PLUMBING WORK MURRAY ROB.pdf

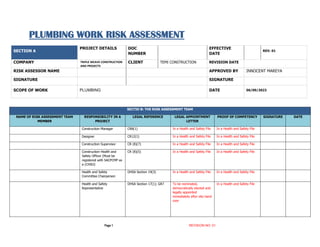

- 1. Page 1 REVISION NO: 01 PLUMBING WORK RISK ASSESSMENT SECTION A PROJECT DETAILS DOC NUMBER EFFECTIVE DATE REV: 01 COMPANY CLIENT TEMI CONSTRUCTION REVISION DATE RISK ASSESSOR NAME APPROVED BY INNOCENT MAREYA SIGNATURE SIGNATURE SCOPE OF WORK PLUMBING DATE 06/09/2023 SECTIO B: THE RISK ASSESSMENT TEAM NAME OF RISK ASSESSMENT TEAM MEMBER RESPONSIBILITY IN A PROJECT LEGAL REFERENCE LEGAL APPOINTMENT LETTER PROOF OF COMPETENCY SIGNATURE DATE Construction Manager CR8(1) In a Health and Safety File In a Health and Safety File Designer CR12(1) In a Health and Safety File In a Health and Safety File Construction Supervisor CR (8)(7) In a Health and Safety File In a Health and Safety File Construction Health and Safety Officer (Must be registered with SACPCMP as a (CHSO) CR (8)(5) In a Health and Safety File In a Health and Safety File Health and Safety Committee Chairperson OHSA Section 19(3) In a Health and Safety File In a Health and Safety File Health and Safety Representative OHSA Section 17(1); GR7 To be nominated, democratically elected and legally appointed immediately after site hand over In a Health and Safety File TRIPLE WEAVE CONSTRUCTION AND PROJECTS

- 2. Page 2 REVISION NO: 01 Fall Protection Plan Developer CR10(1) In a Health and Safety File Risk Assessor CR9(1) In a Health and Safety File In a Health and Safety File Incident Investigator GAR9(2) In a Health and Safety File In a Health and Safety File First Aider GSR3 In a Health and Safety File In a Health and Safety File Fire Fighter Equipment Inspector CR29(h) In a Health and Safety File In a Health and Safety File SECTION C: PERSONS AT RISK AND EQUIPMENT TO BE USED TASKED OPERATIVES OTHER SITE PERSONNEL MEMBERS OF THE PUBLIC YOUNG PERSONS OTHERS LIST EQUIPMENT TO BE USED Wheel barrow SECTION D PROJECT OHS DETAILS AVAILABLE ADEQUATE REMARKS

- 3. Page 3 REVISION NO: 01 SECTON E RISK MATRIX FREQUENCY SCALE SEVERITY SCALE PROBABILITY SCALE Frequent occurrence / daily (3) Catastrophic (Many fatalities / > 10 Million damage) (8) Has happened before (3) It has happened / monthly (2) Disaster (Fatal injury / > 1 Million damage) (7) Quite possible (2) Could occur / yearly (1) Very Serious (Reportable Accident / > R100,000 damage) (6) Unusual but possible (1) Serious (Disability Injury (LTI) / > R100,000 damage) (5) Important (Non-disabling Injury / > R1,000 damage) (4) Of Concern (Minor injury / > R100 damage) (3) SETION E CONTINUING Yes No Yes No Scope of Work (Logical steps on how task / work will be performed) X X Procedures: (WI / SOP / Vendor Spec) X X Training (induction) / Competency certificates? Specific training identified / other (instructions) X X Employee’s induction Special permits required (specify) X X Work Permit Equipment / Tool Registers / Others (specify) X X Daily and periodic tools and equipment inspections Code of Practice: X Other:

- 4. Page 4 REVISION NO: 01 RISK RANKING / PRIORITY FACTOR If score is 61 to 72 AA AA Potentially Catastrophic – action needed immediately . If score is 49 to 60 A Potentially Major – action to be taken within 24 hours. If score is 37 to 48 B Potentially Serious – action to be taken within 48 hours. If score is 01 to 36 C C Potentially Minor – action to be taken within 7 days.

