Lecture 6 p

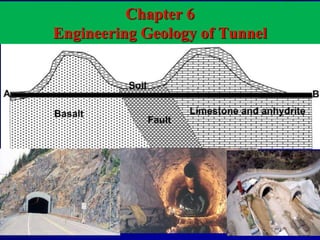

- 1. Chapter 6 Engineering Geology of Tunnel

- 2. Chapter Outline 2 6.1 Introduction to tunnels 6.2 Methods of tunnel excavation 6.3 Geological Considerations for Tunneling 6.4 Geological Structure Considerations for Tunneling 6.5 Site investigation for Tunnels 6.6 Support for Underground Openings

- 3. End Objective Students will be acquire knowledge about tunneling and problems Students will be able to seek engineering solutions for tunneling on difficult ground Will be familiar with tunnel site investigation 3

- 4. Introduction What is tunnel? It is underground passages or routes (or passages through hills or mountains) for different purposes. Unlike other civil engineering constructions, tunnel lie underground (i.e.. within the rocks). For this reason, the needs for their safety and stability is much more important It is usually made to over come the natural obstacle in transportation systems mainly roads and railways, for underground transport to link areas of interest. • However the cost of tunneling is more than its surface alternation, but it help to reduce the distance, improve safety and less environmental impact.

- 5. Effects Of Tunneling On The Ground The tunneling process deteriorates the physical conditions of the ground. This happens because due to heavy and repeated blasting excavation, the rocks gets shattered to great extent and develop numerous cracks and fractures. This reduces the cohesiveness and compactness of rocks. In other words, rocks becomes loose and more fractured and porous. This naturally adversely affects the competence of the rocks concerned. 5

- 6. Tunneling purpose Tunnel is constructed for different purpose, some of them are; Passage ways – Is a tunnel that used as a passage for trains and motor vehicles. Tunnel that used as transportation passage have two or three large parallel line for opposite direction and emergency exist routine. Underground installation: they are used for installation of structures such as underground power plant. Water supply Mining/ underground mining River diversion/ for flood control or irrigation Pipeline/ utilizing water to a given area Secret tunnels/ where the on surface road is difficult for security issues, under ground passage is an alternative.

- 7. Types of Tunnel Tunnel can be classified into four types depending on its purpose; i. Traffic tunnel is a tunnel that constructed underground for the passage of roads and railways ii. Hydropower tunnel is used to pass water under pressure and produce power by colliding with generators. iii. Public utility tunnels: this is relatively small and construct for carrying utility lines for routing power, pipeline and telecom cables. iv. Diversion tunnel: this tunnel is used for flood control or supplying water for different purpose.

- 8. Methods of tunnel excavation In excavation of tunnel, especially for long tunnel different lithological units can be encountered. They may be hard rocks to soft soils (non- cohesive) In some cases, buried channels can be encountered, which can supply excessive water to the tunnel. Depending on geology of different section of tunnel, different methods of excavation can be used. The excavation methods also depends on excavation depth, depth of water table and accessibility of the site. As a general the choice of tunnelling method may be dictated by: Geological and hydrological conditions, Cross-section and length of continuous tunnel, Local experience and time/cost considerations (what is the value of time in the project), Limits of surface disturbance, and many others factors.

- 9. The excavation methods that commonly used are; – Cut-and-cover – Boring machine – Drill and blasting I. Cut-and-cover method This construction method, whereby the site is fully excavated, the structure built and then covered over, uses diaphragm walls as temporary retaining walls within the site area. Step one :Construction of diaphragm walls, pin piles, and decking. Step two :Excavation within the diaphragm walls, installing struts as work progresses. Step three :Construction of permanent floor slabs and walls. Step four : Fitting out the internal structures, backfilling, and reinstating the surface structures.

