Marine System Design

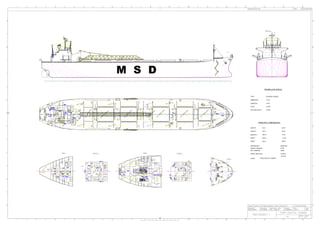

- 1. MIDSHIP SECTION M.R. S.R. A.P. H.B. H.B. BOAT LIFE H.B. H.B. F.M. PROFILE BOSUN STORE BOSUN STORE M S D C.L C.C P.P.F. A.H A.H L.H. L.H. M.H. UP L.H. A.H A.H L.H. A.H L.H. M.H. FAINT A.H DECK STORE LAMP RM. BOS'N STORE C.L. DN A.H A.H L.H. L.H. A.H A.H M.H. L.H. UP C.L C.C P.P.F. FAN ROOM FAN ROOM NO . 3 CARG O HATCH NO . 2 CARG O HATCH NO . 1 CARG O HATCH NO. 2 T. S. T. (S) NO. 1 T. S. T. (P) NO. 2 T. S. T. (P) NO. 1 T. S. T. (S) PILOT LADD ACCOMM LADD C C C.C. B.C F.L. UP. P.C PROT LADD C.C C.L. ACCOMM LADD C.C. TALLY EMERGE RM. STORE CONTROL ROOM M.H. F.L F.L EL. EL. P.C. R.M. DN DN V.T. WORK SHOP V.T. DN A.H. L.H. L.H. A.H. UP UP STORE STORE PROV. PROV. LOBBY HOSPITAL REF. FISH MEAT M. RM. V.T DN V.T STAT FIRE UP. UP GYM SPACE A.H. A.H. L.M. VEG. HOSP. W.C. V.T. DRY RM. PIPE S.P. E.G. C. DECK FAN RM. R.H. L.H. L.H. A.H. A.H. L.H. A.H. A.H. UP M.H. V. C.L. C.C. NO. 5 T. S. T. (P) H.B. ENGINE OPEN LO O P BELT CASING O PENING VENT O PENING VENT O PENING NO . 6 CARG O HATCH NO . 5 CARG O HATCH NO . 4 CARG O HATCH NO. 4 T. S. T. (S) D.O. SERV. PIPE NO. 4 T. S. T. (P) NO.7CARGO HATCH F.L. P.C. (VOID) NO. 5 T. S. T. (P) NO. 3 T. S. T. (P) NO. 3 T. S. T. (S) LENGTH LENGTH BREADTH DEPTH DRAFT CLASS SPEED TRIAL MAX 150M COASTAL TANKER DEADWEIGHT GROSS TONNAGE NET TONNAGE 60939TON 37168 14828 20 knots 18 knots PROPELLER SPECS PRINCIPAL DIMENSIONS (O.A.) (B.P.) (MLD.) (MLD.) (EXT.) 150 M 143 M 11.9 M 24 M 9.95 M 3RD DECK LOW. BRI DECK D. ENGINE CONTROL RM. U. GALLEY U. D. C. L. A.P. E.F.P. RM. 10 15 20 25 30 35 C. L. 40 C. L. 10 D. CREW'S W.C. V.T. D. U. H.B. SAIL (D) SAIL (C) SAIL SAIL CREW'S (A) SHOW RM.(B) D. BOS'N U V.T. O/M (A) O/M (B) O/M (C) 15 20 AIR COND. RM. LKR. JUMP 25 30 V.T. D. V.T. V.T. D. U. BATT. RM. OIL OIL OIL FITT. CREW'S CREW'S SPARE RM. CARPENT 35 C. L. 40 SPARE RM. NO.1 OIL ENGINEOPEN H.B.H.B. UPP. A.P.T.