Recommended

Recommended

More Related Content

What's hot

What's hot (10)

Cutting Aerospace Validation Costs in Half Using Computational Testing

Cutting Aerospace Validation Costs in Half Using Computational Testing

Extend gearbox life with new components and methods 2015.04.21

Extend gearbox life with new components and methods 2015.04.21

Study and Analysis of Tire Changing Machine Components

Study and Analysis of Tire Changing Machine Components

Use of FEA to Improve the Design of Suspension Springs for Reciprocating Comp...

Use of FEA to Improve the Design of Suspension Springs for Reciprocating Comp...

Similar to Expo Poster

Similar to Expo Poster (20)

Development of PLC based Transdermal Patch Evaluation System

Development of PLC based Transdermal Patch Evaluation System

Optimization of Cutting Parameters for MRR in Turning Process of EN-31 Steel ...

Optimization of Cutting Parameters for MRR in Turning Process of EN-31 Steel ...

360 SIMS - The Power of large data for 3D metrology and process control

360 SIMS - The Power of large data for 3D metrology and process control

คาลิเบรท เครื่องจักร CNC ด้วย Renishaw QC20 Ballbar Calibration

คาลิเบรท เครื่องจักร CNC ด้วย Renishaw QC20 Ballbar Calibration

Automated Analysis of Natural-Language Requirements: Industrial Needs and Opp...

Automated Analysis of Natural-Language Requirements: Industrial Needs and Opp...

STUDY AND ANALYSIS OF DIFFERENTIAL CONTROLLED CONTINUOUSLY VARIABLE DRIVE

STUDY AND ANALYSIS OF DIFFERENTIAL CONTROLLED CONTINUOUSLY VARIABLE DRIVE

Expo Poster

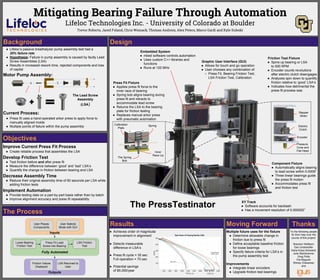

- 1. Design Mitigating Bearing Failure Through Automation Lifeloc Technologies Inc. - University of Colorado at Boulder Trevor Roberts, Jared Foland, Chris Womack, Thomas Andress, Alex Peters, Marco Gardi and Kyle Suleski ● Lifeloc’s passive breathalyzer pump assembly test had a 20% failure rate ● Hypothesis: Failure in pump assembly is caused by faulty Lead Screw Assemblies (LSA) ● Results in increased rework time, rejected components and loss of capital Motor Pump Assembly: Current Process: ● Press fit uses a hand-operated arbor press to apply force to manually aligned molds ● Multiple points of failure within the pump assembly Background ● Achieves order of magnitude improvement in alignment ● Detects measurable difference in LSA’s ● Press fit cycle = 35 sec Full operation = 70 sec ● Potential savings of $5,000/year Results The Lead Screw Assembly (LSA) To the following people for their help over the course of this project: Brandon Wellborn Dan Underkofler Daria Kotys-Schwartz Julie Steinbrenner Greg Potts Pat Maguire Shirley Chessman and Thanks The Process Fully Automated Loose Bearing Friction Test Press Fit Lead Screw into Bearing LSA Friction Test Inputs User Places Components User Selects Mode with GUI Outputs LSA Returned to User Friction Values Displayed Improve Current Press Fit Process ● Create reliable process that assembles the LSA Develop Friction Test ● Test friction before and after press fit ● Measure the difference between ‘good’ and ‘bad’ LSA’s ● Quantify the change in friction between bearing and LSA Decrease Assembly Time ● Reduce their original assembly time of 60 seconds per LSA while adding friction tests Implement Automation ● Provide testing data on a part-by-part basis rather than by batch ● Improve alignment accuracy and press fit repeatability Objectives Bad LSA’s Free Spinning Friction Test Good LSA’s The PressTestinator Graphic User Interface (GUI) ● Allows for touch and go operation ● User chooses any combination of: ○ Press Fit, Bearing Friction Test, LSA Friction Test, Calibration Press Fit Fixture ● Applies press fit force to the inner race of bearing ● Spring bob aligns bearing during press fit and retracts to accommodate lead screw ● Returns the LSA to the bearing plate for friction testing ● Replaces manual arbor press with pneumatic automation Embedded System ● mbed software controls automation ● Uses custom C++ libraries and functions ● Runs at 120 MHz Friction Test Fixture ● Spins up bearing or LSA to 500 RPM ● Encoder counts revolutions after electric clutch disengages ● Analyzes spin down to quantify friction relative to ‘good’ LSA’s ● Indicates how detrimental the press fit process was XY Track ● Software accounts for backlash ● Has a movement resolution of 0.000025” Component Fixture ● Automatically aligns bearing to lead screw within 0.0009” ● Three linear bearings guide the press fit motion ● Accommodates press fit and friction test The Spring Bob Inner Race Lip SpringCalibration Plate Multiple future uses for the fixture ● Determine allowable change in friction due to press fit ● Define acceptable baseline friction for loose bearings ● Specify failure criteria for LSA’s in the pump assembly test Improvements ● Integrate linear encoders ● Upgrade friction test bearings Moving Forward Electric Clutch Encoder Pressure Cone and Flat Head Stepper Motor