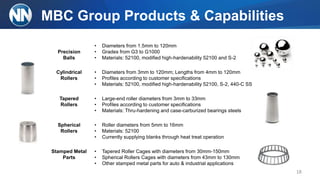

Precision Component Solutions provides high-quality precision components and superior customer service. It has 42 manufacturing facilities globally and is a leading manufacturer of precision components, with expected 2016 revenue of $890 million. It has a history of growth through acquisitions and expansion into new markets and regions. The company has comprehensive design, manufacturing, and production support capabilities.