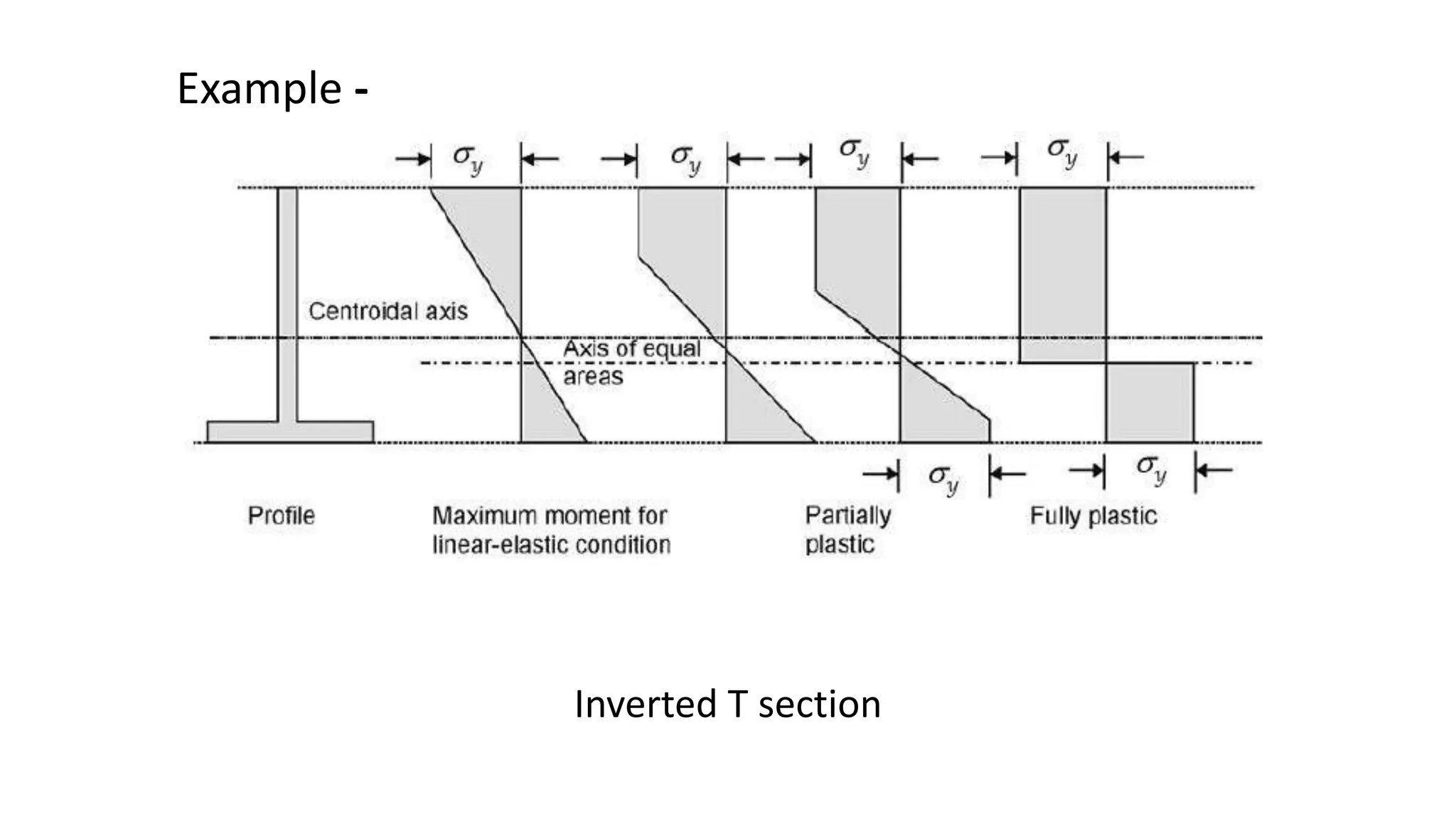

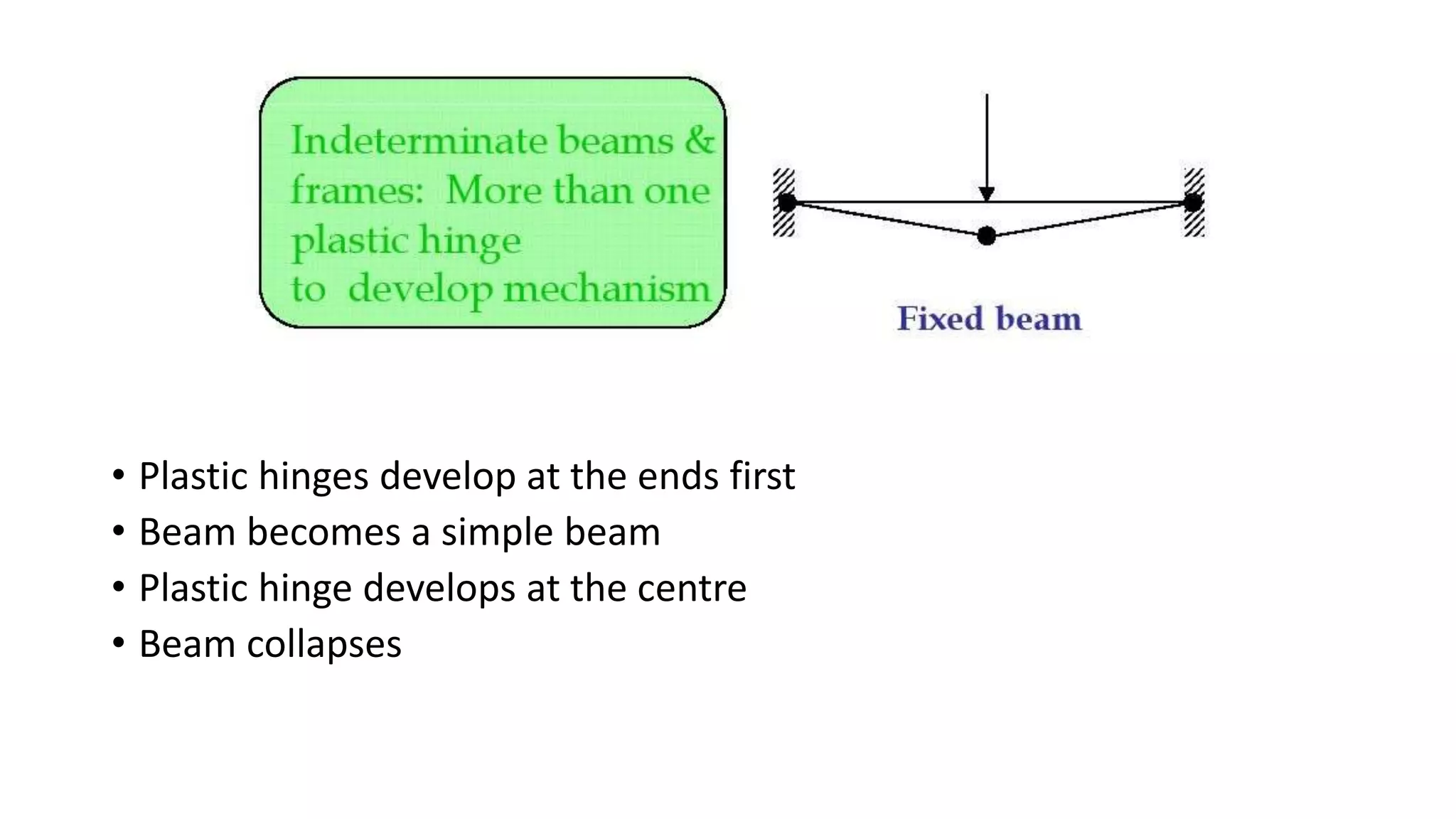

This seminar discusses plastic analysis, which is used to determine the collapse load of structures. It introduces key concepts like plastic hinges, which form at locations of maximum moment and allow large rotations. The plastic section modulus and shape factor are presented as ways to calculate the moment capacity of a fully yielded cross-section. Common collapse mechanisms like simple beams, fixed beams under uniform and point loads, and propped cantilevers are analyzed using the static method of plastic analysis or virtual work method. Determining collapse loads for various structural configurations is demonstrated through examples.