Exj 11

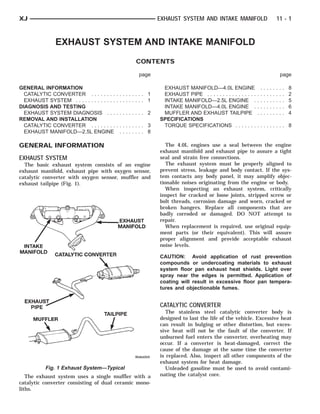

- 1. INTAKE MANIFOLD EXHAUST PIPE MUFFLER CATALYTIC CONVERTER TAILPIPE EXHAUST MANIFOLD XJ EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1 EXHAUST SYSTEM AND INTAKE MANIFOLD CONTENTS page page GENERAL INFORMATION EXHAUST MANIFOLD—4.0L ENGINE . . . . . . . . 8 CATALYTIC CONVERTER . . . . . . . . ......... 1 EXHAUST PIPE . . . . . . . . . . . . . . . . . . . . . . . . . 2 EXHAUST SYSTEM . . . . . . . . . . . . . ......... 1 INTAKE MANIFOLD—2.5L ENGINE . . . . . . . . . . 5 DIAGNOSIS AND TESTING INTAKE MANIFOLD—4.0L ENGINE . . . . . . . . . . 6 EXHAUST SYSTEM DIAGNOSIS . . . ......... 2 MUFFLER AND EXHAUST TAILPIPE . . . . . . . . . 4 REMOVAL AND INSTALLATION SPECIFICATIONS CATALYTIC CONVERTER . . . . . . . . ......... 3 TORQUE SPECIFICATIONS . . . . . . . ......... 8 EXHAUST MANIFOLD—2.5L ENGINE ........ 8 GENERAL INFORMATION The 4.0L engines use a seal between the engine exhaust manifold and exhaust pipe to assure a tight EXHAUST SYSTEM seal and strain free connections. The basic exhaust system consists of an engine The exhaust system must be properly aligned to exhaust manifold, exhaust pipe with oxygen sensor, prevent stress, leakage and body contact. If the sys- catalytic converter with oxygen sensor, muffler and tem contacts any body panel, it may amplify objec- exhaust tailpipe (Fig. 1). tionable noises originating from the engine or body. When inspecting an exhaust system, critically inspect for cracked or loose joints, stripped screw or bolt threads, corrosion damage and worn, cracked or broken hangers. Replace all components that are badly corroded or damaged. DO NOT attempt to repair. When replacement is required, use original equip- ment parts (or their equivalent). This will assure proper alignment and provide acceptable exhaust noise levels. CAUTION: Avoid application of rust prevention compounds or undercoating materials to exhaust system floor pan exhaust heat shields. Light over spray near the edges is permitted. Application of coating will result in excessive floor pan tempera- tures and objectionable fumes. CATALYTIC CONVERTER The stainless steel catalytic converter body is designed to last the life of the vehicle. Excessive heat can result in bulging or other distortion, but exces- sive heat will not be the fault of the converter. If unburned fuel enters the converter, overheating may occur. If a converter is heat-damaged, correct the cause of the damage at the same time the converter is replaced. Also, inspect all other components of the exhaust system for heat damage. Fig. 1 Exhaust System—Typical Unleaded gasoline must be used to avoid contami- The exhaust system uses a single muffler with a nating the catalyst core. catalytic converter consisting of dual ceramic mono- liths.

