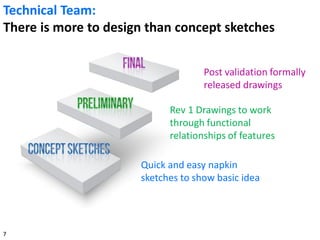

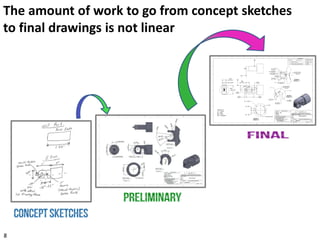

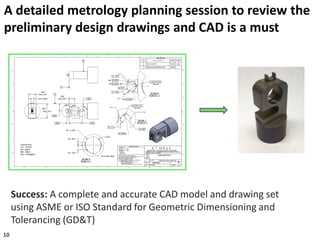

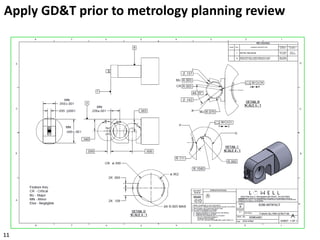

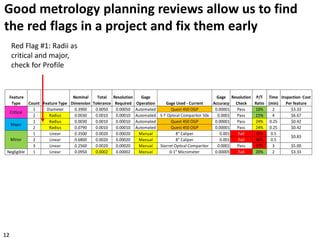

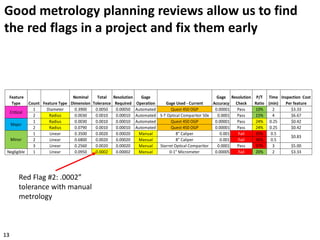

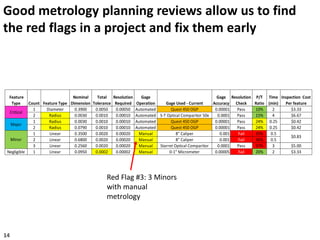

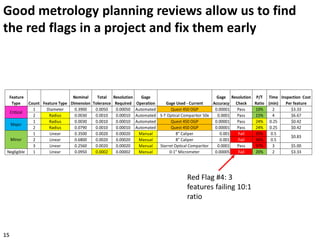

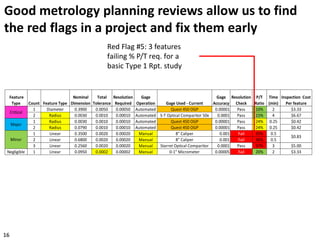

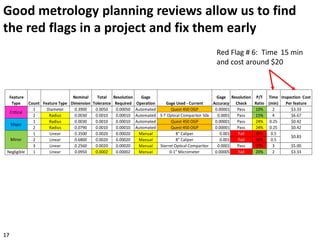

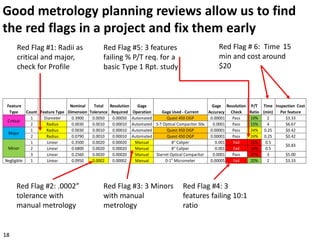

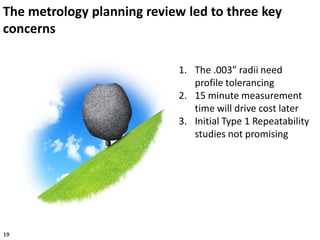

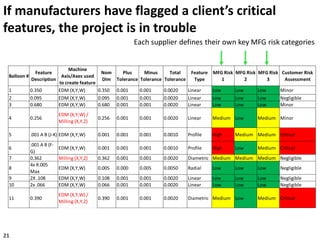

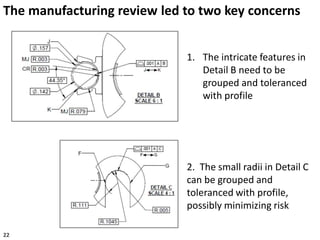

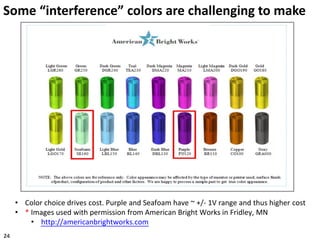

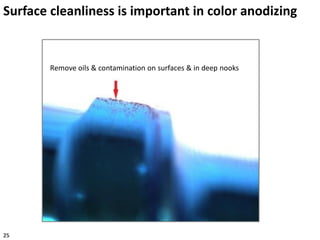

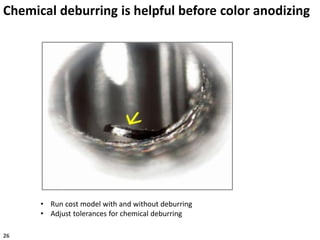

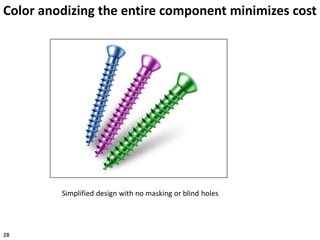

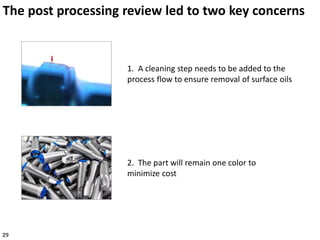

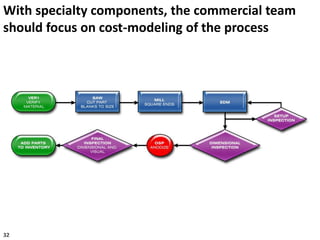

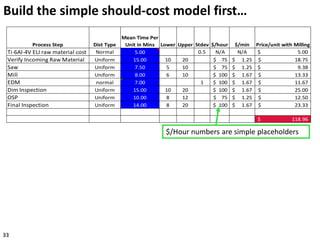

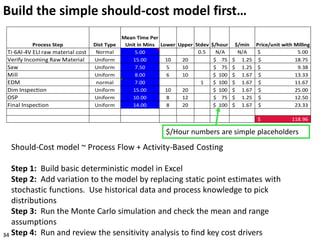

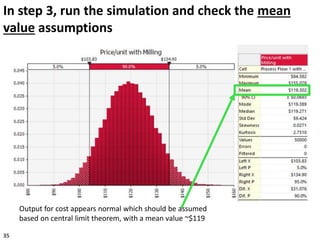