(S.W .) ENG INE O PEN 2ND DECK UPP. BRI DECK WORK SHOP STORE RM. AUX. MACHINERY ROOM U H.B. U U C. L. 0 A.P.A.P. RM. 5 STEER. GEAR U 10 15 20 25 30 35 40 45 50 C.L. 10 15 20 25 U D D V.C D W.C. OFF. U 30 DN. D U D H.B. U D. SPARE SPARE RM. 2/OFF. F.H. 3/OFF. C/OFF. C/OFF. BED RM. ELEC. EQUIPMENT ROOM C/OFF. DAY RM. UP V.T. OFF'S SHOW V.T. RM. 35 LINEN LKR. 3/ENG. 40 V.T. D DAY RM. C/ENG. C.L. ELECT ENG. P/O 1/ENG. DAY RM. 1/ENG. RM. BED 1/ENG. LAV. C/ENG LAV. C/ENG. BED RM. DRI W. T. (S) NO. 2 F. W . T. (P) ENGINEO PEN LOOP BELT CASING ENG INE O PEN NO.1F.W.T.(P) NO.3D.O.T.(S) WIND D. F.N. C. L. 115 120 125 130 135 F.P F.P. U. 140 R.M. S.D. 145 150 C. L. D. WIND F.L. F'CLE DECK P.C. F.L. F.L. F.L. P.C. F.L. F.L. B.L. 0 AP 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 130 135 140 FP 150125 0 AP 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 130 135 140 FP 150125 TYPE IMMERSION DIAMETER PITCH EXP AREA RATIO B-SERIES 3 BLADE 7.8 M 2.34 M 3.9 M 0.55 M

- 2. Tanks and Compartments TANKS AND COMPARTMENTS AP FP Baseline STR ER PUMPROOM FOT 1 PS FOT 1 SB FOT 2 PS FOT 2 SB FWD COMP BT PS (FWD) BT SB (FWD) SLOPCOMPSLOPTK FWT PS (1) FWT BS (1) HOLD 1COT (1) SD BT PS (1) DB BT PS (1) DB BT SB (1) SD BT SB (1) HOLD 2COT (2) SD BT PS (2) DB BT PS (2) SD BT SB (2) DB BT SB (2) HOLD 3COT (3) SD BT PS (3) DB BT PS (3) SD BT SB (3) DB BT SB (3) HOLD 4COT (4) SD BT PS (4) DB BT PS (4) SD BT SB (4) DB BT SB (4) HOLD 5COT (5) SD BT PS (5) DB BT PS (5) SD BT SB (5) DB BT SB (5) HOLD 6COT (6) SD BT PS (6) DB BT PS (6) SD BT SB (6) DB BT SB (6) Zero pt. AP FP Baseline STR ER PUMPROOMFOT 1 PSFOT 1 SB FOT 2 PSFOT 2 SB FWD COMPBT PS (FWD)BT SB (FWD)SLOPCOMPSLOPTKFWT PS (1)FWT BS (1)HOLD 1COT (1)SD BT PS (1) DB BT PS (1)DB BT SB (1) SD BT SB (1) HOLD 2COT (2)SD BT PS (2) DB BT PS (2) SD BT SB (2) DB BT SB (2) HOLD 3COT (3)SD BT PS (3) DB BT PS (3) SD BT SB (3) DB BT SB (3) HOLD 4COT (4)SD BT PS (4) DB BT PS (4) SD BT SB (4) DB BT SB (4) HOLD 5COT (5)SD BT PS (5) DB BT PS (5) SD BT SB (5) DB BT SB (5) HOLD 6COT (6)SD BT PS (6) DB BT PS (6) SD BT SB (6) DB BT SB (6) Zero pt.

