Solid Carbide Thread Mills

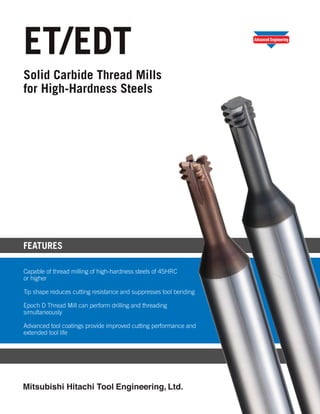

- 1. ET/EDT Solid Carbide Thread Mills for High-Hardness Steels FEATURES Capable of thread milling of high-hardness steels of 45HRC or higher Tip shape reduces cutting resistance and suppresses tool bending Epoch D Thread Mill can perform drilling and threading simultaneously Advanced tool coatings provide improved cutting performance and extended tool life

- 2. © 2016 Mitsubishi Hitachi Tool Engineering, Ltd.2 FeaturesET/EDT 2. Features of Epoch D Thread Mill • No pilot hole needed. This single tool can perform both drilling and threading simultaneously. • High-strength edge shape design suppresses edge tip breakage in severe machining environments including hardened steels. • ATH Coating delivers improved hardness and oxidation resistance. INTRODUCTION The new EDT Series Thread Mill Series is designed to machine precision threads in a range of materials including hardened steels up to 66HRC. Our thread mills deliver improved cutting and chip removal, reducing the risk of the cutting tool breaking off inside of the hole. Additionally, one thread mill can perform a variety of applications including right-hand thread milling, left-hand thread milling, and fine threading simply by changing the NC program. Cutting load is much smaller than conventional taps, and special toolholders are not needed. 1. Features of Epoch Thread Mill • Tough and strong edge design for threading in hardened steels. • Tip shape reduces cutting resistance and suppresses tool bending. • Drastically reduces tool breakage • PN Coating provides excellent adhesion and wear resistance FEATURES 3. New PVD Coating Technology Advanced TH (ATH) Coating: With a hardness of 3800Hv and oxidation temperature of 1200°, our new ATH Coating enables longer life and higher efficiency when cutting high-hardness materials (55HRC or higher). Compared with our previous generation coating, double the tool life and more than double the machining efficiency can be achieved. The ATH Coating is ideal for both dry cutting and wet cutting in a variety of materials including cold-worked die steel, HSS, tool steel, composite materials, carbide alloys and more. Cross-section photograph of ATH coating layer structure ■ Conventional Coating ■ ATH Coating for hard material Pat.No.3934136 5nm High hardness membrane High heat resistance membrane Even finer particle size is nano order.

- 3. 3© 2016 Mitsubishi Hitachi Tool Engineering, Ltd. FeaturesET/EDT 5. Machining Process with Epoch Thread Mill 4. Technology Reduces the risk of tool breaking By using a tool with a diameter smaller than the inside diameter of the thread, cutting chips are smaller and chip evacuation is improved. The risk of the tool breaking off inside the hole is reduced as a result. One tool – various types of thread milling Right-hand, left-hand and fine thread milling can be performed by just changing the NC program. The nominal diameters of the coarse threads and fine threads that can be processed with the same tool are different. (Example: For ET-1.25-16-PN, coarse thread is M8 × P1.25 and fine thread is M10 × P1.25). Cutting conditions can be freely set Unlike when using taps, synchronizing the rotation and feed rates is not necessary. Thread mills can be used in the same manner as end mills and cutting conditions can be set according to the processing environment. Usable on a variety of machines Thread mills can be used even on machines with lower-powered spindles. In addition, special tooling such as tapping holders are not necessary. Provides good finished surfaces Interrupted cutting suppresses gouging to provide good finished surfaces. Thread milling can be performed to the bottom of the hole Epoch Thread Mills are designed with no incomplete crests and Epoch D Thread Mills have only one incomplete crest, making them ideal for when you want to perform thread milling to the bottom of shallow holes. 1. Startup 2. Position for starting point of machining 3. Entry (gradually cutting in) 4. Threading 5. Release (gradually detaching from cutting) 6. Ending Easily Create NC Programs Online Create cutting programs for the ET and EDT mills in our app at: http://www.mmc-hitachitool.co.jp/e/index.html 1 2 3 4 5 6 PN Coating: By optimizing the AI content, the multi-layer PN Coating exhibits both excellent heat-resistance and adhesion to the tool substrate. Combining of the AlCr coating layer with Si produces high hardness (3000HV) as well as good wear resistance. PN Coating provides extended cutting tool life in both wet and dry machining of materials including pre-hardened steel, carbon steel, alloy steel, stainless steel, H13, D2 and more. Epoch D Thread Mill can perform boring simultaneously. Left-hand cutting tool – Reverse spindle rotation should be used.

