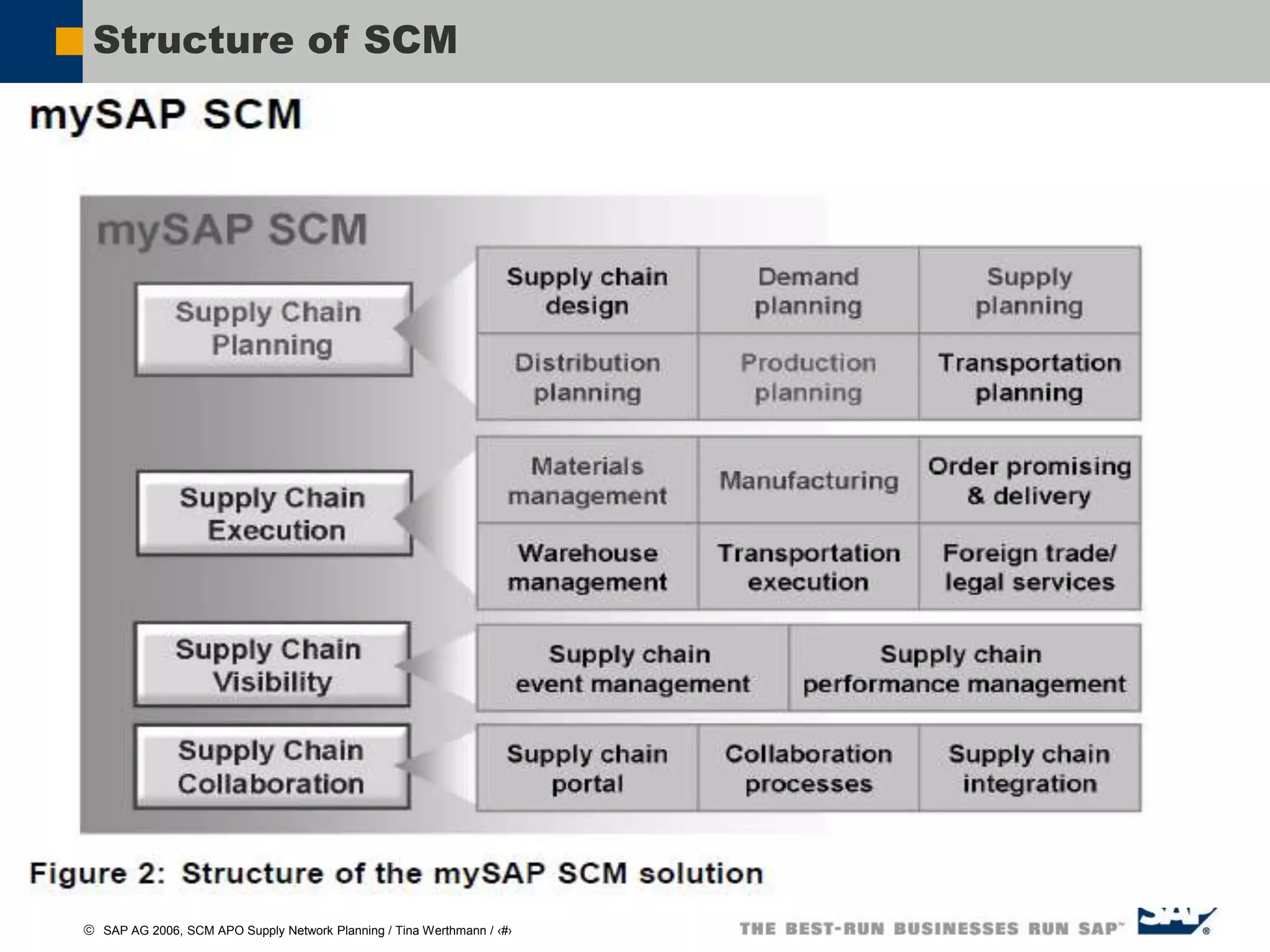

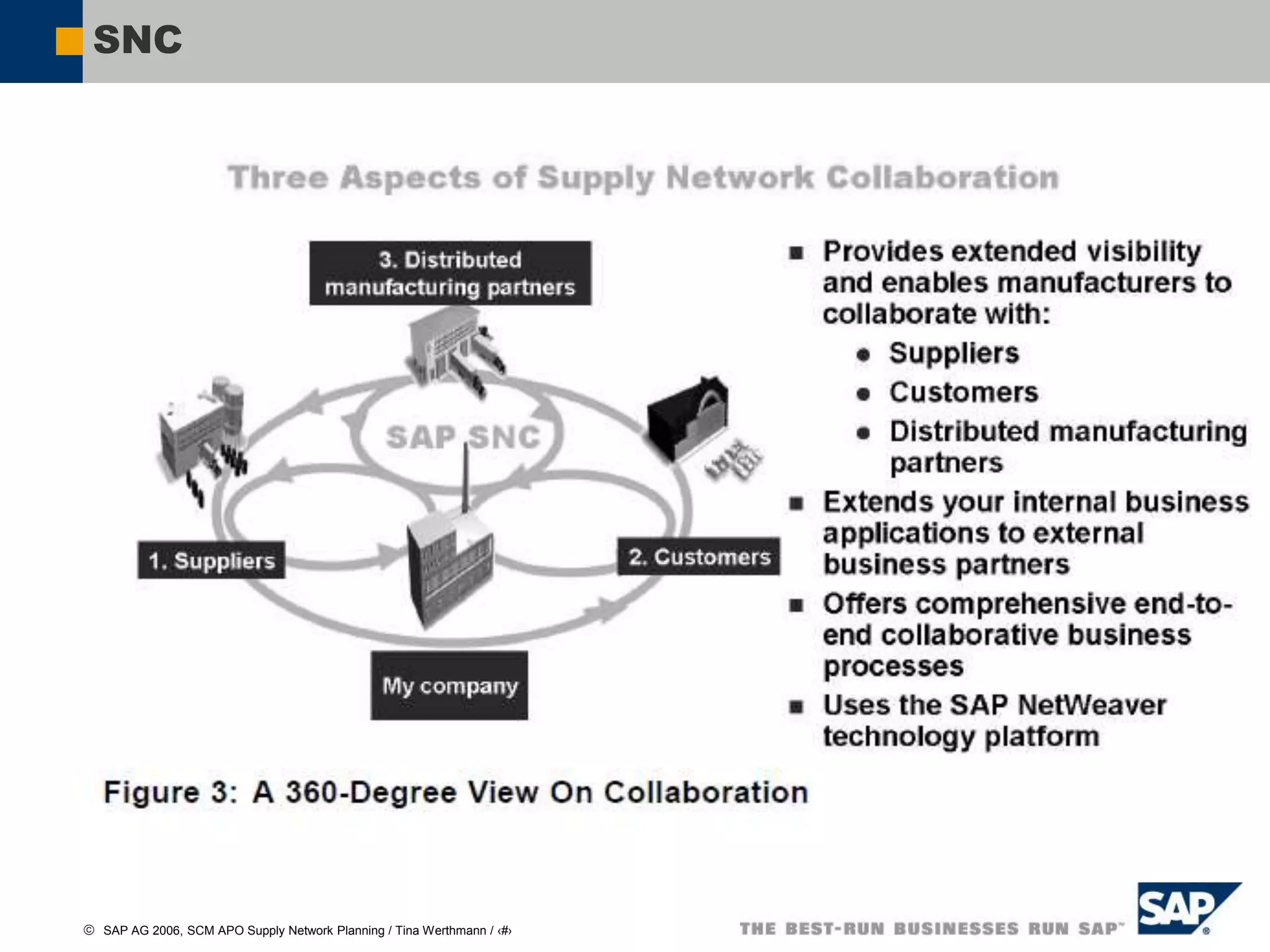

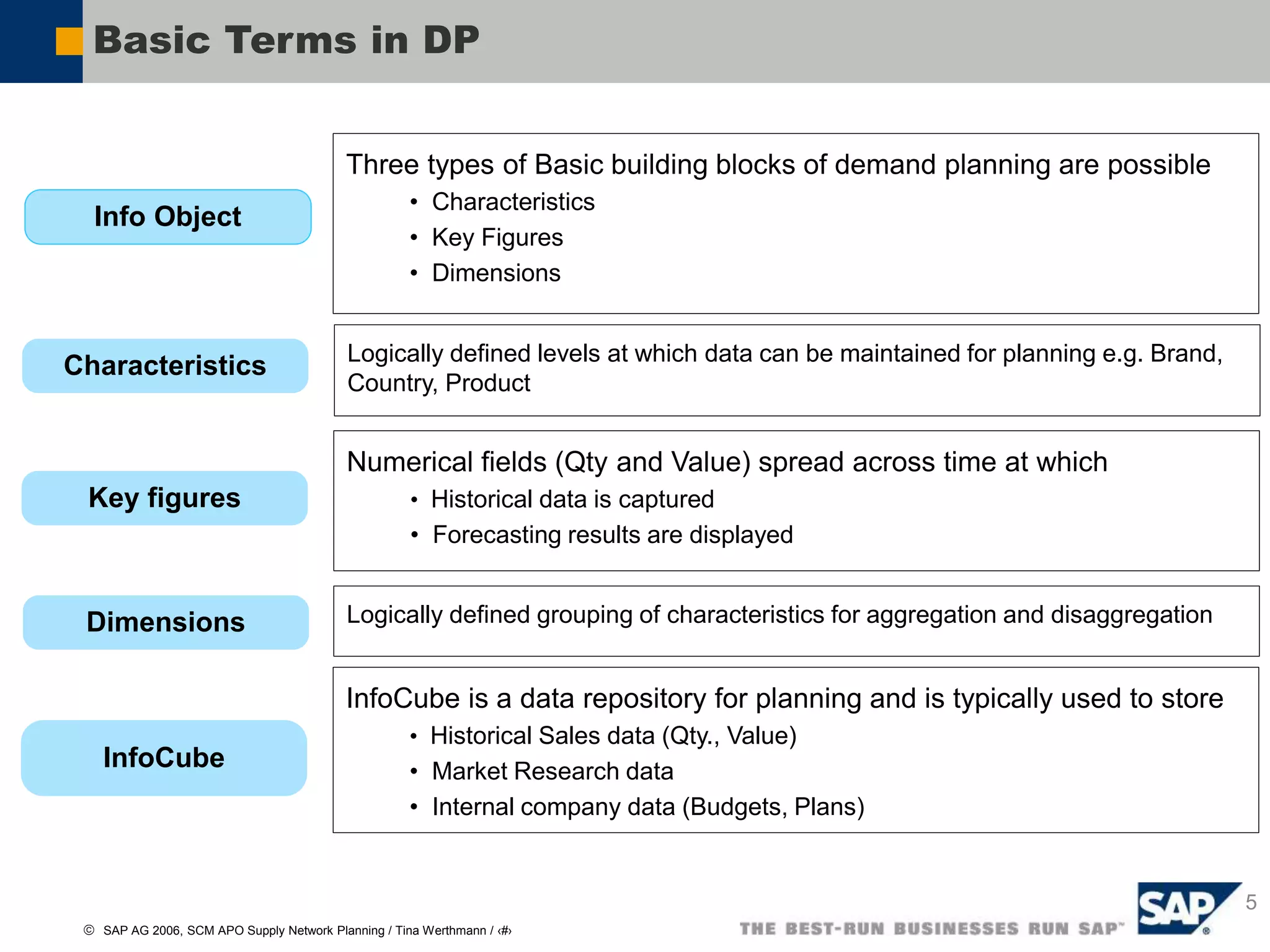

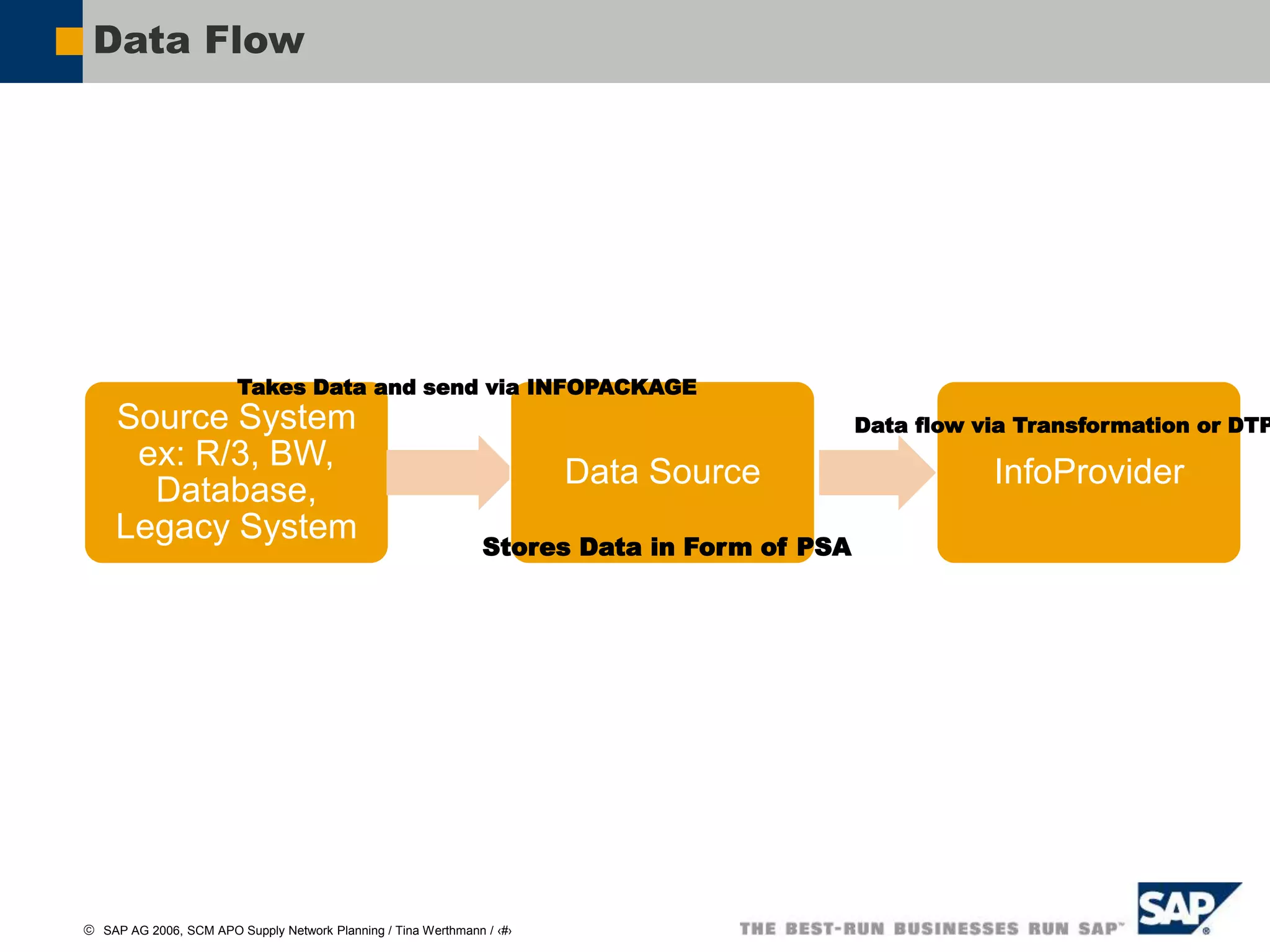

