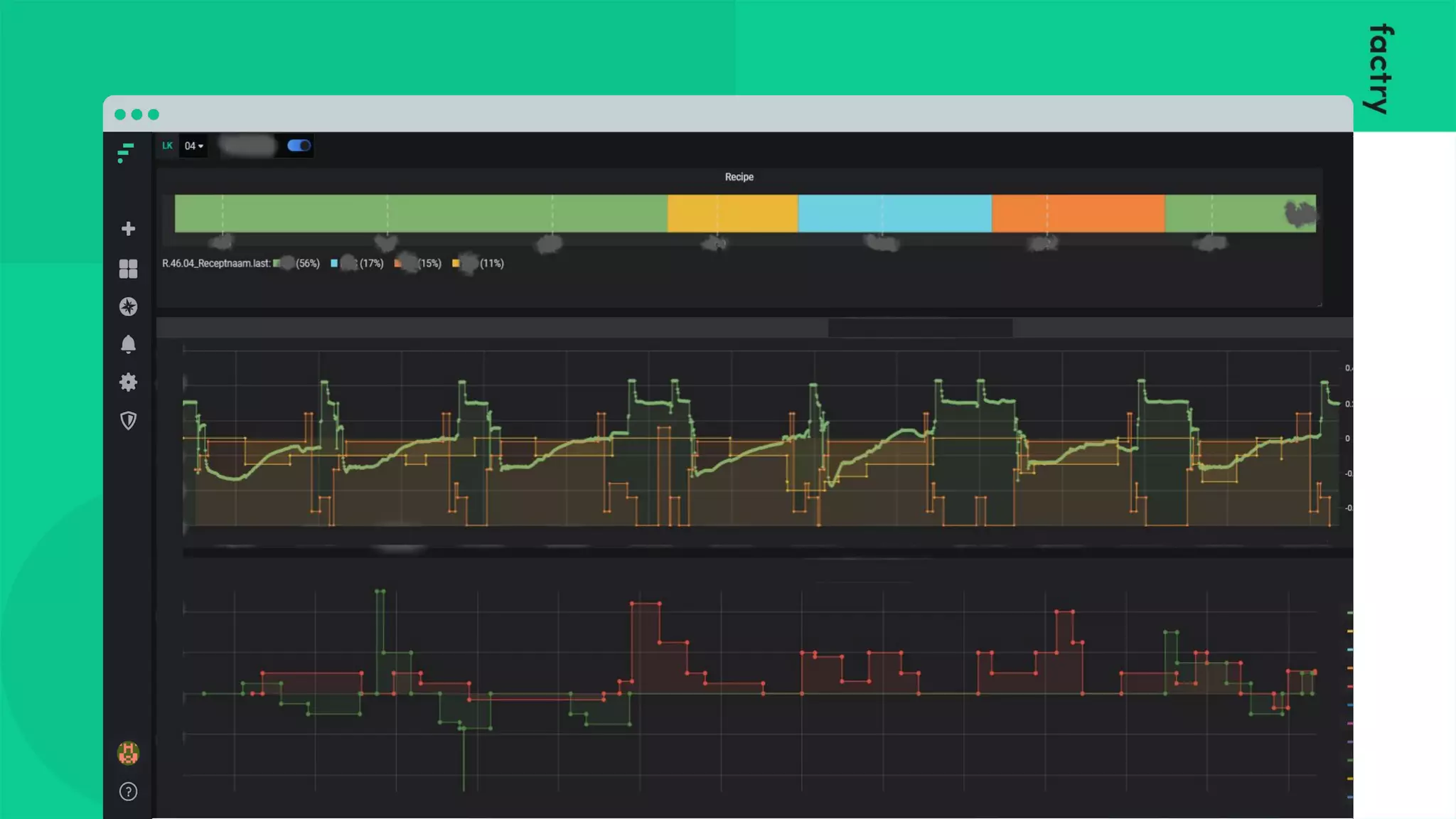

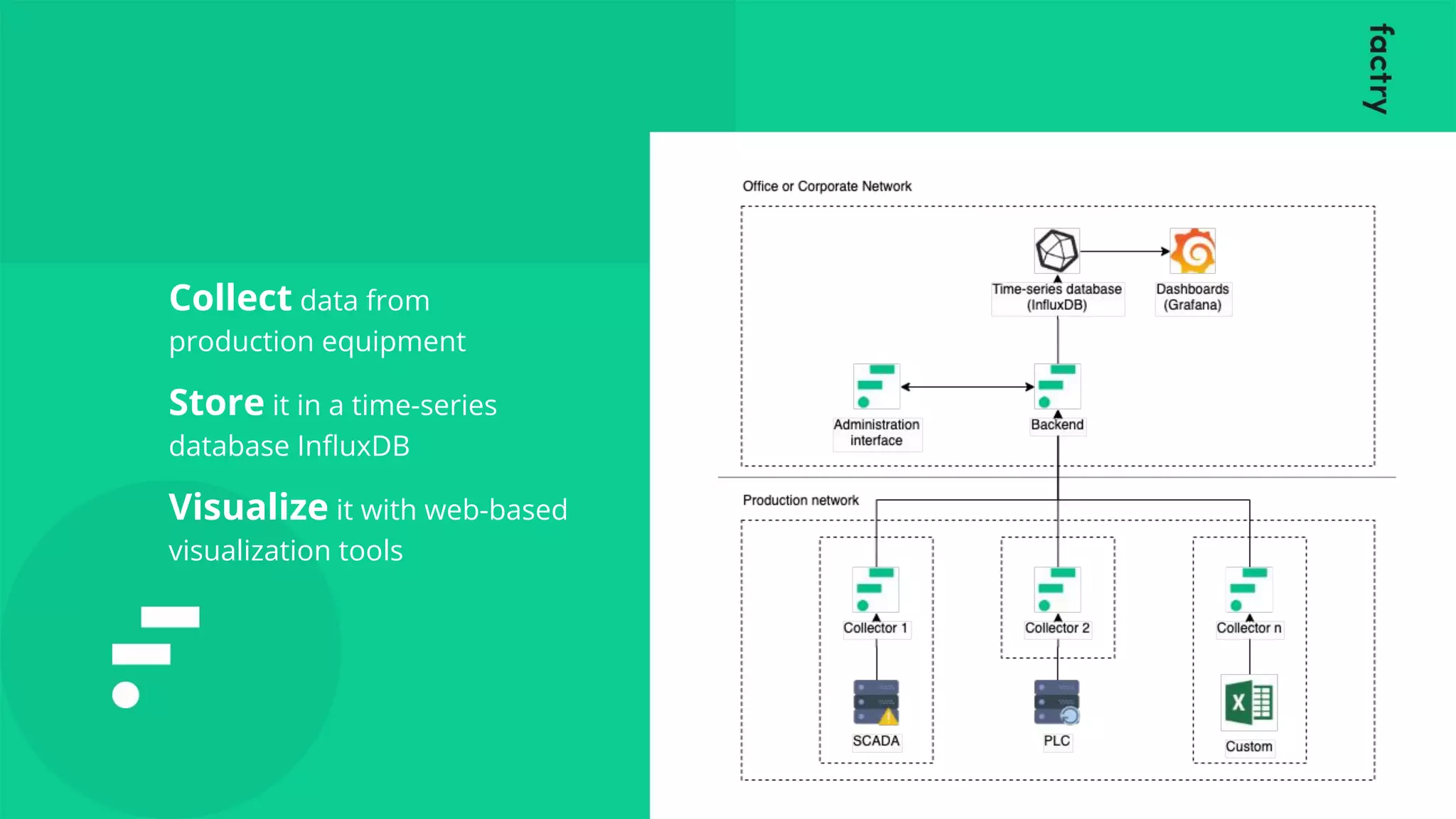

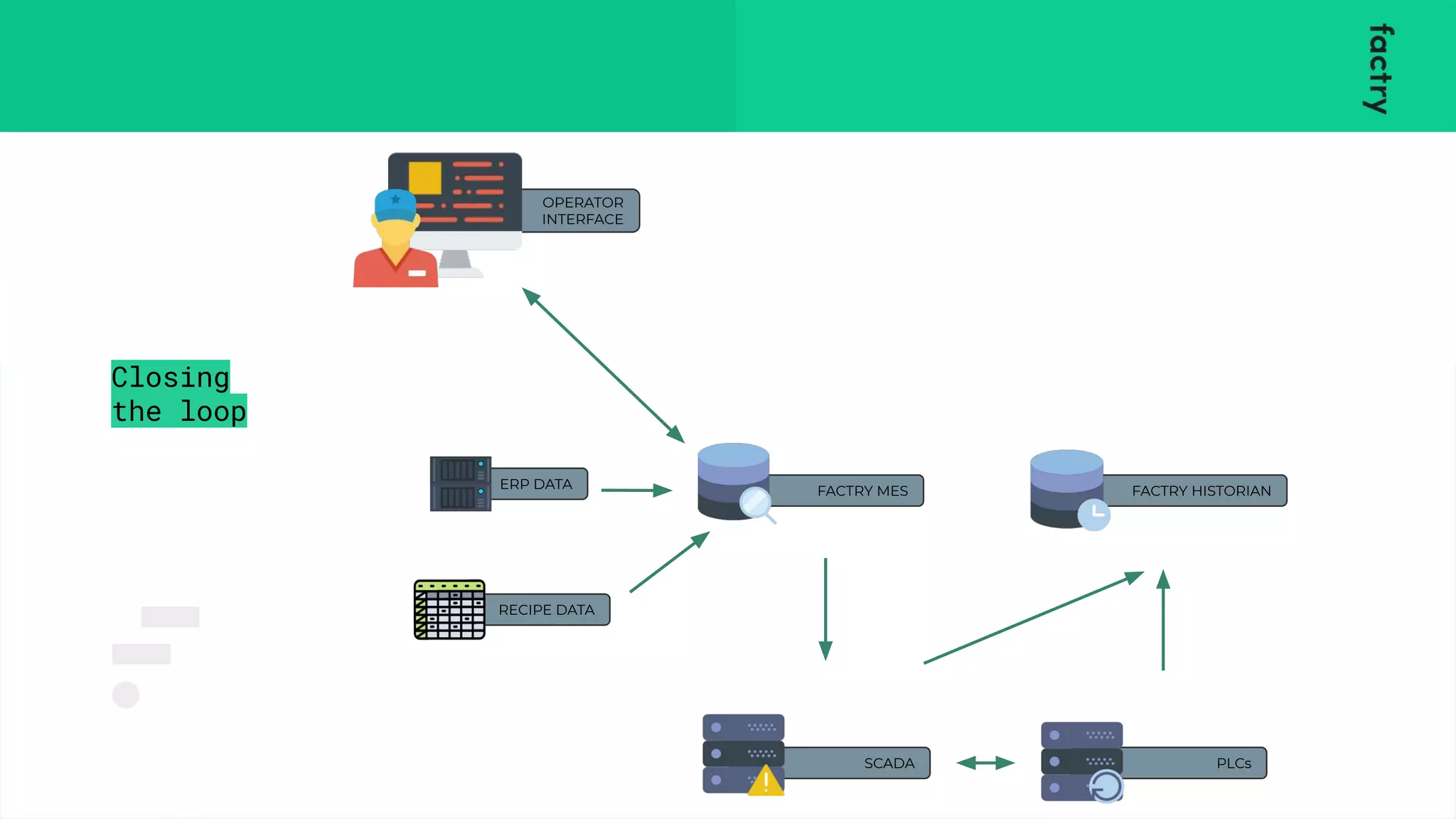

