Report

Share

Download to read offline

Recommended

Warehouse Management is presented by Welingkar’s Distance Learning Division. Warehouse is a combination of two words ”ware” and “House” which means that it is a place to house or store/keep wares i.e. items/articles for sale. This presentation includes different aspects of warehouse like function, storage, types of stacking and others.

For more such innovative content on management studies, join WeSchool PGDM-DLP Program: http://bit.ly/DistMang

Join us on Facebook: http://www.facebook.com/welearnindia

Follow us on Twitter: https://twitter.com/WeLearnIndia

Read our latest blog at: http://welearnindia.wordpress.com

Subscribe to our Slideshare Channel: http://www.slideshare.net/welingkarDLPWarehouse Management

Warehouse Management We Learn - A Continuous Learning Forum from Welingkar's Distance Learning Program.

More Related Content

What's hot

Warehouse Management is presented by Welingkar’s Distance Learning Division. Warehouse is a combination of two words ”ware” and “House” which means that it is a place to house or store/keep wares i.e. items/articles for sale. This presentation includes different aspects of warehouse like function, storage, types of stacking and others.

For more such innovative content on management studies, join WeSchool PGDM-DLP Program: http://bit.ly/DistMang

Join us on Facebook: http://www.facebook.com/welearnindia

Follow us on Twitter: https://twitter.com/WeLearnIndia

Read our latest blog at: http://welearnindia.wordpress.com

Subscribe to our Slideshare Channel: http://www.slideshare.net/welingkarDLPWarehouse Management

Warehouse Management We Learn - A Continuous Learning Forum from Welingkar's Distance Learning Program.

What's hot (20)

Inventory & Inventory Management ( By BU AIS 2nd Batch)

Inventory & Inventory Management ( By BU AIS 2nd Batch)

Similar to Stock take procedure

Similar to Stock take procedure (20)

warehouse Management Systems, Best warehouse practices,

warehouse Management Systems, Best warehouse practices,

NEW ORGANO_ Inventory & Order Mangement console (1)

NEW ORGANO_ Inventory & Order Mangement console (1)

05 Identificación de Tareas y Contexto de Uso (UX)

05 Identificación de Tareas y Contexto de Uso (UX)

Stock take procedure

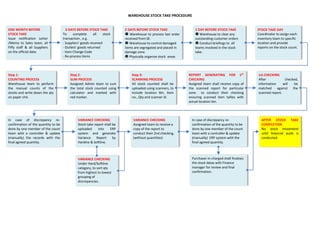

- 1. WAREHOUSE STOCK TAKE PROCEDURE ONE MONTH BEFORE STOCK TAKE Issue notification Letter /Memo to Sales team, all Fiffy staff & all Suppliers on the official date. 3 DAYS BEFORE STOCK TAKE To complete all stock transaction , e.g. - Suppliers' goods received - Outlets' goods returned - Item Change Code - Re-process items 2 DAYS BEFORE STOCK TAKE Warehouse to process last order received from SE. Warehouse to control damaged items are segregated and placed in damage zone. Physically organize stock areas 1 DAY BEFORE STOCK TAKE Warehouse to clear any outstanding customer orders Conduct briefings to all teams involved in the stock take. STOCK TAKE DAY Coordinator to assign each inventory team to specific location and provide reports on the stock count. Step 1: COUNTING PROCESS Warehouse team to perform the manual counts of the stocks and write down the qty on paper chit. Step 2: SUM PROCESS Assigned Admin team to sum the total stock counted using calculator and marked with red marker. Step 3: SCANNING PROCESS All stock counted shall be uploaded using scanners, to include location Bin, Item no., Qty and scanner id. REPORT GENERATING FOR 1ST CHECKING Assigned team shall receive copy of the scanned report for particular zone to conduct their checking ensuring scanned item tallies with actual location bin. In case of discrepancy re- confirmation of the quantity to be done by one member of the count team with a controller & update (manually) the records with the final agreed quantity. 1st CHECKING After checked, information will be matched against the scanned report. VARIANCE CHECKING Stock take report shall be uploaded into ERP system and generate Variance Report by Hardine & Softline. VARIANCE CHECKING Assigned team to receive a copy of the report to conduct their 2nd checking. (without quantities) In case of discrepancy re- confirmation of the quantity to be done by one member of the count team with a controller & update (manually) ERP system with the final agreed quantity. AFTER STOCK TAKE COMPLETION No stock movement until financial audit is conducted. VARIANCE CHECKING Under Hard/Softline category, to sort qty from highest to lowest grouping of discrepancies. Purchaser in-charged shall finalises the stock datas with Finance manager for review and final confirmation.