- 3. Tanks and Compartments HULL STRUCTURE

- 4. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING FITTING/VALVE CONDITION K FACTOR Subject Value Units 45° Elbow Standard radius 0.3 Total Volume Tank (ƩV) 16895.57 m 3 Standard radius 0.6 Discharge Time 4 hours 14400 (s) 4 x 3600 Long radius 0.3 Flow rate (Q) - For Ship 0.293 m 3 /s Return Bend 0.8 Diameter 0.5 m Socket or Coupler Screwed type 0.03 Velocity 1.494 m/s Along line of flow 0.3 Area 0.196 m 2 Through side 0.8 Gate Valve Fully open 0.2 Dynamic Viscosity, ( µ ) 0.09 Pa. s Fully open 6 Density, (ρ) 888.30 Kg/m 3 from Density Table ¾ open 8 Kinematic Viscosity (γ) 0.000004 ½ open 12 ¼ open 24 Re 186737.003 Hinged or swing disc 1.7 (10^6)/ Re 5.355 Ball or poppet type 4 Roughness Value ε 0.045 mm Hinged or swing disc 3 Relative roughness εR 0.00009 Ball or poppet type 7 Contracting 0 (negligible) Laminar 0.000342728 Enlarging 0.75 Turbulent 0.005509531 Sudden contraction 0.25 Sudden enlargement 1 Length from shore 120 m Tank to pipe line Sudden entrance 0.5 Head Static 30 m Pipe line to tank Sudden exit 1 Total Head (ƩHT) 204682.849 Pipe line γ = µ/ρ Formula Q/v Hsystem= HfL+Hfv+Hfstatic HfL = ﴾ f L/d ﴿ v 2 /2g Hfv= ΣK.V 2 /2g Hfstatic= Given in Question (30) 90° Elbow Tee Globe Valve Check Valve Foot Valve with strainer Gradual transition Head Loss Calculation Sheet Not more than 2 m/s CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 5. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING Volume m 3 1129.447 1129.447 1486.584 1486.583 1486.584 1486.584 1495.512 1495.512 1489.057 1489.058 1360.599 1360.599 16895.566 Crude Oil particular 9.8100 888.3000 0.0900 0.000004 LOA= CARGO PUMP= TYPE= RPM= HfL = ﴾ f L/d ﴿ v 2 /2g Hfv= ΣK.V 2 /2g Hfstatic= Given in Question (30) Hsystem= HfL+Hfv+Hfstatic Pump = Gravity.Density.(HfS + Hfstatic) Cargo Oil Tank 4 (S) Cargo Oil Tank 4 (P) Cargo Oil Tank 5 (S) Cargo Oil Tank 5 (P) Total volume Tank Kinematic Viscosity, m2 /s 150M 4x PUMP Split Casing Centrifugal Pumps 1480RPM Dynamic Viscosity Pa.SDensityGravity ITEM Cargo Oil Tank 1 (S) Cargo Oil Tank 1 (P) Cargo Oil Tank 2 (P) Cargo Oil Tank 2 (S) Cargo Oil Tank 6 (S) Cargo Oil Tank 6 (P) General Particular Cargo Oil Tank 3 (S) Cargo Oil Tank 3 (P) CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 6. