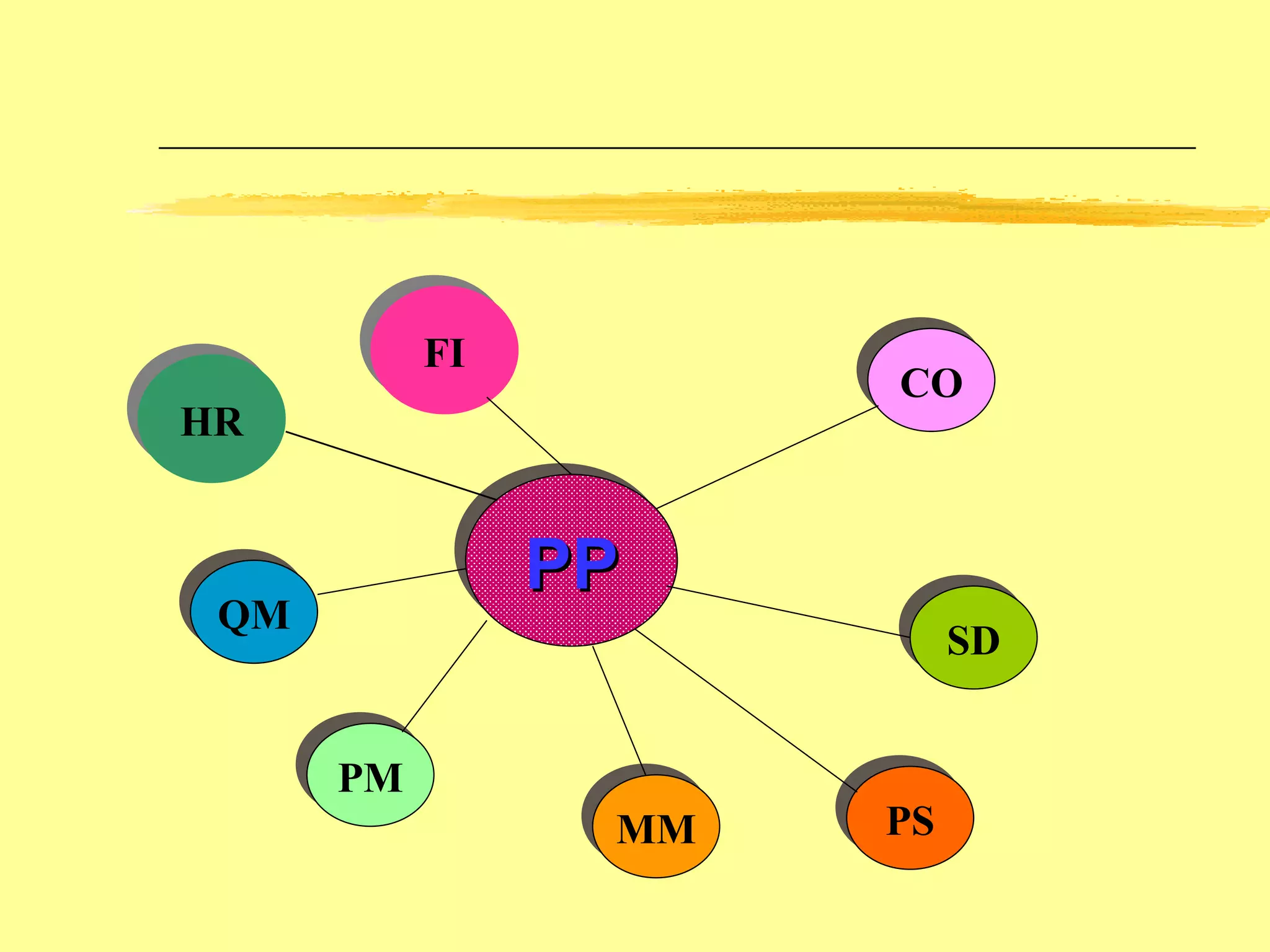