- 2. 11 - 2 EXHAUST SYSTEM AND INTAKE MANIFOLD XJ DIAGNOSIS AND TESTING EXHAUST SYSTEM DIAGNOSIS CAUTION: When servicing and replacing exhaust components, disconnect the oxygen sensor connectors. Allowing the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor. CONDITION POSSIBLE CAUSE CORRECTION EXCESSIVE EXHAUST NOISE OR 1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking LEAKING EXHAUST GASES joints. 2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust system. 3. Broken or rusted out exhaust pipe. 3. Replace exhaust pipe. 4. Exhaust pipe leaking at manifold 4. Tighten/replace flange attaching flange. nuts/bolts. 5. Exhaust manifold cracked or 5. Replace exhaust manifold. broken. 6. Leak between exhaust manifold 6. Tighten exhaust manifold to and cylinder head. cylinder head bolts. 7. Catalytic converter rusted or blown 7. Replace catalytic converter assy. out. 8. Restriction in exhaust system. 8. Remove restriction, if possible. Replace restricted part if necessary. REMOVAL AND INSTALLATION apply heat until the metal becomes cherry red. Dis- connect the exhaust pipe from the catalytic converter EXHAUST PIPE (Fig. 2). Remove the exhaust pipe. WARNING: IF TORCHES ARE USED WHEN WORK- INSTALLATION ING ON THE EXHAUST SYSTEM, DO NOT ALLOW (1) Assemble exhaust pipe to manifold and cata- THE FLAME NEAR THE FUEL LINES. lytic converter loosely to permit proper alignment of all parts. (2) Use a new clamp and tighten the nuts to 61 CAUTION: When servicing exhaust system compo- N·m (45 ft. lbs.) torque. nents, disconnect the oxygen sensor connector. (3) Connect the exhaust pipe to the engine exhaust Allowing the exhaust system to hang by the oxygen manifold. Install a new seal between the exhaust sensor harness will damage the wiring and/or sen- manifold and the exhaust pipe (4.0L engine only). sor. Tighten the nuts to 31 N·m (23 ft. lbs.) torque (Fig. 2). (4) Install the rear crossmember. Install and REMOVAL tighten the four (4) crossmember to rear mount nuts (1) Raise and support the vehicle. to 22 N·m (16 ft. lbs.) Install and tighten the cross- (2) Saturate the bolts and nuts with heat valve member to sill bolts to 42 N·m (31 ft. lbs.) torque. lubricant (Fig. 2). Allow 5 minutes for penetration. Remove the support from the transmission. (3) Disconnect the oxygen sensor connector (Fig. (5) Coat the oxygen sensor with anti-seize com- 3). pound. Install the sensor and tighten the nut to 27 (4) Disconnect the exhaust pipe from the engine N·m (20 ft. lbs.) torque. exhaust manifold. Discard the seal (4.0L engine, (6) Lower the vehicle. only). (7) Start the engine and inspect for exhaust leaks (5) Support the transmission and remove the rear and exhaust system contact with the body panels. crossmember. Adjust the alignment, if needed. (6) Remove the clamp nuts and clamp (Fig. 2). To remove the exhaust pipe from the catalytic converter,

- 3. SEAL (4.0L) MANIFOLD NUT UPSTREAM SENSOR GEN OXY- DOWNSTREAM OXY- GEN SENSOR EXHAUST PIPE TRANSMISSION TRANSMISSION SUPPORT BRACKET CLAMP CATALYTIC CONVERTERCATALYTIC CONVERTER SUPPORT BRACKET EXHAUST PIPE CLAMPS MUFFLER XJ EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3 REMOVAL AND INSTALLATION (Continued) Fig. 2 Exhaust Pipe Removal—2.5L/4.0L REMOVAL (1) Raise and support the vehicle. (2) Remove the clamps from the catalytic converter and muffler connection (Fig. 4). (3) Disconnect and remove the oxygen sensor from the catalytic converter. (4) Heat the catalytic converter and muffler con- nection with an oxyacetylene torch until the metal becomes cherry red. (5) While the metal is still cherry red, twist the muffler assembly back and forth to separate it from the catalytic converter. (6) Disconnect the exhaust pipe from the catalytic converter (Fig. 4). If needed, heat up the pipes to sep- arate. Fig. 3 Oxygen Sensor Location CATALYTIC CONVERTER WARNING: IF TORCHES ARE USED WHEN WORK- ING ON THE EXHAUST SYSTEM, DO NOT ALLOW THE FLAME NEAR THE FUEL LINES. CAUTION: When servicing exhaust system compo- nents, disconnect the oxygen sensor connector. Allowing the exhaust system to hang by the oxygen sensor harness will damage the wiring and/or sen- sor. Fig. 4 Catalytic Converter to Muffler and Exhaust Pipe Connection

