Opm mac subledger

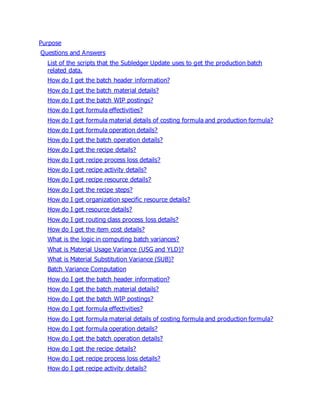

- 1. Purpose Questions and Answers List of the scripts that the Subledger Update uses to get the production batch related data. How do I get the batch header information? How do I get the batch material details? How do I get the batch WIP postings? How do I get formula effectivities? How do I get formula material details of costing formula and production formula? How do I get formula operation details? How do I get the batch operation details? How do I get the recipe details? How do I get recipe process loss details? How do I get recipe activity details? How do I get recipe resource details? How do I get the recipe steps? How do I get organization specific resource details? How do I get resource details? How do I get routing class process loss details? How do I get the item cost details? What is the logic in computing batch variances? What is Material Usage Variance (USG and YLD)? What is Material Substitution Variance (SUB)? Batch Variance Computation How do I get the batch header information? How do I get the batch material details? How do I get the batch WIP postings? How do I get formula effectivities? How do I get formula material details of costing formula and production formula? How do I get formula operation details? How do I get the batch operation details? How do I get the recipe details? How do I get recipe process loss details? How do I get recipe activity details?

- 2. How do I get recipe resource details? How do I get recipe steps? How do I get organization specific resource details? How do I get resource details? How do I get routing class process loss details? How do I get the item cost details? How do I get the resource cost details? What profiles do I need to know about? What is the Logic? What is the Material Usage Variance (USG and YLD)? What is the Material Substitution Variance (SUB)? What is the Resource Usage and Manning Variance (RUV & RMV)? What is Resource Substitution Variance (RSV)? What is Batch Close Variance (CLS)? APPLIES TO: Oracle Process Manufacturing Financials - Version 11.5.10 to 11.5.10.2 [Release 11.5] Information in this document applies to any platform. This document contains information on material usage variances and resource/routing variances. PURPOSE The OPM MAC Subledger calculates manufacturing variances relating to the closing of a production batch. This document contains information on material usage variances and resource/routing variances. QUESTIONS AND ANSWERS List of the scripts that the Subledger Update uses to get the production batch related data. How do I get the batch header information? SELECT bhdr.plant_code,

- 3. bhdr.batch_no, bhdr.batch_id, nvl(bhdr.routing_id,0), bhdr.batch_close_date, bhdr.wip_whse_code, decode(nvl(bhdr.poc_ind, 'N'), 'N', 0, 'Y', 1, 0) poc_indicator FROM gme_batch_header bhdr WHERE bhdr.plant_code = ‘&plant_code’ bhdr.batch_no = ‘&batch_no’ bhdr.batch_close_date is not null AND bhdr.batch_status = 4 AND bhdr.gl_posted_ind = 0 AND nvl(bhdr.update_inventory_ind, 'N') = 'Y'; How do I get the batch material details? SELECT md.batch_id, md.material_detail_id, nvl(md.formulaline_id,0), md.item_id, md.line_type, md.line_no, md.plan_qty, md.item_um, md.actual_qty, md.cost_alloc FROM gme_batch_header bh, gme_material_details md WHERE bh.batch_id = md.batch_id AND bh.batch_id = &batch_id ORDER BY md.batch_id, md.line_type, md.line_no ; How do I get the batch WIP postings? SELECT led.doc_id,

