14 mq11 02-te-0000-ee0012-0

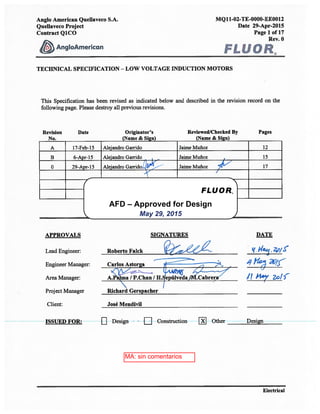

- 1. MA: sin comentarios AFD – Approved for Design ® May 29, 2015

- 2. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 2 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical Record of Revisions Revision N° Date Description A 17-Feb-15 Issued for Internal Review B 6-Apr-15 Issued for Client Approval 0 29-Abr-15 Issued for Design

- 3. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 3 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical Table of Contents 1.0 GENERAL...................................................................................................................................... 4 1.1 Summary............................................................................................................................... 4 1.2 Work and Components Included........................................................................................ 4 1.3 Work and Components Excluded....................................................................................... 4 1.4 Codes and Standards ........................................................................................................... 5 1.5 Performance Requirements................................................................................................. 7 1.6 Submittals ............................................................................................................................. 7 1.7 Quality Assurance and Quality Control ............................................................................ 8 1.8 Sub-Suppliers ....................................................................................................................... 8 1.9 Design and Operating Conditions....................................................................................... 8 1.10 Limitation of Engineering Review Liability ...................................................................... 9 2.0 PRODUCT...................................................................................................................................... 9 2.1 Design Requirement............................................................................................................. 9 2.2 Mechanical Features.......................................................................................................... 11 3.0 EXECUTION ............................................................................................................................... 13 3.1 Engineering Data Requirements....................................................................................... 13 3.2 Inspection and Testing....................................................................................................... 15 3.3 Preservation........................................................................................................................ 16 3.4 Installation, Pre-commissioning, Commissioning, and Start–Up.................................. 16 4.0 ATTACHMENTS ........................................................................................................................ 17

- 4. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 4 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical 1.0 GENERAL 1.1 Summary This specification covers the design, manufacturing, assembly, testing, supply and delivery of NEMA low voltage squirrel cage induction motors rated 187 kW and below (herein referred to as “motors”, “the equipment” or “units”). The specific requirements shall be given on the respective Data Sheet which shall be part of the request for quotation (RFQ) and/or purchase order (PO). The equipment shall be supplied for Quellaveco Project of Anglo American Quellaveco S.A. (AAQSA) in the Torata district, Mariscal Nieto province, Moquegua department, in Perú. The plant and water supply facilities are located approximately at 34 km and 75 km east from Moquegua city, respectively. The seaport facilities are located in Ilo area. The project has five (5) main areas: • Quellaveco, where the Mine, Crusher and Truck Shop are located at 3600 masl. • Papujune, where the Concentrator Plant is located at 3600 masl. • Cortadera, where the Tailing Disposal area is located at 3300 masl. • Titire and Vizcachas, where the water supply facilities are located at 4400 masl. • Seaport facilities in Ilo area, at 20 masl. Bidder shall read carefully this Specification and declare exceptions (if any) to scope of requested supply. 1.2 Work and Components Included The scope of supply for the equipment is described in the following list. Any components, sub-systems, accessories or others not listed herein but necessary to consider for the correct and safe transportation, installation, commissioning, operation and maintenance of the equipment shall be quoted as optional items for evaluation by the Buyer: • Low voltage squirrel cage motor • All necessary and required engineering and documentation. 1.3 Work and Components Excluded The following items will be provided by others and are excluded from the scope of supply.

- 5. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 5 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical • Reception, unloading and storage of the equipment at site. • Foundations and anchor bolts. • Motor couplings and/or sheaves, except mounting thereof when indicated on Data Sheets. • Motor starting equipment. • External facilities such as connecting, interconnecting raceway, and conductors external to equipment. • Field electrical work, including conductors, cables, conduit and wiring external to the equipment. • Installation and testing at jobsite (except technical assistance if requested on the purchase order documents). 1.4 Codes and Standards 1.4.1 Applicable Standards Publications listed form part of this Specification insofar as they give definitions and describe the requirements and tests which the supplied equipment shall meet. • NEMA National Electrical Manufacturer's Association • ANSI American National Standards Institute. • IEEE Institute of Electrical and Electronic Engineers • ASME American Society of Mechanical Engineers. • NEC National Electrical Code (NFPA 70, last edition) • ASTM American Society for Testing and Materials • ABMA American Bearing Manufacturers Association • AFBMA Anti-Friction Bearing Manufacturer’s Association • NESC National Electrical Safety Code

