Pcsd newsletter-special edition-2007

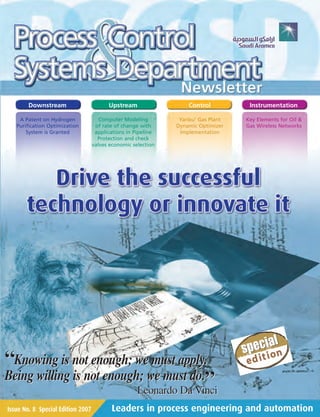

- 1. Downstream Upstream Control Instrumentation A Patent on Hydrogen Computer Modeling Yanbu‘ Gas Plant Key Elements for Oil & Purification Optimization of rate of change with Dynamic Optimizer Gas Wireless Networks System is Granted applications in Pipeline Implementation Protection and check valves economic selection “Knowing is not enough; we must apply. Being willing is not enough; we must do.” Leonardo Da Vinci Issue No. 8 Special Edition 2007 Leaders in process engineering and automation

- 2. ©Copyright 2007, Saudi Aramco All rights reserved

- 3. Message from Vice President It gives me a great pleasure to reach out to our customers in this issue of the Process and Control System Department (P&CSD) newsletter. Our goal at P&CSD is to communicate our dedication to the continuous improvement of facilities' business performance. The development of new leading edge technologies is one of our main “We all drivers in the engineering strategies to achieve operational excellence. committed to We focus on deploying proven process and control technologies that will give our company a competitive edge. As the main stakeholders, our support our customers’ participation and collaboration are essential to the success of facilities with the development and implementation of these technologies. leading edge technologies to We are all aware of the global shortage in technically skilled job achieve candidates. Engineering Services is leading an initiative to develop that operational talent in-Kingdom using technical competency maps. These maps focus on required technical competencies that can be acquired by attending excellence.“ training courses, achieving professional certifications, participating in technical exchange forums and professional society events, as well as learning practical engineering skills in the field. Technical competency maps will guide the development of more than 5000 engineers in our surface facilities. By remaining competitive, we will improve the lives of our people, diversify and grow our economy, and ensure that Saudi Aramco will remain a leader in the oil & gas industry. Isam Al Bayat

- 4. Contents Process & Control Systems Department Newsletter 15 JRD/FCCU MTC Technology Evaluation by FCC Aspen Kinetic Model 7 Troubleshooting YR Cyclemax Regenerator Catalyst Blow out 16 P&CSD Technology Partnership Meeting with YR and RTR 20 Saudi Aramco’s Fuel 8 Distillation Workshop Quality Roadmap P&CSD Supports Local 21 11 A Patent on Hydrogen Purification Optimization is Professional Granted Societies: AIChE-SAS Application of Flare 12 22 Rate of Change Modeling Gas Recovery Systems in Saudi Aramco facilities TORR Technology for 25 Produced Water Treatment Suggested topics and related technical articles for this newsletter are encouraged and welcome, and may be 28 submitted to Abdulaziz Tijani, EOB, E-3410, Dhahran 120 120 100 100 or e-mailed to tijaniah@aramco.com 80 80 ReG ReG 60 60 40 40 20 20 0 0 1.2 1.2 3000 1 1 3000 2000 2000 0.8 1000 0.8 1000 ReL 0.6 0 0.6 0 ReImp ReL ReImp Process & Control Systems Newsletter is published Basket Impeller Column: 250 250 200 200 150 150 ReG ReG 100 100 50 50 Bi-annually by the Process & Control Systems Department 0 0 1.2 1.2 3000 1 1 3000 2000 2000 0.8 1000 0.8 New Approach 1000 ReL 0.6 0 0.6 0 ReImp ReL ReImp

- 5. 30 Data Validation and Reconciliation A Crucial Technology for 44 Industrial Time Processing Plants Synchronization 32 Optimizing Projects with a Main Automation Contractor 46 Trim Integrity for Compressor Anti- surge Valves 36 Advanced Multivariable & Regulatory Control Performance Monitoring 48 Industrial Wireless LAN Security For Oil & Gas Process Automation Networks 38 Yanbu‘ Gas Plant Dynamic Optimizer Implementation Process Automation Alarm System Improvement 51 Focus Team Update 40 at AINDAR GOSP-2 42 52 Engineering the Automatic Valve Future Characterization – Why didn’t we think of that? 43 Key Elements for Oil & Gas Wireless Networks 54 Safety of the Issue HOT SPOT

- 6. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Letter from the Team “The link between Innovation, Plant Experience, and Hard Work” Newsletter team: Abdulaziz Tijani, Omar Halawani, Jim Sprague, Jim Anderson Do you ever wonder how our Saudi Aramco innovators come up with such good ideas? Are they born inventors, bred with special imagination? We think not. Our view is that innovation in Saudi Aramco is much like it was in Thomas Edison’s day, “90% Abdulaziz Tijani perspiration and 10% inspiration”. Now you may ask, where does all that perspiration come from? Well, in our view, a large part of it comes from an innovator’s early years working at the plant, dealing with process and control problems every day — day after day. You work and expend so much energy that the process and its Omar Halawani problems are burned into your consciousness. And guess what, that’s a good thing! Because in the end, all those years of perspiration make you what you are — an experienced specialist with a keen understanding of your plant and its problems. Now here is where the innovation part comes in. If that Jim Sprague experienced specialist keeps a sharp eye out — he will ultimately come across some new technology, gadget, or combination — that can solve one of those problems. Sometimes the technology is already applied somewhere else, and the innovation is applying it to your application. Jim Anderson Sometimes it’s combining multiple technologies into one to 4 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 7. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! come up with a solution. The next important step is to sell and implement that solution. Innovation thrives on risk and change. It is important to understand that new ideas and solutions come from an attitude, an environment, and a culture that embraces change. We know that the world is changing faster than it ever has before and that everyone is part of that change. The old “It is saying of “I paid my dues” has become as obsolete and important to outdated as the typewriter. Today, as an engineer, your dues are understand that paid daily. This means that each of us as a customer, supplier, or new ideas and employee is being evaluated on a daily basis with an ever changing measurement. The key is to stay on top in our field solutions come through continuous learning and updating our experience and from an knowledge. Saudi Aramco’s learning organization initiatives attitude, an can certainly help. environment, In the end, innovation comes from the following: a culture that • the experienced and knowledgeable engineer with embraces • watching out for solutions while change.. ” • anticipating change and managing risks. So, for those of you who are gaining work experiences – and that should include all of us – you are Saudi Aramco’s next innovators. Just make sure you keep your eyes open for the solutions. Remember — rarely does innovation just happen: instead, it is nearly always born in the struggle to solve a problem. Sometimes that innovation solves a completely different problem in a very unanticipated way. Sincerely, P&CSD Newsletter Team Process & Control Systems Department Issue No. 8 – Special Edition 2007 5