- 4. led.ledger_code, led.acctg_unit_id, led.acct_id, sum(led.debit_credit_sign * led.amount_base), FROM gl_subr_led led WHERE led.co_code = ‘&company_code’ AND led.doc_type = 'PROD' AND led.acct_ttl_type = 1530 AND /* GL_AT_WIP */ led.doc_id = &batch_id GROUP BY led.doc_id, led.ledger_code, led.acctg_unit_id, led.acct_id; How do I get formula effectivities? SELECT rvr.recipe_validity_rule_id, r.recipe_id, nvl(r.routing_id, 0), r.formula_id, nvl(rvr.planned_process_loss, 101) FROM gmd_recipe_validity_rules rvr, gmd_recipes_b r WHERE rvr.recipe_id = r.recipe_id AND r.delete_mark = 0 AND rvr.recipe_validity_rule_id in (&formula effectivity id’s) ORDER BY rvr.recipe_validity_rule_id, r.recipe_id ; How do I get formula material detailsof costing formula and production formula? SELECT fm.formula_no, fm.formula_vers, md.formula_id, md.formulaline_id, md.line_type, md.line_m_id, md.qty,

- 5. md.item_um, md.scale_type, md.scrap_factor, nvl(md.contnd, 'Y'), nvtiple, 0), nvl(md.scale_nce, 1), n_direction, 0) FROM fm_form_mst_b fm, fm_matl_dtl md WHERE fm.formula_id = md.formula_id AND fm.formula_id in (&formula id’s) ORDER BY md.formula_id, md.line_type, md.line_no ; How do I get formula operation details? SELECT rh.routing_no, rh.routing_vers, rh.routing_qty, rh.item_um, rh.routing_id, rh.process_loss, rh.routing_class, rd.routingstep_no, d, rd.oprn_id, rd.step_qty, op.process_qty_um, oa.activity_factor, ors.oprn_line_id, ors.rs.resource_count, _usage, ors.process_qty, ors.cost_cmpntcls_id, ors.cost_analysis_code, ors.usage_um, ors.scale_type, ors.min_capacity, ors.max_capacity, ors.capacity_uom

- 6. FROM fm_rout_hdr rh, fm_rout_dtl rd, gmd_operations op, gmd_operation_activities oa, gmd_operation_resources ors, gmd_status_b gs WHERE rh.routing_id = rd.routing_id AND rh.routing_status = gs.status_code AND rd.oprn_id = op.oprn_id AND rd.oprn_id = oa.oprn_id AND oa.oprn_line_id = ors.oprn_line_id and rh.delete_mark = 0 and oa.delete_mark = 0 and rh.routing_id in (&Costing_routing_id, &Production_routing_id) ORDER BY rh.routing_id, rd.routingstep_id, rd.oprn_id, oa.oprn_line_id, ors.resources ; How do I get the batch operation details? SELECT bh.batch_id, nvl(bs.routingstep_id,0), bs.oprn_id, nvl(bs.actual_step_qty,0), nvl(bsa.oprn_line_id,0), nvl(bsa.plan_activity_factor,0), nvl(bsa.actual_activity_factor,0), bsr.resources, bsr.cost_cmpntcls_id, bsr.cost_analysis_code, nvl(bsr.actual_rsrc_count,0), nvl(bsr.actual_rsrc_qty,0), nvl(bsr.actual_rsrc_usage,0) / decode(bsr.actual_rsrc_count,0,1,null,1,bsr.actual_rsrc_count), bsr.plan_rsrc_count, bsr.plan_rsrc_qty, bsr.plan_rsrc_usage, bsr.usage_uom

- 7. FROM gme_batch_header bh, gme_batch_steps bs, gme_batch_step_activities bsa, gme_batch_step_resources bsr WHERE bh.batch_id = &batch_id AND bh.batch_id = bs.batch_id AND bs.batch_id = bsa.batch_id AND bs.batchstep_id = bsa.batchstep_id AND bsa.batchstep_activity_id = bsr.batchstep_activity_id AND bh.batch_close_date is not null AND bh.batch_status = 4 AND bsa.delete_mark = 0 ORDER BY bs.batch_id, nvl(bs.routingstep_id,0), bs.oprn_id, bsa.oprn_line_id, bsr.resources ; How do I get the recipe details? SELECT rc.recipe_id, rc.recipe_no, rc.recipe_version, rc.recipe_status, NVL(rc.planned_process_loss, 101), rc.calculate_step_quantity FROM gmd_status_b gs, gmd_recipes_b rc WHERE rc.recipe_status = gs.status_code AND rc.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY rc.recipe_id ; How do I get recipe process loss details? SELECT DISTINCT rpl.recipe_id,