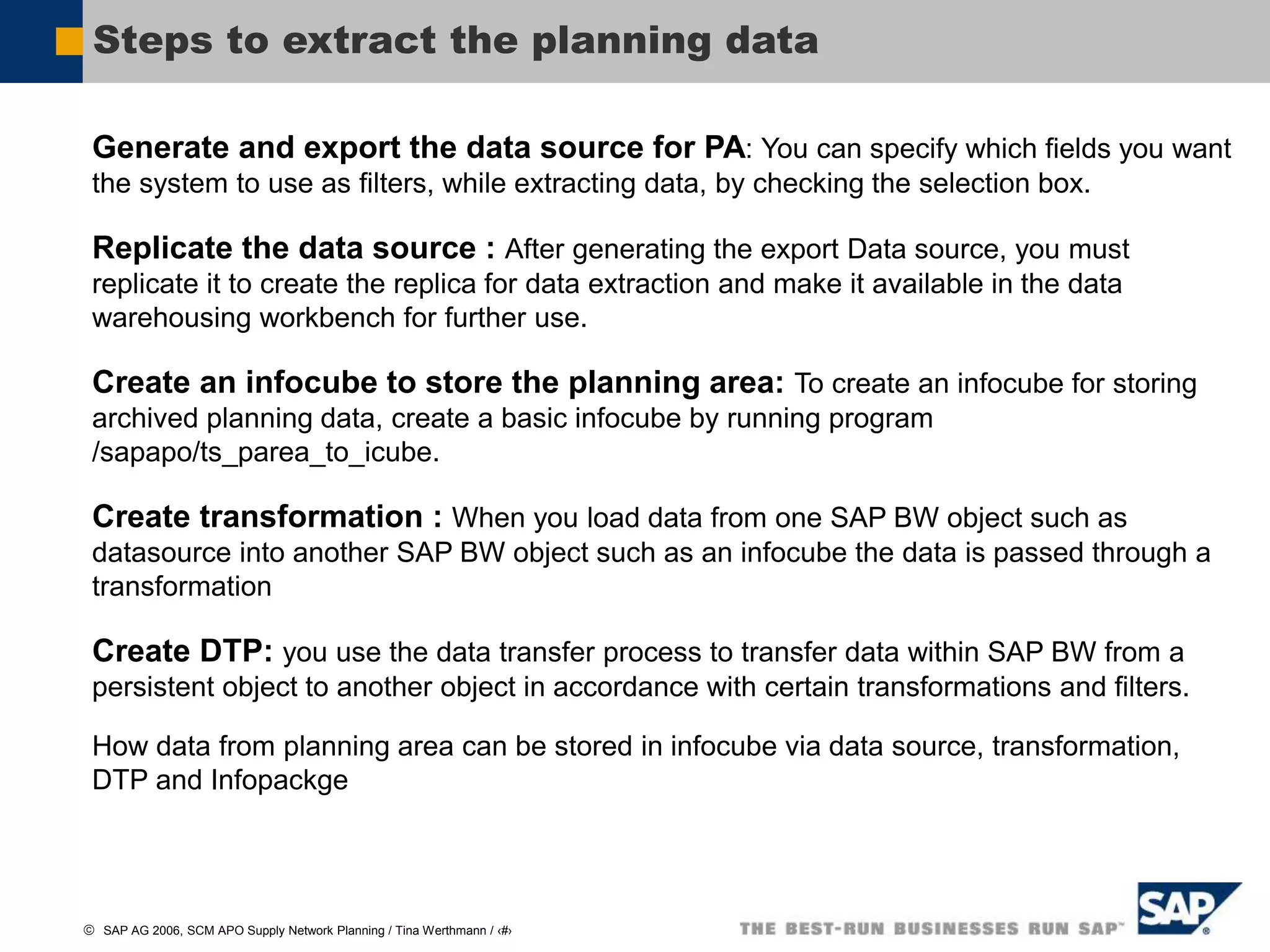

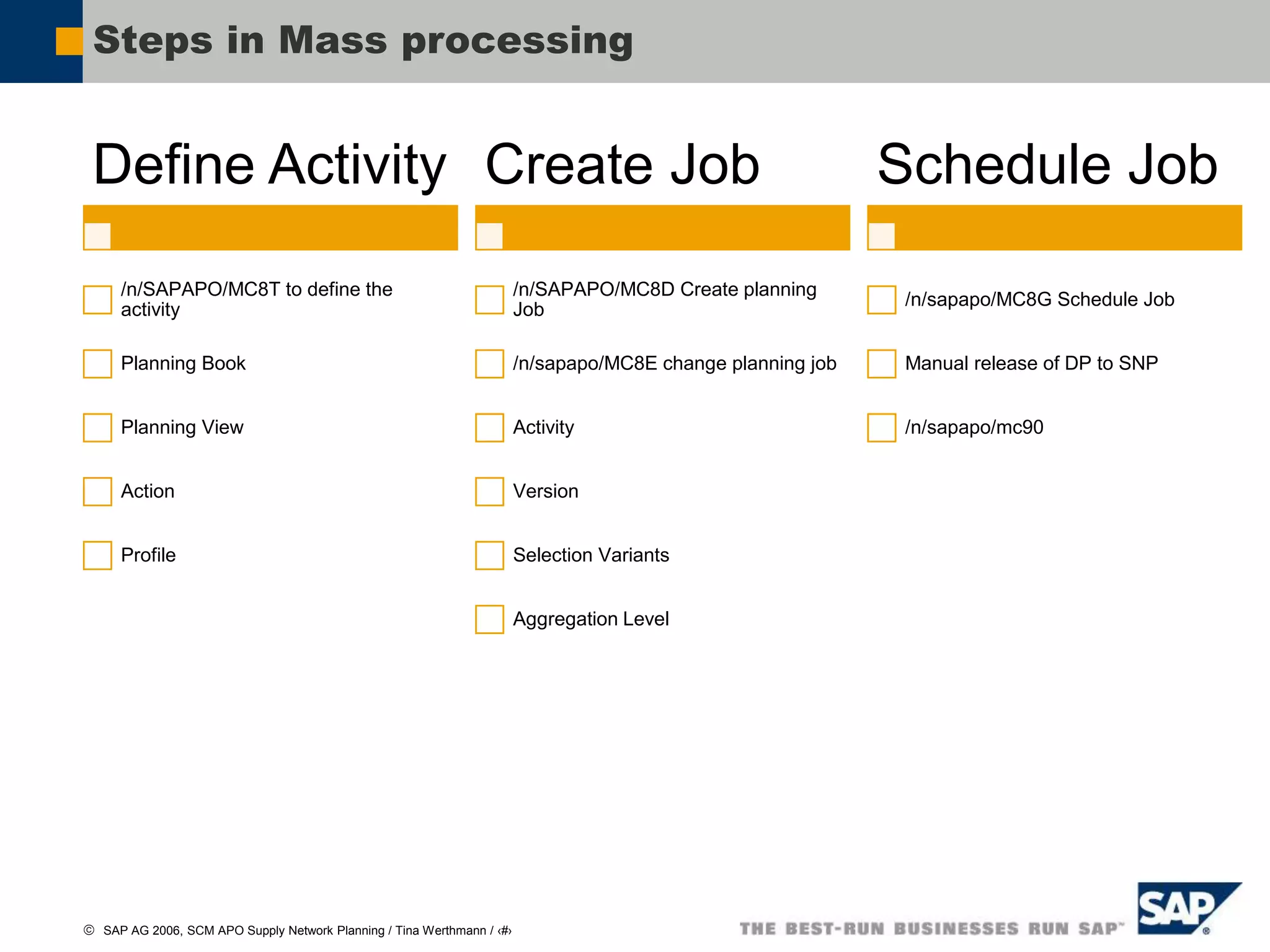

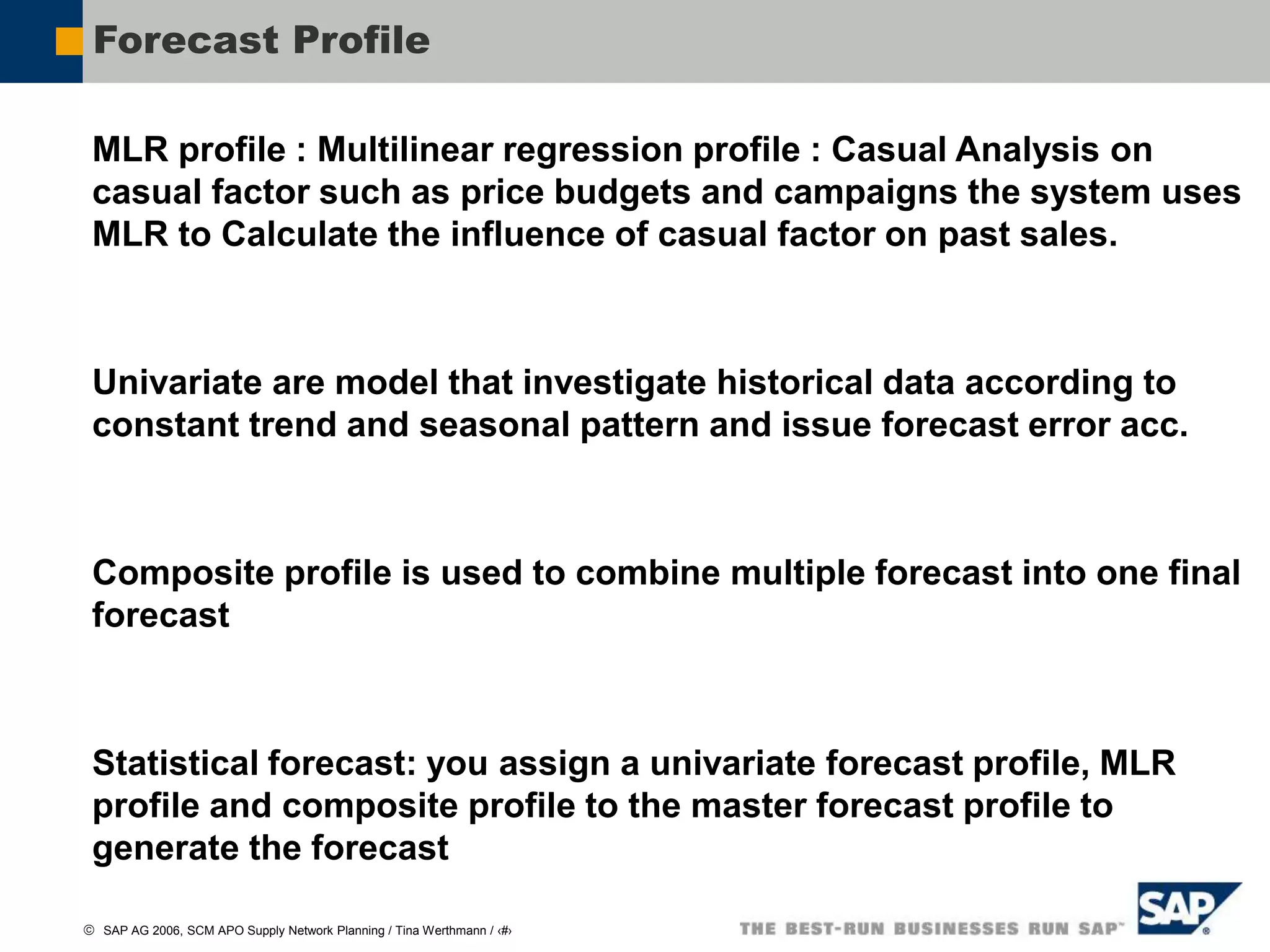