- 8. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Professional Engineers in P&CSD Licensure and certification are the mark of a professional. It demonstrates a commitment to the high standards of professionalism to which the engineering profession subscribes. Licensure and certification are important because they demonstrate the accomplishment of a set of standards to which all engineering professionals recognize. The following engineers in P&CSD carry professional engineering licenses/certifications in various areas that demonstrate their accomplishments to internationally recognized standards. Other engineers are presently pursuing licenses/certifications. Name Unit License/Certification Instrumentation, Control & Automation Jim E. Anderson APCU Certified Automation Professional (CAP), ISA Steve Wagner APCU P.E. (Canada) Henry Chan APCU P.E. (Ontario, Canada) Mohammed Salim CMU MIET CEng (Member of Institute Engineering & Technology - Chartered Engineer) Zia Soofi CMU P.E. (Texas, USA) Ralph Hartman IU P.E. (Texas, USA) Doug Esplin PASU P.E. (Utah, USA) Farrukh Chawla PASU P.E. (Ontario, Canada) Hashim Ghalib PASU Certified Automation Professional (CAP), ISA TüV/CFSEGB Certified Functional Safety Professional Austin Brell PASU P.E. (Chartered Engineering License with European Counsel of IChemE), TUV Certified Functional Safety Professional Computer Networking Abduladhim, Abdullatif CCNU Registered Communications Distribution Designer, by BICSI Abdullah Nufaii CCNU Certified Wireless Network Administrator (CWNA) Mohammed Saeed CCNU Certified Wireless Security Professional (CWSP), Cisco Certified Design Professional (CCDP), Cisco Advanced Wireless LAN Specialist (CAWDS), Cisco Certified Design Associate (CCDA), Cisco Certified Network Associate (CCDA) Soliman Walaie CCNU Certified Wireless Networks Professional (CWNP) Process Engineering Gene Yeh DPED P.E. (Louisiana, USA) Sam Zoker DPED P.E. (Texas, USA) Prasad Pantula DPED P.E. (Corporate member for Engineer’s Australia) Gabriel Fernandez OPU P.E. (Alberta, Canada) Jack Dempsey P&SU Chartered Engineer Registrant for the Engineering Council (UK) Pierre Crevier UPED P.E. Chemical Engineer (Alberta, Canada) Saleh Mulhim UPED P.E. (Texas, USA) Yuv Mehra UPED P.E. (Texas & California, USA) 6 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 9. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! P&CSD Technology Partnership Meeting with YR and RTR P&CSD held one-day “Technology Partnership Meetings” in May and June at Yanbu‘ and Ras Tanura refineries, in line with Engineering Services business line’s strategic initiatives to accelerate technology exploitation. The meetings were organized to promote a selected for further evaluation through an Engineering Service Agreement (ESA) between the two refineries. The technology culture among refinery personal brainstorming sessions in YR and RTR were facilitated by and provide a platform for engineers to Engineering Services’ performance consultant and the brainstorm new technologies that could be leadership center in Dhahran. deployed in a partnership between the refineries and P&CSD. Another goal was to Forty-five engineers participated in the Yanbu’ Refinery increase the awareness of Saudi Aramco’s meeting from Saudi Aramco, Saudi Aramco Mobil Refinery (Samref), Saudi Aramco Lubricating Oil Refinery technology program. Co. (Lubref), American company Honeywell and At the meetings, the Research and Development Center’s Honeywell subsidiary UOP. The Ras Tanura meeting was Technology Management Division presented an overview attended by 33 engineers. of the center’s technology program to encourage future Both meetings were coordinated by Mohammad participation by employees attending the meetiing. Balamesh and Saeed Al-Alloush from P&CSD’s Catalytic P&CSD representative then discussed three new Conversion Unit. technologies that were successfully implemented at the two refineries after P&CSD evaluation, and a Yanbu‘ Refinery representative talked about new technologies that have been implemented at that refinery. Fruitful brainstorming sessions conducted at the meetings identified more than 70 technical items important to the two refineries. The items were categorized, and 11 were Right: Brain Storming Session at Rastanura Refinery Below: Yanbu‘ Refinery Gathering Process & Control Systems Department Issue No. 8 – Special Edition 2007 7

