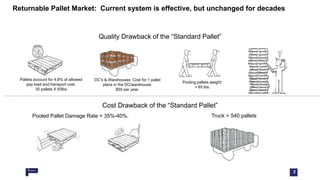

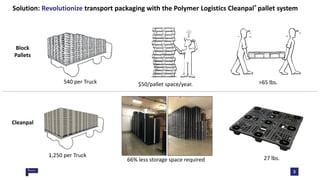

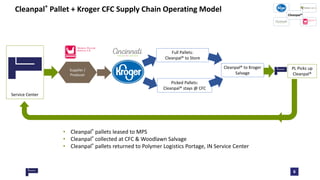

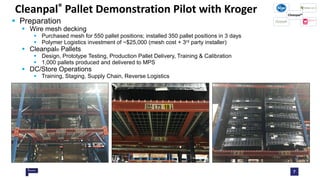

The CleanPal® pilot with Kroger demonstrated significant advantages over traditional wooden pallets, including reduced weight, improved handling, and lower damage rates. The new polymer logistics pallets require less storage space and equipment, leading to overall cost savings and efficiency in the supply chain. Feedback from various stakeholders indicated strong support for transitioning to CleanPal® due to its ergonomic design, durability, and sanitation benefits.