Report

Share

Download to read offline

Recommended

Epoxidized sunflower oil (ESO) has been used to toughen epoxy resin GELR 128 cured with an accelerated aliphatic amine curing agent (Kingcure K-11) at room temperature. There was difference in the properties of the polymer composite materials based on epoxy resin GELR 128 cured by Kingcure K-11 between two processes: one-stage process and two-stage process for mixing ESO with epoxy resin GELR 128 at various content of ESO. The results showed that the two-stage process is considered to be more advantageous than the one-stage process. It can be concluded that the impact strength, critical stress intensity factor Kic and decomposition temperature of the polymer composite materials based on epoxy resin GELR 128 cured by Kingcure K-11 with content of ESO 5 phr in two-stage process was greater ones in one-stage process (impact strength: 35.012 kJ/m2, Kic: 2.72 MPa and decomposition temperature: 385.81 0C respectively).Effects of Kingcure K-11 Hardener and Epoxidized Sunflower Oil on The Propert...

Effects of Kingcure K-11 Hardener and Epoxidized Sunflower Oil on The Propert...International Journal of Innovation Engineering and Science Research

Recommended

Epoxidized sunflower oil (ESO) has been used to toughen epoxy resin GELR 128 cured with an accelerated aliphatic amine curing agent (Kingcure K-11) at room temperature. There was difference in the properties of the polymer composite materials based on epoxy resin GELR 128 cured by Kingcure K-11 between two processes: one-stage process and two-stage process for mixing ESO with epoxy resin GELR 128 at various content of ESO. The results showed that the two-stage process is considered to be more advantageous than the one-stage process. It can be concluded that the impact strength, critical stress intensity factor Kic and decomposition temperature of the polymer composite materials based on epoxy resin GELR 128 cured by Kingcure K-11 with content of ESO 5 phr in two-stage process was greater ones in one-stage process (impact strength: 35.012 kJ/m2, Kic: 2.72 MPa and decomposition temperature: 385.81 0C respectively).Effects of Kingcure K-11 Hardener and Epoxidized Sunflower Oil on The Propert...

Effects of Kingcure K-11 Hardener and Epoxidized Sunflower Oil on The Propert...International Journal of Innovation Engineering and Science Research

More Related Content

What's hot

What's hot (19)

Effect of material processing on properties of materials

Effect of material processing on properties of materials

Study of Effect of Water Treatment on Flexural Properties of GFRP Composites

Study of Effect of Water Treatment on Flexural Properties of GFRP Composites

A Simulation Study on Warpage Analysis of Injection Moulded Plastic Part

A Simulation Study on Warpage Analysis of Injection Moulded Plastic Part

Jc effect of preheated bulk fill composite temperature on Intrapulpal Tempera...

Jc effect of preheated bulk fill composite temperature on Intrapulpal Tempera...

Investigation of Tribological Behaviour of GF Filled Peek Composite under the...

Investigation of Tribological Behaviour of GF Filled Peek Composite under the...

Design of scc mixes based on cement – sp compatibility

Design of scc mixes based on cement – sp compatibility

EFFECT OF INJECTION PRESSURE ON PERFORMANCE PARAMETERS AND COMBUSTION CHARA...

EFFECT OF INJECTION PRESSURE ON PERFORMANCE PARAMETERS AND COMBUSTION CHARA...

IRJET- Research and Development of Advanced Polymer Matrix Composite Mate...

IRJET- Research and Development of Advanced Polymer Matrix Composite Mate...

IRJET- Effect of Bio enzyme – TerraZyme on Compaction, Consistency Limits and...

IRJET- Effect of Bio enzyme – TerraZyme on Compaction, Consistency Limits and...

Similar to expolite_ecnow_pearson

MECHANICAL PROPERTIESAnalysis of mechanical properties of basalt, chopped e glass fiber reinforced...

Analysis of mechanical properties of basalt, chopped e glass fiber reinforced...VenugopalraoSuravara

Similar to expolite_ecnow_pearson (20)

Polymers, Effect of heat on plastic behavior IDM12

Polymers, Effect of heat on plastic behavior IDM12

new presentation ppt 2 about Almond shell powder.pptx

new presentation ppt 2 about Almond shell powder.pptx

Analysis of mechanical properties of basalt, chopped e glass fiber reinforced...

Analysis of mechanical properties of basalt, chopped e glass fiber reinforced...