- 6. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 6 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical 1.4.2 Specific References • NEMA MG-1 Motors and Generators • NEMA MG-2 Safety Std and Guide for Selection, Installation and Use of Electric motor and Generators • NFPA 70 National Electrical Code (NEC). • IEEE Std 43 Recommended Practice for Testing Insulation Resistance of Rotating Machinery. • IEEE Std 85 Test Procedures for Airborne Sound Measurements on Rotating Electric Machinery • IEEE Std 112 Standard Test Procedures for Poly-phase Induction Motors and Generators • IEEE Std 841 Standard for Petroleum and Chemical Industry – Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors - up to and including 370 kW (500 hp). Codes and standards shall be latest revision and addendum in effect on date specification is IFC (Issued for Construction) unless noted otherwise. Except as modified by the requirements specified herein or the details of the drawings, work included in this Specification shall conform to the applicable provisions of publications. The Bidder shall be responsible to be, or to become, knowledgeable of Codes and Standards. The equipment shall comply or exceed the requirements outlined in the codes and standards listed herein. Solution to conflicts or differences between these Standards and Regulations rests with the Buyer. Equipment changes or alterations to comply with Codes and Standards, shall be to manufacturer’s expense.

- 7. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 7 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical 1.5 Performance Requirements Motors shall be in accordance with this Specification and datasheet MQ11-02-DS-0000- EE0012, designed to operate at the specified altitude. Ratings and characteristics, materials, manufacturing and tests shall be in full accordance with the latest applicable standards indicated on section 1.4 as applicable minimum requirements. 1.6 Submittals Bidders shall furnish and timely submit all data and documentation as requested in Form SDDC “Supplier Drawing & Data Commitment”. The SDDC form specifies the data and documents required by the Buyer to be submitted with the Bidder´s proposal, as well as those required after an eventual Purchase Order award. Bidders shall complete the Data Sheet form attached to the RFQ and submit it with the quotation. Bidders shall complete all information required in the Data Sheet in accordance with the equipment specifications. It is no acceptable to fill in the Data Sheet with indications like “see catalog”, “see standard”, or blank fill. All values shown on the bidder completed Data Sheet will be considered guaranteed values within the limits of tolerance specified by the relevant standards. As a minimum, the Bidder shall submit the following information with the proposal: • Completed Data Sheet. The offers with incomplete Data Sheet may be rejected. • A list of recommended spare parts for commissioning and start–up including a description and part number for each item. • A list of recommended capital spare parts including a description and part number for each item. • A list of recommended spare parts for one year operation, including a description and part number for each item. • A list of special tools (if any) required for installation, pre-commissioning, commissioning, operation and maintenance. • A complete deviation list, detailing all deviations, exceptions and/or assumptions contained in the proposal. In absence of such list, it will be assumed that the offered equipment fully complies with all the requirements stated herein and in the Data Sheet. No exceptions shall be allowed unless approved by the Buyer in writing.

- 8. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 8 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical • Daily rates for technical assistance and support at job site for installation, pre- commissioning, commissioning and start–up. 1.7 Quality Assurance and Quality Control The Manufacturer shall have a Quality Control Plan that collects and records similar equipment's field operating informalities and failures due to the design, materials, processes, and workmanship. The Manufacturer is responsible to advise the Buyer of the specified equipment of such informalities before such reports are obtained through other sources. The Manufacturer shall maintain a Quality Assurance Program and related documents and shall be signed by the authorized quality inspector. The Quality Assurance Program must be established, implemented, and maintained in accordance with the QA-QC documentation attached to the RFQ including form Q&CR “Quality and Certification Requirements” Manufacturers meeting the following requirements are acceptable: • The manufacturer shall be regularly engaged in the manufacture of the required equipment. • The equipment sub-components and parts shall be the standard products of established, reputable Manufacturers regularly engaged in the manufacture of such equipment. Motors quoted shall maintain reliable services and make available required parts during installation and field testing and for no less than 30 years thereafter, in large-scale mining projects. 1.8 Sub-Suppliers For components, accessories and auxiliary systems delivered by sub–suppliers, the Main Bidders must clearly identify and indicate the extent of such supply. If the proposed sub– Bidders do not meet the quality requirements, the Buyer reserves the right to request the sub– Bidders to be changed. 1.9 Design and Operating Conditions 1.9.1 Ambient Conditions As described in document MQ11-02-TE-0000-ME0001, “Site Conditions”.