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING HfS Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 2 0.2 0.4 3 Tee Along Line of Flow 1 0.3 0.3 4 90° Elbow Standard Radius 1 0.6 0.6 5 Main Pipeline 1.8 138.6 0.1737199 0.2047 0.378465 30 30.3785 264724.7214 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 2 0.2 0.4 3 90° Elbow Standard Radius 1 0.6 0.6 4 Main Pipeline 1.5 138.4 0.173469222 0.170621 0.34409 30 30.34409 264425.1707 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 2 0.2 0.4 3 Tee Along Line of Flow 2 0.3 0.6 4 90° Elbow Standard Radius 1 0.6 0.6 5 Main Pipeline 2.1 153.25 0.192082068 0.23887 0.430952 30 30.43095 265182.0997 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 0 2 Gate Valve 3 0.2 0.6 0 3 90° Elbow Standard Radius 1 0.6 0.6 0 4 Main Pipeline 1.7 153.05 0.19183139 0.193371 0.385202 30 30.3852 264783.4269 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 3 0.2 0.6 3 Tee Along Line of Flow 3 0.3 0.9 4 90° Elbow Standard Radius 1 0.6 0.6 5 Main Pipeline 2.6 169.52 0.212474729 0.295743 0.508218 30 30.50822 265855.4163 CARGO TANK 3(S) CARGO TANK 3(P) CARGO TANK 1(S) CARGO TANK 1(P) CARGO TANK 2(S) CARGO TANK 2(P) CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 7. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 4 0.2 0.8 3 90° Elbow Standard Radius 1 0.6 0.6 4 Main Pipeline 1.9 169.3 0.212198983 0.21612 0.428319 30 30.42832 265159.1588 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 4 0.2 0.8 3 Tee Along Line of Flow 4 0.3 1.2 4 90° Elbow Standard Radius 1 0.6 0.6 5 Main Pipeline 3.1 185.73 0.232792186 0.352617 0.585409 30 30.58541 266528.0775 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 4 0.2 0.8 3 90° Elbow Standard Radius 1 0.6 0.6 4 Main Pipeline 1.9 185.51 0.23251644 0.21612 0.448637 30 30.44864 265336.2096 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 5 0.2 1 3 Tee Along Line of Flow 5 0.3 1.5 4 90° Elbow Standard Radius 1 0.6 0.6 5 Main Pipeline 3.6 202.42 0.253711271 0.409491 0.663202 30 30.6632 267205.9815 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 5 0.2 1 3 90° Elbow Standard Radius 1 0.6 0.6 4 Main Pipeline 2.1 202.2 0.253435525 0.23887 0.492305 30 30.49231 265716.7474 CARGO TANK 5(P) CARGO TANK 4(S) CARGO TANK 4(P) CARGO TANK 5(S) CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 8. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 5 0.2 1 3 Tee Along Line of Flow 6 0.3 1.8 4 90° Elbow Standard Radius 1 0.6 0.6 5 Main Pipeline 3.9 219.74 0.275419991 0.443615 0.719035 30 30.71904 267692.5224 Item Type of Fitting Qty K factor ΣK factor L HfL Hfv HfL+Hfv Hfstatic Head System Ppump(kPa) 1 sudden entrance 1 0.5 0.5 2 Gate Valve 5 0.2 1 3 90° Elbow Standard Radius 1 0.6 0.6 4 Main Pipeline 2.1 219.52 0.275144246 0.23887 0.514014 30 30.51401 265905.922 1 m 3.28084 ft Q = 0.2933 m3 /s Dia, (m)= 0.5 m 39.37008 inch 4649.2139 gpm 19.68503935 inch 1 