- 4. © 2016 Mitsubishi Hitachi Tool Engineering, Ltd.4 Tool Dimensions InchET THREADING 65HRC 65 4 FLUTES PN COATING øDc øDs L l ET - 2D for Unified Threads Part No. Stock Thread Diameter tpi Dc Flutes L Ds Limit Correction Amount ET-U64-3.7-PN □ 0.073 No.1-64UNC 64 0.055 4 0.146 1.97 6mm 0.00157 ET-U56-4.4-PN □ 0.086 No.2-56UNC 56 0.065 4 0.173 1.97 6mm 0.00197 ET-U48-5-PN □ 0.099 No.3-48UNC 48 0.075 4 0.197 1.97 6mm 0.00236 ET-U40-5.7-PN □ 0.112 No.4-40UNC 40 0.083 4 0.224 1.97 6mm 0.00276 ET-U32-7-PN □ 0.138 No.6-32UNC 32 0.100 4 0.276 1.97 6mm 0.00315 ET-U36-8.3-PN □ 0.164 No.8-36UNF 36 0.130 4 0.327 1.97 6mm 0.00354 ET-U24-9.7-PN □ 0.190 No.10-24UNC 24 0.138 4 0.382 2.76 6mm 0.00433 ET-U20-12.7-PN ● 1/4" No.1/4-20UNC 20 0.187 4 0.500 2.76 6mm 0.00591 ET-U28-12.7-PN ● 1/4" No.1/4-28UNF 28 0.197 4 0.500 2.76 6mm 0.00591 ET-U18-15.9-PN ● 5/16" No.5/16-18UNC 18 0.236 4 0.626 3.15 10mm 0.00709 ET-U16-19.1-PN ● 3/8" No.3/8-16UNC 16 0.264 4 0.752 3.15 10mm 0.00866 ET-U14-22.2-PN □ 7/16" No.7/16-14UNC 14 0.303 4 0.874 3.15 10mm 0.00984 ET-U13-25.4-PN ● 1/2" No.1/2-13UNC 13 0.362 4 1.000 3.15 10mm 0.01142 ET-U12-28.6-PN □ 9/16" No.9/16-12UNC 12 0.413 4 1.126 3.94 12mm 0.01260 ET-U11-31.8-PN ● 5/8" No.5/8-11UNC 11 0.449 4 1.252 3.94 12mm 0.01378 ET - 2.5D for Unified Threads Part No. Stock Thread Diameter tpi Dc Flutes L Ds Limit Correction Amount ET-U64-4.6-PN □ 0.073 No.1-64UNC 64 0.055 4 0.181 1.97 6mm 0.00157 ET-U56-5.5-PN □ 0.086 No.2-56UNC 56 0.065 4 0.217 1.97 6mm 0.00197 ET-U48-6.3-PN □ 0.099 No.3-48UNC 48 0.075 4 0.248 1.97 6mm 0.00236 ET-U40-7.1-PN □ 0.112 No.4-40UNC 40 0.083 4 0.280 1.97 6mm 0.00276 ET-U32-8.8-PN □ 0.138 No.6-32UNC 32 0.100 4 0.346 1.97 6mm 0.00315 ET-U36-10.4-PN □ 0.164 No.8-36UNF 36 0.130 4 0.409 1.97 6mm 0.00354 ET-U24-12.1-PN □ 0.190 No.10-24UNC 24 0.138 4 0.476 2.76 6mm 0.00433 ET-U20-15.9-PN ● 1/4" No.1/4-20UNC 20 0.187 4 0.626 2.76 6mm 0.00591 ET-U28-15.9-PN ● 1/4" No.1/4-28UNF 28 0.197 4 0.626 2.76 6mm 0.00591 ET-U18-19.8-PN ● 5/16" No.5/16-18UNC 18 0.236 4 0.780 3.15 10mm 0.00709 ET-U16-23.8-PN ● 3/8" No.3/8-16UNC 16 0.264 4 0.937 3.15 10mm 0.00866 ET-U14-27.8-PN □ 7/16" No.7/16-14UNC 14 0.303 4 1.094 3.15 10mm 0.00984 ET-U13-31.8-PN ● 1/2" No.1/2-13UNC 13 0.362 4 1.252 3.15 10mm 0.01142 ET-U12-35.7-PN □ 9/16" No.9/16-12UNC 12 0.413 4 1.406 3.94 12mm 0.01260 ET-U11-39.7-PN ● 5/8" No.5/8-11UNC 11 0.449 4 1.563 3.94 12mm 0.01378 Pilot hole required = Stocked in Japan Distributor. Please contact our customer service.

- 5. 5© 2016 Mitsubishi Hitachi Tool Engineering, Ltd. Tool Dimensions MetricET THREADING 65HRC 65 4 FLUTES PN COATING øDc øDs L l ET - 2D for Metric Threads Part No. Stock Size P Dc Flutes L Ds Limit Correction Amount ET-0.4-4-PN □ M2 0.4 1.4 4 4 50 6 0.04 ET-0.45-4.4-PN □ M2.2 0.45 1.6 4 4.4 50 6 0.04 ET-0.45-5-PN □ M2.5 0.45 1.8 4 5 50 6 0.05 ET-0.5-6-PN ● M3 0.5 2.4 4 6 50 6 0.06 ET-0.7-8-PN ● M4 0.7 3.1 4 8 50 6 0.08 ET-0.8-10-PN ● M5 0.8 3.8 4 10 50 6 0.1 ET-1.0-12-PN ● M6 1 4.6 4 12 50 6 0.11 ET-1.25-16-PN ● M8 1.25 6.2 4 16 70 10 0.15 ET-1.5-20-PN ● M10 1.5 7.5 4 20 70 10 0.18 ET-1.75-24-PN ● M12 1.75 9 4 24 80 10 0.22 ET-2-32-PN □ M16 2 11.5 4 32 100 12 0.29 ET-2.5-36-PN □ M18 2.5 14 4 36 135 16 0.32 ET-2.5-40-PN □ M20 2.5 15 4 40 135 16 0.36 ET - 2.5D for Metric Threads Part No. Stock Size P Dc Flutes L Ds Limit Correction Amount ET-0.4-5-PN □ M2 0.4 1.4 4 5 50 6 0.04 ET-0.45-5.5-PN □ M2.2 0.45 1.6 4 5.5 50 6 0.04 ET-0.45-6.25-PN □ M2.5 0.45 1.8 4 6.25 50 6 0.05 ET-0.5-7.5-PN ● M3 0.5 2.4 4 7.5 50 6 0.06 ET-0.7-10-PN ● M4 0.7 3.1 4 10 50 6 0.08 ET-0.8-12.5-PN ● M5 0.8 3.8 4 12.5 50 6 0.1 ET-1.0-15-PN ● M6 1 4.6 4 15 50 6 0.11 ET-1.25-20-PN ● M8 1.25 6.2 4 20 70 10 0.15 ET-1.5-25-PN ● M10 1.5 7.5 4 25 70 10 0.18 ET-1.75-30-PN ● M12 1.75 9 4 30 80 10 0.22 ET-2-40-PN □ M16 2 11.5 4 40 100 12 0.29 ET-2.5-45-PN □ M18 2.5 14 4 45 135 16 0.32 ET-2.5-50-PN □ M20 2.5 15 4 50 135 16 0.36 Pilot hole required = Stocked in Japan Distributor. Please contact our customer service.