- 4. FRONT MUFFLER TAILPIPE HANGER CATALYTIC CONVERTER INSULATOR CLAMP TAILPIPE MUFFLER 11 - 4 EXHAUST SYSTEM AND INTAKE MANIFOLD XJ REMOVAL AND INSTALLATION (Continued) INSTALLATION (1) Connect the catalytic converter to the exhaust pipe and the muffler/tailpipe assy. (Fig. 4). Use a new clamp and tighten the nuts to 61 N·m (45 ft. lbs.) torque. (2) Install the muffler onto the catalytic converter until the alignment tab is inserted into the align- ment slot. (3) Install a new clamp at the muffler and cata- lytic converter connection (Fig. 4). Tighten the clamp nut to 61 N·m (45 ft. lbs.) torque. (4) Coat the oxygen sensor with anti-seize com- pound. Install the sensor and tighten the nut to 27 N·m (20 ft. lbs.) torque. (5) Lower the vehicle. (6) Start the engine and inspect for exhaust leaks and exhaust system contact with the body panels. Adjust the alignment, if needed. MUFFLER AND EXHAUST TAILPIPE All original equipment exhaust systems are manu- factured with the exhaust tailpipe welded to the muf- fler. Service replacement mufflers and exhaust Fig. 5 Front Exhaust Tailpipe Hanger tailpipes are either clamped together or welded together. WARNING: IF TORCHES ARE USED WHEN WORK- ING ON THE EXHAUST SYSTEM, DO NOT ALLOW THE FLAME NEAR THE FUEL LINE. CAUTION: When servicing exhaust system compo- nents, disconnect the oxygen sensor connector. Allowing the exhaust system to hang by the oxygen sensor harness will damage the wiring and/or sen- sor. REMOVAL (1) Raise and support the vehicle. (2) Disconnect front tailpipe hanger from the insu- Fig. 6 Catalytic Converter to Muffler Connection lator (Fig. 5). (3) Remove the front exhaust clamp from the cat- close to the muffler. Collapse the part remaining in alytic converter and muffler connection (Fig. 6). the muffler and remove. (4) Heat the catalytic converter-to-muffler connec- • To remove a service exhaust tailpipe/muffler tion with an oxyacetylene torch until the metal combination, apply heat until the metal becomes becomes cherry red. cherry red. Remove the exhaust tailpipe/muffler (5) While the metal is still cherry red, remove the clamp and twist the exhaust tailpipe out of the muf- exhaust muffler/tailpipe assembly from the catalytic fler. converter. (8) If the tailpipe is also to be replaced (6) Slide the muffler/tailpipe assy. rearward and INSTALLATION out of the rear exhaust tailpipe mounting bracket (1) Install the muffler onto the catalytic converter. (Fig. 7). Install the clamp and tighten the nuts finger tight. (7) Remove the muffler from the exhaust tailpipe: (2) Install the exhaust tailpipe into the rear of the • To remove an original equipment exhaust muf- muffler. fler/tailpipe combination, cut the exhaust tailpipe (3) Install the exhaust tailpipe/muffler assembly on the rear exhaust tailpipe mounting bracket. Make

- 5. MUFFLER/TAILPIPE ASSEM- TAILPIPE BRACKET BLY ING MOUNT- XJ EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 5 REMOVAL AND INSTALLATION (Continued) stallation (refer to Group 14, Fuel System - Quick Connect Fittings). (7) Disconnect the accelerator cable, the cruise control cable (if equipped), and the transmission line pressure cable (if equipped) from the throttle body and remove them from the cable bracket. CAUTION: When disconnecting the cruise control connector at the throttle body, DO NOT pry the con- nector off with pliers or screwdriver. Use finger pressure only. Prying the connector off could break it. (8) Disconnect the electrical connectors. Pull the harnesses away from the manifold and secure them so they do not interfere with the manifold removal and installation process. • The throttle position sensor. • The idle air control motor. • The coolant temperature sensor at the thermo- stat. • The manifold air temperature sensor at the Fig. 7 Rear Exhaust Tailpipe Mounting Bracket intake manifold. • The fuel injectors. sure that the exhaust tailpipe has sufficient clear- • The oxygen sensor. ance from the floor pan. (9) Disconnect the crankcase ventilation (CCV) (4) Install front tailpipe hanger into the insulator vacuum hose and manifold absolute pressure (MAP) (Fig. 5). sensor vacuum hose connector at the intake mani- (5) Align the muffler and tighten the nuts on the fold. muffler-to-catalytic converter clamp to 61 N·m (45 ft. (10) Disconnect vacuum hose from vacuum port on lbs.) torque (Fig. 6). the intake manifold. (6) Align the tailpipe and install a new clamp at (11) Disconnect CCV hose at the cylinder head the muffler to tailpipe connection. cover (Fig. 8). (7) Tighten the muffler to tailpipe clamp to 61 N·m (12) Remove the molded vacuum harness. (45 ft. lbs.) (13) Disconnect the vacuum brake booster hose at (8) Lower the vehicle. the intake manifold. (9) Start the engine and inspect for exhaust leaks (14) Remove bolts 2 through 5 securing the intake and exhaust system contact with the body panels. manifold to the cylinder head (Fig. 11). Slightly Adjust the alignment, if needed. loosen bolt No.1 and nuts 6 and 