API Project Poster

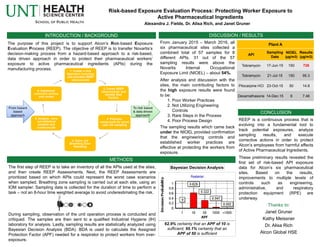

- 1. Risk-based Exposure Evaluation Process: Protecting Worker Exposure to Active Pharmaceutical Ingredients Alexandra J. Fields, Dr. Alisa Rich, and Janet Gruner DISCUSSION / RESULTS METHODS CONCLUSION Thanks to: Janet Gruner Kathy Meissner Dr. Alisa Rich Alcon Global HSE The purpose of this project is to support Alcon’s Risk-based Exposure Evaluation Process (REEP). The objective of REEP is to transfer Novartis’s decision-making process from a hazard-based approach to a risk-based, data driven approach in order to protect their pharmaceutical workers’ exposure to active pharmaceutical ingredients (APIs) during the manufacturing process. The first step of REEP is to take an inventory of all the APIs used at the sties, and then create REEP Assessments. Next, the REEP Assessments are prioritized based on which APIs could represent the worst case scenarios when sampled. Breathing zone sampling is carried out at each site, using an IOM sampler. Sampling data is collected for the duration of time to perform a task – not an 8-hour time weighted average to avoid underestimating the risk. During sampling, observation of the unit operation process is conducted and critiqued. The samples are then sent to a qualified Industrial Hygiene (IH) laboratory for analysis. Lastly, sampling results are statistically analyzed using Bayesian Decision Analysis (BDA). BDA is used to calculate the Assigned Protection Factor (APF) needed for a respirator to protect workers from over- exposure. Bayesian Decision Analysis REEP is a continuous process that is evolving into a fundamental tool to track potential exposures, analyze sampling results, and execute corrective actions in order to protect Alcon’s employees from harmful effects of Active Pharmaceutical Ingredients. These preliminary results revealed the first set of risk-based API exposure data for Alcon’s six pharmaceutical sites. Based on the results, improvements to multiple levels of controls such as engineering, administrative, and respiratory protection equipment (RPE) are underway. From January 2015 – March 2016, all six pharmaceutical sites collected a combined total of 57 samples for 8 different APIs. 31 out of the 57 sampling results were above the Novartis Internal Occupational Exposure Limit (NIOEL) – about 54%. After analysis and discussion with the sites, the main contributing factors to the high exposure results were found to be: 1. Poor Worker Practices 2. Not Utilizing Engineering Controls 3. Rare Steps in the Process 4. Poor Process Design The sampling results which came back under the NIOEL provided confirmation that the engineering controls and established worker practices are effective at protecting the workers from exposure. INTRODUCTION / BACKGROUND Plant A API Sampling Date NIOEL (µg/m3) Results (µg/m3) Tobramycin 17-Jun-15 150 726 Tobramycin 21-Jul-15 150 95.3 Pilocarpine HCl 23-Oct-15 50 14.8 Dexamethasone 14-Dec-15 8 7.46 62.9% certainty that an APF of 10 is sufficient; 95.1% certainty that an APF of 50 is sufficient