m3 /s = 15850 gpm 4x Pumps 1162.303477 Area, (m 2 ) 0.1963 1 Pumps= 3962.5 Item Q (Flow Rate) H. loss ( pipe +fitting) A A2 Q2 H.fluid H.static H.system Q (gpm) H.S (Feet) 1 0 0.7190 0.1963 0.0386 0.000 0 30 30 0 98.4252 2 0.15 0.7190 0.1963 0.0386 0.023 0.419636099 30 30.41964 594.375 99.80196 3 0.3 0.7190 0.1963 0.0386 0.090 1.678544394 30 31.67854 1188.75 103.9322 4 0.45 0.7190 0.1963 0.0386 0.203 3.776724887 30 33.77672 1783.125 110.816 5 0.6 0.7190 0.1963 0.0386 0.360 6.714177577 30 36.71418 2377.5 120.4533 6 0.75 0.7190 0.1963 0.0386 0.563 10.49090246 30 40.4909 2971.875 132.8442 7 0.9 0.7190 0.1963 0.0386 0.810 15.10689955 30 45.1069 3566.25 147.9885 8 1.05 0.7190 0.1963 0.0386 1.103 20.56216883 30 50.56217 4160.625 165.8864 9 1.2 0.7190 0.1963 0.0386 1.440 26.85671031 30 56.85671 4755 186.5378 10 1.35 0.7190 0.1963 0.0386 1.823 33.99052399 30 63.99052 5349.375 209.9427 H = 56.8567 m 186.5377695 ft CARGO TANK 6(S) CARGO TANK 6(P) CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 9. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING Item Q (GPM) Q (m 3 /hr) Q (m 3 /s) H.system (m) Cargo Tank Cargo TankH. loss( pipe +fitting) 1 0.0 0 0 30.00 1 (S) 6(S) 0.7190 2 594.4 0 0.15 30.42 1 (P) 6(P) 0.5140 3 1188.8 0 0.3 31.68 2 (S) 4 1783.1 0 0.45 33.78 2 (P) 5 2377.5 0 0.6 36.71 3 (S) 6 2971.9 0 0.75 40.49 3 (P) 7 3566.3 0 0.9 45.11 4 (S) 8 4160.6 0 1.05 50.56 4 (P) 9 4755.0 0 1.2 56.86 5 (S) 10 5349.4 0 1.35 63.99 5 (P) MAX 0.7190 0.4283 0.5854 0.4486 0.6632 0.4923 0.5082 H. loss( pipe +fitting) 0.3785 0.3441 0.4310 0.3852 0 0.15 0.3 0.45 0.6 0.75 0.9 1.05 1.2 1.35 0 50 100 150 200 250 0 1000 2000 3000 4000 5000 6000 SystemHead(Feet) Flow Rate (gpm)) Head System CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 10. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING 1 m 3.28084 ft Dia, (m)= 0.5 m 39.37008 inch 19.68503935 inch 1 m3 /s = 15850 gpm Area, (m2 ) 0.1963 Q = 0.2933 m3 /s H = 56.8567 m 4649.2139 gpm 186.5377695 ft 1056.129888 m3 /h Qtotal= 18596.85563 gpm 4x pump= 4600 m3 /h 0 50 100 150 200 250 0 1000 2000 3000 4000 5000 6000 Old Flow Rate 4649.2139 gpm System Head 109 ft New Flow Rate 5000 gpm Pump Efficiency = 83 % CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 11. SYSTEM HEAD HEAD LOSS CALCULATION PUMP SIZING 2) Actual discharge time Qnew= 20000 gpm H.pump= 186.5378 1.26183 m 3 /s 56.8567 Impeller size= 14 inch Power= 0.3556 m ft 83.00% T= 3.719371126 m 3) New flow rate is 1.261829653 m 3 /s 150.0000 hp 111.8549808 kW hrs // 3 hours 43 minutes 54 seconds Pump Efficiency = PUMP SPECS System Head 109 ft Old Flow Rate 1056 m3/h 𝑇𝑖𝑚𝑒 = 𝑉𝑜𝑙𝑢𝑚𝑒 𝐹𝑙𝑜𝑤 𝑅𝑎𝑡𝑒 (𝑛𝑒𝑤) 𝐹𝑙𝑜𝑤 𝑅𝑎𝑡𝑒 (𝑛𝑒𝑤) = 𝑉𝑜𝑙𝑢𝑚𝑒 𝑇𝑖𝑚𝑒 CARGO PIPING SYSTEM MARINE SYSTEM DESIGN