7. (15) Remove the intake manifold and gaskets. INTAKE MANIFOLD—2.5L ENGINE Drain the coolant from the manifold. REMOVAL INSTALLATION (1) Disconnect the battery negative cable. (1) Clean the intake manifold and cylinder head (2) Remove the air inlet hose from the throttle mating surfaces. DO NOT allow foreign material body and air cleaner. to enter either the intake manifold or the ports (3) Loosen the accessory drive belt tension and in the cylinder head. remove the belt from the power steering pump (refer (2) Install the new intake manifold gasket over the to Group 07, Cooling Systems for proper procedures). locating dowels. (4) Remove the power steering pump and brackets (3) Position the manifold in place and finger from the water pump and intake manifold. Secure tighten the mounting bolts. power steering pump and bracket out of the way. (4) Tighten the fasteners in sequence and to the (5) Perform fuel system pressure release procedure specified torque (Fig. 11). (refer to Group 14, Fuel System for correct proce- • Fastener No.1—Tighten to 41 N·m (30 ft. lbs.) dure). torque. (6) Disconnect fuel supply tube from the fuel rail. • Fasteners Nos.2 through 7—Tighten to 31 N·m Some fuel lines require a special tool for removal/in- (23 ft. lbs.) torque.

- 6. FIXED AIR ORIFICE INLET TING FITTING AIR COVER FILTER FIT- 11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLD XJ REMOVAL AND INSTALLATION (Continued) (13) Install and tension the accessory drive belt. Refer to Group 7, Cooling System for the proper pro- cedure. CAUTION: Ensure that the accessory drive belt is routed correctly. Failure to do so can cause the water pump to turn in the opposite direction result- ing in engine overheating. Refer to Group 7, Cool- ing System for the proper procedure. (14) Connect the air inlet hose to the throttle body and the air cleaner. (15) Connect the battery negative cable. (16) Start the engine and check for leaks. INTAKE MANIFOLD—4.0L ENGINE The intake and engine exhaust manifolds on the 4.0L engine must be removed and installed together. The two manifolds use a common gasket at the cyl- inder head. REMOVAL (1) Disconnect the battery negative cable. Fig. 8 Crankcase Ventilation (CCV) Hose—2.5L (2) Remove air cleaner inlet hose from throttle Engine plate assembly. (5) Connect fuel supply tube to the fuel rail inlet. (3) Remove the air cleaner assembly. Push tube until a “click” is heard. Before connect- (4) Remove the throttle cable, cruise control cable ing the fuel line to the fuel rail replace the (if equipped) and the transmission line pressure O-rings at the quick-connect fuel line coupling. cable. (6) Pull out on the fuel supply tube to ensure that (5) Disconnect the crankcase ventilation (CCV) it is locked in place. vacuum hose and manifold absolute pressure (MAP) (7) Connect the molded vacuum hoses to the vac- sensor vacuum hose connector at the intake mani- uum port on the intake manifold and the cylinder fold. head cover. (6) Disconnect vacuum hose from vacuum port on (8) Connect the electrical connectors. the intake manifold. • The throttle position sensor. (7) Disconnect CCV hose at the cylinder head • The idle air control motor. cover (Fig. 9). • The coolant temperature sensor at the thermo- (8) Perform fuel system pressure release procedure stat housing. (refer to Group 14, Fuel System for correct proce- • The fuel injectors. dure). • The air manifold temperature sensor. (9) Remove fuel supply line latch clip at injector • The oxygen sensor. rail. (9) Connect the CCV vacuum hose and MAP sen- (10) Disconnect fuel supply tube from the fuel rail. sor vacuum hose connectors to the throttle body. Some fuel lines require a special tool for removal/in- (10) Install the power steering pump and bracket stallation (refer to Group 14, Fuel System - Quick assembly to the water pump and intake manifold. Connect Fittings). Hand start the three (3) tensioner bracket to p/s (11) Disconnect all electrical connectors on the pump to intake manifold bolts and the two (2) ten- intake manifold. sioner bracket to water pump bolts. • The throttle position sensor. (11) Tighten the power steering pump bolts to 28 • The idle air control motor. N·m (21 ft. lbs.) Tighten the tensioner bracket to • The coolant temperature sensor at the thermo- water pump bolts to 28 N·m (21 ft. lbs.). stat. (12) Connect the accelerator cable, cruise control • The manifold air temperature sensor at the cable (if equipped), and the transmission line pres- intake manifold. sure cable (if equipped) to the hold-down bracket and • The fuel injectors. the throttle lever. • The oxygen sensor.

