Forklift impact detection,Defender imp install copy

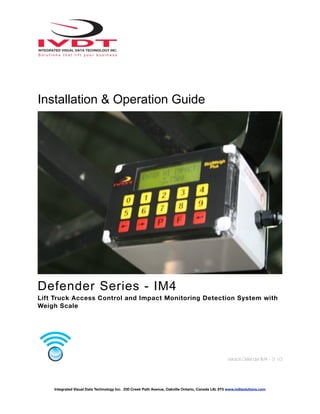

- 1. Installation & Operation Guide Defender Series - IM4 Lift Truck Access Control and Impact Monitoring Detection System with Weigh Scale Version:Defender IM4 - 3 V3 Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 2. General Installation This Defender Series - IM4 installation & operation guide describes how to install the unit, input for low / high impact values and calibrate the hydraulic scale in order to use your on-board system. Following the instructions in this guide will enable you to get your system operating quickly, easily and effectively. In the event that you require additional assistance, please contact customer support via e-mail at support@skidweigh.com , or phone 905-469-0985. Safety Always disconnect the vehicle battery while installing any of the Defender systems or any other electronic product. Route the cables where they will be protected. Use commonly accepted install practices for after market industrial vehicle electronic devices. The installation of the Defender systems should only be performed by an acknowledged lift truck dealer technician or other personnel with certified electrical and hydraulic technical experience. Here are two acceptable methods of making a wire connections: * Soldering your connections (recommended) * Crimp connectors (with the use of the proper crimping tool) Regardless of the method you choose, ensure that the connection is mechanically secure and properly insulated. Use high quality electrical tape and or preferred shrink tubing where necessary. This product connects directly to the vehicle’s ignition switch, 12 to 55 V DC. There is no on-off switch on the unit. Defender Series - IM4 Upgrades Our policy is one of continuous improvement and the information in this document is subject to change without notice. For future re-installations please check and request an updated version of this guide at www.ivdtsultions.com. Overview of Components The standard Defender - IM4 system consist of a digital indicator complete with 2 Channel Monitoring equipped, a wiring harness with mounting bracket and a hydraulic pressure transducer for weight verification. Additional options may include a timed audible alarm, data logging port with USB collection and or a cellular modem for use with Bolero Wireless or Wi-Fi base station networking utilizing Real Time Data. Visual Warnings/Data Display The standard Defender - IM4 system shows actual G values in increments of 0.5G up to a maximum of 7.5G as impacts occur and are recorded by the accelerometer and displayed on the indicator. For those applications that require different or varied G ranges other than the standard system, customized accelerator / software integration is available. Load weight display is shown in preset units kg/ib of 1,5,10,20,50 or 100. Additional options may include data displaying accumulated load weights, two independent weighing channels, excessive engine idling and overload notification. Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 3. Defender Installation Precautions Do not mount the Defender indicator to the dashboard console or any plastic surface. The installation on “soft” surface areas will act as a shock absorber and effect the ability of the unit to accurately record impacts as they occur. Selecting the Defender Mounting Location Mount the Defender indicator in front of the operator so that the operator has an unobstructed but clear view of the LCD display. The Defender indicator must be position so that the ‘arrow’ on the outside of the unit is facing in the direction of the vehicles forward travel. The Defender indicator must be mounted on a solid be metal surface (extension of chassis that meets dashboard, upper railing, side railing, etc.). Defender universal mounting brackets can be used to secure the indicator to the overhead guard or side railing if necessary. Installing the Pressure Transducer The IM4 system provides a load weighing function that utilizes a pressure transducer mounted in the vehicle and connected to the indicator. The pressure transducer must be installed in hydraulic lift line between the lift control valve and lift cylinder(s). Most installations will require a hydraulic T-piece to be connected to the hydraulic line. In some cases you can install the pressure transducer in the flow divider, drilling and tapping for a 1/4”-18 NPT male Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 4. connection in the spare plug or in the body of the flow divider (simplex or duplex mast configurations). In addition, you can drill and tap on any “larger elbow” that might be available in the hydraulic lifting circuit found in vehicles with larger hoses to accommodate larger vehicle lifting capacities. Hydraulic accumulator Connection of the pressure transducer to a T-piece Important Precautionary Note: Before installation of the pressure transducer the hydraulic lift circuit must be relieved and free of existing pressure. Lower the forks to the ground continuing to hold the lever till all pressure is removed from the hydraulic system. In addition, tilt the mast forward to its furthest point to ensure the system is pressure free. The chains should show signs of slack. Another common method to ensure that pressure is relieved from the hydraulic system is to positioned the lowered forks on top of an supporting fixture lowering both the lower and forward tilt to their combined lowest positions. Make sure that the installation placement of the pressure transducer will not interfere with moving parts from either the mast or carriage during operation of the vehicle. The pressure transducer has a 1/4”-18 NPT male thread, use thread seal to ensure a tight permanent connection. Lift Trucks with Hydraulic Accumulators require an option at time of order. Electrical Connections and Electro-Magnetic Compatibility All Defender IM4 