- 10. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Saudi Aramco’s Fuel Quality Roadmap Author: Walid A. Al-Naeem A cross-functional team composed of EPD, FPD, RTSD, OSPAS, and chaired by P&CSD was charged with the development of a transportation fuel quality roadmap to enhance the overall gasoline and diesel qualities to be environmen- tally friendly. This team along with a reputable consultancy firm IFQC the Green House Gases (GHG) – the main cause of climate (International Fuel Quality Center) has done extensive change. Saudi Aramco believes that the best way to data gathering and analysis to develop the roadmap. The combat climate change is to look forward and act main parameters that are affected by the roadmap is a proactively. So far, Saudi Aramco has already taken reduction in sulfur content in both the gasoline and diesel serious steps to improve the environmental situation in products to 50 ppm & ultimately to 10 ppm, a reduction the Kingdom by establishing an Environmental Master in the gasoline benzene to 1.0 vol. % or less, and a Plan that addresses all sources of contamination to the air, reduction in benzene aromatic contents to 35 vol. %. earth, and water. This master plan was endorsed by the These reductions is planned to take place at different Saudi Aramco board in 2001. stages of the roadmap. Those stages are: So far, Saudi Aramco has Step 1: Immediate operational changes that do not require capital investments. already taken serious steps to Step 2: Changes that require capital projects and can improve the environmental be implemented by 2013. Step 3: More stringent specifications that require situation in the Kingdom by additional capital projects to step 2 and can establishing an Environmental be implemented by 2016. Master Plan that addresses all Background Today, the world’s policy makers and business leaders are sources of contamination to the increasingly in agreement that climate change is occurring and it has to be addressed. As a responsible air, earth, and water. corporate citizen, Saudi Aramco is committed to reduce Figure 1 Gasoline Quality Roadmap Figure 2 Diesel Quality Roadmap 8 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 11. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! The primary objective of the master plan is to bring all Saudi Aramco facilities into compliance with the government environmental regulations. It is also in line with the company’s strategic initiatives to protect the environment and ultimately improve public health. In addition and due to high sulfur levels in transportation diesel, which eventually contributes to high SO2 emissions, the company has decided to include transportation diesel fuel into the master plan with the idea of addressing other fuels and air pollutants in the future. As a result, the master plan has recommended to lower sulfur in transportation diesel from 10,000 ppm to 500 ppm mitigating SO2 emissions from diesel engines. Figure 3 Sophisticated Emission Control Systems As a result, the master plan has Impact of Fuel Quality on Vehicle recommended to lower sulfur Performance in transportation diesel from There is without doubt global recognition that climate change abatement and the drive toward lesser GHG can 10,000 ppm to 500 ppm only be achieved if vehicle manufacturers, refiners and legislation work together. Since fuels and engines are mitigating SO2 emissions from technically linked with each other, the improvement in gasoline and diesel fuels quality will permit the adoption diesel engines. of up-to-date low emission engines in the kingdom as opposed to the currently available. It is important to mention at this point in time that vehicle manufacturers have been supplying high emission vehicles to the Future Environmental Challenges kingdom in the past and they continue to do so at the to KSA present time. This is because their up to date engine Since future challenges are always their ahead of us, components are very sensitive to high sulfur fuels, which Saudi Aramco has taken proactive measures by will cause it to be in-effective in a short while. For establishing the fuel quality roadmap (Figures 1 & 2) that example, NOx and PM pollutants require special emission will ensure compliance to the government environmental control systems to be embedded into the vehicles to trap regulations at all times. and convert those pollutants into friendly gases. For those systems to operate efficiently (Figure 3), sulfur in The fuel quality roadmap, which was recently both gasoline and diesel fuels need to be further reduced approved by the company board, has provided an from 500 ppm to 50 as an intermediate step and ultimately to 10 ppm. At 10 ppm the emission control update to the existing environmental master plan, systems will give the utmost optimum performance that bearing in mind the following future challenges: will drastically mitigate the NO2/PM emissions to the least. • The kingdom has high urbanization level, Therefore, it is clear that reduction of NO2 and PM meaning that people tend to move to bigger cities emissions are solely dependent on low emission engine which ultimately cause high population and traffic technology. To introduce those low emission engines to densities, especially in Riyadh, Jiddah, Makkah, the kingdom’s fleet, it requires around 18 years to have and Dammam. full replacement of our high emission vehicle fleet. As a result, the actual realization of NO2 and PM emissions • Since 1998 the number of registered vehicles has reduction will take more time as compared with the other increased by 45%. pollutants. Process & Control Systems Department Issue No. 8 – Special Edition 2007 9

- 12. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! For this year, it is planned to conduct two workshops for scientists during December 9–10, 2007, and for executives during December 11, 2007. The objective of this year’s workshops is to underscore, at a strategic level, the inter- On the other hand, the required relation between stringent fuel specifications, engine performance, environment protection and the capital investment program sustainability of oil market. Several other concepts will be addressed, as well as the future of Dieselization and the associated with implementing Kingdom’s environment, as a result of the recently approved Fuel Quality Roadmap. the long term strategy of the roadmap has been recently approved by the company Today, the world’s policy board to be injected into the makers and business leaders 2009 – 2013 business plan cycle. are increasingly in agreement that climate change is occurring Updates and it has to be addressed. The transportation fuel quality roadmap was presented to the Management Committee on June 5, 2007. and successfully acquired the MC‘s endorsement, to be injected into the environmental master plan. In addition, several roadmap parameters were already implemented such as 800 ppm sulfur diesel (in major cities) and 5000 Acknowledgment ppm sulfur diesel (country wide) as compared to 10,000 P&CSD would like to thank all the multidepartmental ppm sulfur diesel, updating MTBE specification to 15 vol. members who participated in the development of the % as opposed to 10 vol. %, etc. Fuel Quality Roadmap for their great efforts and continuous support. Their time, dedication, and The required capital investment program associated with contribution towards the completion of the roadmap implementing the long term strategy of the roadmap has added great value. recently been approved by the company board to be included in the 2009 – 2013 business plan cycle. Fuels Technology In line with Engineering Services knowledge sharing strategy and to promote the understanding of the ever changing dynamics of vehicles technology and its relation with fuel quality, P&CSD conducts regular workshops for Walid A. Al-Naeem is the Supervisor of Distillation and Saudi Aramco executives and scientists. Treating Unit of P&CSD. He is also the Chairman of Saudi Aramco Products Specifications Committee which is com- In 2006, P&CSD sponsored a full-day manager’s workshop posed of cross functional members from various departments such as FPD, EPD, R&DC, OSPAS, Distribution, RTSD, Sales and titled “Importance of Fuel Quality & Effect on Vehicle Marketing, and Domestic Refineries. This committee is Performance” on December 2nd, 2006. This workshop charged to look after various issues related to Saudi Aramco Products and Fuels Specifications. Walid holds a Master was designed for relevant department managers who Degree in Chemical Engineering from KFUPM since 2003. directly deal with fuels production, distribution, and Walid is a member in several local and international techni- specifications. The primary objective was to raise their cal societies and very active in IK / OOK events as chairman, speaker, and as a delegate. awareness to the global trend towards producing clean fuels and to underscore the interaction between engine and fuel technologies. 10 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 13. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! A Patent on Hydrogen Purification Optimization System is Granted Author: Ibrahim M. Al-Babtain This patent relates to the recovery of hydrogen from gas mixtures and, more particularly, to a method for obtaining increased hydrogen recovery from oil refineries and petrochemical or natural gas operations by combining a steam reformer hydrogen product stream with an off gas stream and utilizing a combined stream as a feed to a single Pressures Swing Adsorption (PSA) unit. This idea was generated during the initial start up of a has provided his support and encouragement to consider new refinery that includes multiple PSA units utilized to implementing this patent in the project if applicable as treat different feed streams of CCR off gas and refinery significant capital savings could potentially be realized. off gas. One of these streams exceeded the capacity of the The sketches below show the system before and after the related PSA unit and this portion of the excess gas is not modification. effectively utilized and typically sent to the flare or fuel gas system in the refinery. Another disadvantage is that one of the PSA units is operating at high feed capacity which can increase the probability of damaging the adsorbent material within the PSA unit and carrying impurities between the adsorbent layers. Also, flaring this portion of excess gas requires compensation of same flared quantity from another feed stream that feeds the other PSA unit. Prior to development of this invention, there has been no single method of hydrogen recovery in refinery operations in which some or all of the feed streams from Figure 1 System before the modification separate PSA units were combined and utilized as feed for a single PSA unit, and in which some or all of a steam reformer product stream and a refinery offgas stream being used as feed streams for separate PSA units were combined and utilized as feed for a single PSA unit. By applying this invention in the refinery, the total hydrogen recovery was increased in the refinery by effectively utilizing the excess gases that were flared, the load on the steam reformer was reduced by lowering reformer feed rate, the refinery fuel gas consumption was reduced in the steam reformer furnace, and the hydrocarbon content and heating value of the tail gas, from the PSA unit fed by the steam reformer product stream, was Figure 2 System after the modification enriched. The full utility patent application for this invention was filed at the United States Patent & Trademark office (USPTO) on July 2003 and the patent was granted under Ibrahim M. Al-Babtain is a Refining Specialist in the Downstream Process Engineering Division of Saudi Aramco. US Patent # US 7,252,702 dated August 7, 2007. Ibrahim has 18 years of experience in refining business. Joined P&CSD and participated with FPD and NBD as a With regard to implementing this invention, Yanbu‘ technical member in the development of major refining projects and evaluation of several technologies. Export Refinery Project’s director; Mohammad S. Al-Subhi Process & Control Systems Department Issue No. 8 – Special Edition 2007 11