- 11. II. Tunneling by tunnel boring machine (TBM) Bored tunneling by using a Tunnel Boring Machine (TBM) is often used for excavating long tunnels. This methods involves horizontal cylindrical metal that rotate and pressurized to excavate long tunnel. An effective TMB method requires the selection of appropriate equipment for different rock mass and geological conditions. The TBM may be suitable for excavating tunnels which contain competent rocks that can provide adequate geological stability for boring a long section tunnel without structural support. However, extremely hard rock can cause significant wear/crushed of the TBM rock cutter and may slow down the progress of the tunneling works to the point where TBM becomes inefficient and uneconomical and may take longer time. 11

- 12. 12 Types of Tunnel Boring Machine (TBM) Open Beam TBM Shielded TBM

- 13. Advantages using TBM excavation are: It requires less rock support. It gives smoother tunnel walls and reduced head loss in water tunnels. Longer tunnel sections can be excavated between adits. It has higher tunneling capacity. It gives better working conditions for the crew. The disadvantages of TBM are: o More (better) geological information from the pre-investigation stage is required. o More sensitive to tunneling problems in poor rock mass conditions. o Fixed circular geometry, limited flexibility in response to extremes of geologic conditions, longer mobilization time, and higher capital costs. o Only longer tunnel sections can be bored more economically (because of larger investment and rigging costs) o The TBM may get stuck under squeezing rock conditions. o It is difficult to perform / install rock support at the tunnel face. 13

- 14. 14 III. Drill and Blast Method This tunneling method involves the use of explosives. Drilling rigs are used to bore blast holes on the proposed tunnel surface to a designated depth for blasting. Explosives and timed detonators are then placed in the blast holes. Once blasting is carried out, waste rocks and soils are transported out of the tunnel before further blasting. Most tunneling construction in rock involves in ground that is somewhere between two extreme conditions of hard rock and soft ground. Hence adequate structural support measures are required when adopting this method for tunneling. A temporary magazine site is often needed for storage of explosives.

- 15. Compared with bored tunneling by TBM, blasting generally results in higher cost but lesser duration of vibration levels. Advantages: The drill & blast method has several advantages mentioned below: Almost any type and cross sectional shapes can be made. It can be applied to nearly any type of rock. It gives great flexibility in the performance of the excavation. The rock support can be installed easily and quickly. Some of the disadvantages are: o Production of toxic gases and smoke from the explosives. o Vibrations on nearby structures from the blasting; o Rough surface gives head loss for water tunnels; o The blasting creates new cracks in the rocks, which leads to increased need of rock support; o Potential hazard associated with establishment of a temporary magazine site for storage of explosives shall be addressed through avoiding populated areas in the site selection process. 15

- 16. 16 Reading Assignments 1. Tunneling in hard Rocks 2. Tunneling in Soft Ground or Soft Rock

- 17. 17 Site Investigations for Tunnels Geological, geotechnical, and hydrological factors are more than any other factors determine the degree of difficulty and cost of constructing an underground facility. Geologic profile (stratigraphy, structure, and identification of principal rock types and their general characteristics). Rock mass characteristics and geomechanical properties. Hydrogeology (groundwater reservoirs, aquifers, and pressures). Exposure to construction risk (major water-bearing faults, methane gas, etc.).

- 18. 18 Explorations for reconnaissance and feasibility studies Methods of data acquisition include the following: Available data acquisition and study. Remote sensing. Preliminary geologic field mapping. Geophysical explorations if appropriate. Selected exploratory borings in critical locations.

- 19. 19 I. Sources of available information: Topographic maps. Geologic maps. In urban areas and where site improvements have been made (e.g., highways), private and public owners will frequently have information about past geotechnical and geologic investigations. Local geotechnical firms regularly maintain files of such information. Case histories of underground works in the region, or in similar types of rock, are sometimes available and are very useful additions to the geotechnical database. II. Remote sensing techniques:

- 20. 20 III. Field mapping: (a) Initial onsite studies should start with a careful reconnaissance over the tunnel alignment, paying particular attention to the potential portal and shaft locations. Features identified on maps and air photos should be verified. Rock outcrops, often exposed in road cuts, provide a source for information about rock mass fracturing and bedding and the location of rock type boundaries, faults, dikes, and other geologic features.

- 21. 21 the field survey should pay attention to Slides, new or old, particularly in portal areas. Major faults. Sinkholes and karstic terrain. Hot springs. Volcanic activity. Anhydrite, gypsum, or swelling shales. Caves. Stress relief cracks. Zones of deep weathering or talus.