- 6. © 2016 Mitsubishi Hitachi Tool Engineering, Ltd.6 Tool Dimensions InchEDT øDc øDs L l THREADING 65HRC 65 4 FLUTES ATH COATING EDT - 2D for Unified Threads Part No. Stock Thread Diameter tpi Dc Flutes L Ds Oil Hole Limit Correction Amount EDT-U64-3.7-TH □ 0.073 No.1-64UNC 64 0.0551 4 0.146 1.97 6mm - 0.00157 EDT-U56-4.4-TH □ 0.086 No.2-56UNC 56 0.0650 4 0.173 1.97 6mm - 0.00197 EDT-U48-5-TH □ 0.099 No.3-48UNC 48 0.0748 4 0.197 1.97 6mm - 0.00236 EDT-U40-5.7-TH □ 0.112 No.4-40UNC 40 0.0827 4 0.224 1.97 6mm - 0.00276 EDT-U32-7-TH □ 0.138 No.6-32UNC 32 0.1004 4 0.276 1.97 6mm - 0.00315 EDT-U36-8.3-TH □ 0.164 No.8-36UNF 36 0.1299 4 0.327 1.97 6mm - 0.00354 EDT-U24-9.7-TH □ 0.190 No.10-24UNC 24 0.1378 4 0.382 2.76 6mm - 0.00433 EDT-U20-12.7-TH ● 1/4” No.1/4-20UNC 20 0.1870 4 0.500 2.76 6mm - 0.00591 EDT-U28-12.7-TH ● 1/4” No.1/4-28UNF 28 0.1969 4 0.500 2.76 6mm - 0.00591 EDT-U18-15.9-TH ● 5/16” No.5/16-18UNC 18 0.2362 4 0.626 3.15 10mm - 0.00709 EDT-U16-19.1-TH ● 3/8” No.3/8-16UNC 16 0.2638 4 0.752 3.15 10mm - 0.00866 EDT-U14-22.2-TH □ 7/16” No.7/16-14UNC 14 0.3031 4 0.874 3.15 10mm ○ 0.00984 EDT-U13-25.4-TH ● 1/2” No.1/2-13UNC 13 0.3622 4 1.000 3.15 10mm ○ 0.01142 EDT-U12-28.6-TH □ 9/16” No.9/16-12UNC 12 0.4134 4 1.126 3.94 12mm ○ 0.01260 EDT-U11-31.8-TH ● 5/8” No.5/8-11UNC 11 0.4488 4 1.252 3.94 12mm ○ 0.01378 EDT - 2.5D for Unified Threads Part No. Stock Thread Diameter tpi Dc Flutes L Ds Oil Hole Limit Correction Amount EDT-U64-4.6-TH □ 0.073 No.1-64UNC 64 0.0551 4 0.181 1.97 6mm - 0.00157 EDT-U56-5.5-TH □ 0.086 No.2-56UNC 56 0.0650 4 0.217 1.97 6mm - 0.00197 EDT-U48-6.3-TH □ 0.099 No.3-48UNC 48 0.0748 4 0.248 1.97 6mm - 0.00236 EDT-U40-7.1-TH □ 0.112 No.4-40UNC 40 0.0827 4 0.280 1.97 6mm - 0.00276 EDT-U32-8.8-TH □ 0.138 No.6-32UNC 32 0.1004 4 0.346 1.97 6mm - 0.00315 EDT-U36-10.4-TH □ 0.164 No.8-36UNF 36 0.1299 4 0.409 1.97 6mm - 0.00354 EDT-U24-12.1-TH □ 0.190 No.10-24UNC 24 0.1378 4 0.476 2.76 6mm - 0.00433 EDT-U20-15.9-TH ● 1/4” No.1/4-20UNC 20 0.1870 4 0.626 2.76 6mm - 0.00591 EDT-U28-15.9-TH ● 1/4” No.1/4-28UNF 28 0.1969 4 0.626 2.76 6mm - 0.00591 EDT-U18-19.8-TH ● 5/16” No.5/16-18UNC 18 0.2362 4 0.780 3.15 10mm - 0.00709 EDT-U16-23.8-TH ● 3/8” No.3/8-16UNC 16 0.2638 4 0.937 3.15 10mm - 0.00866 EDT-U14-27.8-TH □ 7/16” No.7/16-14UNC 14 0.3031 4 1.094 3.15 10mm ○ 0.00984 EDT-U13-31.8-TH ● 1/2” No.1/2-13UNC 13 0.3622 4 1.252 3.15 10mm ○ 0.01142 EDT-U12-35.7-TH □ 9/16” No.9/16-12UNC 12 0.4134 4 1.406 3.94 12mm ○ 0.01260 EDT-U11-39.7-TH ● 5/8” No.5/8-11UNC 11 0.4488 4 1.563 3.94 12mm ○ 0.01378 Pilot hole not required = Stocked in Japan Distributor. Please contact our customer service.

