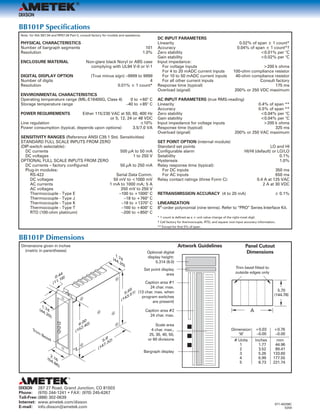

The AMETEK Dixson BB101P programmable bargraph is designed for applications requiring high accuracy, readability, and reliability, serving as a replacement for traditional moving pointer meters. It features a robust microprocessor-based design, optional digital displays, and extensive programmability, making it versatile for both new applications and retrofits of existing systems. Additional options include temperature measurement modules, set point relay control, and various input signal configurations, ensuring adaptability across various industrial environments.