- 22. 22 (b) Once alignment and portal site alternatives have been set, a detailed geologic mapping effort should be carried out. Joints, Faults, and Bedding planes should be mapped and their orientations plotted by stereographic projection so that statistical analysis can be performed (often, today, with computer assistance).

- 23. 23 IV. Hydrogeology • Groundwater has the potential to cause great difficulties for underground work, and a special effort should be made to define the groundwater regime aquifers, sources of water, water quality and temperature, depth to groundwater. • A hydrological survey is necessary to ascertain whether tunnel construction will have a deleterious effect on the groundwater regime and the flora and fauna that depend on it.

- 24. 24 • As a part of the hydrogeological survey, all existing water wells in the area should be located, their history and condition assessed, and groundwater levels taken. • Additional hydrogeological work to be carried out at a later stage includes measurements of groundwater levels or pressures in boreholes, permeability testing using packers in boreholes, and sometimes pumping tests.

- 25. 25 V. Geophysical explorations from the surface The most common geophysical explorations carried out for underground works are seismic refraction or reflection and electric resistivity surveys. Seismic explorations can measure the seismic velocity of under ground materials and discover areas of velocity contrasts, such as between different kinds of rock or at fault zones. They are also useful in determining the depth of the groundwater table.

- 26. 26 VI. Additional explorations during feasibility studies • It is often appropriate to conduct initial field explorations in the form of borings or trenching at this early stage, primarily to verify the presence or location of critical geologic features that could affect the feasibility of the project or have a great effect on the selection of tunnel portals.

- 27. Geological Considerations for Successful Tunneling As already stated, the safety, success and economy of tunneling depend on the various geological conditions prevailing at the site. As usual, the important geological factors which interfere with this civil engineering project (i.e. tunneling) are also lithological, structural and ground water conditions. 27

- 28. Importance of Rock Types The nature of rock types which are encountered along the tunnel alignment is very important for the safety and stability of the tunnel. the competent rocks (i.e. those which are strong, hard and massive) will lead to safe but slow tunneling and incompetent rocks (which are loose or soft or fractured), through amenable for easy tunneling, will be unstable and require lining. 28

- 29. Suitability of Igneous Rocks at the Tunnel Site Massive igneous rocks, i.e. the plutonic and hypabyssal varieties, are very competent but difficult to work. No need lining or any special maintenance. Because they are very strong, tough, hard, rigid, durable, impervious and tunneling, do not succumb to collapse, floor bumps, side bulges or to any other deformation. The volcanic rocks, too in spite of their vesicular or amygdaloidal character are competent and suitable for tunneling. Further, by virtue of frequently present vesicular or amygdaloidal structure, they are more easily workable than intrusive rocks. 29

- 30. Sedimentary Rocks at the Tunnel Site In general, sedimentary rocks are less competent than igneous rocks. Thick bedded, well-cemented and siliceous or ferruginous sandstones are more competent and better suited for tunneling. They will be strong, easily workable and, moreover, do not require any lining. Thus, they possess all the desirable qualities for tunneling, provided they are not affected adversely by any geological structures and ground water conditions. Shales, by virtue of their inherent weakness and lamination, may get badly shattered during blasting. But being soft, they can be easily excavated and hence tunneling progresses faster through shale formations. Proper lining is necessary for tunnels built in Shales. 30

- 31. Among limestones, dolomitic limestone are harder and more durable. They are better than other varieties. On the other hand, calcareous limestones or porous limestones are naturally weaker and softer. In a majority of the cases, sedimentary rocks being relatively softer, facilitate fast progress of work, but by virtue of their weakness requires suitable lining 31

- 32. Metamorphic Rocks at the Tunnel Site Gneisses are nearly similar to granites in terms of their competence, durability and workability. They are capable of withstanding the tunneling process without requiring any lining. The gneissose structure may be advantageous in the excavation process. Phyllites, Schists, etc, which are highly foliated and generally soft, are easily workable but necessarily require good lining. Quartzite are very hard and hence very difficult to work they are more brittle too. They are competent and need no lining. 32