- 14. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Application of Flare Gas Recovery Systems in Saudi Aramco facilities Authors: Ra’ed Husseini, Prasad Pantula The corporate Flaring Task Team led by P&CSD developed the Flaring Minimization Roadmap that was endorsed by the Management committee in June 2006, The roadmap recommended installing flare gas recovery (FGRS) units in company locations where the normal daily flare gas exceeds 1-2 MMSCFD. This article presents the concepts of FGRS and its application in Saudi Aramco. “Protecting the Environment,” “Managing and The emissions of sulfur dioxide, ozone precursors Protecting Resources,” and “Improving Health & Safety” and particulates have a significant environmental are all part of our Business Line Strategies to meet the and health impact. Corporate Imperatives. Installing a Flare gas recovery sys- tem (FGRS) at the tail end of a gas plant or a refinery will • It provides an economic incentive in returning the achieve all the above strategies, plus recover fuel gas recovered flared gas to the value chain, thus saving worth $2/MMBtu. The Flaring Minimization Roadmap as on plant fuel gas. endorsed by the Management Committee in June 2006, • FGRS improves the reliability of the main flare tip. recommended installing flare gas recovery units in com- This is an important consideration for the larger pany facilities where the normal daily flare gas rate diameter flares that are prone to damage from oper- exceeds 1-2 MMSCFD, after exhausting all possible flaring ation at the low daily flaring rates. With FGRS, the minimization efforts. main flare is in stand-by mode, which improves its reliability and life, and minimizes the recurring cost Why Flare Gas Recovery? of flare tip replacement The main drivers for a FGRS project are; • It’s a proven technology • The project has a potential for emission trading and CO2 credits, thus generating additional revenue. • It eliminates daily flaring, except for the pilots, thus providing intangible benefits from reduced emis- • FRGS reinforces Saudi Aramco’s (& the Kingdom’s) sions of CO2 (green house gas), SOX, NOX, & VOCs. positive image as a responsible corporate citizen. Recovered Gas to Process Flare Gas Knockout Drum FGRS 6 MMSCFD N2 Purge Existing Flares HP/ACID or INLET New Staging Device Figure 1 FGRS concept 12 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 15. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! FGRS Components ever flow is detected. Basically, the staging devices enable A flare gas recovery installation for an existing plant will safe operation of the entire system through sealing the consist of four main components: elevated flares and provide backpressure in the flare 1. A compression based package (FGRS) to recover the header, allowing the flare gases to be routed to the FGRS. flare gases for re-use in the existing processing facili- ties Process Design of FGRS package 2. Staging devices to safely allow diverting the routine As shown above, the FGRS is a compression based pack- daily flared gases to the FGRS package but not the age designed to recover the flare gases for reuse in the emergency or abnormal relief loads. Figure 1 illus- existing processing facilities. The system configuration is trates the integration of the FGRS into the flare sys- dependent on the final destination of the recovered gas tem. and the type of compression equipment selected. 3. A nitrogen generation package to supplement exist- ing nitrogen generation capacity. Nitrogen will be Destination of recovered gas: used as purge gas, downstream of the staging device. Some of the potential destinations for the recovered gas 4. Control system within the package and interface with could be; the plant DCS • Plant Fuel Gas header. This requires compression As shown in Figure 1, the Flare gas recovery unit ties into facilities to compress the flare gases from near the flare gas header between the knockout drum and the atmospheric pressure (3.5 psig max.) to approximately staging device, and pulls flare gas from the header when- 100-120 psig. • Plant inlet Gas header. This destination is typically the suction of the LP compressors in the GOSPs (1ñ50 psig) or the Inlet slug catchers in the gas plants (230 psig), which also requires compression facilities to compress the flare gases to the required pressure. Type of Compression equipment The choice of compression equipment will influence greatly the configuration of FGRS system. A detailed survey of existing technologies revealed that the The Flaring Minimization Vendor offered package for FGRS Figure 2 with LRCs (courtesy: Envirocomb ltd) Roadmap as endorsed by the Management Committee in June 2006, recommended installing flare gas recovery units in company facilities where the normal daily flare gas rate exceeds 1-2 MMSCFD, after exhausting all possible Typical Screw compressor package flaring minimization efforts. Figure 3 offered by Man-Turbo Process & Control Systems Department Issue No. 8 – Special Edition 2007 13

