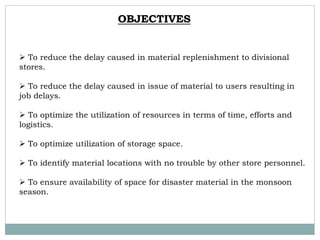

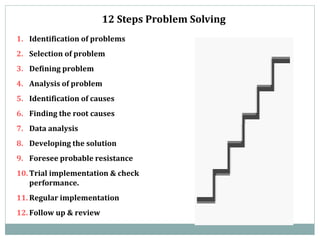

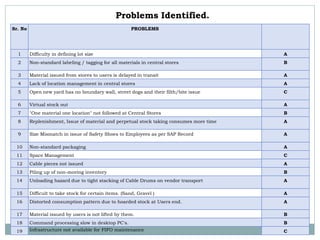

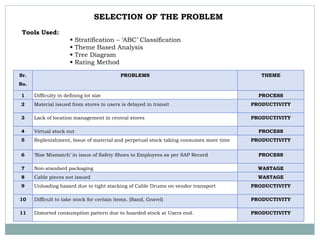

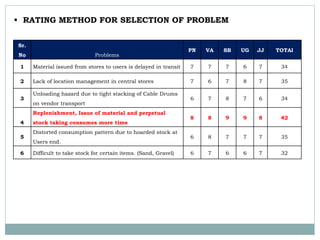

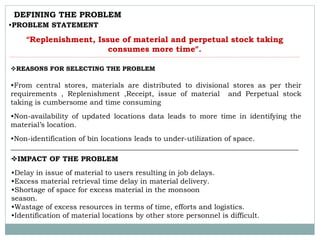

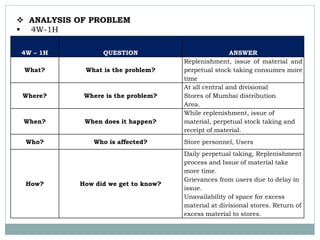

This document summarizes a summer internship project on implementing a warehouse management system. The objectives of the project are to reduce delays in material replenishment and issues, optimize resource utilization, and optimize storage space utilization. The identified problem is that replenishment, material issues, and perpetual stock taking consume more time. Potential solutions developed include implementing radio frequency identification, barcoding materials for retrieval, and a warehouse management system. A trial implementation was conducted and the project will proceed to regular implementation.