- 7. 7© 2016 Mitsubishi Hitachi Tool Engineering, Ltd. Tool Dimensions MetricEDT THREADING 65HRC 65 4 FLUTES ATH COATING øDc øDs L l EDT - 2D for Metric Threads Part No. Stock Size P Dc Flutes L Ds Oil Hole Limit Correction Amount EDT-0.4-4-TH □ M2 0.4 1.4 4 4 50 6 - 0.04 EDT-0.45-4.4-TH □ M2.2 0.45 1.6 4 4.4 50 6 - 0.04 EDT-0.45-5-TH □ M2.5 0.45 1.8 4 5 50 6 - 0.05 EDT-0.5-6-TH ● M3 0.5 2.4 4 6 50 6 - 0.06 EDT-0.7-8-TH ● M4 0.7 3.1 4 8 50 6 - 0.08 EDT-0.8-10-TH ● M5 0.8 3.8 4 10 50 6 - 0.1 EDT-1.0-12-TH ● M6 1 4.6 4 12 50 6 - 0.11 EDT-1.25-16-TH ● M8 1.25 6.2 4 16 70 10 - 0.15 EDT-1.5-20-TH ● M10 1.5 7.5 4 20 70 10 ○ 0.18 EDT-1.75-24-TH ● M12 1.75 9 4 24 80 10 ○ 0.22 EDT-2-32-TH □ M16 2 11.5 4 32 100 12 ○ 0.29 EDT-2.5-36-TH □ M18 2.5 14 4 36 135 16 ○ 0.32 EDT-2.5-40-TH □ M20 2.5 15 4 40 135 16 ○ 0.36 EDT - 2.5D for Metric Threads Part No. Stock Size P Dc Flutes L Ds Oil Hole Limit Correction Amount EDT-0.4-5-TH □ M2 0.4 1.4 4 5 50 6 - 0.04 EDT-0.45-5.5-TH □ M2.2 0.45 1.6 4 5.5 50 6 - 0.04 EDT-0.45-6.25-TH □ M2.5 0.45 1.8 4 6.25 50 6 - 0.05 EDT-0.5-7.5-TH ● M3 0.5 2.4 4 7.5 50 6 - 0.06 EDT-0.7-10-TH ● M4 0.7 3.1 4 10 50 6 - 0.08 EDT-0.8-12.5-TH ● M5 0.8 3.8 4 12.5 50 6 - 0.1 EDT-1.0-15-TH ● M6 1 4.6 4 15 50 6 - 0.11 EDT-1.25-20-TH ● M8 1.25 6.2 4 20 70 10 - 0.15 EDT-1.5-25-TH ● M10 1.5 7.5 4 25 70 10 ○ 0.18 EDT-1.75-30-TH ● M12 1.75 9 4 30 80 10 ○ 0.22 EDT-2-40-TH □ M16 2 11.5 4 40 100 12 ○ 0.29 EDT-2.5-45-TH □ M18 2.5 14 4 45 135 16 ○ 0.32 EDT-2.5-50-TH □ M20 2.5 15 4 50 135 16 ○ 0.36 Pilot hole not required = Stocked in Japan Distributor. Please contact our customer service.