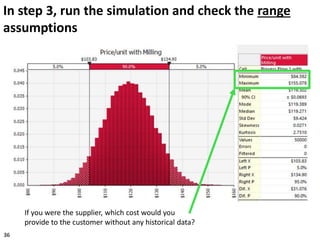

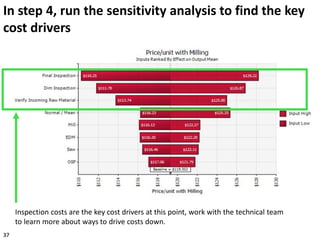

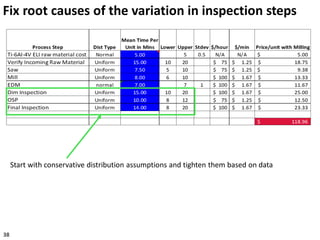

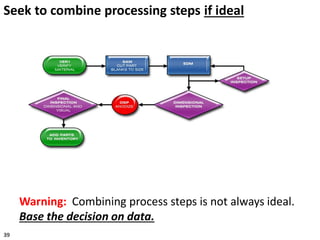

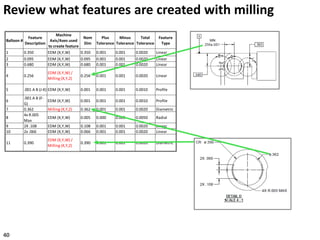

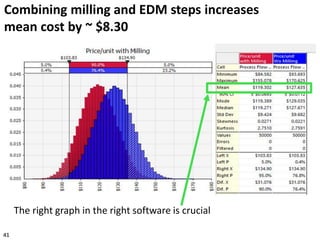

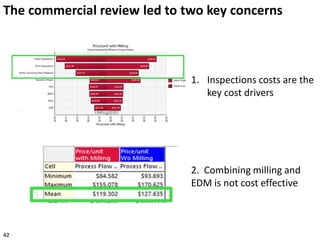

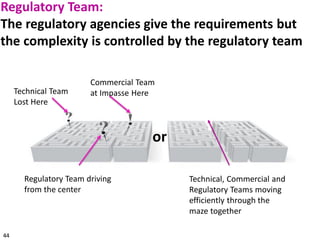

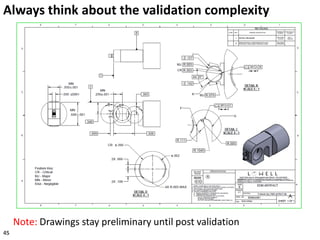

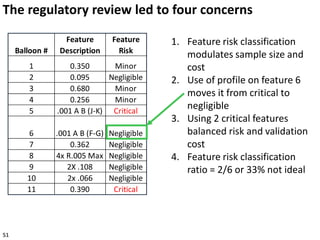

The document presents a detailed overview of the design for manufacturability (DFM) process at Lowell Inc., focusing on the regulatory, commercial, and technical teams involved. It emphasizes the importance of metrology planning reviews to identify and address potential issues early in the design and manufacturing stages, highlighting key red flags such as tolerance challenges and inspection costs. Additionally, it outlines concerns raised during both metrology and manufacturing reviews, stressing the need for careful tolerancing and risk assessment of manufacturing features.