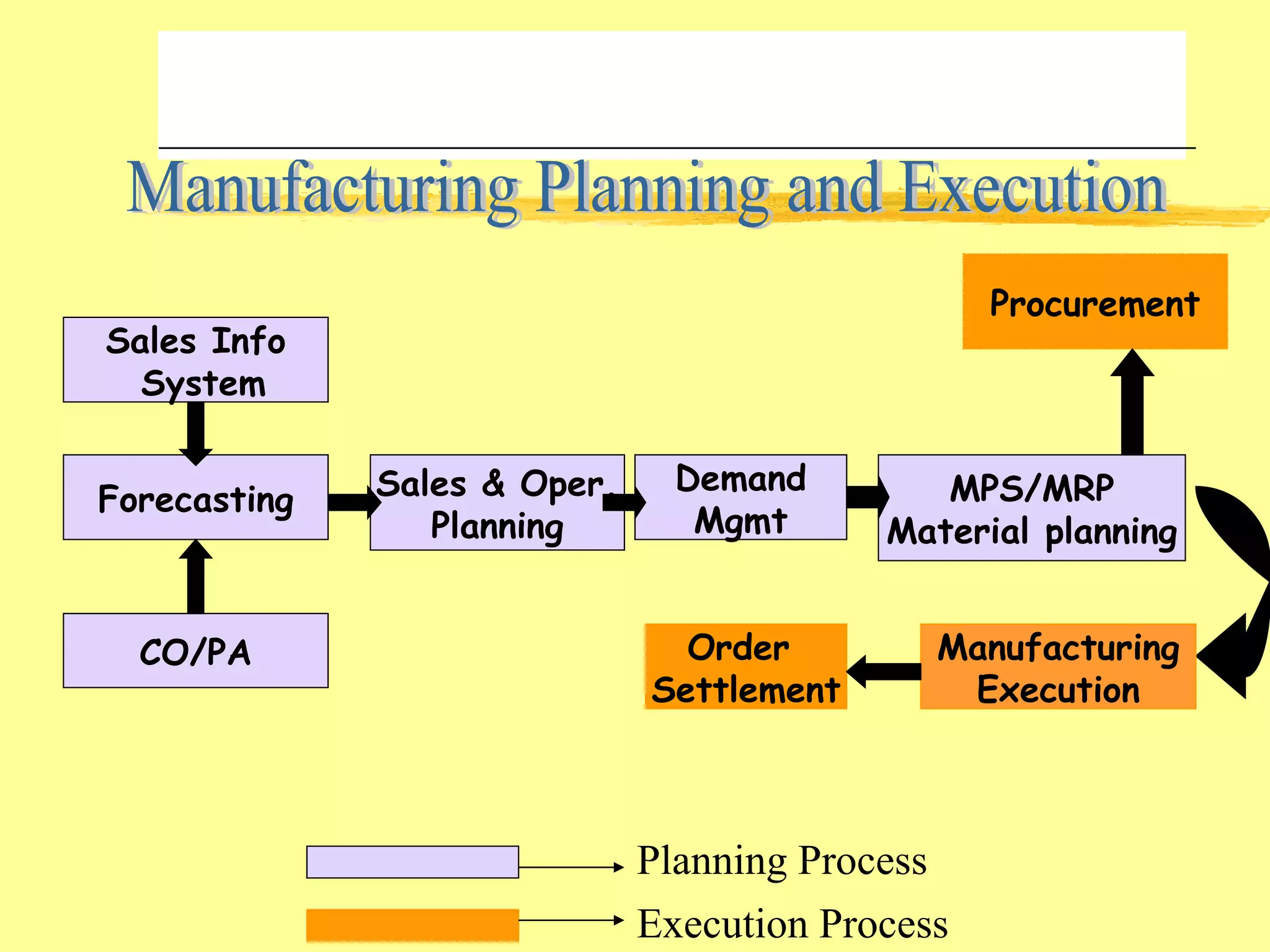

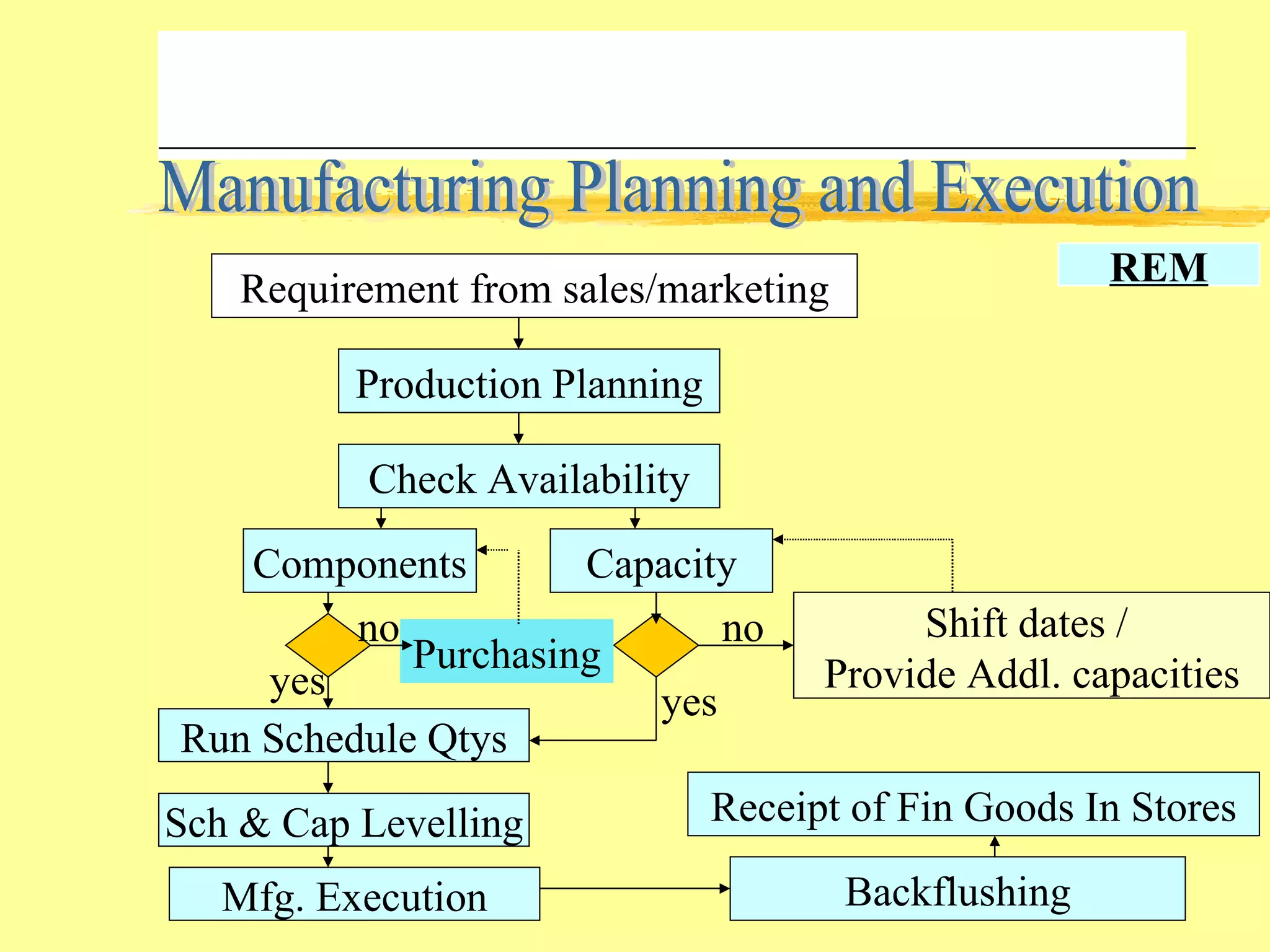