- 5. Page 5 REVISION NO: 01 SECTION F HAZAD IDENTIFICATION, RISK CONTROL AND RATING RECORD Nr TASKS WITH ALL TASK STEPS POTETIAL AND EXISTING HAZARDS POTENTIAL AND EXISTING RISKS PROBABILITY SEVERITY FREQUENCY SCORE RISK PREVENTANTIVE MEASURES AND CONTROLS SITE SPECIFIC PHOTOGRAPHS 1. Demarcate working area with a barricading net using hand tools •Manual handling •Ergonomic effects •Using hand tools: -Hands injury from wooden splint -Hand knocked by hammer -Hammering nails •Unlevelled ground causing falling • Snakes. • Bees & Wasps. • Possible Ticks •Sharing of tools – contact communicable disease • Back injuries • Musculoskeletal injuries •Hand’s injuries •Trip and falling injuries •Snake Bites (Common venomous Kwa-Zulu Natal Snakes: Black mamba, Puff Adder, Boomslang, Rink Hals, Green Mamba, Forest/Black Cobra, Night Adder, etc). •Bee & Wasp Stings causing Anaphylaxis (allergic reaction) •Possible Tick Bites causing tick bit fever/ Lyme disease. 3 6 3 72 AA • Construction Manager CR8(1) will ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit (RWL = 1/3 body weight or 25kg). • All workers to have valid medicals with annexure 3 documents signed and stamped by Occupational Medical Practitioner. • Maintain good housekeeping and prepare and separate a lay down area for stacking and storage. • Supervisors will conduct DSTI’s (Daily Safety Task Instruction) to be conducted and communicated at the beginning of the shift on a daily basis. DSTI close out to be conducted and attendance registered signed by all staff. • Supervisors to brief staff on snake awareness and First Aid Officers must be familiar with contractor’s snake bite procedures. • Supervisors to be trained in capture and CR 8(7) CR 8(5) CR 8(1)

- 6. Page 6 REVISION NO: 01 release of snakes (snakes must not be killed). • Posters and awareness campaigns must be conducted for snakes, bees, tick, etc. and must be regularly discussed in toolbox talks. • Snake catching kit to be on site to facilitate catch and release of snakes. • Supervisors to brief staff on bee and wasp awareness and First Aid Officers must be familiar with contractor’s bee and wasp sting procedures. • Supervisors to brief staff on tick bite awareness and First Aid Officers must be familiar with contractor’s tick bite procedures (i.e., If ticks are found, be patient when removing a tick from your skin, follow these steps: 1. Use Tweezers to grab the tick close to your skin, 2. Gently pull back, making sure the tick’s head is not left in your skin. 3. Do not squeeze the tick’s body, if you do the bacteria may enter your skin. 4. After removing the tick, wash the bite with soap and water. See a Doctor right away if you notice any symptoms of Tick Bite Fever or Lymes Disease). • VIRUS/COVID-19 Requirements” and all Government Rules and

- 7. Page 7 REVISION NO: 01 Regulations including but not limited to the Disaster Management Act 57 of 2002 and Regulations are complied with at all times. • Social distancing, wearing of masks at all times and washing of hands as detailed in our COVID-19 management Plan. • Provide PPE: Safety Boots/Shoes, Hard Hat, Dust Mask, Eye Protection, Reflective Vest, 2 Piece Long Sleeve 2. Toilets to be installed using cement and trowels • Manual Handling of equipment and materials. • Picking 50 kg of cement bags • Contact with mortar •Musculoskeletal injuries •Back injuries •Hand’s injury •Dermatitis 3 6 2 36 • Construction Manager CR8(1) will ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit (RWL = 1/3 body weight or 25kg). • Develop an ergonomic plan, communicate and implement it. • Installation of signs restricting unauthorized entry. • Tools Inspector to inspect and sanitize all tools. Broken tools to be removed from site CR 8(7) CR 8(5) CR 8(1)

- 8. Page 8 REVISION NO: 01 • Proper supervision of work by the supervisor. • The supervisor to read understand and communicate the MSDS copy to employees • Ensure Off-loading area is clear, level, secure and free from slip trip and falling hazards. • Stacking & Storage Supervisor to be appointed to control lay down areas. • Employees must have a valid Medical Certificate of Fitness as conducted by an occupational medical practitioner (including a completed and Annexure 3 form) and Tetanus vaccine. • Provision of safety glasses, safety gloves, hard hat, safety shoes and overalls (long sleeves), reflective vests and cloth masks -double layered 3. Basins to be installed using cement and trowels • Manual Handling of equipment and materials. • Basins falling and backing • Picking 50 kg of cement bags • Contact with mortar •Musculoskeletal injuries •Back injuries •Hand’s injury •Feet injuries •Cut injuries •Dermatitis 3 6 2 36 • Construction Manager CR8(1) will ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit CR 8(7) CR 8(5) CR 8(1)