- 16. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! compressor types widely used for FGRS application are: exceeds the design capacity of the FGRS. • Pressure control, low pressure alarms, and ESD systems • Liquid ring compressor (LRC) with a variety of service fluids, e.g., water, DGA, diesel, etc. should be provided at the inlet of the package to ensure that positive pressure in the flare headers is • Multistaged screw compressors (MSSC) always maintained. The major advantages of the above compressors types • The staging control valve/seal drum should be are as follows; designed to open to existing flare stacks when each • Can handle a wide range of gases with varying corresponding flare header flow exceeds the design molecular weights with no effect on their capacity of the FGRS. performance • Can handle flow from zero to full capacity with a Nitrogen purge robust recycle system. To ensure positive pressure in the flare headers while the • Can tolerate liquid in the feed better than any other FGRS is in use, the flare headers will be continuously type of compressors. purged with nitrogen at a point downstream of the Typical vendor offered packages are illustrated in Figures staging devices or the water seal drum. As a backup to the 2 & 3. The flare gas stream can be compressed in a LRC nitrogen purge, fuel gas from the existing fuel gas purge based compression system to 100-110 psig with water as a header can be provided, with automatic controls. service liquid in a closed loop. A heat exchanger to cool the circulating water and a three phase separator to Impact on the existing flare system remove oil and water are part of the package. The staging device seals the existing flare and imposes a Alternately, a screw compressor package may be utilized. positive back pressure on the flare gas header. This allows routing the flare gas to FGRS while maintaining a positive The system configuration is dependent flare gas header pressure, which is important with regard to the safety of the flare headers. Generally the maximum on the final destination of the backpressure allowed will have no impact on the existing recovered gas and the type of PZVs connected to the flare header; however the actual impact should be checked with flare simulation models compression equipment selected. during the detailed engineering stage. Design of staging device Conclusions The flare gas stream is intercepted at a point downstream FGRS is a widely proven technology, though it has not of the corresponding Flare Knockout drums by a staging been applied in Saudi Aramco. In future, all potential sites device. The staging device is set to divert the routine will be considered for a detailed evaluation for its flaring rate of flared gas to the FGRS or to the elevated application. Currently a DBSP is under development for flare if the rate exceeds the capacity of FGRS. The staging installing a 6 MMSCFD FGRS units at ShGP & UGP . Other devices required to seal the elevated flare can be a water potential sites being evaluated are Safaniya GOSP1 and seal drum or a Buckling Pin/fast acting control valve Riyadh Refinery. Hawiyah NGL Recovery, Khurais arrangement, similar to what is currently used at BGP, Development and potentially Khursaniyah are providing HGP, HdGP, and proposed for the Hawiyah NGL project. tie-ins for future units. Control System The control system within the FGRS package and DCS Ra’ed Husseini is a Senior Engineering Consultant with P&CSD. He has over 23 years of Aramco experience in gas interface should be part of the FGRS process detailed processing, refining and in upstream. design. The FGRS Process design vendors can provide the control system design and interface to the DCS without compromising process safety. The following are some recommended features that should be part of a FGRS package; Prasad Pantula is with F&RSU /DPED since 2002. He has 25 • The FGRS package should be isolated and safely shut- years of experience in upstream crude oil processing, petroleum refineries and process plant design. down or put in recycle mode automatically when the staging device opens, in the event the flaring rate 14 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 17. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! JRD/FCCU MTC Technology Evaluation By FCC Aspen Kinetic Model Authors: Saeed Al-Alloush, Sidney Anderson, Talal Al- Ashwal The purpose of this study is to determine the feasibility of installing the Mix Temperature Control (MTC) technology from Stone & Webster/IFP New Technology to improve Jeddah Refinery profitability by increasing conversions of gasoline and LPG on the Fluid Catalytic Cracking Unit (FCCU). The evaluation study will identify for JR major impacts of the use of MTC. These are: 2. Control of the optimum the implementation of this technology by focusing in the regenerator temperature. following area: unit conversion, gasoline sulfur content, 3. Adjustment of the feed Rx velocity, vapor line velocity and overhead cooling temperature up to its bubble point to achieve capacity after recycling all LCO stream. P&CSD/DPED/CCU better atomization and has signed with JR an Engineering Service Agreement faster vaporization. (ESA) to evaluate this technology by utilizing FCC Aspen 4. The heat absorbed with the Kinetic Models. recycle quench is recovered as steam production, preheating, or reboiling in Fig. 1 Mix Temperature Control at Proposed Technology the fractionation section of FCCU Feed Riser Section the FCCU. The MTC technology allows for independent temperature control of the catalyst cracking zone that results in Study Conclusion decreasing yields of less desirable products (coke and gas). The study evaluates the implementation and potential MTC is performed by injecting a recycle quench stream of application of MTC at JRD/FCCU by FCC Kinetic Model either cracked FCC naphtha or light cycle oil, further up simulation model. The annual revenue incremental from the reactor riser downstream of the combined feed applying this technology is significant. P&CSD injection point (See Figure 1) recommends consideration of the following future work This recycle quench stream results in separating the if JR plans to implement the MTC technology: reactor riser into two separate reaction zones. Consider MTC technology for increasing the unit • The first zone, (Zone 1), between the fresh feed conversion and production of more gasoline yield. injection point and the recycle quench stream Utilize of the FCC Aspen Kinetic Model to evaluate several injection point, is characterized by high temperature, scenarios at different feedstock conditions. high catalyst to oil ratio and very short contact time of The author acknowledges the support from Graham Jones, Ahmad oil and catalyst. Al-Othman from Pipeline & Simulation unit, Christopher Dean, • The second zone, (Zone 2), between the recycle Abdulaziz Al-Ghamdi and Adel Bawizer for finishing the ESA with quench stream injection point and the riser JRD on time. termination into the reactor vessel, is where reactions occur under more conventional and milder catalytic cracking conditions. The primary objectives of the MTC system are: Saeed S. Al-Alloush is a senior process engineer in the 1. To provide independent control of the catalyst and oil mix Downstream Process Engineering Division, Process & Control temperature in Zone 1. Systems Dept. (P&CSD). He has 15 years of experience with Saudi Aramco in refining area and mainly in Fluid Catalytic This recycle quench is a heat sink that behaves similarly to a steam Cracking area . He graduated with Master Degree of Science cooler or a catalyst cooler in the regenerator side of the FCC in Engineering from University of Tulsa (TU), USA. He is a reaction section. By behaving as a cooler the regenerated catalyst member in American Institute of Chemical Engineering temperature can somewhat be controlled during the catalyst (AICHE) since 1997. regeneration. Usually the minimum regenerated catalyst temperature is the one that results with adequate catalyst Sidney V. Anderson is an Engineer II in Saudi Aramco’s Jiddah regeneration of coke. The cooler catalyst temperature causes Refinery Operation Engineering Unit. He has over 38 years of higher catalyst circulation rates for meeting the heat requirements process engineering and refinery management experience for the cracking reactions and maintaining reactor outlet and has previously served on the NPRA Q&A panel. He has temperature. Additionally, there are also secondary objectives from also written or co-authored several other papers related to FCCU operations. Process & Control Systems Department Issue No. 8 – Special Edition 2007 15