- 8. © 2016 Mitsubishi Hitachi Tool Engineering, Ltd.8 ET Inch Cutting Conditions Work Material Cast Iron, Carbon Steels 150~200HB Tool Steels 25~35HRC Pre-hardened Steels 35~45HRC Vc (sfm) 262~279~295 230~246~262 197~213~230 Thread Size Tool Dia. (in) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) No.1-64UNC 0.0551 19300 6.69 0.00035 17100 5.28 0.00031 14800 4.57 0.00031 No.2-56UNC 0.0650 16400 6.93 0.00043 14500 6.14 0.00043 12500 4.80 0.00039 No.3-48UNC 0.0748 14200 7.13 0.00051 12600 5.83 0.00047 10900 4.61 0.00043 No.4-40UNC 0.0827 12900 7.99 0.00059 11400 6.57 0.00055 9900 5.31 0.00051 No.6-32UNC 0.1004 10600 8.19 0.00071 9400 6.85 0.00067 8100 5.55 0.00063 No.8-36UNF 0.1299 8200 6.69 0.00098 7200 5.67 0.00094 6300 4.53 0.00087 No.10-24UNC 0.1378 7700 8.98 0.00106 6800 7.36 0.00098 5900 5.87 0.00091 No.1/4-20UNC 0.1870 5700 8.58 0.00150 5000 7.13 0.00142 4400 5.75 0.00130 No.1/4-28UNF 0.1969 5400 7.24 0.00157 4800 6.10 0.00150 4100 4.80 0.00138 No.5/16-18UNC 0.2362 4500 8.31 0.00189 4000 6.93 0.00177 3400 5.47 0.00165 No.3/8-16UNC 0.2638 4000 10.08 0.00213 3600 8.43 0.00197 3100 6.81 0.00185 No.7/16-14UNC 0.3031 3500 10.51 0.00244 3100 8.70 0.00228 2700 7.05 0.00213 No.1/2-13UNC 0.3622 2900 9.33 0.00291 2600 7.80 0.00272 2200 6.10 0.00252 No.9/16-12UNC 0.4134 2600 8.70 0.00315 2300 7.20 0.00295 2000 5.83 0.00276 No.5/8-11UNC 0.4488 2400 8.74 0.00323 2100 7.17 0.00303 1800 5.75 0.00283 Work Material Hardened Steels 45~55HRC Hardned Steels 50~62HRC Hardned Steels 62~66HRC Vc (sfm) 164~180~197 131~148~164 98~115~131 Thread Size Tool Dia. (in) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) No.1-64UNC 0.0551 12500 3.39 0.00028 10200 2.362 0.00024 8000 1.850 0.00024 No.2-56UNC 0.0650 10600 3.66 0.00035 8700 2.362 0.00028 6800 1.850 0.00028 No.3-48UNC 0.0748 9200 3.54 0.00039 7500 2.323 0.00031 5900 1.811 0.00031 No.4-40UNC 0.0827 8300 4.09 0.00047 6800 2.520 0.00035 5300 1.969 0.00035 No.6-32UNC 0.1004 6900 4.45 0.00059 5600 2.638 0.00043 4400 2.087 0.00043 No.8-36UNF 0.1299 5300 3.46 0.00079 4300 2.244 0.00063 3400 1.772 0.00063 No.10-24UNC 0.1378 5000 4.76 0.00087 4100 3.031 0.00067 3200 2.362 0.00067 No.1/4-20UNC 0.1870 3700 4.57 0.00122 3000 2.874 0.00094 2300 2.205 0.00094 No.1/4-28UNF 0.1969 3500 3.86 0.00130 2900 2.441 0.00098 2200 1.850 0.00098 No.5/16-18UNC 0.2362 2900 4.33 0.00154 2400 2.756 0.00118 1900 2.205 0.00118 No.3/8-16UNC 0.2638 2600 5.35 0.00173 2100 3.346 0.00134 1700 2.717 0.00134 No.7/16-14UNC 0.3031 2300 5.55 0.00197 1900 3.583 0.00154 1400 2.638 0.00154 No.1/2-13UNC 0.3622 1900 4.96 0.00236 1600 3.189 0.00181 1200 2.402 0.00181 No.9/16-12UNC 0.4134 1700 4.61 0.00256 1400 2.913 0.00197 1100 2.283 0.00197 No.5/8-11UNC 0.4488 1500 4.45 0.00264 1300 2.953 0.00201 1000 2.283 0.00201 1. ET thread mills are only for threading the inside of holes. 2. The above cutting conditions are for the nominal diameters stated in the table. Cutting conditions for other nominal diameters should be calculated taking into consideration the Cutting Considerations (page 15). 3. The machinery should be a machining center equipped with NC (numerical control) equipment having a helical interpolation function. 4. The feed rate stated in the above conditions table is the feed rate at the tool center during tapping. In addition, the per-tooth feed rate is the numerical value at the cut- ting point. 5. Since there is a risk of cutting chips getting inside the machine, when using tools equipped with oil holes, be sure to use the oil holes. 6. Use the appropriate coolant for the work material and machining shape. 7. These conditions are for general guidance; in actual machining conditions adjust the parameters according to your actual machine conditions.

- 9. 9© 2016 Mitsubishi Hitachi Tool Engineering, Ltd. Work Material Cast Iron, Carbon Steels 150~200HB Tool Steels 25~35HRC Pre-hardened Steels 35~45HRC Vc(m/min) 80~85~90 70~75~80 60~65~70 Thread Size Tool Dia. (mm) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) M2 1.4 19300 208 0.009 17100 164 0.008 14800 142 0.008 M2.2 1.6 16900 203 0.011 14900 163 0.01 12900 141 0.01 M2.5 1.8 15000 202 0.012 13300 164 0.011 11500 142 0.011 M3 2.4 11300 154 0.017 9900 127 0.016 8600 103 0.015 M4 3.1 8700 188 0.024 7700 152 0.022 6700 127 0.021 M5 3.8 7100 198 0.029 6300 163 0.027 5400 130 0.025 M6 4.6 5900 204 0.037 5200 170 0.035 4500 134 0.032 M8 6.2 4400 198 0.05 3900 165 0.047 3300 128 0.043 M10 7.5 3600 216 0.06 3200 179 0.056 2800 148 0.053 M12 9 3000 216 0.072 2700 184 0.068 2300 145 0.063 M16 11.5 2400 235 0.087 2100 194 0.082 1800 154 0.076 M18 14 1900 171 0.101 1700 144 0.095 1500 117 0.088 M20 15 1800 184 0.102 1600 154 0.096 1400 125 0.089 Work Material Hardened Steels 45~55HRC Hardned Steels 55~62HRC Hardned Steels 62~66HRC Vc(m/min) 50~55~60 40~45~50 30~35~40 Thread Size Tool Dia. (mm) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) M2 1.4 12500 105 0.007 10200 73 0.006 8000 58 0.006 M2.2 1.6 10900 107 0.009 9000 69 0.007 7000 53 0.007 M2.5 1.8 9700 109 0.01 8000 72 0.008 6200 56 0.008 M3 2.4 7300 82 0.014 6000 53 0.011 4600 40 0.011 M4 3.1 5600 96 0.019 4600 62 0.015 3600 49 0.015 M5 3.8 4600 102 0.023 3800 66 0.018 2900 50 0.018 M6 4.6 3800 106 0.03 3100 67 0.023 2400 52 0.023 M8 6.2 2800 101 0.04 2300 64 0.031 1800 50 0.031 M10 7.5 2300 113 0.049 1900 72 0.038 1500 57 0.038 M12 9 1900 112 0.059 1600 72 0.045 1200 54 0.045 M16 11.5 1500 120 0.071 1200 74 0.055 1000 62 0.055 M18 14 1300 95 0.082 1000 56 0.063 800 45 0.063 M20 15 1200 100 0.083 1000 64 0.064 700 45 0.064 ET Metric Cutting Conditions 1. ET thread mills are only for threading the inside of holes. 2. The above cutting conditions are for the nominal diameters stated in the table. Cutting conditions for other nominal diameters should be calculated taking into consideration the Cutting Considerations (page 15). 3. The machinery should be a machining center equipped with NC (numerical control) equipment having a helical interpolation function. 4. The feed rate stated in the above conditions table is the feed rate at the tool center during tapping. In addition, the per-tooth feed rate is the numerical value at the cut- ting point. 5. Since there is a risk of cutting chips getting inside the machine, when using tools equipped with oil holes, be sure to use the oil holes. 6. Use the appropriate coolant for the work material and machining shape. 7. These conditions are for general guidance; in actual machining conditions adjust the parameters according to your actual machine conditions.