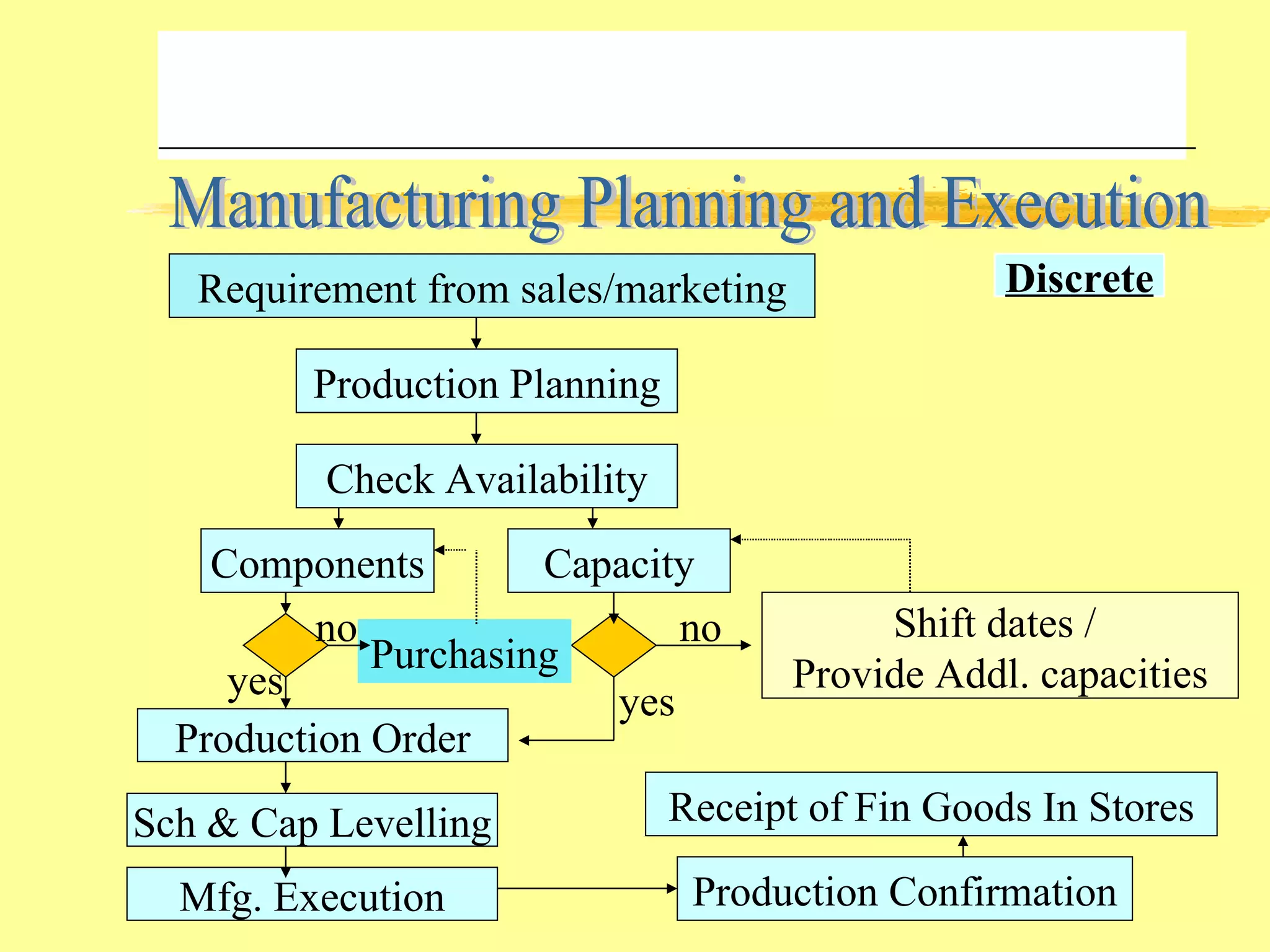