- 18. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Troubleshooting YR Cyclemax Regenerator Catalyst Blow out Authors: Rabea M. Al-Saggaf, Hamzah Z. Abuduraihem, Neelay Bhattacharya, Sajeesh Padmanabhan P&CSD/DPED/CCU assisted Yanbu‘ Refinery Engineering in resolving the recent CCR Platformer regeneration catalyst pinning and blow out problem that resulted from the over-design of the regeneration gas blower by installing a restriction orifice in the Regeneration gas blower suction line. P&CSD Downstream Process Engineering has promptly spent catalyst is regenerated in four steps: 1) Coke extended troubleshooting support to Yanbu‘ Refinery Burning; 2) Oxychlorination – for dispersing the catalyst Engineering and recommended a course of action to put metals and adjusting the catalyst chloride content; 3) the unit in a normal mode of operation. The Continuous Catalyst Drying; 4) Reduction – for changing the catalyst Catalyst Regeneration (CCR) section of Yanbu‘ Refinery metals to the reduced state. Finally, the regenerated (YR) CCR Platformer Plant experienced successive catalyst catalyst is circulated back to the first Platforming reactor. blowouts leading to the regeneration section shutdown. Over a period of time catalyst fines plugs the Regenerator This caused the Platformer section to operate at reduced screen. The CCR has to be shutdown and the screen feed rate and severity. Prolonged shutdown of the removed for cleaning every 12 months. catalyst regeneration section would have led to the shutdown of the Platformer Plant and the consequence of Incident Background losing the gasoline production. Since the first startup in June 2006, the CCR Regeneration Tower has been operating with a partially plugged screen Introduction as a result of catalyst fines generated in the system from The Yanbu‘ Refinery Platformer unit was revamped in the containment loss in the Platformer reactors. This has June 2006 from a fixed bed unit to a Continuous Catalyst effectively reduced the Regeneration gas flow without Regeneration Unit. Coked spent catalyst from the affecting the CCR operability. It was recommended by the Platforming reactors is continuously sent to the CCR licensor to clean the screen at the earliest opportunity. Regeneration Tower where the coke is burnt off and the The CCR was shutdown for a period of 5 days to carry out Figure 1 DCS Pressure Trends 16 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 19. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! Table 1: Regeneration Tower Normal and Incident procedure at 50˚C/Hr. When the blower was switched to Temperature Profiles low speed at 350˚C a blowout was again observed. A Licenser similar phenomenon was observed when the blower was Normal Shifted TI Specified Profile Profile switched from low speed to high speed during the reheat. Range There was no improvement in the unit performance. TI -1 479-510˚C 380˚C 250˚C Therefore, the regeneration section was again shutdown as a result of repetitive blow out occurring between the TI -2 493-593˚C 563˚C 465˚C disengaging hopper and the regeneration tower. The CCR TI -3 493-593˚C 557˚C 475˚C Platformer throughput was lowered from the design of 40 to 30 MBD and 95.0 operating severity to control coke TI -4 493-560˚C 503˚C 511˚C lay down. TI -5 491-504o˚C 492˚C 543˚C Analysis & Findings TI -6 491-504˚C 487˚C 479˚C It is very unusual for a blowout to take place in a CCR TI -7 491-504˚C 485˚C 472˚C because it is normally catalyst full. During normal operation the catalyst flows down due to gravity. The TI -8 479-499˚C 485˚C 465˚C Disengaging Hopper operates at approximately 9 kg/cm2(g) and the Regeneration Tower operates at the cleaning of the regeneration tower screen. The unit approximately 2.5 Kg/cm2(g). This huge pressure was restarted in black burn mode. The startup was normal differential is taken by the catalyst in the long transfer and the regeneration tower temperature profile had its pipes between the Disengaging Hopper and the peak at the second TI in the Burn Zone. The operation of Regeneration Tower. If due to any reason a void is created the regenerator for the next 36 hours was absolutely in the Regeneration Tower, the huge differential pressure normal with regenerated catalyst carbon at 0.095 wt% will force the catalyst down, causing a pressure and spent catalyst carbon at 4.3 wt%. fluctuation that generates a lot of fines and dust. The fines will block the Regenerator screen, causing the On Tuesday, January 23, a blow out occurred between the temperature profile to slip down. disengaging hopper and the regeneration tower which caused the disengaging hopper level to drop from 52 % P&CSD analyzed the problem on the to 47 %. The Disengaging pressure dropped and the following lines: Regeneration Tower pressure increased momentarily. 1. One probable cause could be something blocking the Figure 1 below shows the pressure fluctuation and level catalyst transfer pipe. But this would be a one time drop at the time the blow out occurred. occurrence that would get automatically cleared after Due to the blowout, a lot of fines and chips were the blowout. But since the blowout reoccurred it was generated that plugged the Regenerator screen. A shift in obvious that it was not due to plugging of the burn zone temperature profile has being experienced and transfer pipes. the peak temperatures shifted to fifth TI which is at the 2. The only difference between the two startups was the bottom of the burn zone (refer to Table 1). condition of the screen. Since initial startup the unit was operating with a plugged screen. The recent Maintaining a proper burn profile in this section is startup was the first time with a clean screen. extremely important for safe operation of the unit. If the burn profile shifts down, un-regenerated catalyst will 3. The blowout was clearly related to the blower enter the chlorination zone potentially causing catalyst to operation because the blowout had happened on two agglomerate and damage the Regenerator internals. occasions when the blower speed was switched. Intensive discussions were held between Refinery Analysis of the previous operating data showed that the engineers and licensor experts on this subject and it was blower flow was 102 % of design even with a partially concluded that it is very difficult to pin-point the root plugged screen. Once the screen was cleaned the flow cause of the blowout. An attempt was made as suggested increased causing the catalyst to pin in the Regeneration by licensor to stop the regeneration blower and carry out Tower. Since the Lock Hopper is removing catalyst, a void cold circulation of the catalyst in order to clear the screen. was created at some location in the Regeneration Tower. Accordingly the regeneration tower was cooled as per When the differential pressure between the Disengaging Process & Control Systems Department Issue No. 8 – Special Edition 2007 17