- 7. AIR INLET TING FIT- FWDIXED F ORIFICE FITTING AIR COVER FILTER CYLINDER HEAD DOWEL EXHAUST INTAKE MANI- MANI- FOLD FOLD CYLINDER HEADDOWEL XJ EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 7 REMOVAL AND INSTALLATION (Continued) (8) Tighten the fasteners in sequence and to the specified torque (Fig. 10). • Fasteners Nos.1 through 5—Tighten to 33 N·m (24 ft. lbs.) torque. • Fasteners Nos.6 and 7—Tighten to 31 N·m (23 ft. lbs.) torque. • Fasteners Nos.8 through 11—Tighten to 33 N·m (24 ft. lbs.) torque. Fig. 9 Crankcase Ventilation (CCV) Hose —4.0L Engine Fig. 10 Intake/Engine Exhaust Manifold Installation (12) Loosen the accessory drive belt tension and (4.0L Engine) remove the belt from the power steering pump (refer to Group 07, Cooling Systems for proper procedures). (9) Install the power steering pump and bracket to (13) Remove the power steering pump and bracket the intake manifold and water pump. Tighten the from the intake manifold and water pump and set belt to specification (Refer to Group 7, Cooling Sys- aside. tem for the proper procedures). (14) Raise the vehicle. (10) Connect fuel supply tube to the fuel rail inlet. (15) Disconnect the exhaust pipe from the engine Push tube until a “click” is heard. Before connect- exhaust manifold. Discard the seal. ing the fuel line to the fuel rail replace the (16) Lower the vehicle. O-rings at the quick-connect fuel line coupling. (17) Remove the intake manifold and engine (11) Pull out on the fuel supply tube to ensure that exhaust manifold. it is locked in place. (12) Replace latch clip. INSTALLATION (13) Connect all electrical connections on the (1) Clean the mating surfaces of the cylinder head intake manifold. and the manifold if the original manifold is to be re- (14) Connect the vacuum connector on the intake installed. manifold and install it in the bracket. (2) If the manifold is being replaced, ensure all the (15) Install throttle cable, cruise control cable (if sensors, fittings, etc. are transferred to the replace- equipped). ment manifold. (16) Install the transmission line pressure cable (if (3) Install a new exhaust/intake manifold gasket equipped). Refer to Group 21, Transmission for the over the alignment dowels on the cylinder head. adjustment procedures. (4) Position the engine exhaust manifold to the (17) Install air cleaner assembly. cylinder head. Install fastener No.3 and finger (18) Connect air inlet hose to the throttle plate tighten at this time (Fig. 10). assembly. (5) Install intake manifold on the cylinder head (19) Raise the vehicle on a side mounted hoist. dowels. (20) Using a new seal, connect the exhaust pipe to (6) Install washers and fasteners Nos.1, 2, 4, 5, 8, the engine exhaust manifold. Tighten the bolts to 31 9, 10 and 11 (Fig. 10). N·m (23 ft. lbs.) torque. (7) Install washers and fasteners Nos.6 and 7 (Fig. (21) Lower the vehicle. 10). (22) Connect the battery negative cable. (23) Start the engine and check for leaks.

