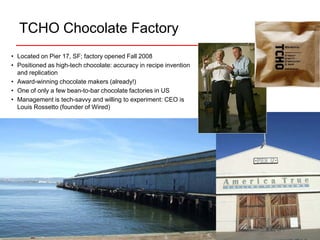

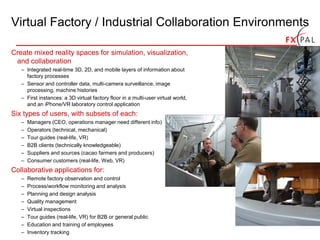

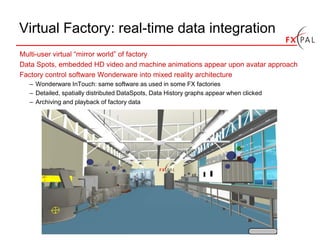

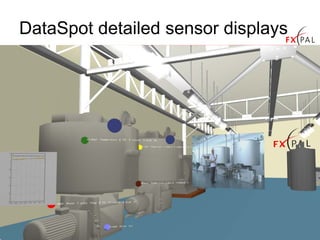

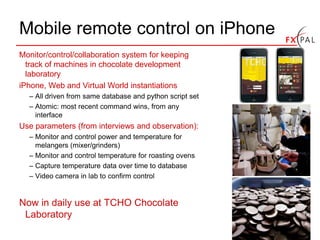

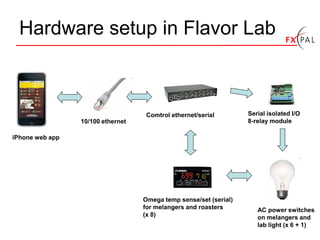

The document discusses the collaboration between FX Palo Alto Laboratory (FXPAL) and Tcho Chocolate Factory to implement advanced collaboration technologies in a factory environment. It outlines the virtual factory concept, which includes creating mixed reality spaces for monitoring and controlling factory processes with real-time data integration and various user applications. The system leverages mobile and virtual interfaces to manage chocolate-making equipment, providing remote observation and control functionalities.