- 8. rpl.orgn_code, NVL(rpl.process_loss, 101) FROM gmd_recipe_process_loss rpl AND WHERE rpl.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY rpl.recipe_id, rpl.orgn_code ; How do I get recipe activity details? SELECT ra.recipe_id, ra.orgn_code, ra.routingstep_id, ra.oprn_line_id, ra.activity_factor FROM gmd_recipe_orgn_activities ra WHERE ra.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY ra.recipe_id, ra.orgn_code, ra.routingstep_id, ra.oprn_line_id ; How do I get recipe resource details? SELECT rr.recipe_id, rr.orgn_code, rr.routingstep_id, rr.oprn_line_id, rr.resources, rr.min_capacity, rr.max_capacity, rr.resource_usage, rr.usage_um, rr.process_qty, rr.process_uom FROM gmd_recipe_orgn_resources rr

- 9. WHERE rr.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY rr.recipe_id, rr.orgn_code, rr.routingstep_id, rr.oprn_line_id, rr.resources ; How do I get the recipe steps? SELECT rrs.recipe_id, rrs.routingstep_id, rrs.step_qty FROM gmd_recipe_routing_steps rrs WHERE rrs.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY rrs.recipe_ingstep_id ; How do I get organization specific resource details? SELECT rd.orgn_code, rd.resources, rd.min_capacity, rd.max_capacity, rd.capacity_constraint, rd.capacity_uom FROM cr_rsrc_dtl rd ORDER BY rd.orgn_code, rd.resources ; How do I get resource details? SELECT r.resources, r.min_capacity,

- 10. r.max_capacity, r.capacity_constraint, r.capacity_uom FROM cr_rsrc_mst r ORDER BY r.resources ; How do I get routing class process loss details? SELECT pl.routing_class, NVL(pl.max_quantity, -1), pl.process_loss FROM gmd_process_loss pl ORDER BY pl.routing_class, NVL(pl.max_quantity, -1) DESC ; How do I get the item cost details? SELECT orgn_code, whse_code, item_id, cost_mthd_code, calendar_code, period_code, acctg_cost, nvl(fmeff_id,0), itemcost_id FROM gl_item_cst WHERE whse_code = ‘&whse_code’ AND item_id = ‘&item_id’ AND cost_mthd_code = ‘&cost_mthd_code’ AND calendar_code = ‘&cost_calendar_code’ AND period_code = ‘&cost_period_code’ AND delete_mark = 0 ORDER BY orgn_code, whse_code, item_id, cost_mthd_code, calendar_code, period_code;

- 11. What is the logic in computing batch variances? Subledger Update compares the recipe/routing used on the production batch to the costing recipe/routing (used to generate the product cost) to compute the variances like, Usage Variance (USG), Yield Variance (YLD), Substitution Variance (SUB), Resource Usage Variance (RUV), etc. For each batch the process performance following steps to compute these variance. Identify the primary product of the batch Loop thru batch material detail records (script 2) and search for record with line_type = 1 and line_no = 1 Get cost details for the product item Use wip warehouse, batch close date and cost method on fiscal policy to get the cost details (script 15) Using fmeff_id (costing recipe validity rule id) get costing recipe validity rules data (script 3). Using fmeff_id (costing recipe validity rule id) get material details of costing formula (script 4) Compute the material scale factor Convert batch primary product’s planned quantity to item’s uom. Convert product quantity on the costing formula to it’s item uom. Material Scale Factor = Converted batch product planned quantity ---------------------------------------------------- Converted costing formula product quantity What is Material Usage Variance (USG and YLD)? This is the difference between the value of the actual ingredient usage and the value of the standard ingredient usage on the production batch, as scaled from the ingredient input specified in the formula used in the Standard Cost Roll-up process Loop thru and compare aipt 2) and costing formula material lines (script 4). When a en compute the usage var line to line’s item uom. If different convert the quantity to item’s uom. Scale the converted quantity by the material scale factor.