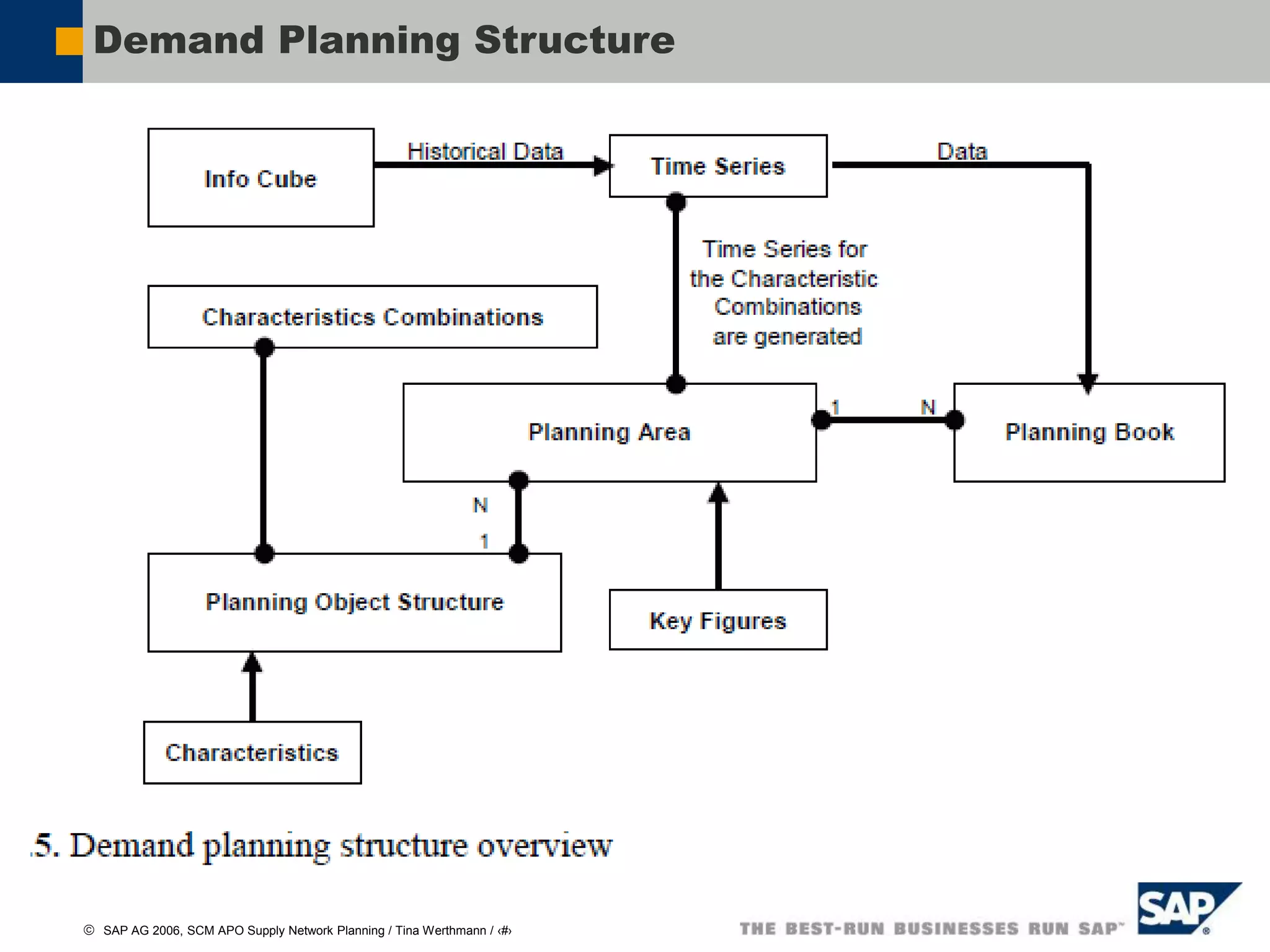

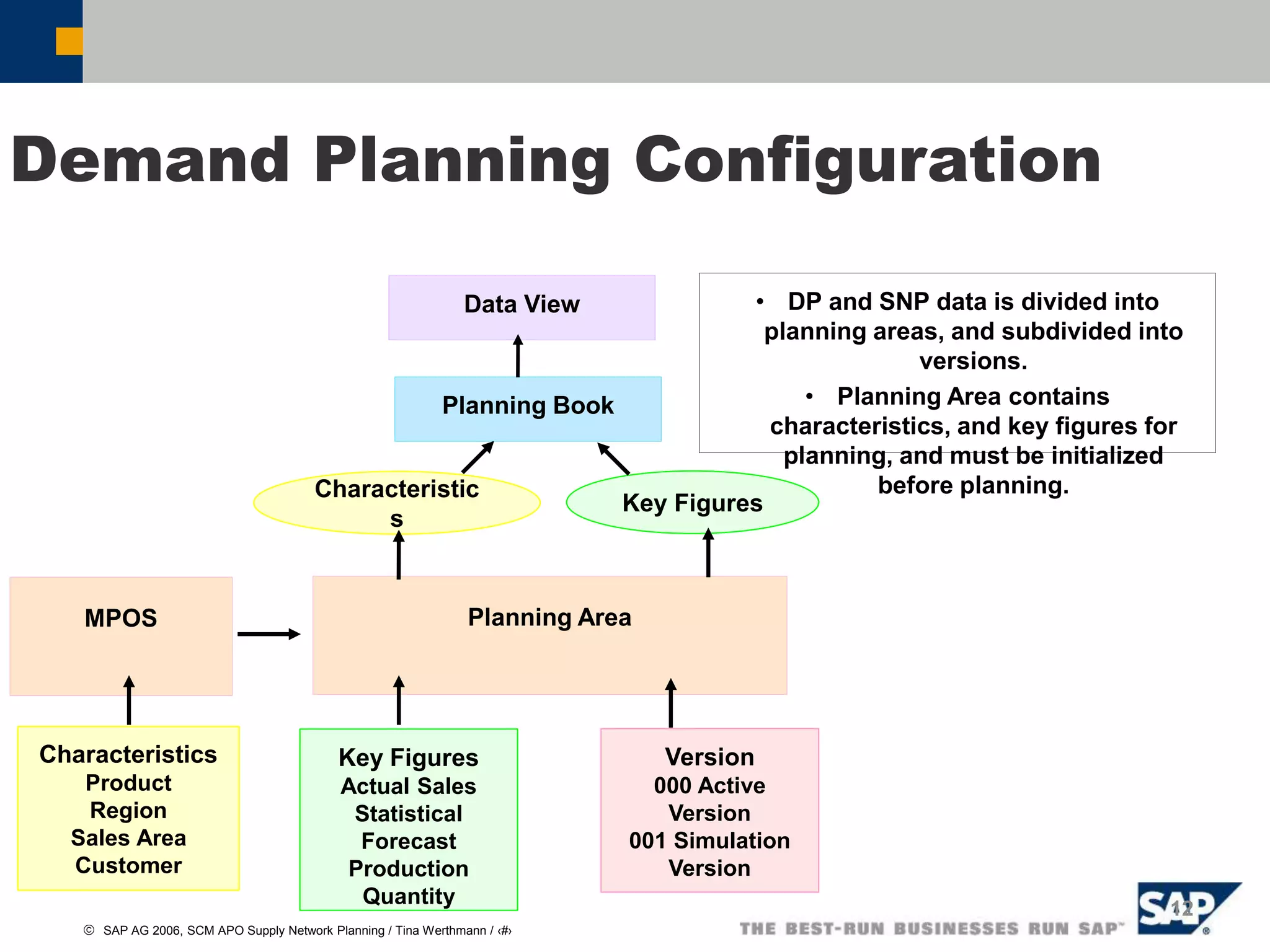

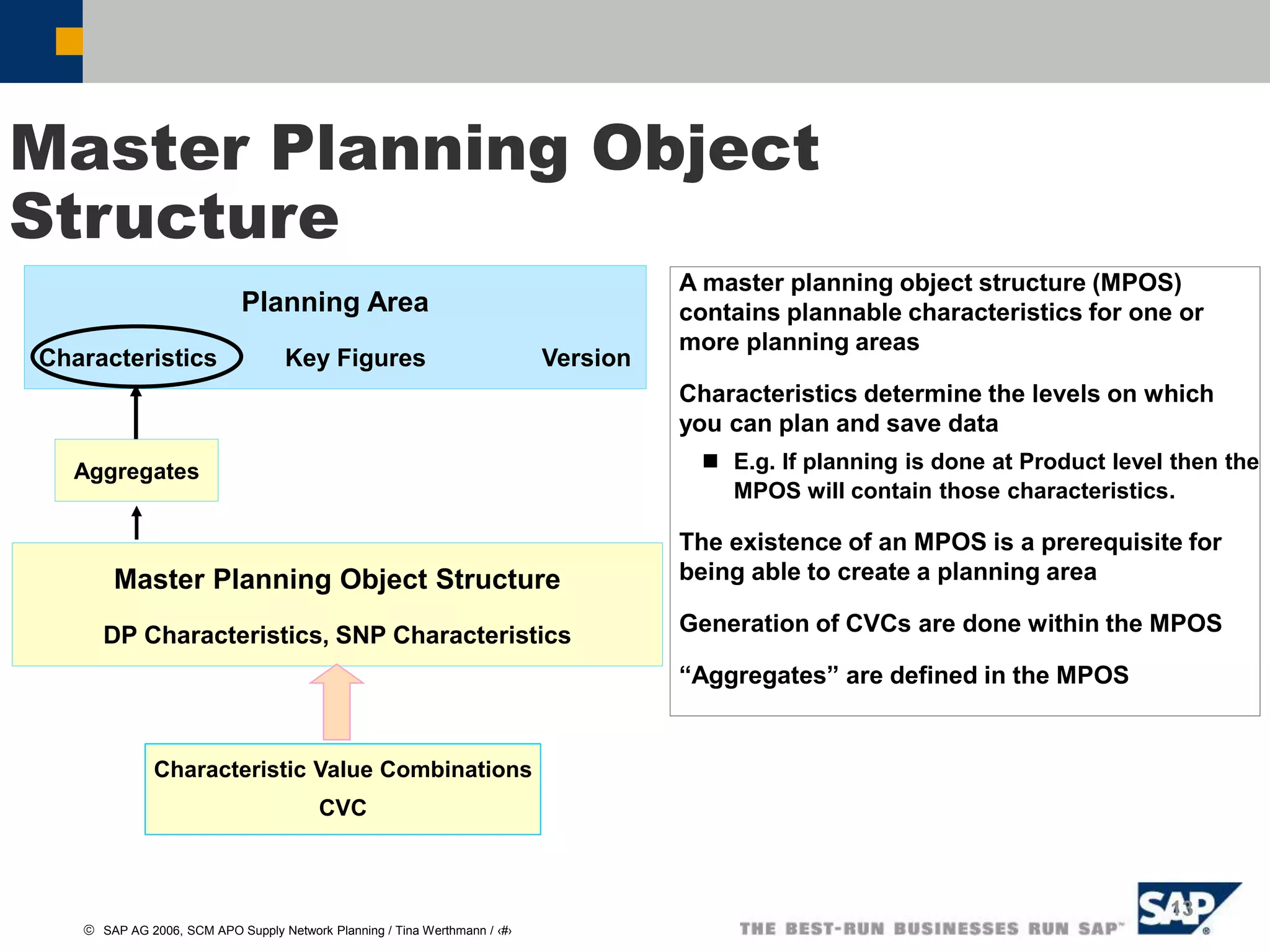

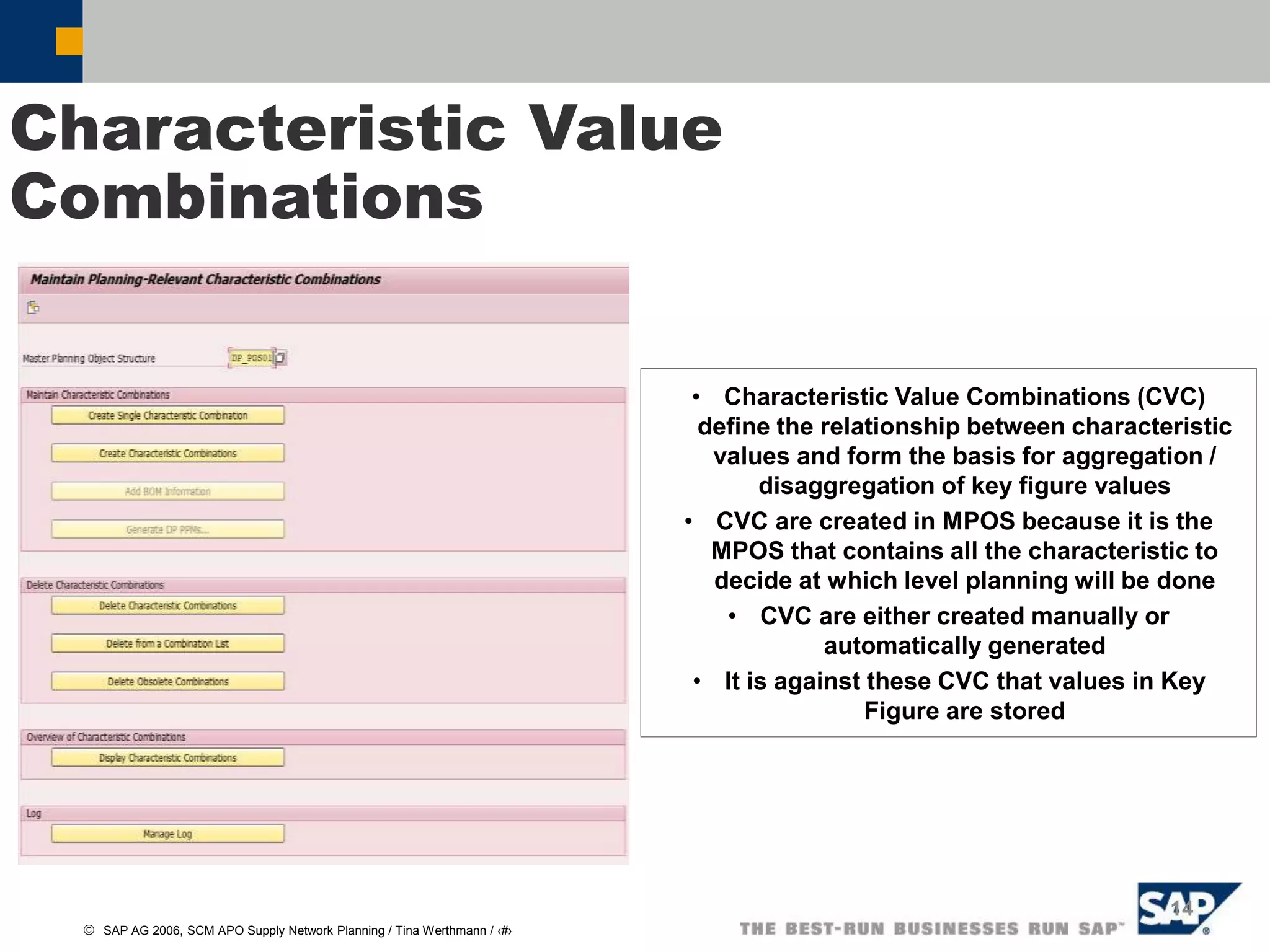