- 20. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Hopper and the Regeneration Tower was high enough, it to install a restriction orifice in the regeneration gas forced the catalyst to fill the void creating a blowout. This outlet line, to reduce the regeneration gas blower flow by would also explain why the blowout occurred when the approximately 15%, and prevent catalyst pinning on the blower speed was changed. The first time when the regeneration tower screen. Unit licensor designed a blower was switched from high speed to low speed the restriction orifice with a bore size of 340mm, which was catalyst unpinned, causing an immediate blowout. The fabricated by YR and installed in the Regeneration gas second time the blower was switched from low speed to outlet line to reduce the flow by approximately 15%. high speed caused the catalyst to pin. The blowout did not occur immediately. During subsequent heat up the CCR Restart catalyst slumped, creating a void below the pinned area, The regeneration section was restarted on Feb 6, 2007, causing a blowout. after the installation of the restriction orifice. The startup was smooth without any pressure fluctuations or signs of A conference call was initiated by YR Engineering and blowout. The circulation rate was slowly increased to 95 P&CSD with the Licenser on January 31, 2007. P&CSD % of design and the oxygen concentration was slowly convinced the licensor that the blower could be a highly reduced from 1.0 mole% to 0.9 mole%. Laboratory results probable cause for the blowout and it was decided that: showed less than 0.07 wt% carbon, indicating complete 1. The licensor would size a restriction orifice to reduce regeneration. The temperature profile in the the Regeneration Gas flow by 15-20 % to avoid regeneration section was satisfactory, indicating no pinning. YR would keep it ready for installation in the reduction in the unit capacity. Regeneration tower gas outlet line. In conclusion, installation of the restriction orifice on the 2. Conduct inspection of the disengaging hopper and regeneration gas blower suction eliminated the pinning regeneration tower screen. problem from the over-design of the blower. Normal CCR Platformer operation resumed. 3. If inspection did not reveal any obvious reason to explain the blowouts, then install the restriction orifice in the Regeneration gas outlet line and observe the unit performance on restart. Field Inspection Rabea M. Al-Saggaf is a process engineer working with Saudi Aramco Yanbu‘ Refinery Department. He has 10 years The regeneration tower and the Disengaging Hopper experience in refineries. Rabea holds a B.S degree in chemical engineering from King Abdulaziz University, Jeddah 1996. were open for inspection. While unloading the catalyst, He joined Saudi Aramco in 1996. the last few drums from the Disengaging Hopper contained fresh catalyst. YR had added 12 drums of fresh catalyst to the Disengaging hopper during the recent reload. Since the catalyst had been circulated for 500 Neelay Bhattacharya is a process engineer working with Saudi Aramco Process and Control Systems Department. He cycles there should not have been any fresh catalyst has 17 years experience in Refineries and Petrochemical remaining in the Disengaging Hopper. This clearly plants. Neelay holds a B.E degree in Petroleum and Petrochemicals from Pune University, India 1990. He joined indicated that the catalyst was not moving as a result of Saudi Aramco in 2006. localized catalyst pinning on the regeneration tower screen. No clumps or debris were found between the disengaging hopper and the regeneration tower. The Hamzah Z. Abuduraihem is a process engineer working with Regeneration screen was heavily plugged. There was no Saudi Aramco Process and Control Systems Department. He has 15 years experience in refinery operation and project. sign of integrity loss or severe damage to the screen. Hamzah holds a M.S degree in Chemical Engineering and P&CSD concluded that the root cause for this problem was Petroleum Refining from Colorado School of Mines, USA 2001. He joined Saudi Aramco in 1992. the oversizing of the regeneration gas blower. Recommendations Sajeesh Padmanabhan is a chemical engineer and works with P&CSD recommended installing a restriction orifice in the the Operation Engineering & Automation Unit at Yanbu‘ Regeneration gas blower suction line to reduce the Refinery. He has 11 years of experience in Hydrotreating, Plaforming and Petrochemicals. He joined Saudi Aramco in Regeneration gas flow and increase the pinning margin. Jan 2005. YR and Licenser supported P&CSD’s findings and decided 18 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 22. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Distillation Workshop DHAHRAN — As company refineries look for new technologies and ways to revamp operations and best practices, more than 100 engineers, specialists and consultants gathered on March 28 to discuss the latest crude and vacuum distillation technologies. Personnel came from Saudi Aramco domestic refineries and central engineering services to join worldwide industry experts on March 28 for the first Distillation Workshop. The event was conducted and organized by the Process and Control Systems Department (P&CSD) at the Research and Development Technical Exchange Center under the theme, “Distillation: Revamping, Troubleshooting, Technology and Energy Conservation.” The aim was to create a learning organization, a stated goal of Engineering and Operations Services. Saleh A. Al-Zaid, manager of P&CSD left talks with Said Al-Zahrani & Mohammed Slamah during break time. P&CSD Manager Saleh A. Al-Zaid highlighted the importance of the distillation process in every plant and The Sulzer representative delivered the second refinery. He also concentrated on the importance of technology presentation, “Maximize Distillate Recovery P&CSD in supporting Saudi Aramco’s domestic refineries, by Means of Advanced Mass Components.” That was especially given the rise in fuel demand. followed by a panel discussion on energy conservation at “The importance of this workshop is derived from the crude distillation units, moderated by Tariq A. Al-Zahrani importance of crude and vacuum distillation processes,” and Khalid S. Al-Otaibi from P&CSD’s Distillation and Al-Zaid said. “Crude and vacuum units are the heart and Treating Unit. the main gate of every refinery in the world. Their “It was a great opportunity to exchange experiences importance is not negotiable.” with engineers, specialists and consultants from Representatives from two leading companies in crude different organizations within Saudi Aramco and distillation process revamps and technologies, Koch-Glitch worldwide industries,” said Mohammed S. Al-Ghamdi, and Sulzer Chemtic, presented “Primary Refinery Yanbu‘Refinery Operations Engineering and Automation Treatment: Process and Technology.” That was followed Unit supervisor, of the value of the workshop. by panel discussions on Crude Distillation Walid A. Al-Naeem, supervisor of D&TU, concluded the (Atmospheric/Vacuum) and Crude Handling and workshop by thanking the attendees for their Desalting, featuring panelists from Saudi Aramco, and participation. Sulzer and Koch-Glitsch. Distillation workshop attendees, organizers and panelists pose for a picture in R&DC Technical Exchange Center. 20 Process & Control Systems Department Issue No. 8 – Special Edition 2007