- 12. Apply scrap factor to the scaled formula qty fm_qty = (Scaled Formula Qty) ( 1 + Scrap Factor) Compare the uom on the batch material line to the item’s uom. If different convert the actual quantity to item’s uom. What is Material Substitution Variance (SUB)? This is the value of the substitute ingredients used. These a not on the formula used in the Standard Cost Roll-up process. It also includes the value of ingredients that were on the formula used in the Standard Cost Roll-up process but which were not used at all in the batch. Loop thru and compare all batch material lines (script 2) and costing formula material lines (script 4). When a match is NOT foundthen compute the substitution variance o Compare the uom on the formula line to line’s item uom. If different then convert the quantity to item’s uom. Scale the converted quantity by the material scale factor. o Apply scrap factor to the scaled formula qty fm_qty = (Scaled Formula Qty) ( 1 + Scrap Factor) o Compare the uom on the batch material line to the item’s uom. If different convert the actual quantity to item’s uom. o Multiply the quantity (fm_qty or converted batch material qty) with the items cost to get the variance amount. If item is ingredient then this contributes to Substitution Variance (SUB) and if it is product then it contributes to Yield Variance (YLD). Off set accounts for these are RUV/WIP. Batch Variance Computation How do I get the batch header information? SELECT bhdr.plant_code, bhdr.batch_no, bhdr.batch_id, nvl(bhdr.routing_id,0), bhdr.batch_close_date, bhdr.wip_whse_code, decode(nvl(bhdr.poc_ind, 'N'), 'N', 0, 'Y', 1, 0) poc_indicator FROM gme_batch_header bhdr WHERE

- 13. bhdr.plant_code = ‘&plant_code’ bhdr.batch_no = ‘&batch_no’ bhdr.batch_close_date is not null AND bhdr.batch_status = 4 AND bhdr.gl_posted_ind = 0 AND nvl(bhdr.update_inventory_ind, 'N') = 'Y'; How do I get the batch material details? SELECT md.batch_id, md.material_detail_id, nvl(md.formulaline_id,0), md.item_id, md.line_type, md.line_no, md.plan_qty, md.item_um, md.actual_qty, md.cost_alloc FROM gme_batch_header bh, gme_material_details md WHERE bh.batch_id = md.batch_id AND bh.batch_id = &batch_id ORDER BY md.batch_id, md.line_type, md.line_no ; How do I get the batch WIP postings? SELECT led.doc_id, led.ledger_code, led.acctg_unit_id, led.acct_id, sum(led.debit_credit_sign * led.amount_base), FROM gl_subr_led led WHERE led.co_code = ‘&company_code’ AND led.doc_type = 'PROD' AND

- 14. led.acct_ttl_type = 1530 AND /* GL_AT_WIP */ led.doc_id = &batch_id GROUP BY led.doc_id, led.ledger_code, led.acctg_unit_id, led.acct_id; How do I get formula effectivities? SELECT rvr.recipe_validity_rule_id, r.recipe_id, nvl(r.routing_id, 0), r.formula_id, nvl(rvr.planned_process_loss, 101) FROM gmd_recipe_validity_rules rvr, gmd_recipes_b r WHERE rvr.recipe_id = r.recipe_id AND r.delete_mark = 0 AND rvr.recipe_validity_rule_id in (&formula effectivity id’s) ORDER BY rvr.recipe_validity_rule_id, r.recipe_id ; How do I get formula material detailsof costing formula and production formula? SELECT fm.formula_no, fm.formula_vers, md.formula_id, md.formulaline_id, md.line_type, md.line_no, md.item_id, md.qty, md.item_um, md.scale_type, md.scrap_factor, nvl(md.contribute_yield_ind, 'Y'), nvl(md.scale_multiple, 0), nvl(md.scale_rounding_variance, 1), nvl(md.rounding_direction, 0) FROM