- 9. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 9 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical 1.9.2 Electrical Conditions The equipment shall be connected to an electrical distribution system with the following characteristics. • Low Voltage Power Distribution 480 V (ac), 3 phases, 60 Hz, Icc = 65 kA, solidly grounded • Auxiliary Power Distribution 231 V (ac), 1 phases, 60 Hz, Icc = 14 kA, solidly grounded 1.9.3 Seismic Conditions As indicated in document MQ11-02-DC-0000-SC0001. 1.9.4 Ratings Conditions. In accordance with the Data Sheet. 1.10 Limitation of Engineering Review Liability Review by Buyer of Vendor’s drawing shall not relieve the Vendor of his responsibility for furnishing properly designed equipment, mechanically and electrically suited to meet operating conditions, nor for results arising from errors or omissions, nor for any faults or defects, nor for failure in the matter of guarantee which may become evident during erection or subsequent operation. Acceptance of the Buyer shall occur after equipment operates successfully. Final acceptance will be subject to full, complete and satisfactory performance of the operation, certified data submission and safety compliance. All third party warranties and certifications obtained by the equipment manufacturer for accessories used in the supplied equipment shall be made extensive to the Buyer in all their terms of covering. 2.0 PRODUCT 2.1 Design Requirement Low voltage motors shall be 250 HP (187 kW) or less. All motors shall be squirrel cage and shall meet or exceed the specifications defined in NEMA MG-1.

- 10. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 10 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical Motors shall be designed to perform satisfactorily at the site conditions shown on the Data Sheet. Moreover, they shall be designed to operate at the site elevation above sea level indicated on the Data Sheet. Altitude derating factor shall not be used. Unless otherwise specified on the Data Sheet, motors rated ½ Hp and above shall be TEFC, 460 V, 60 Hz, 3 phase, NEMA Premium® Efficiency and shall be rated for continuous operation, S1, with 1.15 service factor. Motors rated less than ½ Hp shall be shall be TENV, 220 V, 60 Hz, 1 phase, and may have a 1.0 service factor or higher. Motors shall have class F insulation and shall not exceed class B temperature rise. All motors operated with Variable Frequency Drives (VFDs) shall be inverter duty in accordance with NEMA MG-1, Part 31. Upon technical evaluation by the Buyer, special attention shall be given to the compliance of the following features with the mentioned standards: • Bearing protection shall be in accordance with NEMA MG-1 or IEEE 841 as applicable. • Vibration levels shall be in accordance with NEMA MG-1, Part 7.8.2 or IEEE 841, Part 6.9 as applicable. • Foot-flatness shall be in accordance with NEMA MG-1, Part 4.15. • Testing in accordance with NEMA MG-1, Part 12. • Energy efficiency: The operational costs associated to the energy losses due to inefficiencies (i.e. cost of inefficiency) of each unit operating at 100% and 75% of its full capacity will be considered during the evaluation process by using the following formula: 𝐶𝑜𝑠𝑡 𝑜𝑓 𝑖𝑛𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 = 𝑇𝑜𝑡𝑎𝑙 𝐿𝑜𝑠𝑠𝑒𝑠 [𝑘𝑊] ∗ 8079 � 𝑈𝑆𝐷 𝑘𝑊 � All arc-producing devices such as sliding contacts, switching mechanisms, and resistance devices shall be suitable for the area classification specified on the Data Sheet. If specified on the Data Sheet, the motor shall be provided with a temperature switch. Specific application, load type, and other requirements for each motor shall be in accordance with the Data Sheet.

- 11. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 11 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical 2.2 Mechanical Features 2.2.1 Mounting Mounting position shall be indicated on the Data Sheet. Horizontally mounted motor are preferred. If specified on the Data Sheet, motors vertical motors installed with shaft end down shall have a non-corrosive drip cover over fan cover. A shield or cover shall be provided to protect the motor against wind-driven rain during operating or idle conditions. 2.2.2 Terminal Box Motor terminal boxes shall be in accordance with NEMA MG-1, section 4.19. For motors rated 75 Hp and above the size of the terminal box to be provided shall be that of the immediately superior frame size. Unless otherwise specified on the Data Sheet, the location of terminal housing shall be as shown in NEMA MG-1, Figure 4-6, assembly symbol F-1. 2.2.3 Bearings Bearings shall be re-greasable without disassembly of fans or fan covers. Bearings shall be suitable for and provided with rust-inhibiting grease compatible with polyurea-thickened grease. Grease fittings shall only be provided on motors with re-greasable bearings. Grease fitting shall be zerk type fitting unless otherwise indicated on the Data Sheet. If specified on the Data Sheet, other types of bearing lubrication methods (e.g., oil mist or non-regreasable factory-lubricated sealed bearings) shall be provided. 2.2.4 Fans Unless otherwise specified on the the Data Sheet, all fans shall be bidirectional. If unidirectional fans are specified, the direction of rotation shall be shown by permanent, legible markings. The cooling fan shall be of the non-sparking corrosion resistant type and shall be sufficiently conductive to prevent accumulation of a static charge.

