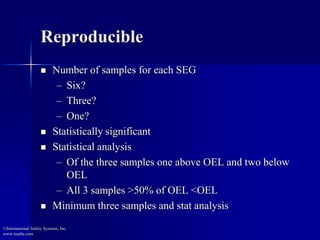

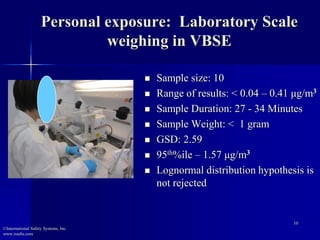

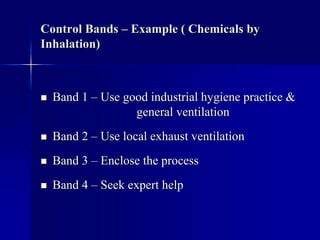

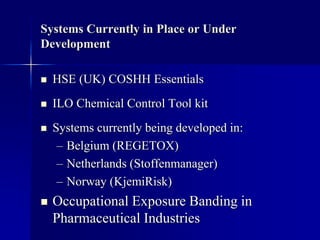

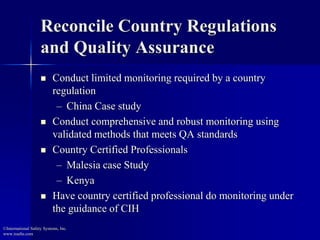

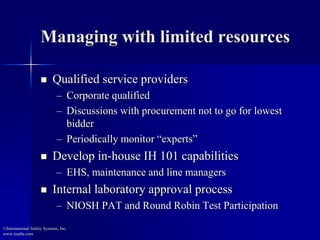

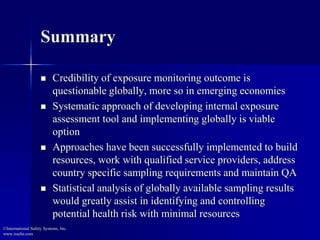

This document discusses challenges with industrial hygiene and environmental sampling globally. It notes issues with reliably, representativeness, and reproducibility of sampling. Solutions proposed include qualitative exposure assessments before sampling, statistical analysis of data, and control banding approaches. Frameworks for occupational hygiene in South Africa, Kenya and Nigeria are also summarized.