- 8. SPACER EXHAUST MANI- FOLD CYLINDER HEAD DOWELS INTAKE MANI- FOLDSPACER 11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLD XJ REMOVAL AND INSTALLATION (Continued) EXHAUST MANIFOLD—2.5L ENGINE (8) Tighten nuts 6 and 7 to 31 N·m (23 ft. lbs.) torque (Fig. 11). REMOVAL (9) Install all components to the intake manifold. (1) Disconnect the battery negative cable. (10) Raise the vehicle. (2) Raise the vehicle. (11) Connect the exhaust pipe to the engine (3) Disconnect the exhaust pipe from the engine exhaust manifold. Tighten the bolts to 31 N·m (23 ft. exhaust manifold. lbs.) torque. (4) Lower the vehicle. (12) Lower the vehicle. (5) Remove intake manifold (refer to procedure in (13) Connect the battery negative cable. this section) (14) Start the engine and check for leaks. (6) Remove fasteners 2 through 5 and remove the intake manifold (Fig. 11). EXHAUST MANIFOLD—4.0L ENGINE (7) Remove fasteners 1, 6 and 7 and remove the The intake and engine exhaust manifolds on the engine exhaust manifold (Fig. 11). 4.0L engine must be removed and installed together. The manifolds use a common gasket at the cylinder head. Refer to Intake Manifold—4.0L Engine in this sec- tion for the proper removal and installation proce- dures. SPECIFICATIONS TORQUE SPECIFICATIONS Description Torque Catalytic Converter/Exhaust Pipe Exhaust Clamp Nut . . . . . . . . . . 61 N·m (45 ft. lbs.) Crossmember to Sill Bolts . . . . . . . . . . . . . . . . . . . . . . 42 N·m (31 ft. lbs.) Fig. 11 Intake/Exhaust Manifold Removal/ Crossmember to Transmission Mount Installation—2.5L Engine Nuts . . . . . . . . . . . . . . . . . . . . . . 22 N·m (16 ft. lbs.) Exhaust Pipe to Manifold INSTALLATION Nuts . . . . . . . . . . . . . . . . . . . . . . 31 N·m (23 ft. lbs.) (1) Clean the intake and engine exhaust manifolds Exhaust Manifold–2.5L Engine and cylinder head mating surfaces. DO NOT allow Bolt #1 . . . . . . . . . . . . . . . . . . . . 41 N·m (30 ft. lbs.) foreign material to enter either the intake man- Exhaust Manifold–2.5L Engine ifold or the ports in the cylinder head. Bolts #2–5 . . . . . . . . . . . . . . . . . . 31 N·m (23 ft. lbs.) (2) Install a new intake manifold gasket over the alignment dowels on the cylinder head. Exhaust Manifold–4.0L Engine (3) Install the engine exhaust manifold assembly. Nuts/Bolts #1–5 & #8–11 . . . . . . 33 N·m (24 ft. lbs.) Exhaust manifold must be centrally located Exhaust Manifold–2.5L Engine over the end studs and spacer (Fig. 11). Nuts #6&7 . . . . . . . . . . . . . . . . . 31 N·m (23 ft. lbs.) (4) Tighten bolt No.1 to 41 N·m (30 ft. lbs.) torque Exhaust Manifold–4.0L Engine (Fig. 11). Nuts #6&7 . . . . . . . . . . . . . . . . . 31 N·m (23 ft. lbs.) (5) Install the intake manifold on the cylinder Intake Manifold–2.5L Engine head dowels (Fig. 11). Bolt #1 . . . . . . . . . . . . . . . . . . . . 41 N·m (30 ft. lbs.) (6) Install bolts 2 through 5 (Fig. 11). Tighten Intake Manifold–2.5L Engine these bolts to 31 N·m (23 ft. lbs.) torque. Bolt #2–5 . . . . . . . . . . . . . . . . . . 31 N·m (23 ft. lbs.) (7) Install new engine exhaust manifold spacers Muffler to Catalytic Converter over the engine exhaust manifold mounting studs in Exhaust Clamp Nut . . . . . . . . . . 61 N·m (45 ft. lbs.) the cylinder head (Fig. 11). Oxygen Sensors Nut . . . . . . . . . . . . . . . . . . . . . . . 27 N·m (20 ft. lbs.) Rear Tail Pipe Hanger Nuts . . . . . . . . . . . . . . . . . . . . . . 54 N·m (40 ft. lbs.)

