Experienced Mechanical Engineer resume

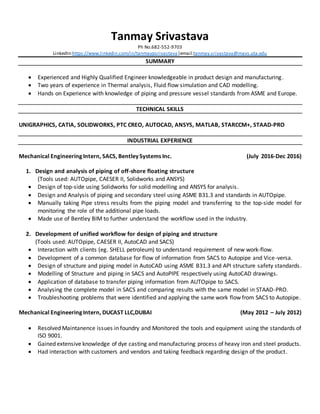

- 1. Tanmay Srivastava Ph No.682-552-9703 LinkedIn:https://www.linkedin.com/in/tanmaypsrivastava|email:tanmay.srivastava@mavs.uta.edu SUMMARY Experienced and Highly Qualified Engineer knowledgeable in product design and manufacturing. Two years of experience in Thermal analysis, Fluid flow simulation and CAD modelling. Hands on Experience with knowledge of piping and pressure vessel standards from ASME and Europe. TECHNICAL SKILLS UNIGRAPHICS, CATIA, SOLIDWORKS, PTC CREO, AUTOCAD, ANSYS, MATLAB, STARCCM+, STAAD-PRO INDUSTRIAL EXPERIENCE Mechanical Engineering Intern, SACS, Bentley Systems Inc. (July 2016-Dec 2016) 1. Design and analysis of piping of off-shore floating structure (Tools used: AUTOpipe, CAESER II, Solidworks and ANSYS) Design of top-side using Solidworks for solid modelling and ANSYS for analysis. Design and Analysis of piping and secondary steel using ASME B31.3 and standards in AUTOpipe. Manually taking Pipe stress results from the piping model and transferring to the top-side model for monitoring the role of the additional pipe loads. Made use of Bentley BIM to further understand the workflow used in the industry. 2. Development of unified workflow for design of piping and structure (Tools used: AUTOpipe, CAESER II, AutoCAD and SACS) Interaction with clients (eg. SHELL petroleum) to understand requirement of new work-flow. Development of a common database for flow of information from SACS to Autopipe and Vice-versa. Design of structure and piping model in AutoCAD using ASME B31.3 and API structure safety standards. Modelling of Structure and piping in SACS and AutoPIPE respectively using AutoCAD drawings. Application of database to transfer piping information from AUTOpipe to SACS. Analysing the complete model in SACS and comparing results with the same model in STAAD-PRO. Troubleshooting problems that were identified and applying the same work flow from SACS to Autopipe. Mechanical Engineering Intern, DUCAST LLC,DUBAI (May 2012 – July 2012) Resolved Maintanence issues in foundry and Monitored the tools and equipment using the standards of ISO 9001. Gained extensive knowledge of dye casting and manufacturing process of heavy iron and steel products. Had interaction with customers and vendors and taking feedback regarding design of the product.

- 2. ACADEMIC PROJECTS Design, Analysis and Material optimization of 5 ton Automobile screw jack (May 2014-December 2015) Development of Solid and surface model in CATIA V5 using dimensions from a live model screw jack. Developing FEA mesh in Hypermesh to accurately give results in areas of concern. Running Finite Element analysis of the model in ANSYS and storing information in a MATLAB file. Using optimization functions in MATLAB and re-running the analysis in ANSYS for FEA results. Responsible for smoothening the jagged contours after every optimization run in CATIA V5. Stopping loop of analysis and optimization when in desirable results have been found. Decreased weight by 15 percent while no noticeable reduction of capacity of the part. Design and optimization of complex contours in Automobile parts (Jan 2015-December 2015) Design and development of door frames and interior car seats in Unigraphics NX 9 and CATIA. Slicing through the model and defining contours at places where possibility of reduction of material. Defining B-spline curve using contour and running optimization using ANSYS and other tools. Auto-smoothening of curve using plug-in code designed in MATLAB for CATIA. EDUCATION Master of Science – Mechanical Engineering GPA – 3.18/4 (May 2016) University of Texas at Arlington Bachelor of Technology – Mechanical Engineering GPA – 3.1/4 (May 2014) College of Engineering Pune, University of Pune RESEARCH PAPER Experimental Flow Visualization for Flow around Multiple In-Line CircularCylinders at Low Reynolds Number The paper gave a detailed account of the flow around multiple in-line circular cylinders at low Reynolds number at various spacing between rods to diameter of rod ratios the results could be used as reference to validate various numerical simulations, and the wake interference was studied that occurred between the rods Published in the Journal of 40th National Conference on Fluid Mechanics and Fluid Power PROFESSIONAL MEMBERSHIPS American Society of Mechanical Engineers, ASME (2010-2016) Society of Automotive Engineers, SAE (2012-2016) Fluid Power society of India, FPSI (2013-2016)