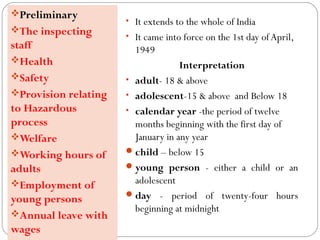

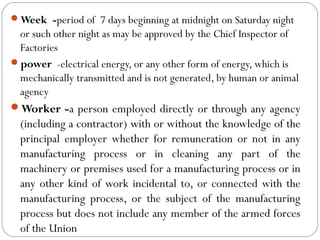

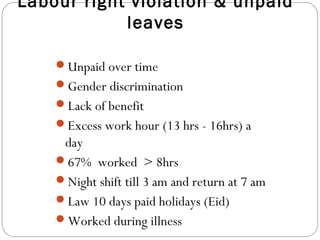

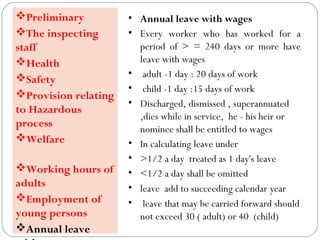

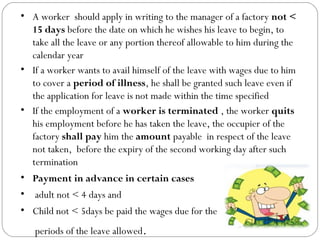

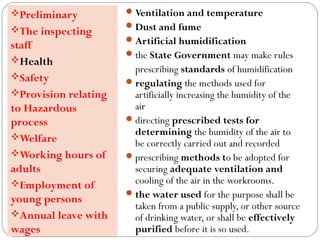

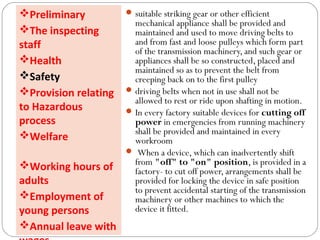

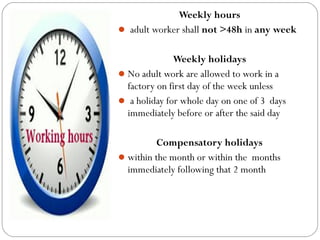

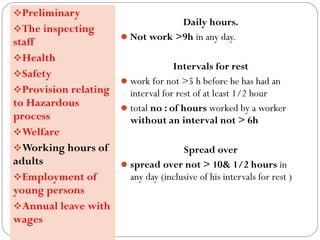

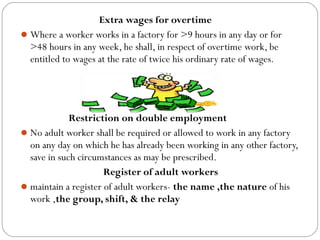

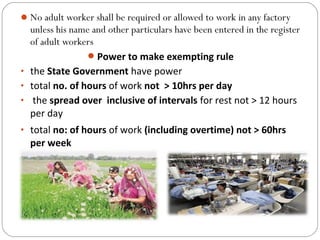

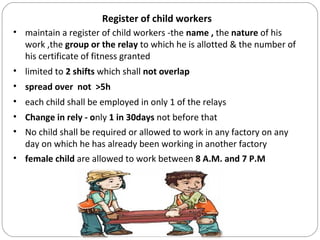

The document summarizes key aspects of the Factories Act of 1948 in India, including definitions, inspections, health and safety provisions, and regulations around employment of young persons and working hours. Some key points covered are:

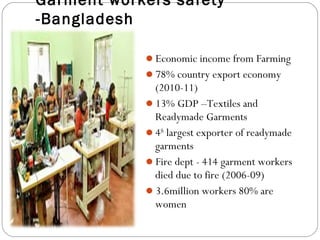

- It aims to regulate working conditions in factories across India and extends to all premises with more than 10 power-assisted or 20 non-power-assisted workers.

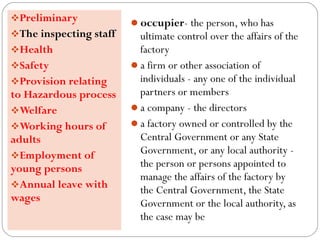

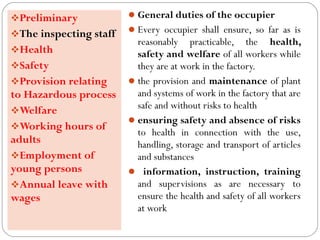

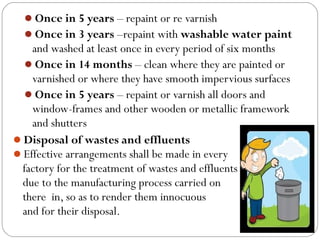

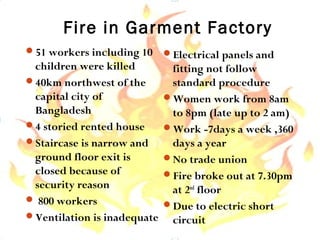

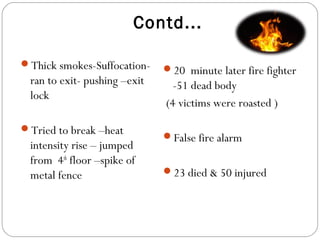

- It defines terms like factory, worker, occupier and establishes standards for facilities, cleanliness, ventilation, lighting, drinking water and sanitation like latrines.

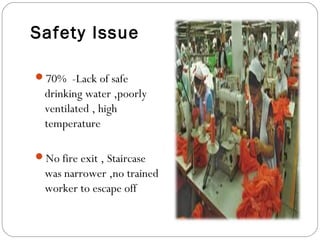

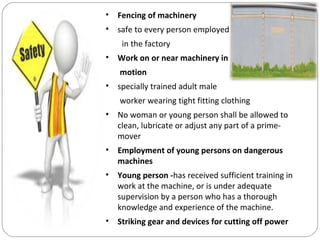

- It has provisions for safety of machinery, their guarding, and prohibition of risky work by women, children and untrained persons. Annual leave and limits on work