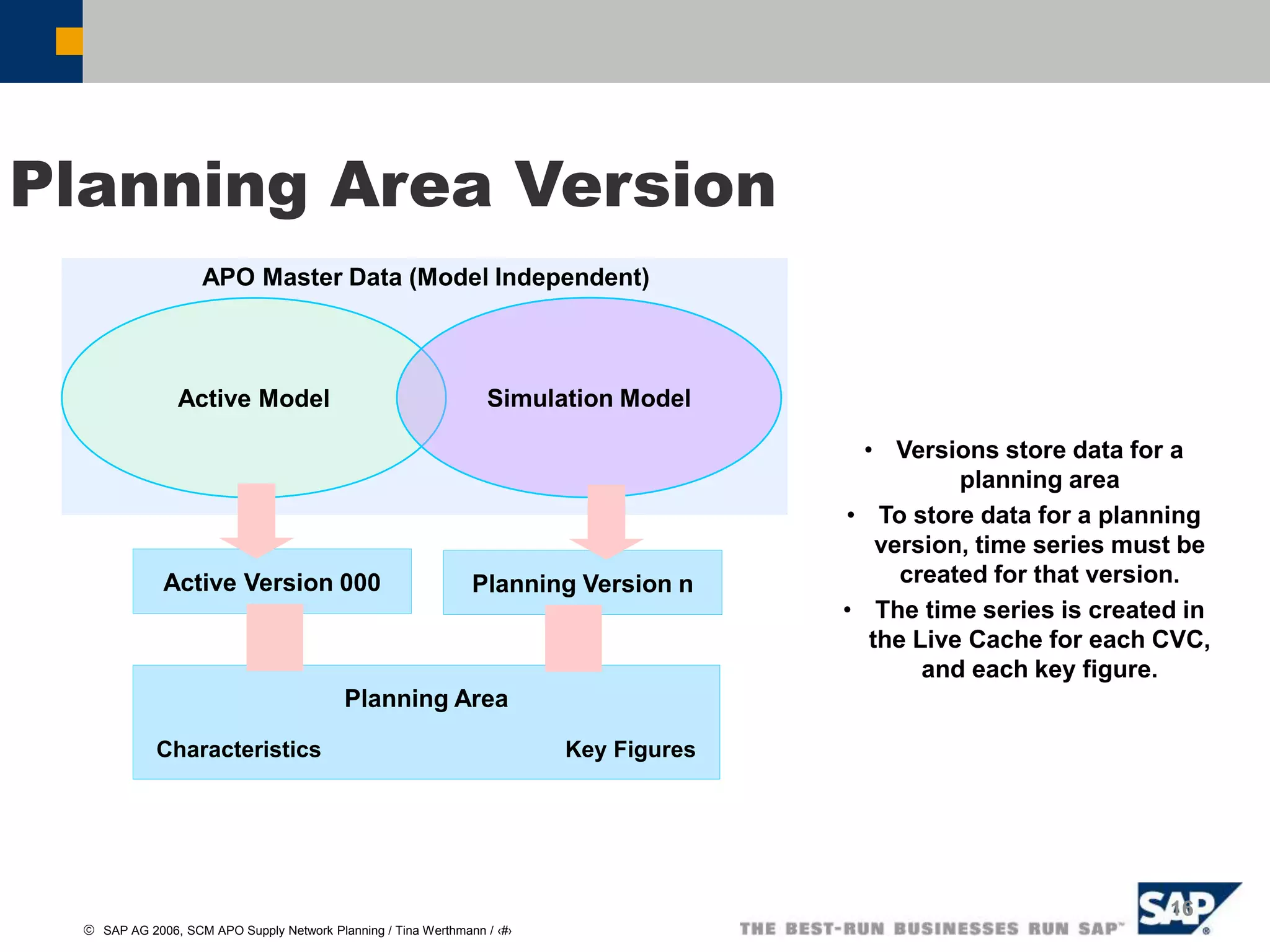

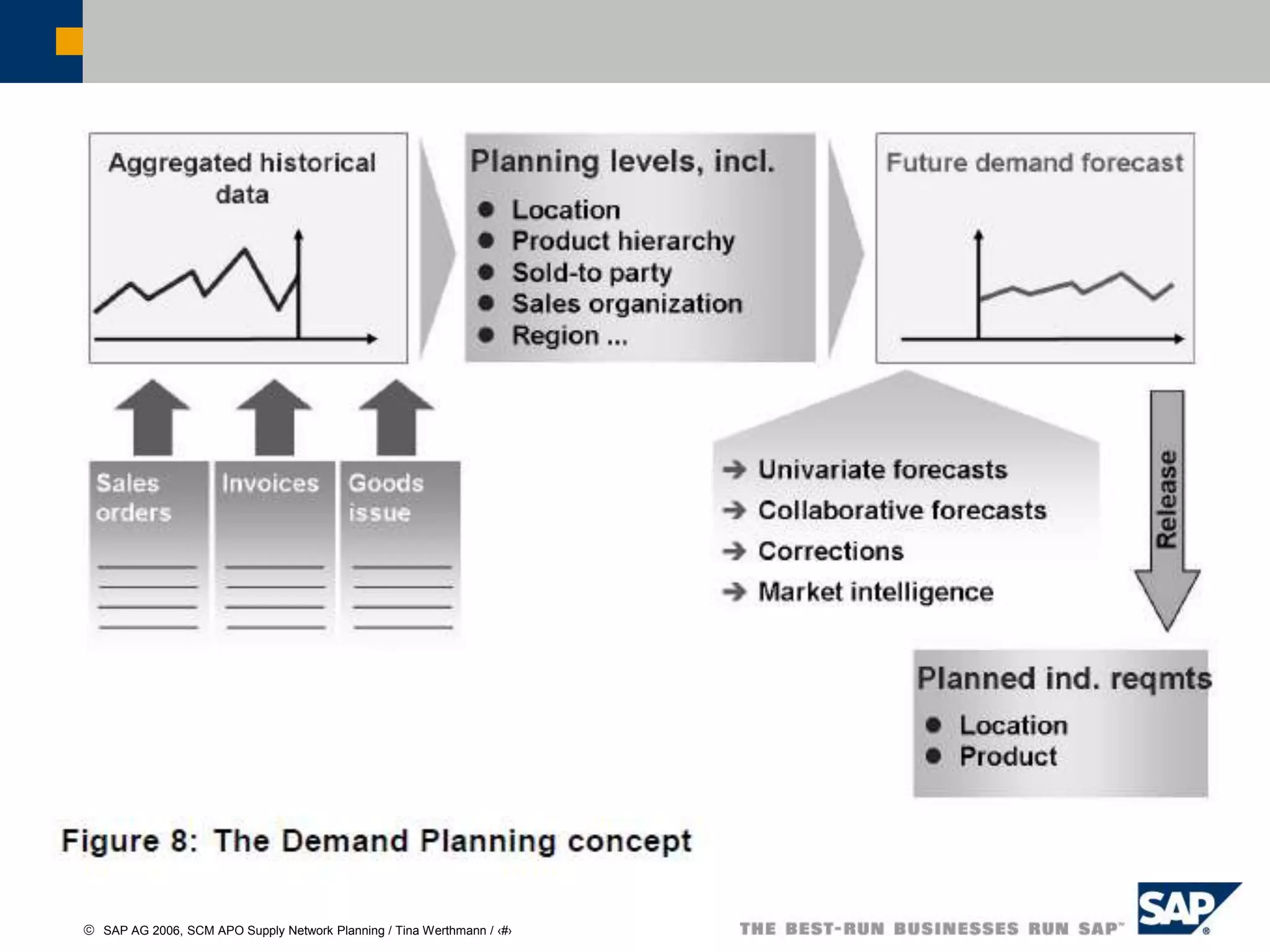

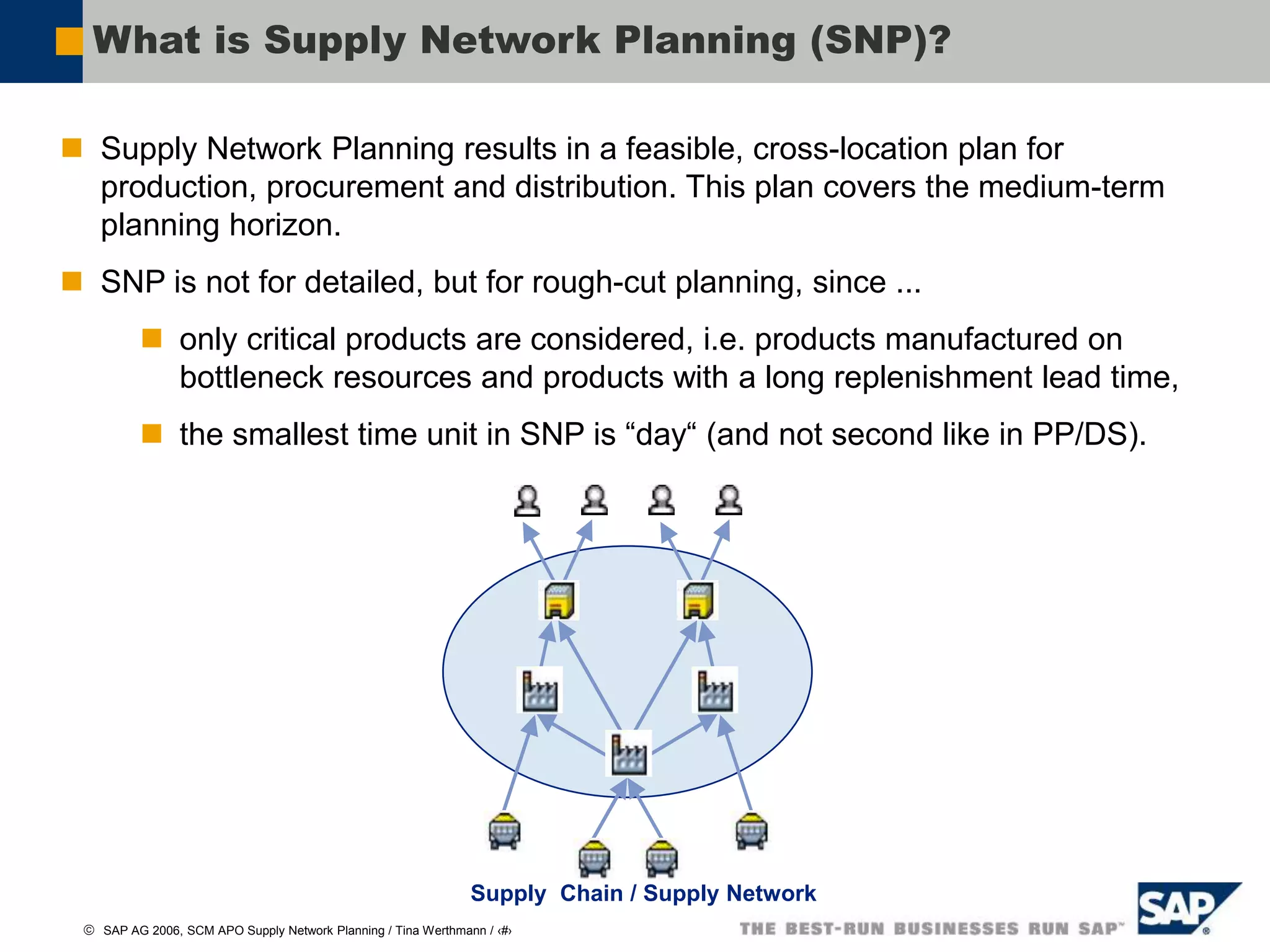

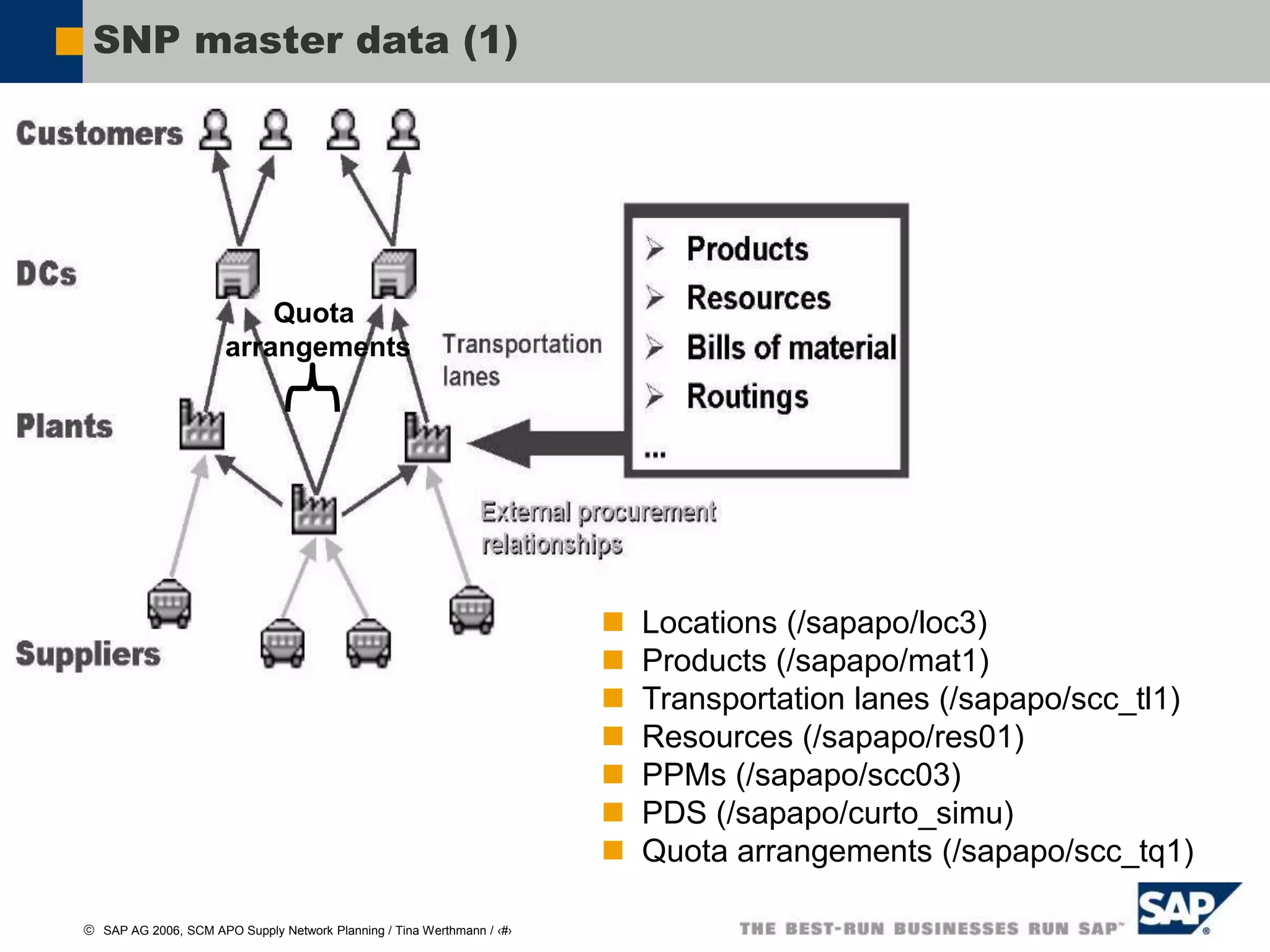