- 33. Water bearing rocks • Excavation a tunnel through the water bearing rock is difficult since ground water rushes into the tunnel and causes flooding during excavation. Swelling rocks • Shale, unconsolidated tuff and anhydrite are examples of swelling rocks. • They absorb moisture and swell when they are exposed to water saturation 33

- 34. Geological structure condition in Tunneling (I) Inclined strata, vertical and horizontal strata (IV) Jointed rocks (II) Folded rocks (III) Fault Zones Inclined strata 1. Tunnel along the strike line: • When a tunnel is driven parallel to the strike direction, there is tendency in the rocks to slide into the tunnel.

- 35. 2.Tunnel across the strike of the rocks: When a tunnel is made across the strike of the rocks, it will pass through different beds of rocks. In such cases, there will be arching action or down ward pressure from the roof. There is also the failure of incompetent layers from the roof. Fig. Tunnel across the strike line of the rocks.

- 36. Horizontal Strata For small tunnels or for short lengths of long tunnels, horizontally layered rocks might be considered quite favorable but When horizontally bedded rock lies above the roof, the thin strata near the opening will tend to detach from the main rock mass and form separated beams. The stability of such beams is great if: There is horizontal stress; The span-to-thickness ratio is fairly small. • Thin beds just above the opening will tend to fall down unless there is immediate support in the form of rock bolts or sets. 36

- 37. Tunnel excavations in the slopes: the discontinuities (layers, fissures) inclined inside or outside of the slope are very important regarding the stress and strength of the tunnel. horizontal, vertical and inclined layers have different kinds of loading conditions for tunnels 37

- 38. Folded rocks 1.Tunnels along troughs: This encounters unfavorable conditions, because rock masses along trough are harder and more resistant. There also seepage problem of groundwater 2.Tunnels along crests: The rock masses along the crest may be in a highly fractured condition due to development of tension joints. As a consequence of this, if tunnels are driven in such places, there may be frequent fall of rocks from the roof. Fig. A= Tunnel along crest and, B= Tunnel along trough

- 39. 3.Tunnel aligned parallel to fold axis through limbs: This is desirable if competent rock is selected because similar rocks with similar properties are encountered along the course of the tunnel. But if there is a problem in one place, it can face all part Fig. Tunnel aligned parallel to fold axis through limbs

- 40. 4.Tunnel aligned perpendicular to fold axis through limbs: This is undesirable because, under such a condition, different rock formations are encountered from place to place along the length of the tunnel. This results in difficulty of excavation, instability of the tunnel and need of support. Fig. Tunnel aligned perpendicular to fold axis through limbs.

- 41. Fault zones: Faults are commonly found associated with a zone of highly crushed rock or fault gouge. The crushed rocks, being highly permeable, allow the ground water to seep into the tunnel. Jointed rocks In one way, the jointed rocks facilitate, easy tunneling. But in the other way they present many difficulties, because the roof of a tunnel can not withstand with out support & there is a water seepage .

- 42. As a general the geological condition to be suitable for tunneling should be; – There should be one type of rocks – There should be no faults and intrusion disturbance. – The rocks should be soft but stiff enough not to need immediate support near the face – The rock should be impermeable and not adversely affected up on air exposure. – The rocks or the soil should not be changed its behavior under the exposure to water (non- expandable) – Not be highly weathered and resulted in collapse.

- 43. 43 The bedding planes in stratified sedimentary rocks (Golden, Colorado).

- 45. Consideration during tunnel excavation i. Natural state of stress: Due to the weight of the overlying rock and overburden, natural stresses increase with depth below the ground surface. Tunneling experiences shows that, for surface tunnels horizontal stress (h) becomes negligibly small and at depths (more than 3Km) h approaches the vertical stress (v) which is called litho- static pressure. Their ratio should be considered. ii. Stress around tunnel openings: No Shape of opening Zone of influence along vertical axis 1 Square 4.5*a 2 Circular 4*a 3 Elliptical (W0/H0)= 0.5(a=radius; W0/= Width of opening; H0=Height of opening) 4.7*a Shape of opening in relation to stress concentration: in elliptical and square tunnel forms the stress concentration factors can rise to higher values than for circular forms. Effect of the shape of an underground opening on its zone of influence is given ff table.