- 10. © 2016 Mitsubishi Hitachi Tool Engineering, Ltd.10 EDT Inch Cutting Conditions Work Material Cast Iron, Carbon Steels 150~200HB Tool Steels 25~35HRC Pre-hardened Steels 35~45HRC Vc (sfm) 262~279~295 230~246~262 197~213~230 Thread Size Tool Dia. (in) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) No.1-64UNC 0.0551 19300 4.45 0.00024 17100 3.94 0.00024 14800 3.43 0.00024 No.2-56UNC 0.0650 16400 4.41 0.00028 14500 3.90 0.00028 12500 3.39 0.00028 No.3-48UNC 0.0748 14200 4.37 0.00031 12600 3.90 0.00031 10900 3.35 0.00031 No.4-40UNC 0.0827 12900 4.80 0.00035 11400 4.21 0.00035 9900 3.66 0.00035 No.6-32UNC 0.1004 10600 5.00 0.00043 9400 4.45 0.00043 8100 3.82 0.00043 No.8-36UNF 0.1299 8200 4.29 0.00063 7200 3.78 0.00063 6300 3.31 0.00063 No.10-24UNC 0.1378 7700 5.67 0.00067 6800 5.00 0.00067 5900 4.33 0.00067 No.1/4-20UNC 0.1870 5700 5.43 0.00094 5000 4.76 0.00094 4400 4.17 0.00094 No.1/4-28UNF 0.1969 5400 4.53 0.00098 4800 4.02 0.00098 4100 3.43 0.00098 No.5/16-18UNC 0.2362 4500 5.20 0.00118 4000 4.61 0.00118 3400 3.94 0.00118 No.3/8-16UNC 0.2638 4000 6.34 0.00134 3600 5.71 0.00134 3100 4.92 0.00134 No.7/16-14UNC 0.3031 3500 6.61 0.00154 3100 5.83 0.00154 2700 5.08 0.00154 No.1/2-13UNC 0.3622 2900 5.79 0.00181 2600 5.20 0.00181 2200 4.41 0.00181 No.9/16-12UNC 0.4134 2600 5.43 0.00197 2300 4.80 0.00197 2000 4.17 0.00197 No.5/8-11UNC 0.4488 2400 5.43 0.00201 2100 4.76 0.00201 1800 4.09 0.00201 Work Material Hardened Steels 45~55HRC Hardned Steels 55~62HRC Hardned Steels 62~66HRC Vc (sfm) 164~180~197 131~148~164 98~115~131 Thread Size Tool Dia. (in) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) RPM (min-1) Feed (in/min) Feed/Tooth (in/t) No.1-64UNC 0.0551 12500 2.87 0.00024 10200 2.36 0.00024 8000 1.85 0.00024 No.2-56UNC 0.0650 10600 2.87 0.00028 8700 2.36 0.00028 6800 1.85 0.00028 No.3-48UNC 0.0748 9200 2.83 0.00031 7500 2.32 0.00031 5900 1.81 0.00031 No.4-40UNC 0.0827 8300 3.07 0.00035 6800 2.52 0.00035 5300 1.97 0.00035 No.6-32UNC 0.1004 6900 3.27 0.00043 5600 2.64 0.00043 4400 2.09 0.00043 No.8-36UNF 0.1299 5300 2.80 0.00063 4300 2.24 0.00063 3400 1.77 0.00063 No.10-24UNC 0.1378 5000 3.66 0.00067 4100 3.03 0.00067 3200 2.36 0.00067 No.1/4-20UNC 0.1870 3700 3.50 0.00094 3000 2.87 0.00094 2300 2.20 0.00094 No.1/4-28UNF 0.1969 3500 2.91 0.00098 2900 2.44 0.00098 2200 1.85 0.00098 No.5/16-18UNC 0.2362 2900 3.35 0.00118 2400 2.76 0.00118 1900 2.20 0.00118 No.3/8-16UNC 0.2638 2600 4.13 0.00134 2100 3.35 0.00134 1700 2.72 0.00134 No.7/16-14UNC 0.3031 2300 4.33 0.00154 1900 3.58 0.00154 1400 2.64 0.00154 No.1/2-13UNC 0.3622 1900 3.78 0.00181 1600 3.19 0.00181 1200 2.40 0.00181 No.9/16-12UNC 0.4134 1700 3.54 0.00197 1400 2.91 0.00197 1100 2.28 0.00197 No.5/8-11UNC 0.4488 1500 3.39 0.00201 1300 2.95 0.00201 1000 2.28 0.00201 1. EDT thread mills are capable of simultaneous boring and threading. 2. The above cutting conditions are for the nominal diameters stated in the table. Cutting conditions for other nominal diameters should be calculated taking into consideration the Cutting Considerations (page 15). 3. The machinery should be a machining center equipped with NC (numerical control) equipment having a helical interpolation function. 4. The feed rate stated in the above conditions table is the feed rate at the tool center during tapping. In addition, the per-tooth feed rate is the numerical value at the cut- ting point. 5. Since there is a risk of cutting chips getting inside the machine, when using tools equipped with oil holes, be sure to use the oil holes. 6. Use the appropriate coolant for the work material and machining shape. 7. These conditions are for general guidance; in actual machining conditions adjust the parameters according to your actual machine conditions.