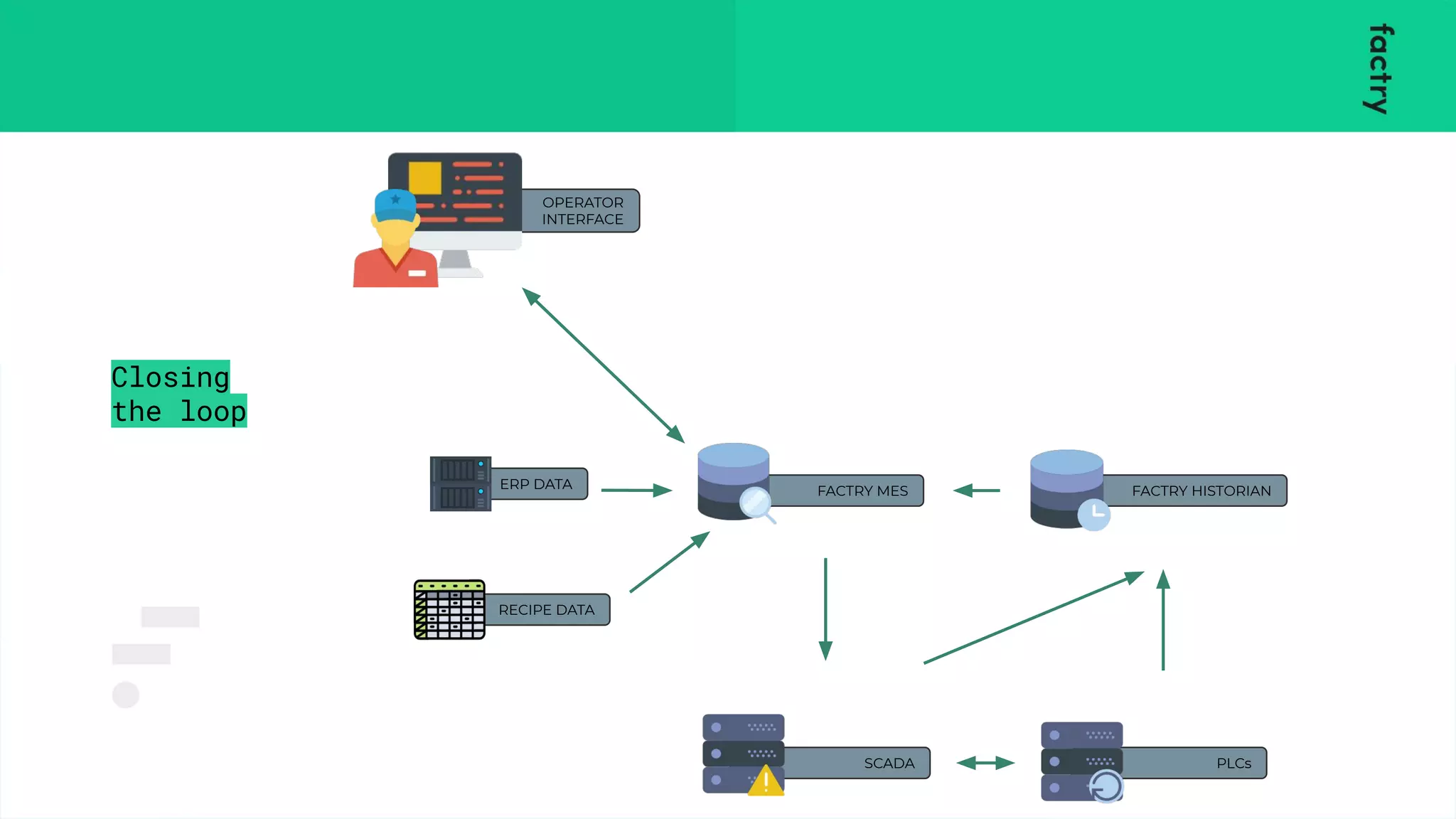

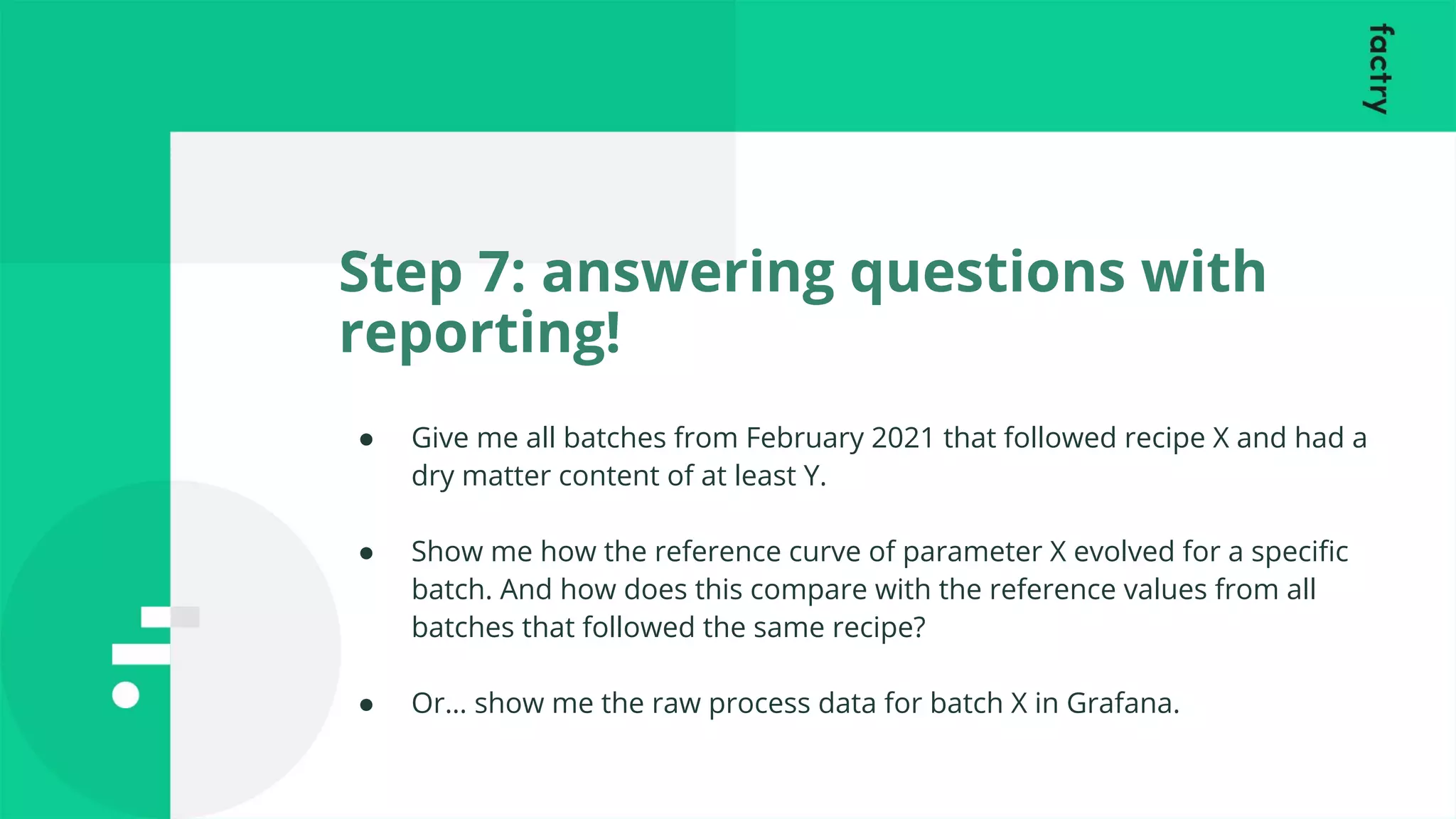

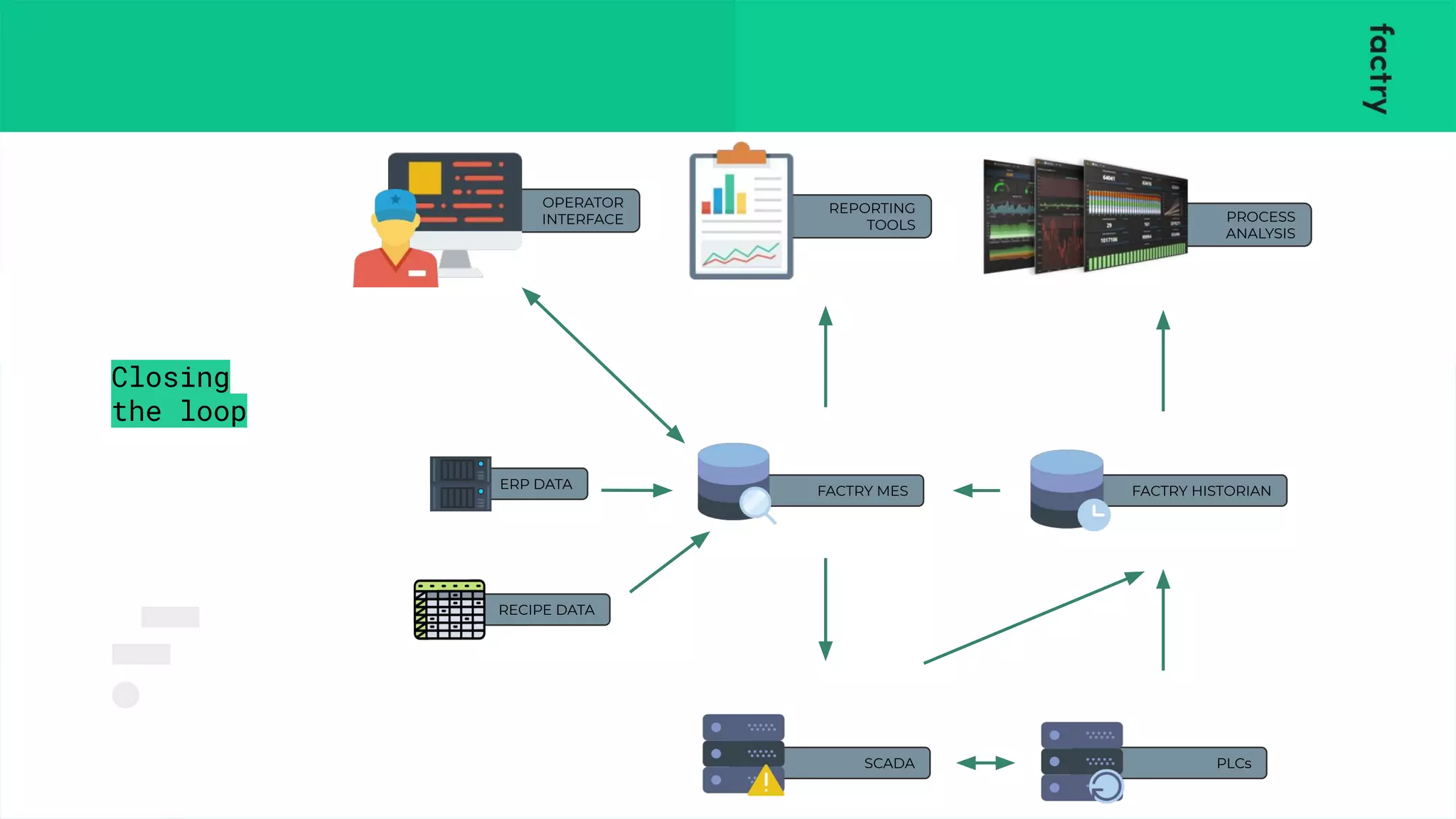