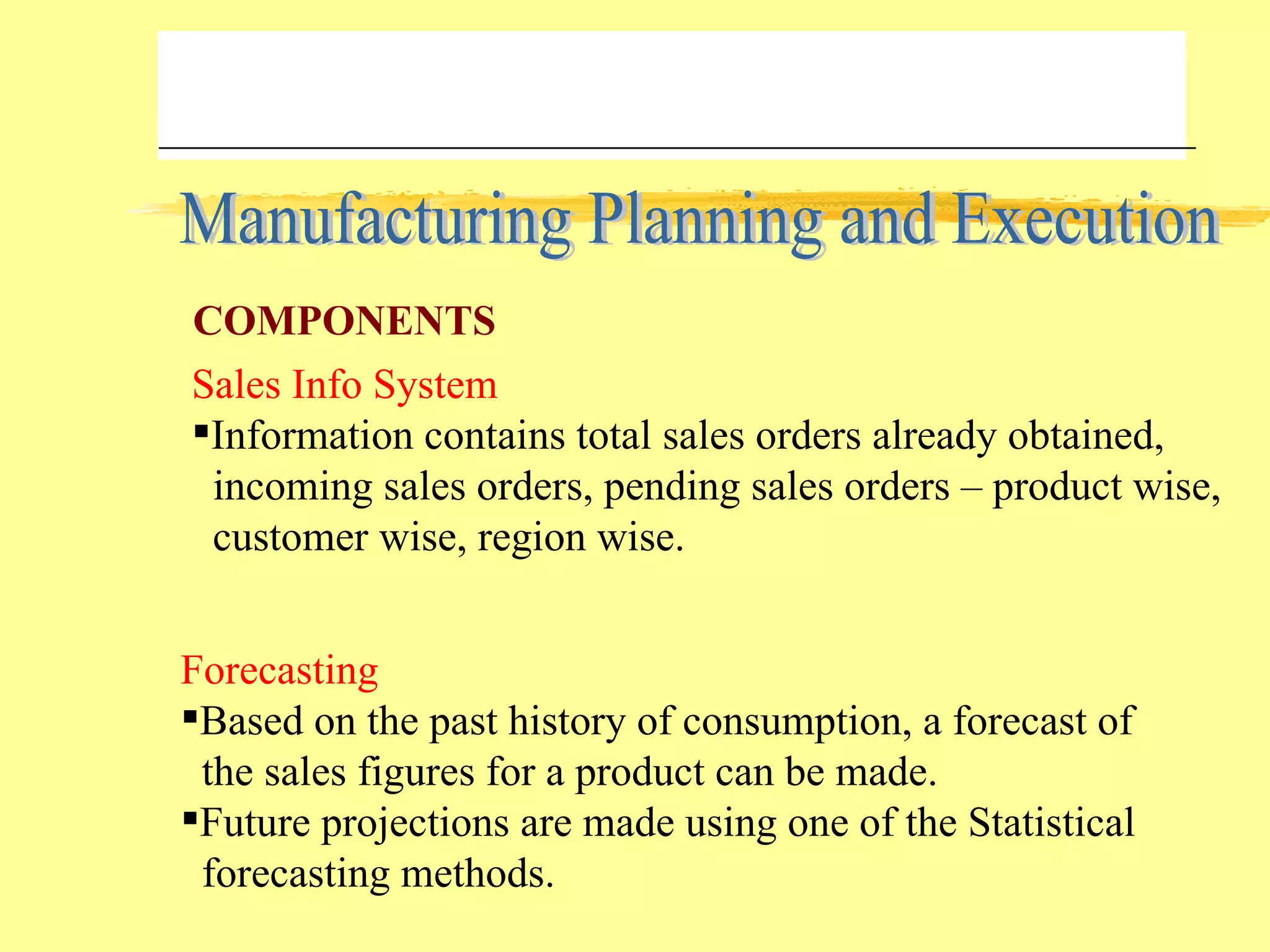

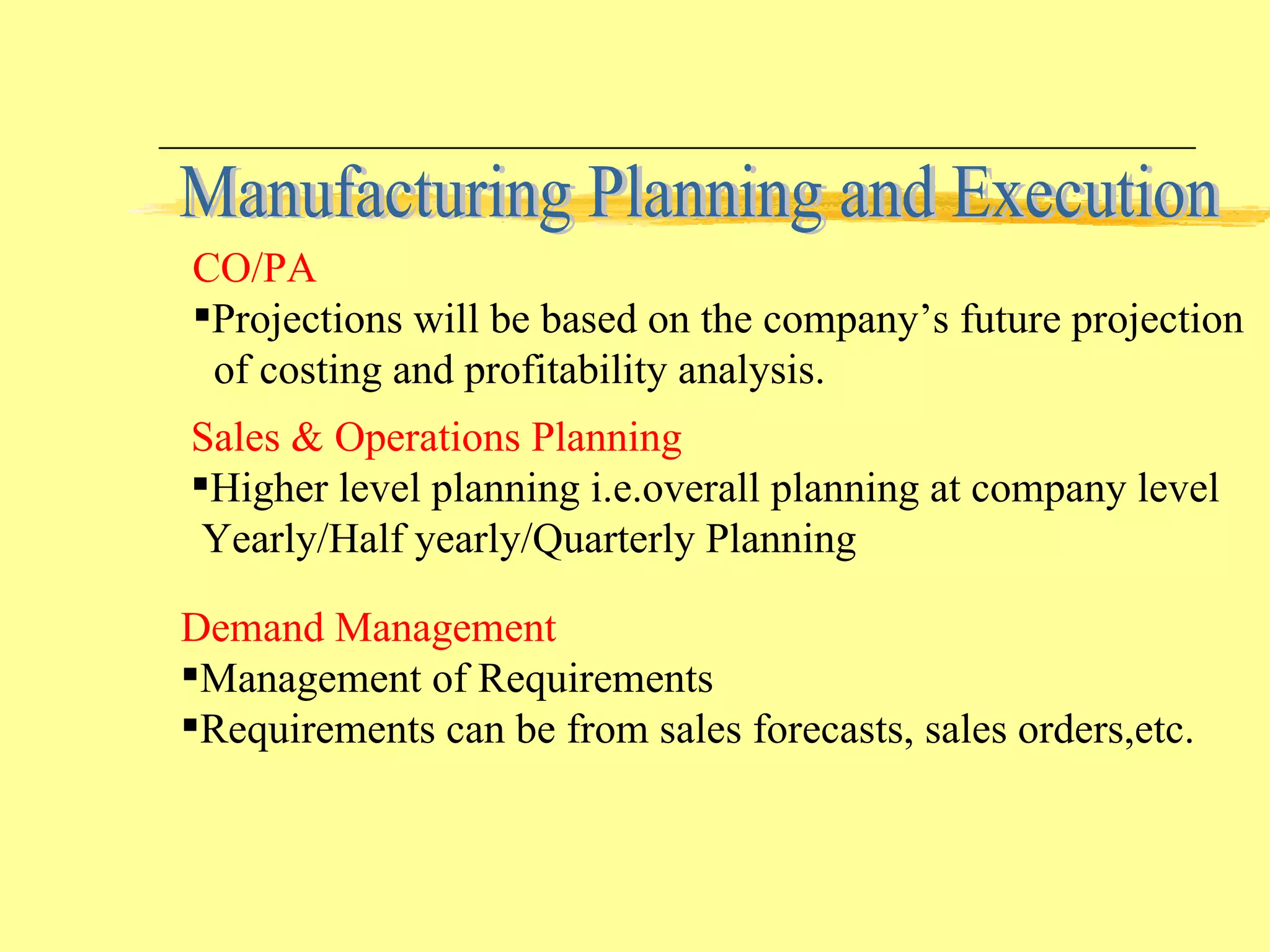