- 12. B.L. 0 AP 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 130 135 140 FP 150125 M.R. S.R. H.B. H 1 2 3 G F E 4 5 6 7 D C B A 31 2 54 876 Title/Name, designation, material, dimension etc Checked by 10 11 12 Designed by Itemref 13 Quantity FilenameApproved by - date 14 15 Article No./Reference Date 16 Edition Sheet Scale H G F E 11109 1312 RevNo Revision note D C B Checked 15 1614 Date Signature A EN, HAMDAN PIPING DESIGN NAIM, JAMAL,IZWAFI XXX MSD PROJECT 2 XXX - 10/4/2019 GROUP 2 10/4/19 L01 1/1 1:400

- 13. VENTILATION SYSTEM Ventilation ρw 1000 kg/m3 ε (mm) = 0.15 γ = 0.00005 ρa 1.099 kg/m3 εR = # Item Type of Fitting Qty K factor ΣK factor ε (mm) Re Lcompt Volume (m3) ACHr Q (m3/s) Φ (m) Area m2 vel. m/s εR fturbulant 2f.L/D 1 Bend 0 0.75 0 2 Exit Flap 1 0.65 0.65 3 Volume Control 1 0.65 0.65 Duct 1.3 0.15 964637.6857 24.6 4545.748 15 18.94061667 0.5 0.196349541 96.46376857 0.0006 0.018444485 1.814937356 0.158763372 # Item Type of Fitting Qty K factor ΣK factor ε (mm) Re Lcompt Volume (m3) ACHr Q (m3/s) Φ (m) Area m2 vel. m/s εR fturbulant 2f.L/D 1 Bend 2 0.75 1.5 2 Exit Flap 1 0.65 0.65 3 Volume Control Damper 0 0.65 0 4 Concentric reducer 2 0.8 1.6 Duct 3.75 0.15 742028.989 24.6 4545.748 15 18.94061667 0.65 0.331830724 57.079153 0.000461538 0.017573588 1.330185461 0.258928923 # Item Type of Fitting Qty K factor ΣK factor ε (mm) Re Lcompt Volume (m3) ACHr Q (m3/s) Φ (m) Area m2 vel. m/s εR fturbulant 2f.L/D 1 Bend 2 0.75 1.5 2 Exit Flap 1 0.65 0.65 3 Volume Control Damper 0 0.65 0 4 Concentric reducer 2 0.8 1.6 Duct 3.75 0.15 742028.989 24.6 4545.748 15 18.94061667 0.65 0.331830724 57.079153 0.000461538 0.017573588 1.330185461 0.258928923 # Item Type of Fitting Qty K factor ΣK factor ε (mm) Re Lcompt Volume (m3) ACHr Q (m3/s) Φ (m) Area m2 vel. m/s εR fturbulant 2f.L/D 1 90 degree Bend 6 0.75 4.5 2 Exit Flap 1 0.75 0.75 3 Inlet grill and cowling 2 1 2 4 fire damper 1 0.6 0.6 5 expansion joint 4 0.65 2.6 6 Concentric reducer 2 0.8 1.6 7 Wye 0 0.09 0 8 damper gate round 1 0.045 0.045 Duct 12.095 0.15 1205797.107 50 56.82185 1.2 1.130973355 50.24154613 0.00025 0.015398487 1.283207269 0.681865814 Section1Section2Section3MainDuct (2f.L/D + ΣK)/2g (2f.L/D + ΣK)/2g (2f.L/D + ΣK)/2g (2f.L/D + ΣK)/2g 2 4 ( ) 2 air water FLV StaticHeadLoss metres gd r r = 2 ( ) 2 air water V VelocityHeadLoss k metres g r r = VENTILATION SYSTEM DESIGN

