Arunresume

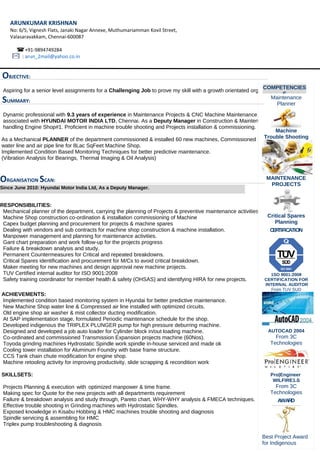

- 1. OBJECTIVE: Aspiring for a senior level assignments for a Challenging Job to prove my skill with a growth orientated organization SUMMARY: Dynamic professional with 9.3 years of experience in Maintenance Projects & CNC Machine Maintenance. Presently associated with HYUNDAI MOTOR INDIA LTD, Chennai. As a Deputy Manager in Construction & Maintenance team, handling Engine Shop#1. Proficient in machine trouble shooting and Projects installation & commissioning. As a Mechanical PLANNER of the department commissioned & installed 60 new machines, Commissioned centralized water line and air pipe line for 8Lac SqFeet Machine Shop. Implemented Condition Based Monitoring Techniques for better predictive maintenance. (Vibration Analysis for Bearings, Thermal Imaging & Oil Analysis) ORGANISATION SCAN: RESPONSIBILITIES: Mechanical planner of the department, carrying the planning of Projects & preventive maintenance activities. Machine Shop construction co-ordination & installation commissioning of Machine Capex budget planning and procurement for projects & machine spares Dealing with vendors and sub contracts for machine shop construction & machine installation. Manpower management and planning for maintenance activities. Gant chart preparation and work follow-up for the projects progress Failure & breakdown analysis and study. Permanent Countermeasures for Critical and repeated breakdowns. Critical Spares identification and procurement for M/Cs to avoid critical breakdown. Maker meeting for new machines and design approval new machine projects. TUV Certified internal auditor for ISO 9001:2008 Safety training coordinator for member health & safety (OHSAS) and identifying HIRA for new projects. ACHIEVEMENTS: Implemented condition based monitoring system in Hyundai for better predictive maintenance. New Machine Shop water line & Compressed air line installed with optimized circuits. Old engine shop air washer & mist collector ducting modification. At SAP implementation stage, formulated Periodic maintenance schedule for the shop. Developed indigenous the TRIPLEX PLUNGER pump for high pressure deburring machine. Designed and developed a job auto loader for Cylinder block in/out loading machine. Co-ordinated and commissioned Transmission Expansion projects machine (60Nos). Toyoda grinding machines Hydrostatic Spindle work spindle in-house serviced and made ok Cooling tower installation for Aluminum Foundry with base frame structure. CCS Tank chain chute modification for engine shop. Machine retooling activity for improving productivity, slide scrapping & recondition work SKILLSETS: Projects Planning & execution with optimized manpower & time frame. Making spec for Quote for the new projects with all departments requirement Failure & breakdown analysis and study through, Pareto chart, WHY-WHY analysis & FMECA techniques. Effective trouble shooting in Grinding machines with Hydrostatic Spindles. Exposed knowledge in Kisabu Hobbing & HMC machines trouble shooting and diagnosis Spindle servicing & assembling for HMC Triplex pump troubleshooting & diagnosis ARUNKUMAR KRISHNAN No: 6/5, Vignesh Flats, Janaki Nagar Annexe, Muthumariamman Kovil Street, Valasaravakkam, Chennai-600087 : +91-9894749284 : arun_2mail@yahoo.co.in Maintenance Planner Machine Trouble Shooting MAINTENANCE PROJECTS Critical Spares Planning CERTIFICATION S 1SO 9001:2008 CERTIFICATION FOR INTERNAL AUDITOR From TUV SUD AUTOCAD 2004 From 3C Technologies Pro|Engineer WILFIRE1.0 From 3C Technologies AWARD S Best Project Award for Indigenous Pump COMPETENCIES S Since June 2010: Hyundai Motor India Ltd, As a Deputy Manager.

- 2. PREVIOUS ASSIGNMENTS: Worked in LAKSHMI MACHINE WORKS PVT LTD as an Engineer in Maintenance department for Heavy Machine shop RESPONSIBILITIES & ACHEIVEMENTS: Shift Incharge for the maintenance department for regular breakdown handlings. Shift manpower planning for the maintenance activities. Planner for the planned preventive maintenance activities. Problem Diagnosis and correction in Mazak, Moriseiki, Zayer,Doosan,Bystronic Laser& Byler Bending machines Budget Planner for Heavy machines and sheet metal machines Installed Nordson Power coating booth chain conveyor. Commissioned & installed 4 BYSTRONIC Laser machines & Bending Machines Commissioned & installed 15 Mazak machines (FH10800, FH8800, FH6800, & FJV 100) with service engineer. Designed & developed an automatic drill & tapping machine. Designed and developed NRV for Mazak machine coolant line. Joined in Design Co India Pvt Ltd as a graduate engineer trainee in In-Process Quality team RESPONSIBILITIES & ACHEIVEMENTS: Developed SOPs for in-process Quality measurement Member for QMS formation team for ISO implementation EDUCATION: Completed BE Mechanical Engineering from Kumaraguru College of technology -Anna University, With an aggregate of 71%, passed out in May 2006. Completed my HSC from GKD Matric higher Secondary School Coimbatore, Passed out in year April2002, With an aggregate of 85.16% ACADEMIC AWARDS: First prize in Work Shop modeling contest held at Karunya Inst of tech-2005. First prize in 3D modeling contest held at GCT Coimbatore-2005 . Second prize in 3D modeling contest held at Karunya Institute of tech-2005. Merit certification for 3D modeling contest held at Park College of tech-2004. PERSONAL DOSSIER: Father Name : M Krishnan Date of Birth : 16th September1984 Age : 32 Marital Status : Married Languages known: English, Tamil I, E.K.ARUN KUMAR do hereby confirm that the information given above is true to the best of my knowledge. PLACE: CHENNAI E K Arun Kumar ITSKILLS Proficient in MS Excel, PPT & Word Super user in SAP PM & -End-User in SAP MM End-user in oracle EAM Module 1st Prize in Workshop Modelling at Karunya Egg College. 1st Prize in Design Modelling at GCT. 2nd Prize in Design Modelling at Karunya Egg College. ACADEMIC AWARDS From Nov 2006 to May 2010: Lakshmi Machine Works Pvt Ltd, As an Engineer. From Jun 2006 to Nov 2006: Design Co India Pvt Ltd, As an Graduate Engineer Trainee. Bachelor Mechanical Engineering: 2002~2006 Higher Secondary School: 2001~2002 Awards during Bachelor Mechanical Engineering: 2002~2006