- 11. 11© 2016 Mitsubishi Hitachi Tool Engineering, Ltd. Work Material Cast Iron, Carbon Steels 150~200HB Tool Steels 25~35HRC Pre-hardened Steels 35~45HRC Vc(m/min) 80~85~90 70~75~80 60~65~70 Thread Size Tool Dia. (mm) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) M2 1.4 19300 139 0.006 17100 123 0.006 14800 107 0.006 M2.2 1.6 16900 129 0.007 14900 114 0.007 12900 99 0.007 M2.5 1.8 15000 134 0.008 13300 119 0.008 11500 103 0.008 M3 2.4 11300 99 0.011 9900 87 0.011 8600 76 0.011 M4 3.1 8700 117 0.015 7700 104 0.015 6700 90 0.015 M5 3.8 7100 123 0.018 6300 109 0.018 5400 93 0.018 M6 4.6 5900 127 0.023 5200 112 0.023 4500 97 0.023 M8 6.2 4400 123 0.031 3900 109 0.031 3300 92 0.031 M10 7.5 3600 137 0.038 3200 122 0.038 2800 106 0.038 M12 9 3000 135 0.045 2700 122 0.045 2300 104 0.045 M16 11.5 2400 149 0.055 2100 130 0.055 1800 111 0.055 M18 14 1900 106 0.063 1700 95 0.063 1500 84 0.063 M20 15 1800 115 0.064 1600 102 0.064 1400 90 0.064 Work Material Hardened Steels 45~55HRC Hardned Steels 55~62HRC Hardned Steels 62~66HRC Vc(m/min) 50~55~60 40~45~50 30~35~40 Thread Size Tool Dia. (mm) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) RPM n(min-1) Vf (mm/min) fz (mm/t) M2 1.4 12500 90 0.006 10200 73 0.006 8000 58 0.006 M2.2 1.6 10900 83 0.007 9000 69 0.007 7000 53 0.007 M2.5 1.8 9700 87 0.008 8000 72 0.008 6200 56 0.008 M3 2.4 7300 64 0.011 6000 53 0.011 4600 40 0.011 M4 3.1 5600 76 0.015 4600 62 0.015 3600 49 0.015 M5 3.8 4600 79 0.018 3800 66 0.018 2900 50 0.018 M6 4.6 3800 82 0.023 3100 67 0.023 2400 52 0.023 M8 6.2 2800 78 0.031 2300 64 0.031 1800 50 0.031 M10 7.5 2300 87 0.038 1900 72 0.038 1500 57 0.038 M12 9 1900 86 0.045 1600 72 0.045 1200 54 0.045 M16 11.5 1500 93 0.055 1200 74 0.055 1000 62 0.055 M18 14 1300 73 0.063 1000 56 0.063 800 45 0.063 M20 15 1200 77 0.064 1000 64 0.064 700 45 0.064 EDT Metric Cutting Conditions 1. EDT thread mills are capable of simultaneous boring and threading. 2. The above cutting conditions are for the nominal diameters stated in the table. Cutting conditions for other nominal diameters should be calculated taking into consideration the Cutting Considerations (page 15). 3. The machinery should be a machining center equipped with NC (numerical control) equipment having a helical interpolation function. 4. The feed rate stated in the above conditions table is the feed rate at the tool center during tapping. In addition, the per-tooth feed rate is the numerical value at the cut- ting point. 5. Since there is a risk of cutting chips getting inside the machine, when using tools equipped with oil holes, be sure to use the oil holes. 6. Use the appropriate coolant for the work material and machining shape. 7. These conditions are for general guidance; in actual machining conditions adjust the parameters according to your actual machine conditions.

- 12. © 2016 Mitsubishi Hitachi Tool Engineering, Ltd.12 Technical DataET Threading of Hardened Steels (M4xP0.7) Threading of sintered HSS material (M4xP0.7) Threading of Pre-hardened steel (M12xP1.75) Work Material: D2 (60HRC) Tool: ET-0.7-8-PN n=4,620min-1 (Vc=45m/min) vf=62mm/min fz=0.015mm/t Threading depth: 8mm, Blind hole Pilot hole dia. x Pilot hole depth: ø3.4x12mm Coolant: Air-blow Work Material: High-Speed Steel (64HRC) Tool: ET-0.7-8-PN n=4,620min-1 (Vc=45m/min) vf=47mm/min fz=0.025mm/t Threading depth: 7mm, Through hole Pilot hole dia. x Pilot hole depth: ø3.4x7mm Coolant: Water-base Work Material: P21 Modified (40HRC) Tool: ET-1.75-24-PN n=3,537min-1 (Vc=100m/min) vf=311mm/min fz=0.088mm/t Threading depth: 22mm, Blind hole Pilot hole dia. x Pilot hole depth: ø10.5x28mm Coolant: Water-base ET thread mill after threading 50 holes ET thread mill after threading 400 holes Conventional after threading 10 holes 摩耗幅=0.3mm Threading hole count (holes) ET Thread Mill Conventional 0 10 20 30 40 50 The first The second Machining up to 50 holes. NOT reached tool life. Damaged on 10th hole Damaged on 7th hole Threading hole count (holes) ET Thread Mill 0 10 20 Machining up to 20 holes. NOT reached tool life. The first The second Provides machining even on sintered HSS material! Cutting Conditions Cutting Conditions Cutting Conditions Machining up to 300 holes, NOT reached tool life.