- 9. XJ EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1 EXHAUST SYSTEM AND INTAKE MANIFOLD CONTENTS page page GENERAL INFORMATION EXHAUST PIPE . . . . . . . . . . . . . . . .......... 1 EXHAUST HEAT SHIELDS . . . . . . . . . . . . . . . . . 1 INTAKE MANIFOLD . . . . . . . . . . . . .......... 3 EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . 1 MUFFLER AND EXHAUST TAILPIPE ......... 2 REMOVAL AND INSTALLATION SPECIFICATIONS ENGINE EXHAUST MANIFOLD AND TORQUE SPECIFICATIONS . . . . . . .......... 4 TURBOCHARGER . . . . . . . . . . . . . . . . . . . . . 2 GENERAL INFORMATION EXHAUST SYSTEM The basic exhaust system consists of an engine exhaust manifold, exhaust pipe, exhaust heat shield(s), muffler and exhaust tailpipe The exhaust system uses a single muffler. The exhaust system must be properly aligned to prevent stress, leakage and body contact. If the sys- tem contacts any body panel, it may amplify objec- tionable noises originating from the engine or body. When inspecting an exhaust system, critically inspect for cracked or loose joints, stripped screw or bolt threads, corrosion damage and worn, cracked or broken hangers. Replace all components that are badly corroded or damaged. DO NOT attempt to repair. Fig. 1 Heat Shields When replacement is required, use original equip- REMOVAL AND INSTALLATION ment parts (or equivalent). This will assure proper alignment and provide acceptable exhaust noise lev- EXHAUST PIPE els. WARNING: IF TORCHES ARE USED WHEN WORK- CAUTION: Avoid application of rust prevention ING ON THE EXHAUST SYSTEM, DO NOT ALLOW compounds or undercoating materials to exhaust THE FLAME NEAR THE FUEL LINES. system floor pan exhaust heat shields. Light over- spray near the edges is permitted. Application of coating will result in excessive floor pan tempera- REMOVAL tures and objectionable fumes. (1) Raise and support the vehicle. (2) Saturate the bolts and nuts at turbo down pipe to exhaust pipe with heat valve lubricant. Allow 5 EXHAUST HEAT SHIELDS minutes for penetration.. Exhaust heat shields are needed to protect both (3) Disconnect bolts from exhaust pipe to turbo the vehicle and the environment from the high tem- down pipe (Fig. 2). peratures (Fig. 1). (4) Remove the clamp nuts at muffler (Fig. 3). To DO NOT allow the engine to operate at fast idle for remove the exhaust pipe from the muffler, apply heat extended periods (over 5 minutes). This condition until the metal becomes cherry red. Disconnect the may result in excessive temperatures in the exhaust exhaust pipe from the muffler. Remove the exhaust system and on the floor pan. pipe. INSTALLATION (1) Assemble exhaust pipe to muffler, loosely to permit proper alignment of all parts.

- 10. 11 - 2 EXHAUST SYSTEM AND INTAKE MANIFOLD XJ REMOVAL AND INSTALLATION (Continued) REMOVAL (1) Raise and support the vehicle. (2) Remove the front muffler clamp from the exhaust pipe and muffler connection. (3) Remove the rear exhaust tailpipe hanger clamp and remove the exhaust tailpipe from the front exhaust tailpipe hanger. (4) Remove the exhaust tailpipe assembly from the muffler. INSTALLATION (1) Install the muffler onto the exhaust pipe. Install the clamp and tighten the nuts finger tight. (2) Install the exhaust tailpipe into the rear of the muffler. (3) Install the exhaust tailpipe/muffler assembly Fig. 2 Exhaust Down Pipe to Front Exhaust Pipe on the rear exhaust tailpipe hanger. Make sure that the exhaust tailpipe has sufficient clearance from the floor pan. (4) Install the remaining clamps and the front exhaust tailpipe hanger. (5) Tighten the nuts on the muffler-to-exhaust pipe clamp to 43 N·m torque. (6) Tighten the nuts on the muffler-to-exhaust pipe clamp to 43 N·m torque. (7) Lower the vehicle. (8) Start the engine and inspect for exhaust leaks and exhaust system contact with the body panels. Adjust the alignment, if needed. ENGINE EXHAUST MANIFOLD AND TURBOCHARGER REMOVAL Fig. 3 Front Pipe to Muffler (1) Disconnect the battery negative cable. (2) Connect the exhaust pipe to the turbo down (2) Remove air cleaner hoses from turbocharger. pipe manifold. Tighten the bolts to 22.5 N·m torque. (3) Remove air cleaner assembly. (3) Use a new clamp and tighten the nuts to 43 (4) Remove charge air cooler hoses from turbo- N·m torque. charger and intake manifold. (4) Lower the vehicle. (5) Remove all components attached to the intake (5) Start the engine and inspect for exhaust leaks manifold. and exhaust system contact with the body panels. (6) Remove the EGR tube and EGR valve. Adjust the alignment, if needed. (7) Remove exhaust manifold heat shield. (8) Remove turbocharger oil feed line (Fig. 4). MUFFLER AND EXHAUST TAILPIPE (9) Remove exhaust down pipe from turbo. All original equipment exhaust systems are manu- (10) Raise the vehicle factured with the exhaust tailpipe welded to the muf- (11) Remove oil drain tube from turbocharger fler. Service replacement mufflers and exhaust (12) Lower the vehicle tailpipes are either clamped together or welded (13) Remove turbocharger and exhaust manifold as together. an assembly (Fig. 5). WARNING: IF TORCHES ARE USED WHEN WORK- CLEANING ING ON THE EXHAUST SYSTEM, DO NOT ALLOW Clean the exhaust manifold and cylinder head mat- THE FLAME NEAR THE FUEL LINES. ing surfaces.