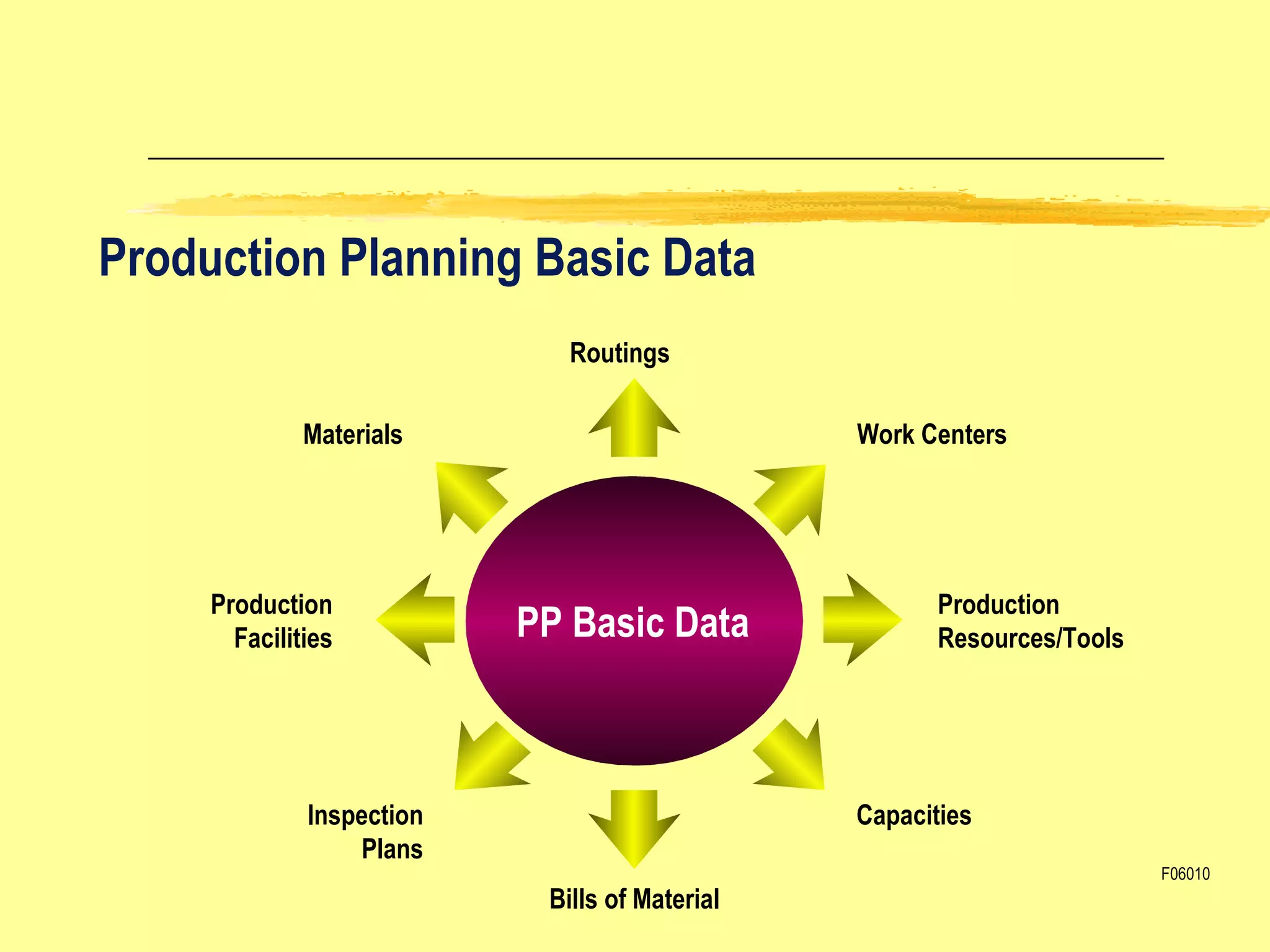