- 9. Page 9 REVISION NO: 01 (RWL = 1/3 body weight or 25kg). • Develop an ergonomic plan, communicate and implement it. • Installation of signs restricting unauthorized entry. • Tools Inspector to inspect and sanitize all tools. Broken tools to be removed from site • Proper supervision of work by the supervisor. • Ensure Off-loading area is clear, level, secure and free from slip trip and falling hazards. • Stacking & Storage Supervisor to be appointed to control lay down areas. • The supervisor to read understand and communicate the MSDS copy to employees • Employees must have a valid Medical Certificate of Fitness as conducted by an occupational medical practitioner (including a completed and Annexure 3 form) and Tetanus vaccine. • Provision of safety glasses, safety gloves, hard hat, safety shoes and overalls (long sleeves), reflective vests and cloth masks -double layered

- 10. Page 10 REVISION NO: 01 4 Pipes to be measured and cut using pipe cutter and hacksaw on work benches • Manual Handling of equipment and materials. • Cutting the pipe with Hacksaw on the benches – falling of pipes •Musculoskeletal injuries •Back injuries •Cut hand’s injury •Body injuries 3 6 2 36 • Construction Manager CR8(1) will ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit (RWL = 1/3 body weight or 25kg). • Develop an ergonomic plan, communicate and implement it. • Installation of signs restricting unauthorized entry to restrict walking next to the cutting bench • Tools Inspector to inspect and sanitize all tools. Broken tools to be removed from site • Proper supervision of work by the supervisor. • Supervisor to ensure the pipe is supported. • The assistance should ensure to hold the pipe whilst being cutted. • Ensure Off-loading area is clear, level, secure and free from slip trip and falling hazards. • Stacking & Storage Supervisor to be appointed to control lay down areas. CR 8(7) CR 8(5) CR 8(1)

- 11. Page 11 REVISION NO: 01 • Employees must have a valid Medical Certificate of Fitness as conducted by an occupational medical practitioner (including a completed and Annexure 3 form) and Tetanus vaccine. • Provision of safety glasses, safety gloves, hard hat, safety shoes and overalls (long sleeves), reflective vests and cloth masks -double layered 5. Copper pipe to be brazed on site using flux and brazing kit •Manual lifting •Ergonomic issues • Falling objects • Brazing without the kit • Fire •Fumes •Musculoskeletal injuries •Back injuries •Hand’s injury •Eye infection •burns •Chest problem 2 7 3 42 B • Construction Manager CR8(1) will ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit (RWL = 1/3 body weight or 25kg). • Develop an ergonomic plan, communicate it and implement. • The store man or the appointed tools inspector to inspect all the tools prior working. • Proper supervision of work by the supervisor. • Tools inspector Supervisor to be inspect tools and equipment prior use. CR 8(7) CR 8(5) CR 8(1)

- 12. Page 12 REVISION NO: 01 • Fire watch personnel to be posted at the working area. • Fire extinguisher to be placed nearby the work area. • Provision of safety glasses, safety gloves, hard hat, safety shoes and overalls (long sleeves) and reflective vests •Provide PPE: Safety Boots/Shoes, Sun Hat, Dust Mask, Eye Protection, Reflective Vest, 2 Piece-Long Sleeves. 6. All PVC pipes to be glued using PVC weld •Manual lifting •Ergonomic issues • Falling objects • PVC weld glue Fumes • PVC skin contact •Musculoskeletal injuries •Back injuries •Hand’s injury •Eye infection •Fumes •Respiratory system problems •Dizziness •Drowsiness •Fatigue •Confusion 3 7 2 42 B • Construction Manager CR8(1) will ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit (RWL = 1/3 body weight or 25kg). • Develop an ergonomic plan, communicate it and implement. • The store man or the appointed tools inspector to inspect all the tools prior working. • Proper supervision of work by the supervisor. • The Supervisor to keep the MSDS and to CR 8(7) CR 8(5) CR 8(1)

