STM-METHOD-FOR-SUBGRADE.docx

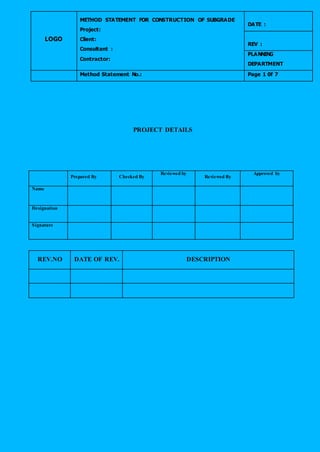

- 1. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 PROJECT DETAILS Prepared By Checked By Reviewed by Reviewed By Approved by Name Designation Signature REV.NO DATE OF REV. DESCRIPTION

- 2. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 INDEX 1. INTRODUCTION 2. PURPOSE 3. RESPONSIBLITY 4. REFERENCE DOCUMENTS 5. MAJOR EQUIPMENTS DEPLOYED 6. BRIEF METHOD OF CONSTRUCTION 7. JOB BREAKDOWN 8. RISK INVOLVED 9. SAFETY PRECAUTIONS 10. ANNEXURES

- 3. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 INTRODUCTION To draw a suitable methodology for construction of Subgrade with approved materials from borrow areas, as per the specification’s requirement of the Job. It also assesses the Risks involved in construction and states the Safety precautions to be taken care of, while performing the activities. PURPOSE This method statement describes the Construction Procedure of Subgrade for Agra lucknow green field expressway Project RESPONSIBILITY Site Engineer/Supervisor : For management of all equipment, labour and construction activities with all required safety measures. Section in Charge : For all activities related to Subgrade construction and safety measures. QA/QC Engineer : Ensure the quality of work as per the specifications Safety Engineer : Ensure the safety of workers during the progress of work. REFERENCE DOCUMENTS MORTH Rev. 5 Technical Specifications of Contract Relevant Drawings IS 2720 Codes MAJOR EQUIPMENTS DEPLOYED The equipments deployed is given below are (per set) Excavators : 1 Nos.

- 4. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 Dumpers : 5 Nos. Dozers / Tractor Dozer : 1 Nos. (where required) Grader : 1 Nos. Vibratory Rollers : 1 Nos. Water tankers : 1 Nos. BRIEF METHOD OF CONSTRUCTION Initially the alignment / limits are to be marked on the prepared Embankment surface. The filling material for Subgrade has to be laid and spread with chaindozer/tractor dozer and after grading and watering, compacted with vibratory roller; it should be compacted until it reaches its required compaction of 97% of MDD. JOB BREAKDOWN The hierarchy for construction procedure of Subgrade involves the following activities stated below: SETTING OUT After completion of Embankment, the toe limits of Subgrade shall be marked by fixing pegs at regular intervals before commencing the Subgrade construction. Marked toe will be more than the design toe to ensure proper compaction on edge. DEWATERING (If required) Water is drained out by channeling and drawn manually where small quantities are involved. If required, dewatering shall be done using stand-alone water pumps or water tanker mounted pumps. STRIPPING AND STORING TOP SOIL This work shall be executed, as directed by Engineer’s representative, as per the Clause 305.3.3 of MORTH specifications.

- 5. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 SELECTION AND APPROVAL OF BORROW MATERIAL The filling material used is mainly from the borrow areas. The material from the sources shall be thoroughly tested as per Clause 903.2.1. It shall be free from logs, stumps, roots, rubbish & any other material detrimental to the stability of Subgrade. The required testing as per IS 2720 shall be completed and material shall be assessed for its suitability well in advance. All test reports shall be documented and kept in QC Lab at site. A summary of approved borrow areas shall be available at site for necessary use by execution staff. EXCAVATION AND TRANSPORTATION FROM BORROW AREA The filling material will be hauled from nearby approved borrow area to the work stretch. Before starting the excavation for filling material from the borrow areas, the top 150mm of the soil will be removed and kept a side so that borrow material shall be free from logs, stumps, roots and any other detrimental material. Required equipments viz. Excavators and Tippers are mobilized as per the quantity of material to be transported to the working stretch. DUMPING OF MATERIAL ON THE STRETCH First layer of the sub grade shall be dumped on the compacted and approved top layer of embankment. In case the top layer has been disturbed by the vehicle movement, It shall be re- compacted so as to achieve minimum density as specified in table 300-2. Excavation at approved borrow areas shall be carried out with excavator and transportation of borrow earth shall be done by dumpers. SPREADING AND GRADING THE MATERIAL The dumped material shall be spread over the entire area using tractor dozer / chain dozer, in layers not exceeding 250 mm thick compacted layer. After initial dozing is complete, motor grader shall be used to grade the material to required levels and slope. When existing Sub Grade is to be widened, continuous horizontal benches at 300 mm width shall be cut out into the old slope to ensure adequate bond with present filling. Moisture content of the material shall be checked at the site of placement by rapid moisture meter.