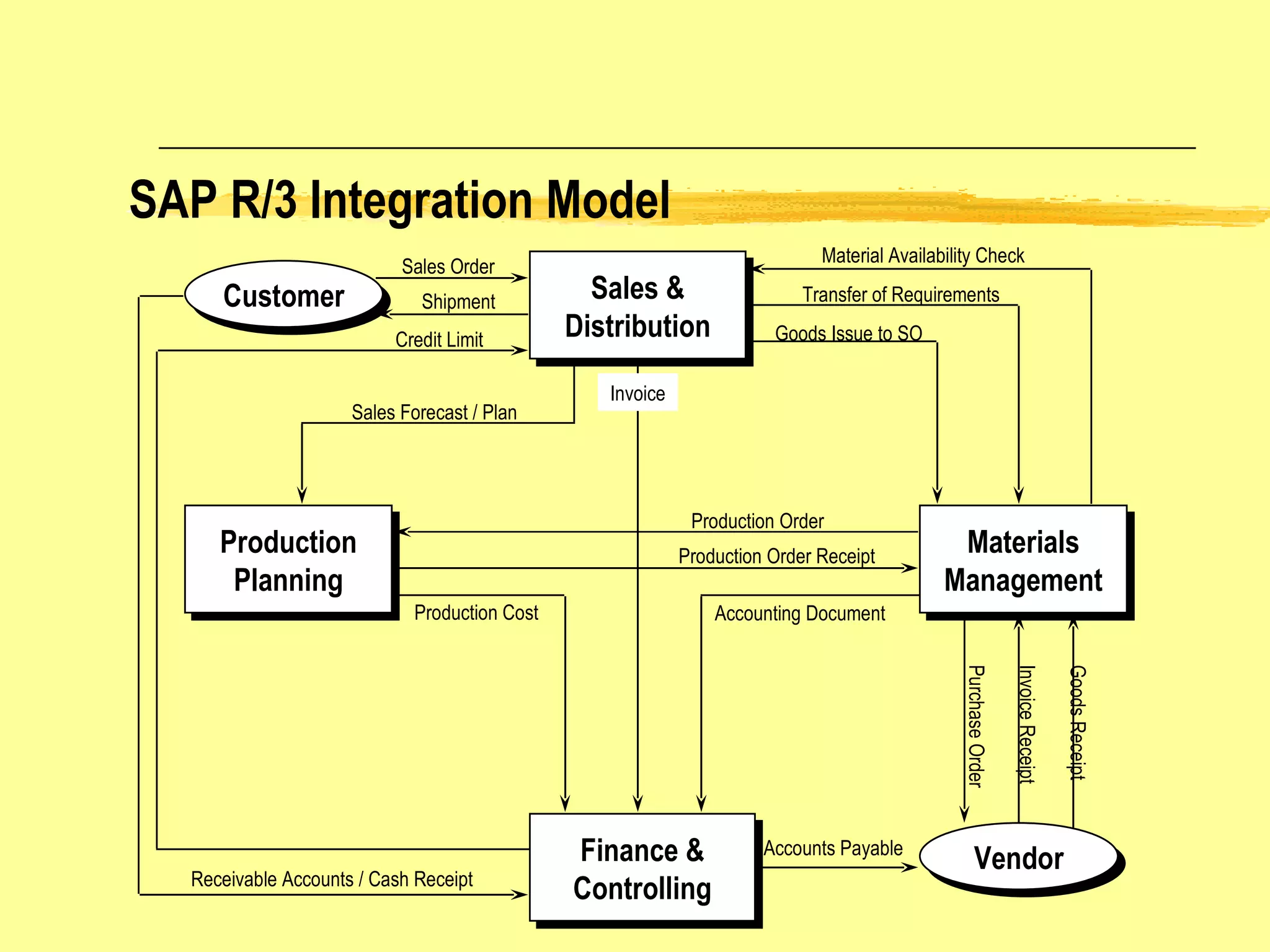