- 13. Page 13 REVISION NO: 01 communicated to employees. • Provision of safety glasses, safety gloves, hard hat, safety shoes and overalls (long sleeves) and reflective vests •Provide PPE: Safety Boots/Shoes, Sun Hat, Dust Mask, Eye Protection, Reflective Vest, 2 Piece- Long Sleeves. 7. Install saddles using drill and hand tools •Twisting and turning •Ergonomic issues • Poor housekeeping •Using the drill • Pinch point •Musculoskeletal injuries •Back injuries •Hand’s injury •Trip and falling injuries •Hand injury and nip points •Electrical shock 2 7 3 42 B • Construction Manager CR8(1) will ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit (RWL = 1/3 body weight or 25kg). • Develop an ergonomic plan, communicate it and implement. • The store man or the appointed tools inspector to inspect all the tools prior working. • Proper supervision of work by the supervisor. • Housekeeping supervisor be inspect and ensure good housekeeping. •Provide PPE: Safety Boots/Shoes, Sun Hat, Dust Mask, Eye Protection, Reflective CR 8(7) CR 8(5) CR 8(1)

- 14. Page 14 REVISION NO: 01 Vest, 2 Piece-Long Sleeves. 9. Housekeeping Cleaning working area using brooms • Dust emitted • Slips, trips from stones and material on the floor Dust being inhaled/ getting in eyes(silicosis) • Slips, trips and falls from stones and material on the floor • 3 5 2 30 C • Apply a wet process to reduce dust exposure • Use dust masks to prevent inhalation of dust Contractor to conduct DSTI’s (Daily Safety Task Instruction) to be conducted and communicated at the beginning of the shift on a daily basis. DSTI close out to be conducted and attendance registered signed by all staff. • Ensure waste is disposed correctly into an allocated skip or bin. • Provide PPE: Safety Boots/Shoes, Hard Hat, Dust Mask, Eye Protection, Reflective Vest, 2 Piece Long Sleeve CR 8(7) CR 8(5) CR 8(1) 10 All activities • COVID-19 spread through: - physical contact - through sharing of tools - touching equipment -working close to one another no social distancing • COVID-19 easily spread The symptoms include a combination of: - Fever, - Cough, - Difficulty breathing, - Muscle Pain, - Tiredness. - Skin rash - Discoloring of hands and feet - Conjunctivitis Contracting COVID-19 could result in: - Spreading the infection to others, 3 8 3 72 AA •COVID-19 Policy and COVID-19 Prevention and Control Management Plan. •Avoid close contact with sick people, especially people who are coughing or sneezing. •Cough and sneeze into your elbow or in a tissue, NOT your hand. Dispose of the used tissue immediately in a closed bin and wash your hands with soap and water. •Avoid touching your eyes, nose and mouth without washing your hands first. CR 8(7) CR 8(5) CR 8(1) Compliance Officer

- 15. Page 15 REVISION NO: 01 - Serious respiratory illness •Regularly wash your hands with soap and water for at least 20 seconds OR use an alcohol-based disinfectant after coughing/sneezing, before eating and preparing food, after toilet use, after touching surfaces in public places or tools and equipment on site. •Practice social distancing: Maintain at least 1.5 meters (Preferably 2m) distance between yourself and others, especially anyone who is coughing or sneezing. Site Close Out: 11 Waste disposal in an accredited land fill site -Disposal certificate • Disposal of waste in an un authorized site • Selling waste to local residents • Exposure to medical waste • Contacting disease • Sickness from infectious diseases • Sickness from contagious virus • Environmental pollution 3 8 3 72 AA Construction Manager to appoint an accredited waste management service provider or ensure waste disposal is monitored to and from the disposal site, • Waste manual slips and waste disposal certificates should be issued to confirm proper waste disposal. The waste disposal certificate to be kept in a safety file. CR 8(7) CR 8(5) CR 8(1) 12 Packing and loading tools and equipment • Manual handling • Dust •Loose material flying • Back injuries • Ergonomic injury • Inhalation of dust • Serious injuries 2 6 3 36 C • Supervisor to ensure that all employees are training in manual handling – where load is lifted bend at the knees not back do not twist body with load in hands, adhere to the recommended weight limit CR 8(7) CR 8(5) CR 8(1)