- 46. iii) stand-up time Stand-up time is the length of time a tunnel will support itself without any added structures. Knowing this time allows the engineers to determine how much can be excavated before support is needed. The longer the stand-up time is the faster the excavating will go. Generally certain configurations of rock and clay will have the greatest stand-up time whereas sand/ fine soils will have a much lower stand- up time. Tunnel shape is very important in determining stand-up time. The force from gravity is straight down on a tunnel. the circular have longer stand-up time than the square or rectangle. And also, if the tunnel is wider than its high it will have a harder time supporting itself, decreasing its stand-up time. And if a tunnel is higher than its width the stand up time will increase making the project easier.

- 47. iv) Tunnel support: Support and ground reinforcement may be applied before, during and after excavation. This depends on the stand up time of tunnel. Its purpose is to strengthen and support the ground surrounding the tunnel and to prevent falling of ground or flow of water into the tunnel. Some of the tunnel support methods include a)Ground improvement ahead of the tunnel face: excavation conditions may be improved by: Injection of cement into the ground (grouting) Freezing of the water saturated zone. Drainage of water out of the area to be tunneled. b) Support during excavation: Shield tunneling in very soft ground. Bentonite tunneling with boring machine. Caisson tunneling to counteract water pressure.

- 48. C) Support after excavation: Bolts, Anchor, Steel ribs, Shot crete, Wire mesh or steel mats, Perforated concrete + backfill mortar, Formed concrete. Underground openings have a relatively limited zone of influence on the stress distribution in the surrounding rock. The stress concentration values along a tunnel wall depend on the shape and on the ratio of vertical stress/horizontal stress not the size of the tunnel.

- 49. v) Moisture in tunnel The effect of water on tunnels reveals itself in three respects: Static and dynamic pressure head (loading action). Physical: dissolving and chemical (modifying action). Decomposing and harmful against certain linings (attacking action). Generally seeping and moving water exerts more harmful action, than standing or banked up backwater. Which quantities and what kind of water will enter the tunnel during construction depends primarily on the character and distribution of water-conveying passages (aquifer). The length and depth below the terrain surface of the cavities, precipitation and local geological conditions are also important.

- 50. To reduce the effects of moisture; – A governing principle of tunnel alignment: waterlogged areas and spots should be possibly avoided by any underground cavity/drainages – If possible, the tunnel should not be located under the groundwater table. – However, where construction in such a layer is unavoidable special tunnelling methods and techniques must be resorted to (shield driving, dewatering by compressed air). – If the tunnel can be located above the groundwater table then only drainage of periodically percolating meteoric water should be provided.

- 51. vi. Gasses in tunneling Carbon monoxide (CO) Carbon dioxide (CO2) Methane (CH4) Highly explosive with air (marsh gas Hydrogene sulphide (H2S) Highly toxic and explosive Sulphur dioxide (SO2) Owing to the enclosed space of a tunnel, fires can have very serious effects on users. The main dangers are gas and smoke production, with even low concentrations of carbon monoxide being highly toxic.

- 52. 52 Support for Underground Openings Support and ground reinforcement may be applied before, during and after excavation. Its purpose is to strengthen and support the ground surrounding the tunnel and to prevent falling of ground or flow of water into the tunnel. Some of the tunnel support methods include the following: (a) Ground improvement ahead of the tunnel face: excavation conditions may be improved by: Injection of cement milk into the ground (grouting). Freezing of the water saturated zone. Drainage of water out of the area to be tunnelled.

- 53. 53 (b) Support during excavation: Shield tunnelling in very soft ground. Bentonite tunnelling with boring machine. Caisson tunnelling to counteract water pressure. With shotcrete (sprayed grout) on the tunnel face and freshly excavated tunnel sides. (c) Support after excavation: Bolts. Anchore. Steel ribs Shotcrete. Wire mesh or steel mats. Perforated concrete+backfill mortar. Formed concrete.

- 54. What is tunnel ?