- 23. MISSION - We i n n o v a t e a n d o p t i m i z e o p e r a t i o n s f o r i m p r o v e d p e r f o r m a n c e t h r o u g h l e a d e r s h i p and professional services in process engineering and process automation! P&CSD Supports Local Professional Societies: AIChE-SAS The American Institute of Chemical Engineers (AIChE) – Saudi Arabian Section (SAS) is a non-profit professional association. It has memberships from all major companies of Saudi Arabia including SABIC, Saudi Aramco, KFUPM, SWCC, Royal Commission, and many other private companies. One of the major activities is the Monthly Technical Dinner Meeting of the members. The Meeting is highlighted with presentation from a well-known expert/specialist on chemical engineering-related subjects and major activities in the downstream industries. Further information about the meeting or the society can be viewed by visiting our web-site @: http://www.kfupm.edu.sa/sas-aiche. Process & Control Systems Dept. (P&CSD) has sponsored April 8, 2007, Meeting of AIChE-SAS in the Meridian Hotel, Khobar. The Guest Speaker was Mr. Khaled The Guest Speaker Mr. Khaled Al-Faleh, Sr. VP. Al-Faleh, Sr. VP, Industrial Relations of Saudi Arabian Oil Company (Saudi Industrial Relations of Saudi Aramco). Mr. Al-Faleh discusses Saudi Aramco’s global and national business Arabian Oil Company (Saudi Aramco) addressed his challenges and the need to elevate IK educational outcomes to meet the presentation “Educational Outcomes & Industry Needs: country’s rapid economic growth and international competition. In this regard, Saudi Aramco’s Perspective” during AIChE-SAS April he has addressed the state of the Kingdom’s educational system and its monthly meeting sponsored competitiveness at an international level. In addition, three key Board Officers by P&CSD. from P&CSD are investing a lot of after-hours to make this chapter successful and serve the chemical engineering society for the year 2007. ague e society pl hand on th Chairman, AIChe-SAS ntribution. -Majnouni, k him for hi s co ohsen D. Al er, to than Mr. Abdulm CSD Manag h Al-Zaid, P& to Mr. Sale Process & Control Systems Department Issue No. 8 – Special Edition 2007 21

- 24. VISION - To b e c o m e l e a d e r s i n p r o c e s s e n g i n e e r i n g a n d a u t o m a t i o n ! Rate of Change Modeling Authors: M. A. Al-Rasheed, Nazar A. Al-Nasr A New Method is proposed to simulate rate of change of process variables. The method can be appllied in the oil and gas industry such as in pipelines overpressure protection and valve selection. N. A. Al-Nasr and M.A. Al-Rasheed co-authored a joint Pipeline Simulation Interest Group (PSIG) that will take paper titled “A Method of Simulating Rate of Change place in October this year in Canada. with Applications in Pipelines Protection and Check Valves Selection.” The paper has been accepted for The paper introduces new method of simulating a process presentation and publication in the 2007 Conference of variable (PV) rate of change with respect to time (time N.UWSS1.SUCT N.UWSS1.DISCH E.UWSS1.SUCT UPUMP1 NODE5 UBLOCK1 B.UWHW.IN NODE7 LOOP NODE8 T.UWSS1B.HCWIP NODE3 B.SRV UPUMP2 UBLOCK2 T.UWSS1A.HCWIP B.UWHW.OUT NODE1 NODE6 HWELLS NHCWIP001 V.SRV E.SRV NODE4 H.SRV NODE2 Figure 1 Schematic of water injection pipeline system derivative d(PV)/dt), that is usually not readily available or directly calculated by some dynamic pipeline simulators. The method makes use of elementary concepts of Proportional-Integral-Derivative (PID) controllers along with commercial software packages of pipeline dynamic simulators, like Stoner Pipeline Simulator (SPS). The paper describes the method and its application in the oil and gas industry. One application is related to overpressure protection of cross-country pipelines (Figure-1). The method can also be applied to the proper selection of a check valve as an integral part of a pipeline system (Graph-1). In pipelines process dynamic simulation packages, flow, pressure and temperature are the most commonly used Pressure & Flow Profile of the Simulated calculated PVs. Flow, on the other hand, is the most Graph 1 Pipeline System common PV rate of change of mass or volume with 22 Process & Control Systems Department Issue No. 8 – Special Edition 2007