systems operate from a range of 12 to 55 V DC. There are only seven (7) wires to be connected to the vehicle. Unit Power Source Connection (all wires are enclosed in a grey protective encasing) Orange Wire - Ignition switch Brown Wire - Battery negative or vehicle ground Red / Black / White Wire - Connected to corresponding Pressure Transducer wiring cable system Green / Blue - Vehicle operational disabling system Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 5. Defender utilizes a vehicle access control system requiring a valid operator ID# to begin operation of the truck. This system is connected to the operation of the truck through two additional wires green and blue that are used to disable vehicle. The internal relay contacts, S.P.S.T. in the Defender unit are ‘open’ and will remain open until a valid operator ID# is inputed into the system. When system accepts a valid operator ID# the relay contact will ‘close’ and remain closed until next time vehicle ignition ( power on /off system) s turned off. Important Precautionary Note: Depending on the vehicle (Electric or internal combustion) it is up to qualified service technician to connect these two wires to disable the vehicle operation in a manner that is safe and acceptable according to industry standard. If uncertain as to the safest and most suitable connection point to disable the vehicle, contact the original end manufacturer, OEM. Relay and traces on PC board can handle a maximum of up to 2 Amps. If you are disabling vehicle at an electrical point that requires more than 2 Amps you MUST USE EXTERNAL RELAY. Electro-Magnetic Compatibility CE conformity to EC directive 89/336 (EMC) by application of harmonized standards: Interference stability EN 61000-6-2 and EN 61326-1 interference emit EN 61000-6-3, EN 61326-1 for the pressure transducer. How to Configure and Calibrate the Defender - IM4 Note: Units equipped with Access Control disabling vehicle operation will come with a factory set default ID. The system will prompt you to enter a valid ID to begin the initializing process. The factory set default ID is 111. ENTER ID NUMBER ID = 111 One you have entered the factory set default the system will show time / date on LCD display and allow for normal vehicle operation and the ability to configure and the calibrate the system to the application required. How to Set Time and Date With the LCD display showing date and time, press and hold for the F key. The LCD display will request the programmer to enter number. Press number 3 in conjunction with the F key and LCD display will show time /date as per example below: Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 6. SEP 29, 2012 15:34:16 Cursor will prompt the programmer to select month, press left or right arrow key to scroll through options. When the desired month is selected press enter key to save. The cursor will move to date, year, hours, etc. Keep using left or right arrow to get to the right value and press enter key each time to save the entered value. How to set Language (English or French) With the LCD display showing date and time, press and hold for the F key. The LCD display will request the programmer to enter number. Press number 5 in conjunction with the F key and LCD display will show: Language English Press Left or Right arrow to set desired language and then press Enter Key to set. How to Set the Low and High Impact Notification Thresholds With the LCD display showing date and time, press and hold the F key. The LCD display will request the programmer to enter number. Press number 4 in conjunction with the F key and LCD display will show: ENTER LOW IMPACT 1.500g Press and scroll the Left or Right arrows to set desired ‘Low impact’ value and then press the Enter Key. After pressing the Enter Key the LCD display will advance to: ENTER HI IMPACT 2.500g Press and scroll the Left or Right arrows to set desired ‘High impact’ value and then press the Enter Key. After pressing Enter Key the LCD display will go back to normal operational mode showing data and time. Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 7. Important Note: The newly configured G impact values are saved into the system and are now the standard defaults upon vehicle start up. Finding the optimum G impact setting for an application will require fine tuning on behalf of the end user or project manager. It is recommended that you start the ‘Low Impact’ setting at 4G and the ‘High Impact’ at 7.5G and find the optimum setting that depicts safe and unsafe usage in a specific application. How to Program the Vehicle Access Control System Defender series impact monitoring devices provide an Access Control System that allows only authorized users to operate the vehicle. Standard Defender units allow up to 50 different users any combination of a 3 digit ID code to identify them as an authorized user. 1. Turn power on to the system. The LCD display will show ‘IVDT, Software version and Serial number’, after a brief period of time the prompt will default to ENTER ID NUMBER. ENTER ID NUMBER ID = _ 2. Enter number 999 and then press the Enter key to start the procedure of the input mode to create valid operator ID#’s. ENTER ID NUMBER ID = 999 3. The LCD display will show ENTER VALID IDS . ID 1 = _ will be shown on the lower LCD bar. ENTER VALID IDs ID 1 = _ 4. Enter valid first operator ID# (Any number between 1 to 998) Note: Once you have entered your ID number press the Enter key. The system will then prompt you to then enter a Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 8. second ID number, ID 2. Repeat the process of entering ID numbers followed by the Enter key to move to the next ID until all desired ID’s have been entered into the system. ENTER VALID IDs ID 27 = _ 5. Once you have entered the last required valid ID# (As of example ID 27), press the Enter key. The system will automatically forward to the next valid ID prompt, as in this example ID 28, at this