- 12. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 12 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical 2.2.5 Space Heaters Space heaters shall not be required for low voltage motors. 2.2.6 Terminal Leads Terminal leads from the motor shall be stranded copper conductors. Except for larger motors where two leads per phase may be provided for large conductor sizes to allow for flexibility, one terminal lead per phase shall be provided. 2.2.7 UL Label Motor required for installation in classified area shall be approved by Underwriters Laboratories (UL) with maximum temperature identification number specified on the name plate as shown on Data Sheet. 2.2.8 Rating Plates and Nameplates Two stainless steel metal plates shall be permanently attached to each motor frame. One metal plate for the motor nameplate and other for the engraved motor tag number. The Motor tag number shall be engraved with 3/4 in. high characters. Unidirectional motors shall have a stainless steel rotation arrow plate attached on the shaft end bearing bracket. Bi–directional design motors shall be so marked with a stainless steel nameplate. 2.2.9 Corrosion Protection and Coating Corrosion protection in accordance with the motor Bidder’s standard procedures is generally acceptable for non–aggressive site conditions. Motor stator and rotor inside of the motor frame air gap surfaces shall be properly sealed with moisture resistant coating that will withstand the effect of the requirements listed in NEMA MG–1. Internal surfaces, shaft, rotor, stator iron, end bells and parts shall be covered with a corrosion resistant coating of epoxy paint or equal material of 2 mils minimum dry film thickness for increased life against saline adverse environmental conditions. Shaft extension shall be protected with a rust preventive strippable coating capable of being peeled off or unwrapped.

- 13. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 13 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical Document Number MQ11-02-TE-0000-GA0001 - "Especificación de Pinturas" specifies the painting schemes that shall be applied to mechanical equipment (including motors) and establishes the required scheme for each area of the project according to its particular environmental conditions and exposure to corrosive agents. Motors to be installed in areas where the required painting schemes are anti- corrosive shall additionally comply with all the requirements stated in IEEE 841. 2.2.10 Finish The equipment enclosure shall be cleaned, primed, and painted in accordance with document MQ11-02-TE-0000-GA0001, “Especificación Técnica de Pintura”. The finish color shall be as indicated on the same document. The Vendor shall supply paint, matching each color used, for field "touch–up" after installation of the equipment. 3.0 EXECUTION 3.1 Engineering Data Requirements The awarded Bidder shall furnish and submit engineering data for the equipment as specified and ordered. Engineering data, as listed below, shall be supplied in accordance with the form SDDC “Supplier Drawing & Data Commitment” attached to the requisition. Typical data is not acceptable unless it is revised to show the equipment as being furnished. All symbols and wiring identification systems shall be in accordance with the applicable ANSI standard. 3.1.1 Engineering Data The Supplier shall provide all engineering drawings and documentation in English and Spanish. Fabrication shall begin only after approval of the respective drawings and documents by the Buyer. Expenses derived from modifications or changes to units or parts manufactured before fulfilling the above-mentioned requirement, shall be at the Supplier’s expense. The documentation shall include, but not be limited to the following list. • Completed by Supplier Data Sheet. • Dimensional outline drawing showing location and size of customer connections to junction boxes.

- 14. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 14 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical • Supplier shall provide the recommended number of motor starts per hour and the minimum time between consecutive starts. • Characteristics curves: power v/s efficiency, power factor and current. • Characteristics curves of speed v/s torque, current, efficiency, power factor (for 100% and 80% of voltage). • Curves of thermal limit showing time of blocked rotor and overload conditions (Safe Stall). • Anchor bolt diameter design and bolt specification. Load table according to MQ11-02-TE-0000-SS0002, Structural Requirements for Equipment. • All service requirement for foundations (vibration, allowable displacements and/or others). • Factory and field test procedures. • Factory and field test certified reports. • Preservation instructions for extended periods of indoor or outdoor storage before installation. 3.1.2 Material List Detailed bill of material with description and catalog number of all sub-components, identifying sub-Suppliers and country of origin in each case. 3.1.3 Spare Parts List The Supplier shall submit a list of recommended capital spare parts, spare parts for commissioning and start–up and spare parts for one year of operation. It shall be provided in a native usable format such as Excel data base, where available. 3.1.4 Installation, Operating and Maintenance Manuals (IOM) The Seller shall submit IOM manuals supplied on CD’s and hard copy in the quantities indicated on the Form SDDC “Supplier Drawing & Data Commitment”.