- 14. VENTILATION SYSTEM # Q Q2 Area2 (m4 ) Hsystem PL (Pa) 1 0 0 1.2791 0.00 0 2 1 1 1.2791 0.0012 11.4503154 3 2 4 1.2791 0.0047 45.8012616 4 3 9 1.2791 0.0105 103.0528386 5 4 16 1.2791 0.0187 183.2050464 6 5 25 1.2791 0.0292 286.257885 7 6 36 1.2791 0.001493 0.0420 412.2113544 8 7 49 1.2791 0.001493 0.0572 561.0654547 9 8 64 1.2791 0.001493 0.0747 732.8201857 10 9 81 1.2791 0.001493 0.0945 927.4755475 11 10 100 1.2791 0.001493 0.1167 1145.03154 12 11 121 1.2791 0.001493 0.1412 1385.488164 PARAMETERS VALUE UNITS Engine Power @ 18knt MTU 8000kW 8000 kW η 98.20% % H 160 kW ρ air 1.099 kg/m3 ρ water 1000 kg/m3 Cp 0.017 kW.min/kg.degC ΔT 12 ᵒC Volume Engine Room 4545.748 m3 Combustion Air 0.107 m3/min/brake KW Routing Factor 2.5 F Ventilation Air Flow 1784.420652 m3/min H/D*Cp*ΔT 713.6612607 H= P*(1-EFF) 160 Parameters Value Units Ventilation Air Required 1784.420652 m3/min Flow Rate 18.94061667 m³/s Velocity 96.46376857 m/s Diameter² 0.25 m2 Diameter 0.5 m Area 0.196349541 m² Kinematic Viscosity 0.00001606 Reynolds Numbers 964637.6857 F Laminar Absolute Roughness 0.15 m Relative Roughness εR 0.0006 m F Turbulence 0.018444485 0.001492977 Σ(2f.L/D + ΣK)ρa/2g/ρw 0.001492977 0.001492977 0.001492977 0.001492977 0.001492977 0 0.5 1 1.5 2 2.5 3 0 2 4 6 8 10 12 HSYSTEM HSYSTEM Hsystem (m) Q (m3/s) Pascalsg g vk g vk g vk dg vLf P w w ann w a L )) 2 .... 22 (( 2 4 ( 22 22 2 11 2 VENTILATION SYSTEM DESIGN

- 15. M.R. S.R. H.B. 0 AP 10 15 20 25 30 35 U C. L. 0 10 15 20 25 30 35 40 45 50 U D DN. UP DRI W. T. (S) NO. 2 F. W . T. (P) LOOP BELT CASING NO.1F.W.T.(P) NO.3D.O.T.(S)

- 16. Date: 30/5/2019 Network 50Hz 415V 3 Phase 4-Wire System CABLING AND POWERING AWG STANDARD/IEC STANDARD AC / DC Diversity Factor Diversifie d (kW) Voltage (V) Current (A) Diversi ty Factor Diversified (kW) Voltage (V) Current (A) Diversity Factor Diversified (kW) Voltage (V) Current (A) Cable Size (mm 2 ) AWG 1 Bilge/ Ballast Pump 2 5.5 11 AC 3 0.8 8.8 440 20.00 0.8 8.8 440 20.00 0.8 8.8 440 20.00 2.5 13 2 General Service/Fire Pump 2 5.5 11 AC 3 0.8 8.8 440 20.00 0.8 8.8 440 20.00 0.8 8.8 440 20.00 1.5 15 3 Engine Room Blower Fan No.1 - Port1 4 4 AC 3 1 4 400 10.00 1 4 400 10.00 1 4 400 10.00 4 11 4 Engine Room Blower Fan No.1 - Stbd1 4 4 AC 3 1 4 400 10.00 1 4 400 10.00 1 4 400 10.00 4 11 5 Sewage Pump 2 1.4 2.8 AC 3 1 2.8 440 6.36 1 2.8 440 6.36 1 2.8 440 6.36 1.5 15 6 Sea Water Pump (Domestic) 2 4 8 AC 3 0.5 4 440 9.09 0.5 4 440 9.09 0.5 4 440 9.09 1.5 15 7 Fuel Oil Transfer Pump 2 2.238 4.476 AC 3 0.7 3.1332 440 7.12 1 4.476 440 10.17 0.7 3.1332 440 7.12 1.5 15 8 Fresh Water Pump 2 2.2 4.4 AC 3 0.5 2.2 440 5.00 0.5 2.2 440 5.00 0.5 2.2 440 5.00 1.5 15 9 Oil Bilge Separator 1 0.4 0.4 AC 1 0.8 0.32 