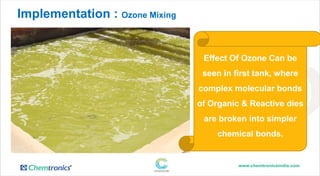

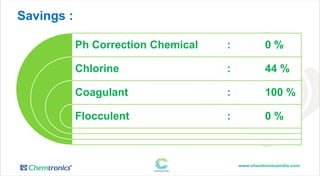

This document discusses the implementation of an ozone oxidation system at a textile plant in Nairobi, Kenya to treat its wastewater. The current treatment process uses large amounts of chemicals but produces high TDS water. The proposed solution adds ozone treatment in the primary equalization tank to break down dye compounds before further treatment. This is expected to significantly reduce chemical usage and costs, lowering the operating costs by $23,725 per year. With a total project cost of $35,000, the return on investment is estimated to be 1.47 years or 18 months.

![INDEX

1. Site Data

2. Present Scenario

3. Objective

4. Offered Solution & Technology

5. General Arrangement Drawing & PFD

6. Implementation – Site Pictures & Video

7. Operation & Maintenance

8. Consumables & Replacements

9. Savings

10. Return On Investment [ROI]](https://image.slidesharecdn.com/ppt14casestudy-textileetpspinnersspinners-160525014343/85/Case-study-Textile-ETP-Spinners-Spinners-2-320.jpg)

![Savings & Returns On Investments [ROI] :

Chemicals

Chemical

Specification

Quantity Per Day Rate

Per

Unit

Cost Per Day

SavingsBefore

Ozonation

After

Ozonation

Before

Ozonation

After

Ozonation

Name Kg or Ltrs Kg or Ltrs KS KS KS KS

Chlorine 45 25 180 8,100 4,500 3,600

Ph Adjust NaOH 10 10 70 700 700 -

Coagulant 25 - 90 2,250

-

2,250

Flocculent 0.4 0.4 716 286 286 -

Total Cost

Per Day

11,336 5,486 5,850

Total Cost

Per Year

4,137,786 2,002,536 2,135,250

Savings in

USD per Yr

45,975 22,250 $ 23,725

Ozonation Project Cost in USD [Including Supply + Wooden Packing + Air Freight + I & C] $ 35,000

Return On Investment [In Years] KS – Kenya Shilling 1.48](https://image.slidesharecdn.com/ppt14casestudy-textileetpspinnersspinners-160525014343/85/Case-study-Textile-ETP-Spinners-Spinners-13-320.jpg)

![Benefits :

Reduction In Chemical Cost – Reduction in OPEX

Less Storage, Transport & Handling – Space & Time saving

Higher Quality of Treated Waste Water

Lower Operational Time – [Higher Plant Capacity]

Higher Recovery – Less Blow Down [Lower Waste Water TDS]

Lower Sludge Formation & Handling](https://image.slidesharecdn.com/ppt14casestudy-textileetpspinnersspinners-160525014343/85/Case-study-Textile-ETP-Spinners-Spinners-15-320.jpg)

![Operation & Maintenance :

Ozonator is fully electrical operated. [No Consumables]

Ozonator should be operated 24 x 7

Routine maintenance frequency is once in months

Break-down repair/maintenance will be attained in 48 hrs.

(Depending on site criticality & reliability of equipment, standby

units are recommended)](https://image.slidesharecdn.com/ppt14casestudy-textileetpspinnersspinners-160525014343/85/Case-study-Textile-ETP-Spinners-Spinners-17-320.jpg)