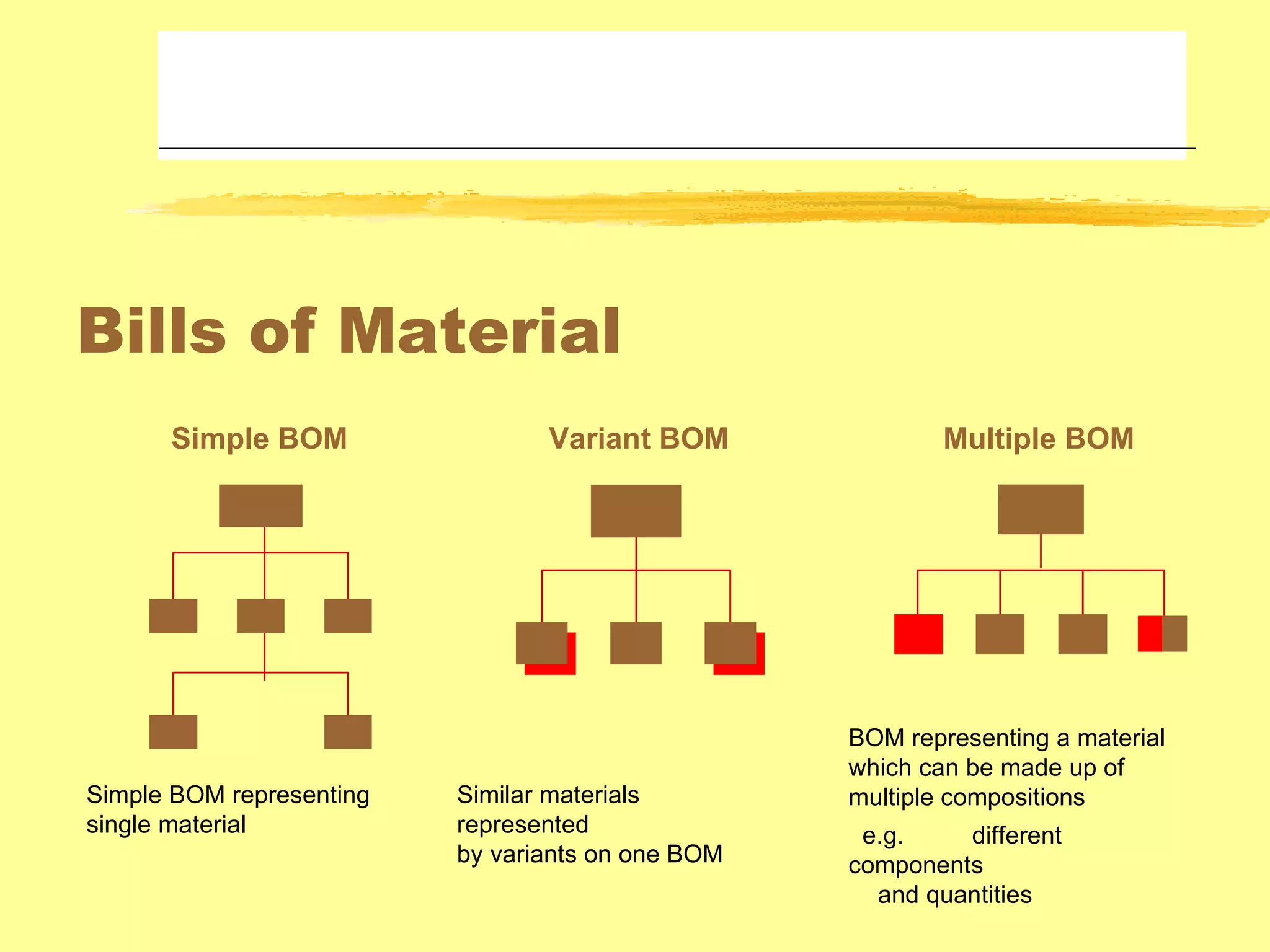

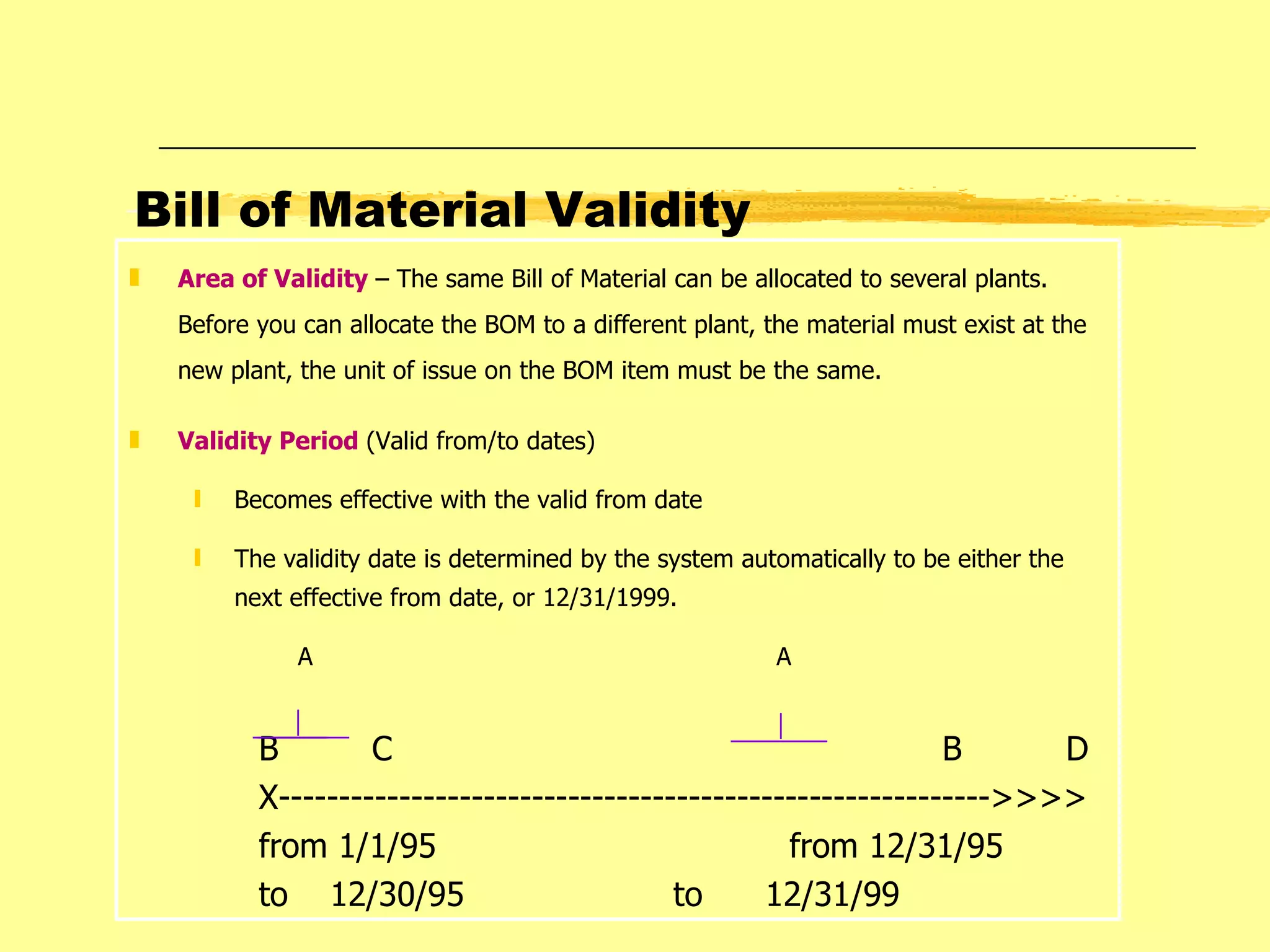