point press the F key to exit. All ID’s inputted into the system are now Vehicle Access Control defaults and will be required to be input upon starting the vehicle. Important Note: It is recommended that the end user or project manager program a few additional operator ID’s for the purpose of temporary employment, servicing lift truck technicians and or required management. Calibration and Operation of the IM4 Weigh Scale Calibrating the IM4 is a simple automatic process that requires the system acknowledge and record two weights one with the forks unloaded and one with a known weight. Before you begin the calibration process please make sure that you have an accurate known weight on hand. Important Note: for maximum accuracy please secure a load that has been weight verified by a reliable source such as an existing floor scale. In addition ensure that the secured load is between 40 - 60% of the capacity of the lift truck. For example, if the truck has a standard capacity rating of 5000lb’s the optimum weigh to use for calibration would be between 2000 and 3000lb’s. To initiate weight calibration ensure that the system is showing date and time. Press and hold the F key until the LCD display shows Enter Function, press 0 and the LCD display will prompt the following. Lift Empty Forks At this point lift the forks, utilizing the lift lever only, about 2 to 4” off the ground. After a few seconds the system will prompt the following. Lower Forks Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 9. Weight = 2655 After the system has detected the empty forks to be lowered the LCD indicator will display Weight = with a flashing cursor prompting the known verified weight to be entered. Once that weight is entered press the Enter key. The system will then prompt the following. Lift Load At this point lift the Loaded Forks the same way as the first lift with only the lift lever and uninterrupted about 2 - 4” off the ground. After a few seconds the system will prompt the following. Lower Forks Once the system detects the Lowering of the Loaded Forks the LCD display will automatically show the time and date indicating that the IM4 system is now calibrated and ready to use. Important Note: The system can be used in both pounds and kilograms but will only accurately reflect the weight in the unit that it was calibrated in. For example, if it is calibrated in lb’s then its accuracy will reflect that of lb’s and the same holds true for kg’s. Operation of Defender IM4 Upon prompting start up of the vehicle the unit will power on and the LCD display will show ‘IVDT, Software version and Serial number’, after a brief period of time the prompt will default to ENTER ID NUMBER. Enter a correct ID number and the system display will change to time and date and allow for operation of the lift truck. The time and date is the standard LCD display of the IM4 system and indicates that it is ready and in use. If an invalid operator ID is entered, one not previously programmed into the system, the LCD indicator will display INVALID ID#, and re-prompt for a correct ID. Other than inputting their specific ID for authorized usage of the vehicle the operator is not required to program, change or input any settings during normal operation of the vehicle. The operational principal of the IM4 system is that it is operation friendly as it requires minimal or no operator input to manage the requirements of the application for which it was installed. SEP 29, 2012 16:34:16 Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com

- 10. The Defender - IM4 with 2 Channel Monitoring detection will notify the operator, end user or project manager of detected impacts surpassing pre-set G thresholds utilizing the following system. The first impact notification is the ‘LOW IMPACT’ which will be shown only to the operator of the vehicle on the LCD unit display. LOW IMPACT should be a setting that notifies the operator that they are getting close to potentially dangerous or damaging operating practices such as hitting dock plates to hard, or abrupt turns at high speeds. The LOW IMPACT notification is designed to be preventative mechanism to forewarn operators and create a safer material handling environment. The second notification is the ‘HIGH IMPACT’ which too will show on the LCD display of the unit but also be recorded in the data logger port of the Defender unit which is accessed by USB. Additional options may include a timed audible alarm and or Bolero Wireless integration with modem. The ‘HIGH IMPACT’ should be a notification setting where based on the application the potential for compromised safety of the operator and or damage to the vehicle and surrounding area may have resulted and therefore investigation is warranted. It is recommended that end users and or project managers opt for either a Real Time Data or Bolero Wireless system to provide notifications when they happen with an email sent to a PDA device to begin a timely investigation of the impact. The data logger port with USB retrieval records the ‘HIGH IMPACT’ and the operator ID at time of that impact. The Defender - IM4 weigh scale can be used anytime once the access control has been accepted and vehicle operation has commenced. The system automatically acknowledges when a weight has been lifted and the LCD display will show the weight on the loaded forks. Important Usage Note: (Weighing Function) The IM4 is engineered to deliver industry leading accuracy as the operator would normally lift a load, quick and abrupt. - Loaded forks must be lowered to the ground. - LCD display must show time and data to initiate a proper weighing cycle. - In a stationary position using only the lift lever raise the load 2 - 4” above the ground and wait for the load to be displayed before moving or further adjusting the hydraulic controls. Integrated Visual Data Technology Inc. 230 Creek Path Avenue, Oakville Ontario, Canada L6L 6T5 www.ivdtsolutions.com