Innobioplast 2013 presentation dwa coffee cup development

Innobioplast 2013 presentation dwa coffee cup development

expolite_ecnow_pearson

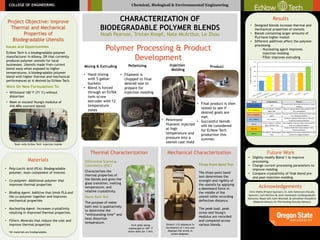

- 1. COLLEGE OF ENGINEERING Chemical, Biological & Environmental Engineering CHARACTERIZATION OF BIODEGRADABLE POLYMER BLENDS Noah Pearson, Tristan Knopf, Nate McArthur, Le Zhou • Poly-Lactic Acid (PLA): Biodegradable polymer; main component of interest • Co-polymer: Additional polymer that improves thermal properties • Binding Agent: Additive that binds PLA and the co-polymer together and improves mechanical properties • Nucleating Agent: Increases crystallinity resulting in improved thermal properties. • Fillers: Minerals that reduce the cost and improve thermal properties *All materials are biodegradable. Results Mixing & Extruding Pelletizing Injection Molding Product Polymer Processing & Product Development Thermal Characterization Mechanical Characterization Three-Point Bend Test The three point bend test determines the strength and rigidity of the utensils by applying a downward force in the middle of the utensil while recording deflection distance. The peak load, peak stress and Young’s modulus are recorded and compared across various blends. • Hand mixing with 5 gallon buckets • Blend is forced through an EnTek twin-screw extruder with 12 temperature zones • Filament is chopped to final desired size to prepare for injection molding • Pelletized filament injected at high temperature and pressure into a utensil cast mold Project Objective: Improve Thermal and Mechanical Properties of Biodegradable Utensils Issues and Opportunities EcNow Tech is a biodegradable polymer manufacturer in Albany, OR that currently produces polymer utensils for local businesses. Utensils made from current blend warp when exposed to higher temperatures. A biodegradable polymer blend with higher thermal and mechanical performances at is desired by EcNow Tech. Work On New Formulations To: • Withstand 160°F (71°C) without distortion • Meet or exceed Young's modulus of 416 MPa (current blend) Acknowledgements Chris Vitello (Project Sponsor), Dr. John Simonson (Faculty Sponsor), Zack McClure & Jason Sandswich (Undergraduate Advisors), Wyatt Self, Colin Marshall, & Johnathan Hesseltine (Material Advice), Dr. Phil Harding (Faculty Advisor) Differential Scanning Calorimetry (DSC) Characterizes the thermal properties of the blends and gives the glass transition, melting temperature, and relative crystallinity. Water Bath Test The purpose of water bath test is qualitatively to determine the “withstanding time” and heat distortion temperature. Materials • Designed blends increase thermal and mechanical properties of utensils • Blends containing larger amounts of PLA have higher moduli • Different additives affect the polymer processing - Nucleating agent improves injection molding - Filler improves extruding Future Work • Slightly modify Blend 1 to improve processing. • Change current processing parameters to improve molding • Compare crystallinity of final blend pre- and post-injection molding. • Final product is then tested to see if desired goals are met. • Successful blends will be considered for EcNow Tech production this summer. Fork after being submerged in 160 °F water bath for 1 min. Sintech 1/G displaces in increments of 1 mm and displays the stress vs strain diagram. Team visits EcNow Tech injection molder 0 200 400 600 800 1000 1200 Young'sModulus(MPa) Blend Components Results Blend 2 PLA, Additive , Binding Agent, Filler Sticks Slightly to the Injection Mold, Performs Well in Heat Test, Highest Modulus Pure PLA PLA Injection Molds Well, Warps Quickly in Heat, Moderate Modulus PLA + Additive PLA + Additive Shatters in Injection Mold, Superior Thermal Properties, Moderate Modulus PLA + Co-Polymer 2 PLA, Co-Polymer 2, Binding Agent Processes Well, Performs Moderately Well in Heat Test, Moderate Modulus Blend 1 PLA, Co-Polymer 2, Binding Agent, Additive, Filler Sticks Slightly to Injection Mold, Performs Well in Heat Test, Moderate Modulus Current Blend N/A Processes Well, Worst Heat Performance, Lowest Modulus PLA + Co-Polymer 1 PLA, Co-Polymer 1, Binding Agent, Filler Sticks to Injection Mold, Performs Well in Heat Test, Low Modulus