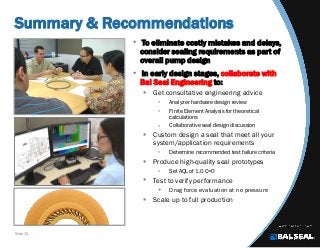

Designing clinical analyzers that deliver consistent, long-term service, efficiency, and accuracy is one tough job. But choosing the right seal can make it a lot easier.

That’s why we’ve prepared this short presentation for you. It examines the relationship between seal selection and the performance of hematology, urinalysis, and other analyzer types, and it addresses important design criteria, such as seal jacket material, lip geometry, and energizer force. It also suggests some ways to avoid common sealing mistakes that may be costing you time, money, and market share.