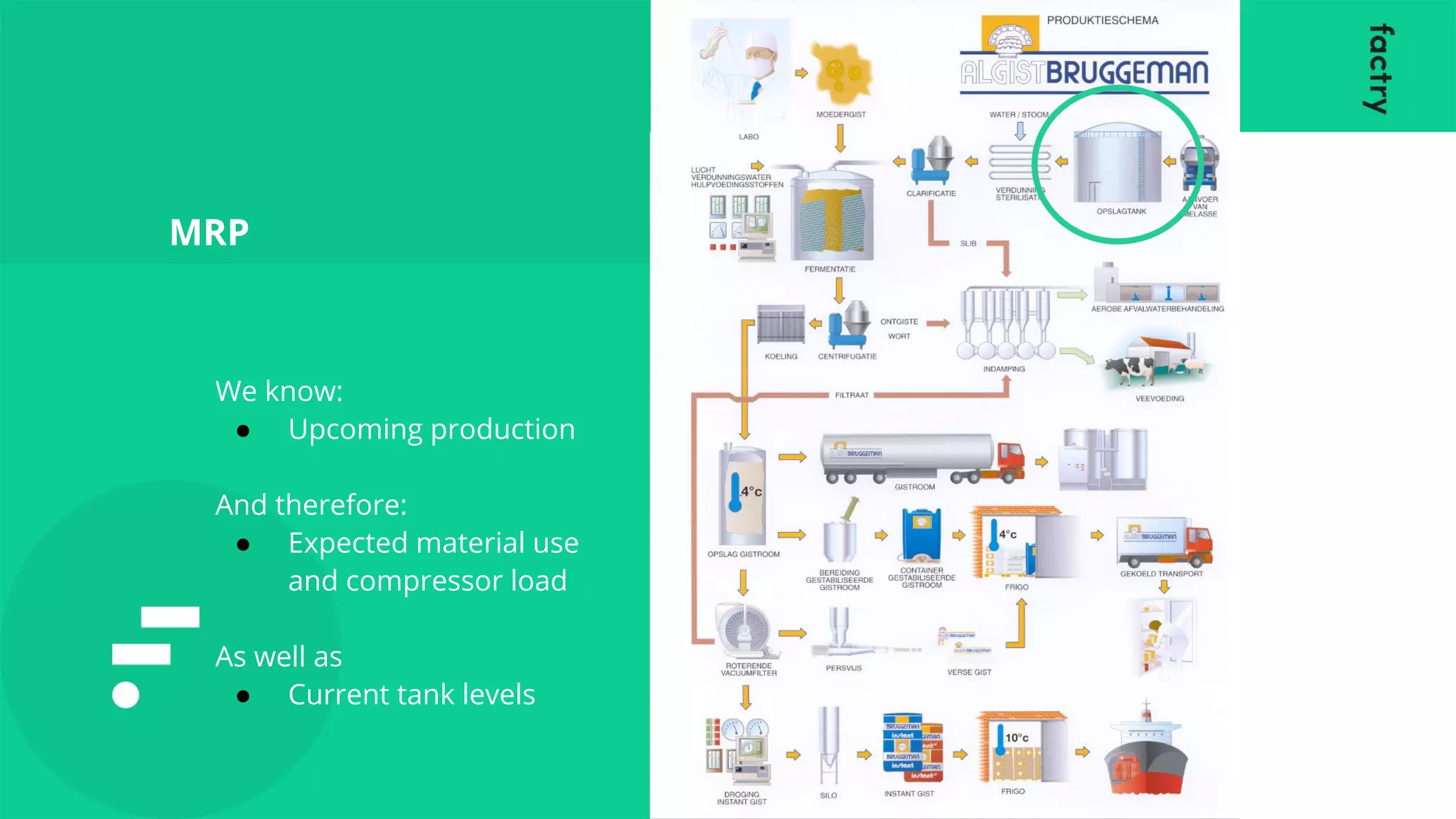

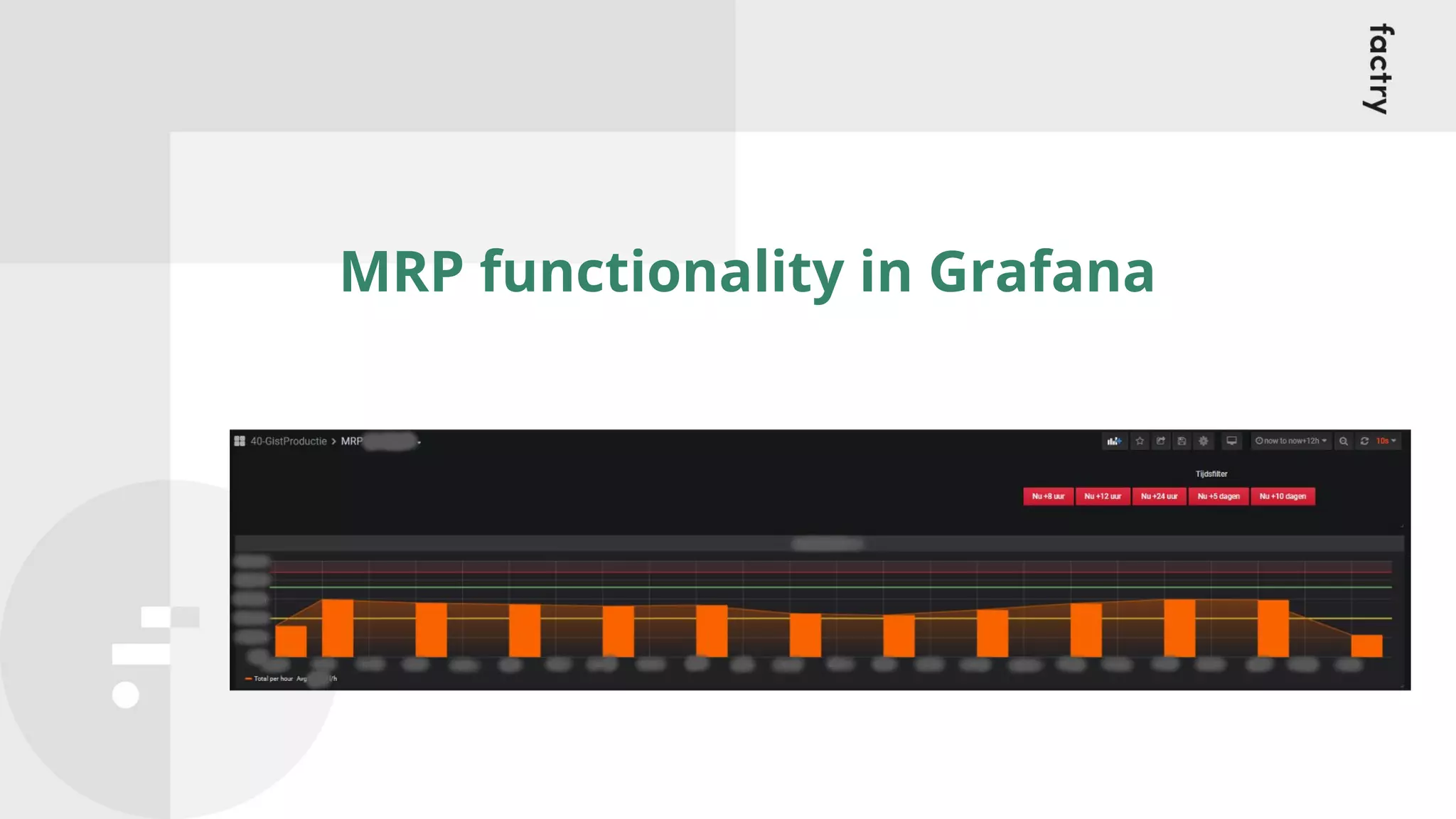

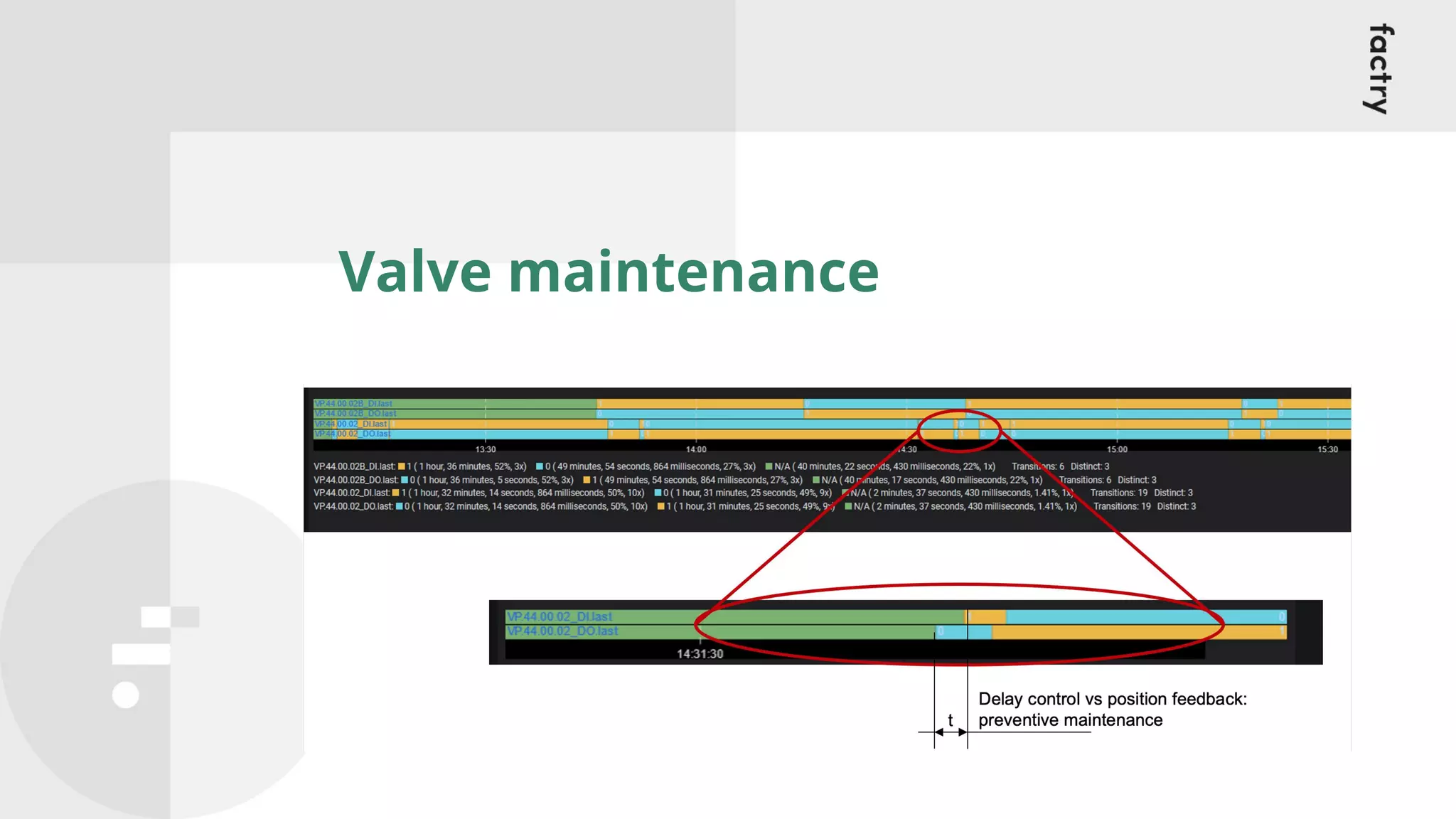