- 13. 13© 2016 Mitsubishi Hitachi Tool Engineering, Ltd. EDT Technical Data 0 10 20 30 Machining up to 30 holes. Interrupted cutting is possible. Threading hole count (holes) EDT Thread Mill The first The second Simultaneous Threading and Drilling on Hardened Steels (M8xP1.25) Simultaneous Threading and Drilling on Hardened Steels (M8xP1.25) Simultaneous Threading and Drilling on Pre-hardened Steels (M4xP0.7) Work Material: D2 (62HRC) Tool: EDT-1.25-16-TH n=2,060min-1 (Vc=40m/min) vf=47mm/min fz=0.025mm/t Threading depth: 15mm, Blind hole Coolant: Air-blow Work Material: H13 (45HRC) Tool: EDT-1.25-16-TH n=2,820min-1 (Vc=55m/min) vf=75mm/min fz=0.03mm/t Threading depth: 16mm, Blind hole Coolant: Air-blow Work Material: Pre-hardened steel (40HRC) Tool: EDT-0.7-10-TH n=5,650min-1 (Vc=55m/min) vf=75mm/min fz=0.015mm/t Threading depth: 10mm, Blind hole Coolant: Air-blow Tool condition of EDT thread mill after machining 30 holes. Wear condition is good with no chipping or damage! Cutting Conditions Cutting Conditions Cutting Conditions Machining up to 150 holes, NOT reached tool life. Machining up to 400 holes, NOT reached tool life. EDT thread mill after threading 150 holes. EDT thread mill after threading 400 holes.

- 14. © 2016 Mitsubishi Hitachi Tool Engineering, Ltd.14 TroubleshootingET/EDT Regarding Thread Diameter Expansion/Contraction Dimensional Accuracy Worsens When Moving Toward the Bottom of the Hole (Deflection) Regarding Tool Breakage NC Program Created by Hitachi Tool’s NC Program Creation Software Doesn’t Work Properly Regarding Upper Limit on Machinable Thread Diameters Suitable tool diameter compensation should be performed according to the work material and tool wear condition. Also, please be careful not to forget to input the tool diameter compensation value into the machine. For information about diameter correction, refer to the Cutting Considerations on page 15. A characteristic of the thread milling method is that tool deflection increases as the tool progresses toward the bottom of the hole. It may be necessary to perform zero cutting in order to perform high-accuracy thread milling with low deflection. As a countermeasure against tool breakage, performing processing with a reduced feed rate is effective. In addition, when processing with tool extended or when large rough cutting chips are produced, breakage due to chip clogging should be considered. In such cases, if processing is performed with a higher cutting speed, the cutting chips will be broken into smaller bits which may improve conditions. Changes in cutting chip conditions due to different cutting speeds Simultaneous boring and thread milling (M8 × P1.25) of carbon steel) There are differences in the programming code for the machine being used. Please contact the machine manufacturer for details. Please note that since the Epoch D Thread Mill performs boring simultaneously, it cannot perform thread milling for diameters of more than 1.68 times the tool diameter Dc. There are no particular similar limitations on using the ET mill. Cutting SpeedLow High

- 15. 15© 2016 Mitsubishi Hitachi Tool Engineering, Ltd. Cutting ConsiderationsET/EDT About tool feed rate About tool diameter correction About coolant When performing thread milling by helical interpolation, the cutting point feed rate should be multiplied by a coefficient to determine the tool center feed rate. The equation for calculating the tool center feed rate is shown at right. When performing thread milling by helical interpolation, it may be necessary to compensate for increased cutting resistance due to differences in work materials or tool wear condition. In the NC programs created using Hitachi Tool’s NC program creation software, tool diameter compensation is in radius designation format. Correction example: Threading of hardened material (60HRC) (M8xP1.25) Work material: D2 (60HRC) Tool: ET-1.25-20-PN Pilot Hole Dia: ø6.2 Pilot hole depth: ø6.8x25mm n=2,060min-1 vc=40m/min vf=56mm/min fz=0.03mm/t Threading depth: 20mm Threading hole count (holes) 10 20 30 40 Tool dia. correction value (mm) 3.09 3.08 3.06 3.04 • When using coolant, air blower is recommended. Water-soluble cutting fluids are suitable for some work materials or improving the grade of processed surfaces. Oil-based cutting fluids are not suitable because they degrade chip removal characteristics. • The holder should grip the tool shank so that the holder does not block the hole. The shank projection amount is 1 to 2 times the shank diameter. The coolant nozzle should be positioned so that the coolant will reach the bottom of the hole. In addition, coolant pressure should be adjusted so that it removes cutting chips. If the setting is bad, cutting chip clogging may lead to flute tip damage or tool breakage. • Since there is a risk of cutting chips getting inside the machine, when using tools equipped with oil holes, be sure to perform processing using the oil holes. vf=fz×z×n× D1 D1-Dc vf Feed rate (mm/min) fz Feed per tooth (mm/t) z No. of flutes n Rotation (min -1) D1 Thread dia. (mm) Dc Tool diameter (mm) 1 to 2 times shank diameter Not reached tool life.