- 15. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 15 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical 3.2 Inspection and Testing 3.2.1 Inspection Inspection shall be as detailed in the Q&CR form. The Supplier shall grant the Buyer's representative free access to shops at all times and shall arrange all reasonable facilities, necessary to verify that the materials and fabrication are in accordance with Buyer's specifications. However, such inspections or waiving of inspection by the Buyer shall neither relieve Supplier of responsibility for furnishing the equipment conforming to the requirements of the specification nor invalidate any claims that Buyer may make because of defective or unsatisfactory material and workmanship. The Buyer shall have the right to witness all tests and shall be notified at least two weeks in advance of any tests to allow a representative to be present at no extra cost. Release of the equipment for shipment shall not relieve the Supplier of any responsibility or guarantee. Acceptance of shop tests shall not constitute a waiver of field performance requirements under specified operating conditions, nor shall shop inspection by the Buyer relieve the Supplier of responsibilities in case of later discovery of defective material or workmanship. 3.2.2 Design Tests Supplier shall provide documentation certifying that the design of the units being provided has been tested in accordance with the applicable design tests according to the relevant standards. 3.2.3 Production and Conformance Tests at the Factory The equipment shall be completely assembled prior to shipment, wired, and tested by manufacturer. Testing methods shall be in accordance with IEEE Std. 112 Unless otherwise specified on the Data Sheet, the motors shall be subject to all applicable routine tests specified in NEMA MG-1, Part 12, section 12.55. Certified test reports shall be promptly furnished to Buyer. The test reports shall include both the raw data and the conclusions that are drawn from or calculated from the data.

- 16. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 16 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical Test reports shall detail all defects detected as a result of testing activities. Reparation procedures for defective equipment and replacement of parts or accessories shall be authorized by the Buyer in writing. The Buyer reserves the right to reject defective units, which shall be replaced be newly fabricated ones. Buyer reserves the right to observe the testing, dismantling, inspection, and reassembly of units, as specified. Tests shall be performed on the fully assembled units, using contract components, instrumentation, and accessories. Materials or sub-components improperly detailed, fabricated, or assembled, so that its installation in the field requires extra work, shall be the responsibility of the Supplier, who shall replace or repair defective goods at his own expense. Certified copies of the factory routine tests on each completely assembled unit shall be provided to the Buyer. 3.3 Preservation A preservation plan and schedule shall be submitted to the Buyer identifying all measures to be taken in order to avoid damage to the equipment and maintain manufacturer warranties during the storage period before installation. The equipment shall be prepared for extended indoor and outdoor storage periods. Motor bearings shall be protected with either a grease covering or liquid preservative. The motors shall be tagged to show that a preservative has been used. Exterior machined surfaces, including shafts, shall be given a coating of rust–inhibiting compound prior to shipment. The procedure to be followed before motors are placed in operation shall be indicated in the Installation, Operating and Maintenance Instructions. 3.4 Installation, Pre-commissioning, Commissioning, and Start–Up. During the installation, pre-commissioning, commissioning, and start–up period an experienced engineer, representing the supplier, may be requested to supervise the following work: • Monitoring mounting and installation • Pre-commissioning and Commissioning Tests • Training of the Buyer’s operation and maintenance personnel

- 17. ® Anglo American Quellaveco S.A. MQ11-02-TE-0000-EE0012 Quellaveco Project Date 29-Apr-2015 Contract Q1CO Page 17 of 17 Rev. 0 TECHNICAL SPECIFICATION – LOW VOLTAGE INDUCTION MOTORS Electrical • Operating Performance measurements 4.0 ATTACHMENTS The following documents related to the design and manufacturing of the LV Motors to motors, describe the Buyer’s intent respect to quality standards and project suitability: • MQ11-02-DS-0000-EE0012 Data Sheet for Low Voltage Induction Motors. • MQ11-02-TE-0000-ME0001 Site Conditions. • MQ11-02-DC-0000-EE0001 Electrical Design Criteria (English Version). • MQ11-02-TE-0000-GA0001 Especificación Técnica de Pintura • MQ11-02-DC-0000-SC0001 Structural design criteria • MQ11-02-TE-0000-SS0002 Structural Requirements for Equipment • AA AFRS 000005 Anglo Fatal Risk Standard: Equipment Safeguarding • AA AFRS 000006 Anglo Fatal Risk Standard: Isolation. End of Specification