- 15. fm_form_mst_b fm, fm_matl_dtl md WHERE fm.formula_id = md.formula_id AND fm.formula_id in (&formula id’s) ORDER BY md.formula_id, md.line_type, md.line_no ; How do I get formula operation details? SELECT rh.routing_no, rh.routing_vers, rh.routing_qty, rh.item_um, rh.routing_id, rh.process_loss, rh.routing_class, rd.routingstep_no, rd.routingsy_um, oa.activity_factor, ors.oprn_line_id, ors.resources, ors.resource_count, ors.resource_usage, ors.process_qty, ors.cost_cmpntcls_id, ors.cost_analysis_code, ors.usage_um, ors.scale_type, ors.min_capacity, ors.max_capacity, ors.capacity_uom FROM fm_rout_hdr rh, fm_rout_dtl rd, gmd_operations op, gmd_operation_activities oa, gmd_operation_resources ors, gmd_status_b gs WHERE rh.routing_id = rd.routing_id AND

- 16. rh.routing_status = gs.status_code AND rd.oprn_id = op.oprn_id AND rd.oprn_id = oa.oprn_id AND oa.oprn_line_id = ors.oprn_line_id and rh.delete_mark = 0 and oa.delete_mark = 0 and rh.routing_id in (&Costing_routing_id, &Production_routing_id) ORDER BY rh.routing_id, rd.routingstep_id, rd.oprn_id, oa.oprn_line_id, ors.resources ; How do I get the batch operation details? SELECT bh.batch_id, nvl(bs.routingstep_id,0), bs.oprn_id, nvl(bs.actual_step_qty,0), nvl(bsa.oprn_line_id,0), nvl(bsa.plan_activity_factor,0), nvl(bsa.actual_activity_factor,0), bsr.resources, bsr.cost_cmpntcls_id, bsr.cost_analysis_code, nvl(bsr.actual_rsrc_count,0), nvl(bsr.actual_rsrc_qty,0), nvl(bsr.actual_rsrc_usage,0) / decode(bsr.actual_rsrc_count,0,1,null,1,bsr.actual_rsrc_count) actual_rsrc_usage, bsr.plan_rsrc_count, bsr.plan_rsrc_qty, bsr.plan_rsrc_usage, bsr.usage_uom FROM gme_batch_header bh, gme_batch_steps bs, gme_batch_step_activities bsa, gme_batch_step_resources bsr WHERE bh.batch_id = &batch_id AND bh.batch_id = bs.batch_id AND

- 17. bs.batch_id = bsa.batch_id AND bs.batchstep_id = bsa.batchstep_id AND bsa.batchstep_activity_id = bsr.batchstep_activity_id AND bh.batch_close_date is not null AND bh.batch_status = 4 AND bsa.delete_mark = 0 ORDER BY bs.batch_id, nvl(bs.routingstep_id,0), bs.oprn_id, bsa.oprn_line_id, bsr.resources ; How do I get the recipe details? SELECT rc.recipe_id, rc.recipe_no, rc.recipe_version, rc.recipe_status, NVL(rc.planned_process_loss, 101), rc.calculate_step_quantity FROM gmd_status_b gs, gmd_recipes_b rc WHERE rc.recipe_status = gs.status_code AND rc.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY rc.recipe_id ; How do I get recipe process loss details? SELECT DISTINCT rpl.recipe_id, rpl.orgn_code, NVL(rpl.process_loss, 101) FROM gmd_recipe_process_loss rpl AND WHERE rpl.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY

- 18. rpl.recipe_id, rpl.orgn_code ; How do I get recipe activity details? SELECT ra.recipe_id, ra.orgn_code, ra.routingstep_id, ra.oprn_line_id, ra.activity_factor WHERE ra.recipe_amp;production_recie_r>ra._id ; How do I get recipe resource details? SELECT rr.recipe_id, rr.orgn_code, rr.routingstep_id, rr.oprn_line_id, rr.resources, rr.min_capacity, rr.max_capacity, rr.resource_usage, rr.usage_um, rr.process_qty, rr.process_uom FROM gmd_recipe_orgn_resources rr WHERE rr.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY rr.recipe_id, rr.orgn_code,rr.oprn_liner; How do I get recipe steps? SELECT rrs.recipe_id, rrs.routingstep_id, rrs.step_qty FROM gmd_recipe_routing_steps rrs WHERE

- 19. rrs.recipe_id in (&costing_recipe_id, &production_recipe_id) ORDER BY rrs.recipe_id, rrs.routingstep_id ; How do I get organization specific resource details? SELECT rd.orgn_code, rd.resources, rd.min_capacity, rd.max_capacity, rd.capacity_constraint, rd.capacity_uom FROM cr_rsrc_dtl rd ORDER BY rd.orgn_code, rd.resources ; How do I get resource details? SELECT r.resources, r.min_capacity, r.max_capacity, r.capacity_constraint, r.capacity_uom FROM cr_rsrc_mst r ORDER BY r.resources ; How do I get routing class process loss details? SELECT pl.routing_class, NVL(pl.max_quantity, -1), pl.process_loss FROM gmd_process_loss pl ORDER BY

- 20. pl.routing_class, NVL(pl.max_quantity, -1) DESC ; How do I get the item cost details? SELECT orgn_code, whse_code, item_id, cost_mthd_code, calendar_code, period_code, acctg_cost, nvl(fmeff_id,0), itemcost_id FROM gl_item_cst WHERE whse_code = ‘&whse_code’ AND item_id = ‘&item_id’ AND cost_mthd_code = ‘&cost_mthd_code’ AND calendar_code = ‘&cost_calendar_code’ AND period_code = ‘&cost_period_code’ AND delete_mark = 0 ORDER BY orgn_code, whse_code, item_id, cost_mthd_code, calendar_code, period_code; How do I get the resource cost details? SELECT r.orgn_code, r.resources, r.calendar_code, r.period_code, r.cost_mthd_code, r.usage_um, r.nominal_cost FROM cm_rsrc_dtl r, cm_cldr_dtl d WHERE r.resources = &resource_name and r.resources = &plant_code and r.calendar_code = d.calendar_code and

- 21. r.period_code = d.period_code and d.start_date >= TO_DATE(&transaction_date, ‘dd-mon-yy hh24:mi:ss’) and d.end_date <= TO_DATE(&transaction_date, ‘dd-mon-yy hh24:mi:ss’) and r.delete_mark = 0 and d.delete_mark = 0; What profiles do I need to know about? o GMF: Subledger Variance Type Possible Values: Scale to Plan Scale to Actual Aggregate o GMF: Log All Subledger Variances Possible Values: Yes No What is the Logic? Identify the primary product of the batch Loop thru batch material details records (script 2) and search for record with line_type = 1 and line_no = 1 Get cost details for the product item Use wip warehouse, batch close date and cost method on fiscal policy to get the cost details (script 15) Using fmeff_id (costing recipe validity rule id) get costing recipe validity rules data (script 3). Using fmeff_id (costing recipe validity rule id) get material details of costing formula (script 4) Compute the material scale factor Convert batch primary product’s planned quantity to item’s uom. Convert product quantity on the costing formula to it’s item uom. Material Scale Factor = Converted batch product planned quantity ---------------------------------------------------- Converted costing formula product quantity What is the Material Usage Variance (USG and YLD)?