- 16. Page 16 REVISION NO: 01 (RWL =1/3body weight or 25kgs • Employees must ensure that they wear dusk masks •Supervisor to ensure that all loose material is put in bags and dumped by the office waste segregation area. 13. De-mobilize from site •Manual Handling of equipment and materials. •Dust. •Materials/Objects in the walkways. •Fatigue. •Other vehicles driving unsafely. •Inclement Weather. •Sun •Manual handling injuries. •Vehicle Collision & Damage. •Collisions with Pedestrians. •Material Damage. •Equipment Damage. •Slips, trips and falls •Rain causing slippery conditions. •Heat stroke from being exposed to the sun for too long and sun burn. 2 8 2 32 C •Responsible 16.2 to ensure Instructions are given on Manual handling using Safe Work Procedure (SWP) for Manual Handling: Where load is lifted, bending at the knees, not the back. Do not twist body with load in hands, always carry load close to the body, adhere to the recommended weight limit (RWL = 1/3 body weight or 25kg). •Contractor to conduct DSTI’s (Daily Safety Task Instruction) to be conducted and communicated at the beginning of the shift on a daily basis. DSTI close out to be conducted and attendance registered signed by all staff. •Ensure Off-loading area is clear, level, secure and free from slip trip and falling hazards. •Stacking & Storage Supervisor to be appointed to control lay down areas. •All workers to have valid medicals with annexure 3 CR 8(7) CR 8(5) CR 8(1)

- 17. Page 17 REVISION NO: 01 documents signed and stamped by Occupational Medical Practitioner. •Stacking and Storing to only be in designated areas and Contractor to develop and implement Stacking & Storing Guidelines to cove items such as Ventilation, Lighting, Manoeuvring Space, Stacking Requirements, Emergency Exits, Access & egress, etc. •Keep to safe speed limit 15km/h when driving on site. •All Drivers Licences must be valid in order to drive any vehicle. •All drives are to be warned about the road conditions. •All passengers are to remain seated at all times with seatbelts fastened. •At no time will passengers be allowed to ride on the back of an open van, truck or trailer. •Recommended to have an alternative driver available to share driving time (where required on long commutes). •Do Not exceed Speed Limits, and ensure speeds are kept to a safe limit giving the driver enough time to make an emergency stop.

- 18. Page 18 REVISION NO: 01 •Drivers are to drive a safe distance away from the roads edge to avoid the vehicle losing control (Includes no Yellow Line Driving). •All Vehicles must be regularly serviced and in good working order. •Inspection Records must be kept for all vehicles and plant. •Drivers must have a valid Medical Certificate of Fitness as conducted by an occupational medical practitioner (including a completed and Annexure 3 form). •“Construction Vehicle” Sign to be placed on rear of vehicle. •Site Office sign posts with Mandatory PPE signage, contact details and “no Unauthorised entry signage” to be the last items to be removed from site to ensure site is still secure during de- establishment. Access is to be controlled by Security to safe guard the site camp and to ensure no unauthorised entry into site camp area during de- establishment. •All hand tools are to be inspected prior to use and inspected at least once per month. Inspections must

- 19. Page 19 REVISION NO: 01 SECTION G: DECLARATION OF INTENT I, ______________________________________-, testify that this risk assessment is a team’s collective effort and we and my risk assessment team commit to abide by the content of this document. We shall ensure that this information is conveyed effectively to all the workers who will be involved on site including those of other contractors. We will also ensure that this assessment is implemented accordingly. Furthermore, we commit to comply with the provisions of the Occupational Health and Safety Act No 85 0f 2003 as amended and associated regulations including the Construction Regulations 2014, in particular CR9. This baseline risk assessment will be monitored and updated when: 1. There are new risks identified 2. There is change of equipment 3. There is change in legislation 4. It is reasonably necessary to do so Signed: ________________________________ Date: ________________________________ Construction Manager Signed: ________________________________ Date: ________________________________ Construction Health and Safety Officer Signed: ________________________________ Date: ________________________________ Risk Assessor be recorded on tool inspection check sheets. •During Hot periods, regular breaks must be taken. Drinking water must be made available on site close to work areas. • Provide PPE: Safety Boots/Shoes, Hard Hat, Dust Mask, Eye Protection, Reflective Vest, 2 Piece Long Sleeve Overall, Gloves.