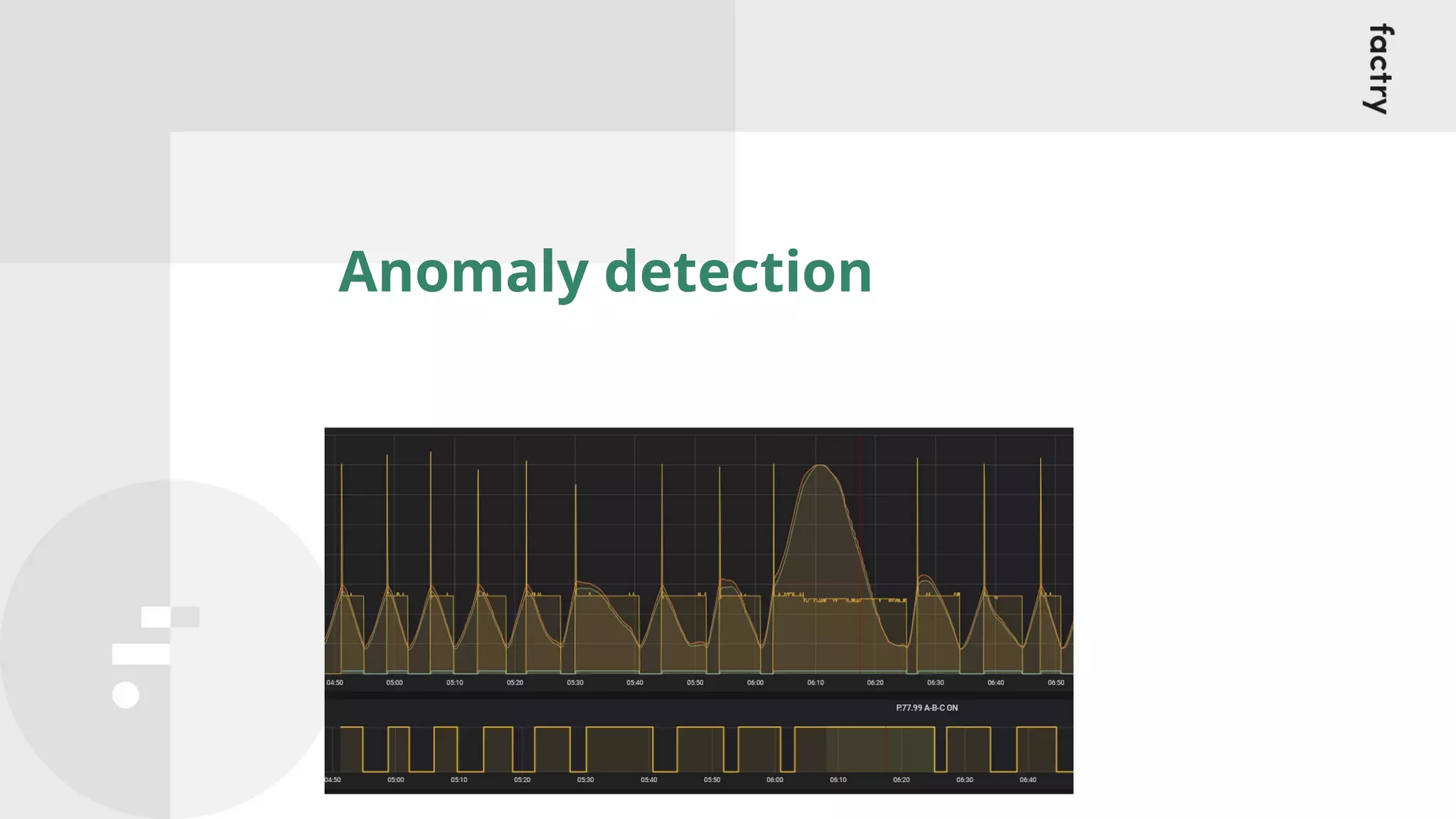

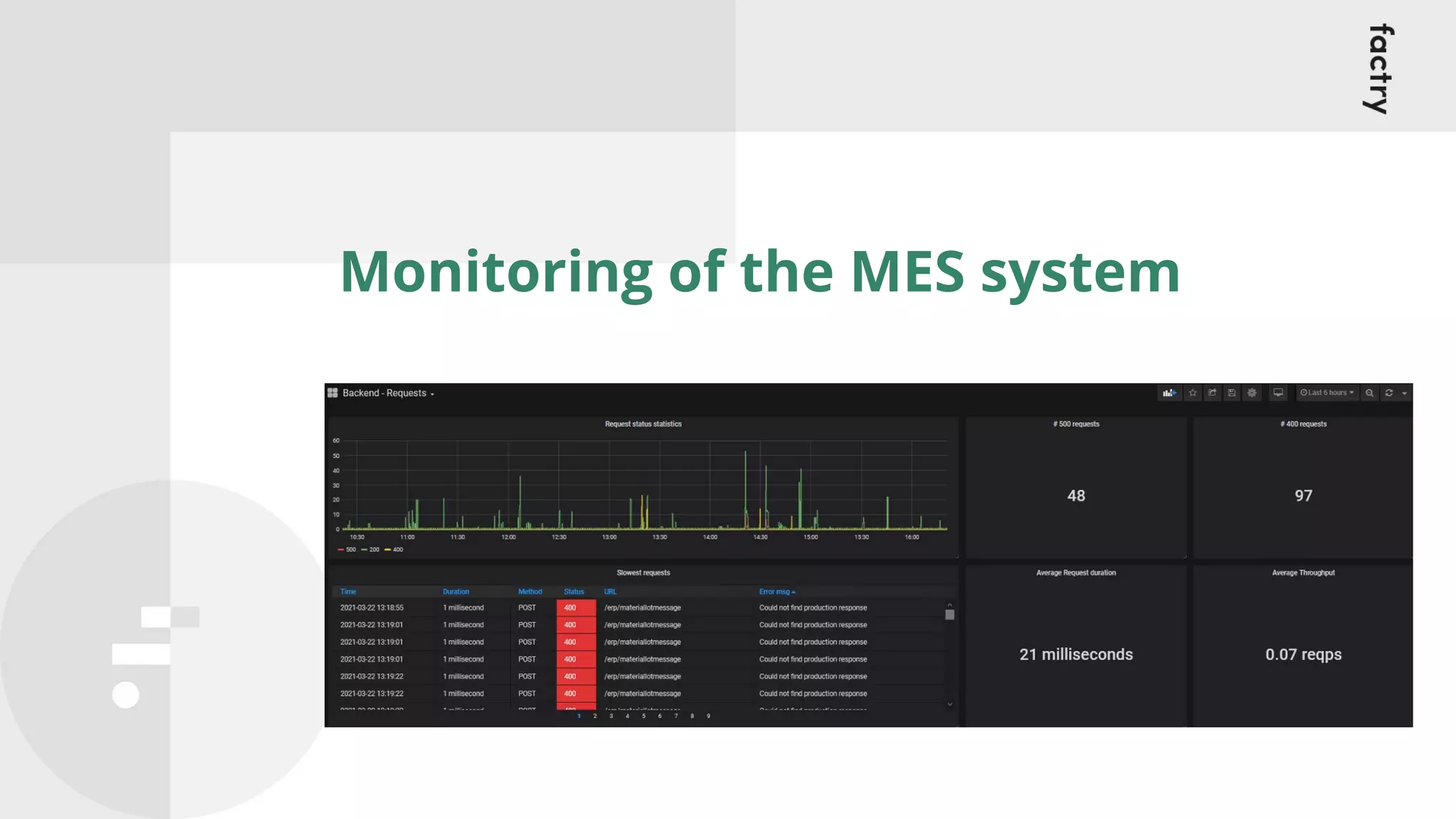

The document discusses a webinar hosted by Factry on improving operational intelligence through data integration, specifically using OPC-UA to collect IIOT time series data from PLC and SCADA systems. It highlights the challenges faced by Algist Bruggeman in managing fermentation data, the solutions implemented to streamline data collection and analysis, and the unexpected benefits achieved since integrating these systems. Key takeaways include the importance of creating a cohesive data platform and the positive impact of proper data management on business operations.