- 22. This is the difference between the value of the actual ingredient usage and the value of the standard ingredient usage on the production batch, as scaled from the ingredient input specified in the formula used in the Standard Cost Roll-up process Loop thru and compare all batch material lines (script 2) and costing formula material lines (script 4). When a match is found, i.e., line_type and item_id is same , then compute the usage variance o Compare the uom on the formula line to line’s item uom. If different convert the quantity to item’s uom. Scale the converted quantity by the material scale factor. o Apply scrap factor to the scaled formula qty fm_qty = (Scaled Formula Qty) ( 1 + Scrap Factor) o If item is ingredient with linear scaling then apply process loss to the scaled formula qty fm_qty = (fm_qty * 100) / (100 - process_loss) o Compare the uom on the batch material line to he actual quantity to item’s uom. o Compute the difference in the scaled formula quantity (fm_qty) with actual quantity on the batch. Multiply the difference with the items cost to get the variance amount. If item is ingredient then this contributes to Usage Variance (USG) and if it is product then it contributes to Yield Variance (YLD). Off set accounts for these are RUV/WIP. What is the Material Substitution Variance (SUB)? This is the value of the substitute ingredients used. These are ingredients that were used in the production batch but which were not on the formula used in the Standard Cost Roll-up process. It also includes the value of ingredients that were on the formula used in the Standard Cost Roll-up process but which were not used at all in the batch. Loop thru and compare all batch material lines (script 2) and costing formula material lines (script 4). When a match is NOT foundthen compute the substitution variance o Compare the uom on the formula line to line’s item uom. If different then convert the quantity to item’s uom. Scale the converted quantity by the material scale factor. o Apply scrap factor to the scaled formula qty fm_qty = (Scaled Formula Qty) ( 1 + Scrap Factor) o If item is ingredient with linear scaling then apply process loss to the scaled formula qty fm_qty = (fm_qty * 100) / (100 - process_loss)

- 23. o Compare the uom on the batch material line to the item’s uom. If different convert the actual quantity to item’s uom. o Multiply the quantity (fm_qty or converted batch material qty) with the items cost to get the variance amount. If item is ingredient then this contributes to Substitution Variance (SUB) and if it is product then it contributes to Yield Variance (YLD). Off set accounts for these are RUV/WIP. What is the Resource Usage and Manning Variance (RUV & RMV)? This is difference between the value of the actual resource usage and the value of the standard resource usage on the production batch, as scaled from the resource usage specified in the routing used in the Cost Roll-up process. Resource Usage, Manning and substitution variances are computed for POC batches (poc_ind = 1) Get Batch Operation Details (script 6) Get Cost Formula Operation Details (script 5) Loop thru and compare batch operation dey matching records When a match is found, i.e., resource is same , then compute the resourceords as processed. Process unmatched itution variance (RSV). o If multiple the products. o Routing qty adjustment factor = Total_output_qty / Costing formula routing_qty o Adjusted step qty = (step_qty from costing formula operation details) * (Routing qty adjustment factor) o Using plant code, resource name, batch close date and fiscal policy cost method, get cost of the resource associated to costing formula operation details record (script 16). o Batch Resource usage actual_rsrc_usage from batch operation details (script 6). Converty the actual_rsrc_usdifferent from the resource uom (scrip>= (Batch Resource usage) * (actual_rsrc_count) * (Resource Cost) o Costing formula Resource Usage resource_usage from costing formula operation details. Convert resource_usage to resource uom if usage_um on the costing formula operation is different from the resource uom (script 10). o Costing formula Resource Usage amount In case of fixed scaling (Costing formula Resource Usage) * actual_rsrc_count * activity_factor *