- 11. XJ EXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3 REMOVAL AND INSTALLATION (Continued) (4) Install exhaust down pipe to turbocharger, tighten bolts to 27 N·m. (5) Install exhaust heat shield, tighten bolts to 11 N·m. (6) Loose install EGR tube and EGR valve to intake manifold. (7) Install EGR valve, tighten bolts to 26 N·m. (8) Tighten EGR tube nut to 26 N·m. (9) Tighten EGR tube flange bolts to 26 N·m. (10) Connect all components to intake manifold. (11) Connect charge air cooler hoses to turbo- charger and intake manifold. (12) Install air cleaner assembly. (13) Connect air cleaner hose to turbocharger. (14) Raise the vehicle (15) Install turbocharger drain line. (16) Lower the vehicle (17) Connect the battery negative cable. (18) Start the engine and check for leaks. INTAKE MANIFOLD Fig. 4 Turbocharger Oil Feed Line REMOVAL (1) Remove exhaust manifold and turbocharger INSTALLATION assembly. (1) Install turbocharger to exhaust manifold (2) Remove water manifold. tighten nuts to 27 N·m. (3) Remove intake manifold. (2) Install assembly to engine, tighten nuts to 30 N·m. CLEANING Clean the intake manifold and cylinder head mat- ing surfaces. DO NOT allow foreign material to enter either the intake manifold or the ports in the cylinder head. INSTALLATION (1) Install the new intake manifold gasket. (2) Position the intake manifold in place and fin- ger tighten the mounting nuts. (3) Tighten the fasteners in sequence and to the specified torque 30 N·m. (4) Position the water manifold in place and finger tighten the mounting nuts. (5) Tighten the fasteners to the specified torque 12 N·m. (6) Install exhaust manifold and turbocharger Fig. 5 Exhaust Manifold and Turbocharger assembly. (7) Install charge air cooler hose to intake mani- (3) Install oil feed line to turbocharger, tighten nut fold. to 26 N·m. (8) Connect the battery negative cable. (9) Start engine and check for leaks.

- 12. 11 - 4 EXHAUST SYSTEM AND INTAKE MANIFOLD XJ SPECIFICATIONS TORQUE SPECIFICATIONS Description Torque EGR Attaching Nuts . . . . . . . . . . . . . . . . . . . . . . . 19 N·m EGR Tube Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 N·m EGR Tube Flange Bolts . . . . . . . . . . . . . . . . . . . . . 26 N·m Exhaust Manifold Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 N·m Exhaust Manifold Heat Shield Nuts . . . . . . . . . . . . . . . . . . . . . 11 N·m Exhaust Pipe Support Clamp Bolts . . . . . . . . . . . . . . . . . 22.5 N·m Exhaust Pipe Support Clamp Screw . . . . . . . . . . . . . . . . 22.5 N·m Intake Manifold Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 N·m Muffler-to-Exhaust Pipe Clamp Nuts . . . . . . . . . . . . . . . . . . . . . . . . . 43 N·m Tail Pipe Clamp Hanger bolt . . . . . . . . . . . . . . . . . . . . . . . . 22.5 N·m Turbocharger-to-Exhaust manifold Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 N·m Turbocharger Oil Feed Line . . . . . . . . . . . . . . . . . . . . . . . 27.4 N·m Turbocharger Down Pipe-to-Exhaust Pipe Bolts/Nuts . . . . . . . . . . . . . . . . . . . . . . . . . 22.5 N·m Turbocharger Down Pipe-to-Turbocharger Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 N·m