- 6. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 Moisture content of each layer should be checked in accordance with IS: 2720 (Part2), and unless otherwise mentioned, shall be so adjusted, making due allowance for evaporation loses, that at time of compaction it is in the range of 1 percent above to 2 percent below the optimum moisture content determined in accordance with IS: IS: 2720(Part8). Where water is required to be added the same shall be sprinkled from a water tanker fitted with sprinkler uniformly on the surface but without flooding and shall be mixed thoroughly in soil by harrowing until uniform moisture content is obtained throughout the depth of the layer. If the material delivered to the work site is too wet, it shall be dried by aeration and exposure to the sun till the moisture content is accepted for compaction. CONTROL OF ALIGNMENT AND LEVEL The extent of work and levels shall be controlled during the grading by the Grade checker and Surveyor by fixing the wooden sticks, at 20 m c/c on the straight stretch and 10 m c/c at curves, marked at 20 cm above the required levels on both side of the work and then checking with a staff or measuring tape. After the grading operation is over Vibratory roller shall be deployed to start compacting the prepared bed. During initial compaction the surveyor shall again check the surface levels and if any surplus or short fall is detected it shall be made good. The surface levels for finished Sub grade shall be within ±20 mm. COMPACTION AND QUALITY CONTROL Once levels are assured, compaction operation using suitable Vibratory Roller of 8 – 10 Tonnes static weight shall be continued, as per the established pattern and in sufficient passes, usually 6 to 9 passes of rolling depending upon the conditions and the type of materials, till required density is achieved. Rolling shall progress parallel to the centerline of the road uniformly overlapping each preceding track by one-third width. Rolling shall be continued till the specified density of 97% is achieved. In case the specified compaction is not achieved. The site sample shall be collected from the bed and re-tested or analyze in the QC lab. The relevant quality assurance shall be build up as per the Quality Assurance Plan for

- 7. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 the concerned item. Subsequent layer shall be placed only after the finished layer has been tested as per the clause 903.2.2 and accepted. The top levels of the Subgrade shall be checked with reference to the longitudinal and cross profile of the road as per drawing to keep the variation within tolerance limit as per table 900-1. Minimum compaction for Sub Grade & Shoulders is 97% of modified proctor. Sr. No. TESTS Specification Frequencies 1 Sand Content IS: 2720 Part-4 2 tests per 3000 M3 . 2 Plasticity test IS: 2720 Part-5 2 tests per 3000 M3 for each type. 3 Max. Dry Density IS: 2720 Part-8 2 tests per 3000 M3 for each type. 4 Deleterious Content IS:2720 Part-27 As & when required by Engineer 5 Compaction Control IS:2720 Part-28 One test per 2000 M2 compacted area. No. of tests in one set of measurement min 10. 6 CBR on Soaked / Un soaked IS:2720 Part-16 One test per 3000 M3 or required by Engineer. 7 Tolerance in Surface Level - ±20 mm REQUEST FOR INSPECTION AND APPROVAL Request for inspection shall be placed a day before for the stretches going to be ready next day with tentatively time, Once the stretch is ready w.r.t. Surface level and compaction, Authority Engineer’s representative shall be requested for verification and approval of the same. If due to unavoidable circumstance the bed could not be get ready the Authority

- 8. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 Engineer shall be pre informed about the stretch and requested to close the RFI’s. The joint level and field density tests shall be conducted as per their instructions and requirements to verify the specification requirements. Authority Engineer’s representative shall give his approval based on these verifications. If any non conformance is detected he shall give his comment on the RFI for necessary corrections. The necessary corrections shall be done and re-verification shall be requested thereafter. Authority Engineer’s representatives shall re-verify and shall give their approval accordingly. After the approval of the said stretch is obtained the next stage of construction shall proceed. ARRANGEMENT OF TRAFFIC AND SAFETY DURING CONSTRUCTION Construction shall be carried out in a safe manner creating least interference possible to the flow of traffic. In case construction is to be carried out after diverting the traffic on a temporary diversion, prior approval of the arrangements at diversion shall be taken. If construction is to be carried out very near to the plying traffic necessary barricades, regulatory / informatory/ warning signs, flags, markers (white painted gunny bags / stones) shall be provided, erected and maintained during the construction. RECORDS 1. Level control sheet 2. Field Density test sheet. 3. RFI 4. Checklist of subgrade RISKS INVOLVED Collision of vehicles while moving on the site and on existing road adjacent to the site Spillage of excavated material on the existing road while transporting Toppling of vehicles/workers/inhabitants/animals in the borrow pits

- 9. LOGO METHOD STATEMENT FOR CONSTRUCTION OF SUBGRADE Project: Client: Consultant : Contractor: DATE : REV : PLANNING DEPARTMENT Method Statement No.: Page 1 0f 7 SAFETY PRECAUTIONS Appropriate Safety Signboards, barriers, delineators and other safeguards shall be provided as required by the nature and location of works. All operations will be carried out in accordance with safety requirements. All field personnel will use PPEs like safety shoes, helmets, reflecting jackets, dust masks etc. The borrow areas/ pits are properly enclosed by caution tape and sign boards to reduce the injuries to inhabitants and animals falling into it. All equipments/vehicles will be fitted with back horns and lightening, if required a Signal man will be provided at the borrow area location and at the dumping site. The hauling path is specified for better movement of vehicles and to reduce collision. Proper lightening will be provided at site if work is done in the night time. Unauthorized persons & visitors shall not be allowed within the construction zone Vehicle tracks shall be kept moist to prevent flying of dust particles with the vehicular movement.