120 2.67 0 0 0 0.00 0.8 0.32 120 2.67 1.5 15 10 Steering Gear 1 2.5 2.5 AC 3 0.8 2 400 5.00 0 0 0 0.00 0.8 2 400 5.00 16 5 11 Winch & Power Pack 2 10 20 AC 3 0.8 16 440 36.36 0.8 16 440 36.36 0.8 16 440 36.36 6 9 12 Floor Standing Air-Con (Air-Con Plant)4 33.25 133 AC 3 1 133 400 332.50 1 133 400 332.50 1 133 400 332.50 1.5 15 13 Battery Charger 2 0.72 1.44 DC 1 0.25 0.36 120 3.00 0 0 0 0.00 0.25 0.36 120 3.00 1 15 14 Navigation Light Panel 2 0.25 0.5 AC 1 1 0.5 120 4.17 1 0.5 120 4.17 1 0.5 120 4.17 1 17 15 Radio Battery Charger 2 0.72 1.44 DC 1 0.25 0.36 120 3.00 0.25 0.36 120 3.00 0.25 0.36 120 3.00 1 17 16 Emergency Battery Charger 4 0.72 2.88 DC 1 0.5 1.44 120 12.00 0.5 1.44 120 12.00 0.5 1.44 120 12.00 1.5 15 17 Lighting 22 0.02 0.8 AC 1 1 0.8 120 6.67 1 0.8 120 6.67 1 0.8 120 6.67 1.5 15 18 Socket Outlet 110 0.02 2.2 AC 1 0.5 1.1 120 9.17 0.5 1.1 120 9.17 0.5 1.1 120 9.17 1 17 19 Toilet/Bath Room Fan 2 0.2 0.4 AC 1 1 0.4 120 3.33 1 0.4 120 3.33 1 0.4 120 3.33 1.5 15 20 Galley Fan 2 0.75 1.5 AC 1 0.4 0.6 120 5.00 0.4 0.6 120 5.00 0.4 0.6 120 5.00 1.5 15 21 Searchlight 4 1 4 AC 1 0.8 3.2 120 26.67 1 4 120 33.33 1 4 120 33.33 2.5 13 22 Floodlight 8 0.5 4 DC 1 0.6 2.4 120 20.00 1 4 120 33.33 1 4 120 33.33 2.5 13 23 Water Heater Bath Room 4 3.72 14.88 DC 1 0.5 7.44 240 31.00 0.5 7.44 240 31.00 0.5 7.44 240 31.00 1.5 15 24 Crane 1 600 600 AC 3 0.8 480 280 1714.29 0.9 540 280 1928.57 1 600 280 2142.86 25 3 25 Ship Whistle 1 1 1 DC 1 0.1 0.1 120 0.83 0 0 0 0.00 0.1 0.1 120 0.83 1 17 26 Hot Plate 1 3.5 3.5 AC 1 0.9 3.15 240 13.13 0 0 0 0.00 0.9 3.15 240 13.13 2.5 13 27 Rice Cooker 4 1.5 6 DC 1 1 6 240 25.00 0 0 0 0.00 1 6 240 25.00 1 17 28 Galley Freezer 2 1.5 3 AC 1 1 3 240 12.50 1 3 240 12.50 1 3 240 12.50 2.5 13 29 Fire Alarm System 4 0.25 1 DC 1 1 1 120 8.33 1 1 120 8.33 1 1 120 8.33 2.5 17 30 Steering Gear Ventilation Fan 1 4 4 DC 1 1 4 240 16.67 1 4 240 16.67 1 4 240 16.67 4 11 31 Radio communication 3 0.25 0.75 AC 1 0.25 0.1875 120 1.56 0.19 0.1425 120 1.19 0.25 0.1875 120 1.56 1.5 15 32 Refrigerator Compressor 2 3 6 DC 1 1 6 240 25.00 0 0 0 0.00 1 6 240 25.00 1.5 15 33 Cargo Oil Pump 4 112 448 AC 3 0.8 358.4 440 814.55 0 0 0 0.00 0.8 358.4 440 814.55 17 Installed (kW) 1312.866 65.643 1378.509 (%) 35.555 37.843 41.675 746.645 794.701 875.165 PieceLoad Description Item No. Max Demand (at Sea) (kW) Max Demand (Harbour) (kW) Normal at Sea Harbour Condition Consumption Total (kW) Phase Consumption Single (kW) 711.091 756.859 Operation Condition Max Demand (Operation) (kW) 833.491Summary Design Margin (5%) Total 1 Generator 60 kW 1458.61324.51244.4 Page 1 of 1