- 24. Resource Cost In case of linear scaling (Costing formula Resource Usage) * actual_rsrc_count * (Adjusted step qty / process_qty) * (activity_factor) * (Resource Cost) If process_qty is zero then (Costing formula Resource Usage) * actual_rsrc_count * activity_factor * Resource Cost o Resource Usage Variance Amount Batch Resource usage amount – Costing formula Resource Usage amount This Resource Usage Variance Amount contributes to Resource Usage Variance (RUV) . Off set account for this is WIP. o Difference in the resource count (actual_rsrc_count from the batch - resource_count from the costing operation detail) o Manning Variance Amount In case of fixed scaling (Difference in the resource count) * (Costing formula Resource Usage) * activity_factor * Resource Cost In case of linear scaling (Difference in the resource count) * (Costing formula Resource Usage) * (Adjusted step qty / process_qty) * (activity_factor) * (Resource Cost) If process_qty is zero then (Difference in the resource count) * (Costing formula Resource Usage) * activity_factor * Resource Cost This Manning Variance Amount contributes to Resource Manning Variance (RMV) . Off set account for this is WIP. What is Resource Substitution Variance (RSV)? This is the value of the substitute resources used. These are resources used that were not on the routing used in the Cost Roll-up process. It also includes the

- 25. value of resources that were on the routing used in the Cost Roll-up process but which were not used at all in the batch. Get Batch Operation Details (script 6) Get Cost Formula Operation Details (script 5) As part of computing resource usage variance, operation details records on the batch and costing formula are compared, marked the records that are matching and computed resource usage variance for those matched records. Resource substitution variance is computed for the unmatched records. Loop thru batch operation details that are not in cost formula operation details (i.e., batch operation detail records that are not marked in RUV processing) and compute resource substitution variance as below: o Using plant code, resource name, batch close date and fiscal policy cost method, get cost of the resource associated to costing formula operation details record (script 16). o Batch Resource usage actual_rsrc_usage from batch operation details (script 6). Converty the actual_rsrc_usage to resource uom if usage_um on the batch is different from the resource uom (script 10). o Batch Resource usage amount (Batch Resource usage) * (actual_rsrc_count) * (Resource Cost) o This Batch Resource usage amount contributes to Resource Substitution Variance (RSV) . Off set account for this is WIP. Loop thru cost formula operation details that are not in batch operation details (i.e., cost formula operation detail records that are not marked in RUV processing) and compute resource substitution variance as below: o If multiple product items exist on the costing formula/recipe then sum all those products quantities. Total_output_qty = sum of the product quantity of all the products. o Routing qty adjustment factor = Total_output_qty / Costing formula routing_qty o Adjusted step qty = (step_qty from costing formula operation details) * (Routing qty adjustment factor) o Using plant code, resource name, batch close date and fiscal policy cost method, get cost of the resource associated to costing formula operation details record (script 16). o Costing formula Resource Usage

- 26. resource_usage from costing formula operation details. Convert resource_usage to resource uom if usage_um on the costing formula operation is different from the resource uom (script 10). o Costing formula Resource Usage amount In case of fixed scaling (Costing formula Resource Usage) * actual_rsrc_count * activity_factor * Resource Cost In cr scaling (Costing formula Resource Usage) * actual_rsrc_count * (Adjusted step qty / process_qty) * (activity_factor) * (Resource Cost) If process_qty is zero then (Costing formula Resource Usage) * actual_rsrc_count * activity_factor * Resource Cost o This Costing formula Resource usage amount contributes to Resource Substitution Variance (RSV). Off set account for this is WIP. What is Batch Close Variance (CLS)? This is the amount required to balance the journal created by the CLOS Batch Close process. Net amount posted to WIP account in a batch should total to 0. o Sum WIP amount postings in Batch Release, Batch Certification and Batch Step Certification sub-events and WIP amount postings in Batch Close sub-event related to off-sets of YLD, USG, RUV, RMV, RSV, …etc. If net amount is non-zero then it contributes to batch close variance (CLS). Off set account for this is WIP.