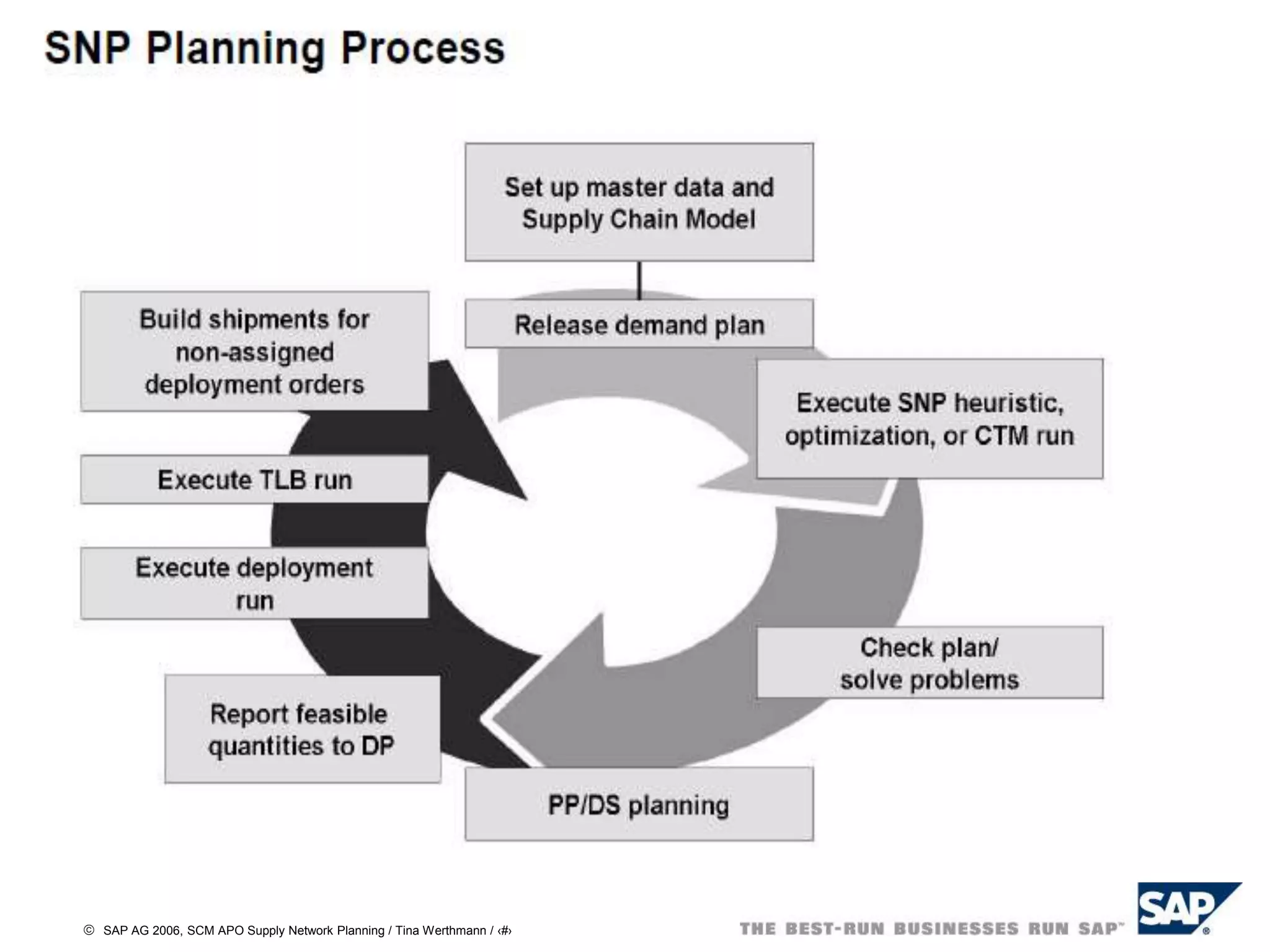

The document provides an overview of demand planning in SAP APO, including discussing the basic terms and components involved in demand planning like info objects, info cubes, master planning object structures, and planning area versions. It also summarizes the basic process of demand planning including importing data, generating forecasts, planning promotions and scenarios, and releasing the final demand plan. Key capabilities of demand planning discussed include statistical forecasting, collaborative planning, flexible multi-level planning, and planning by exception.