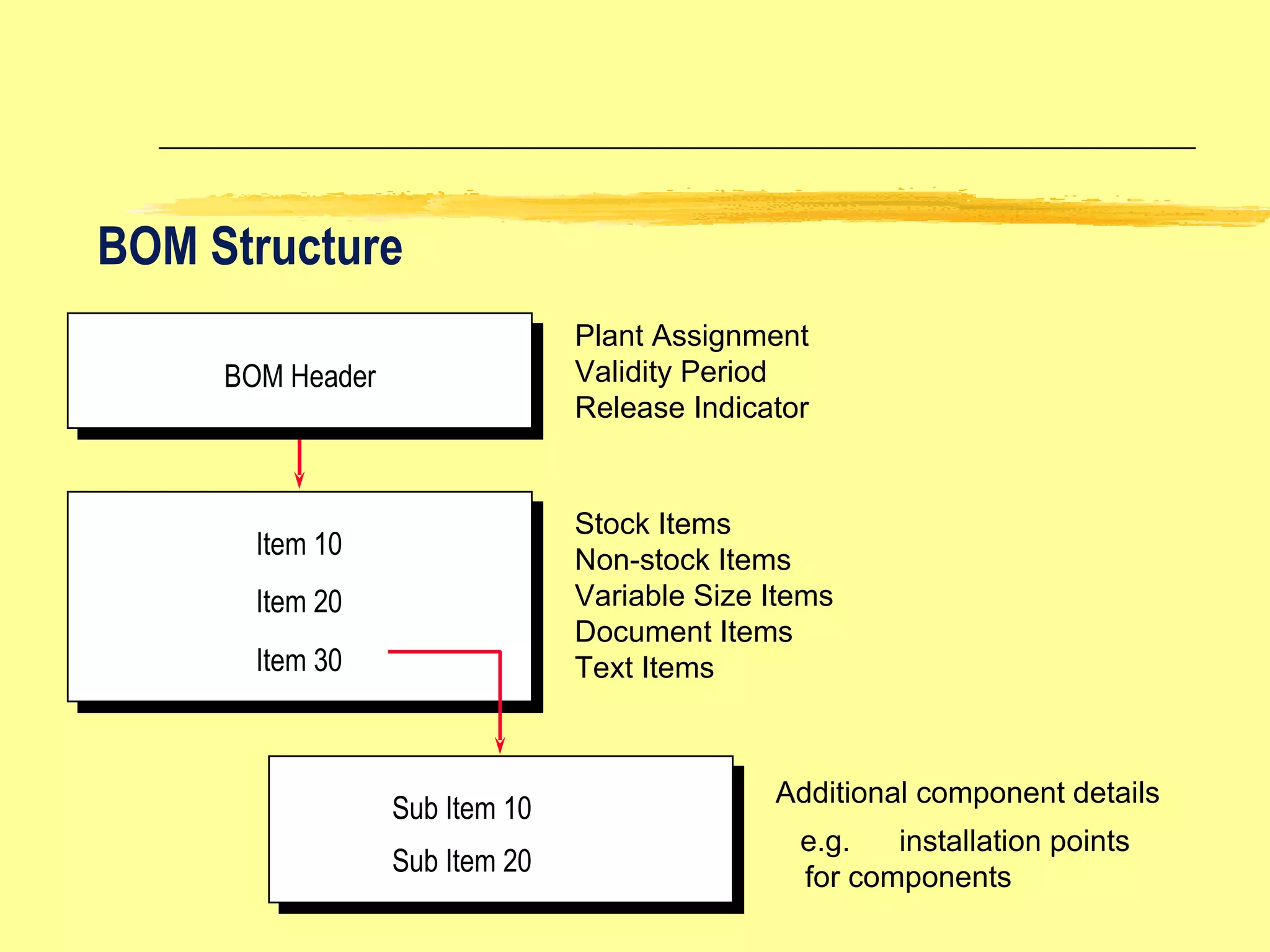

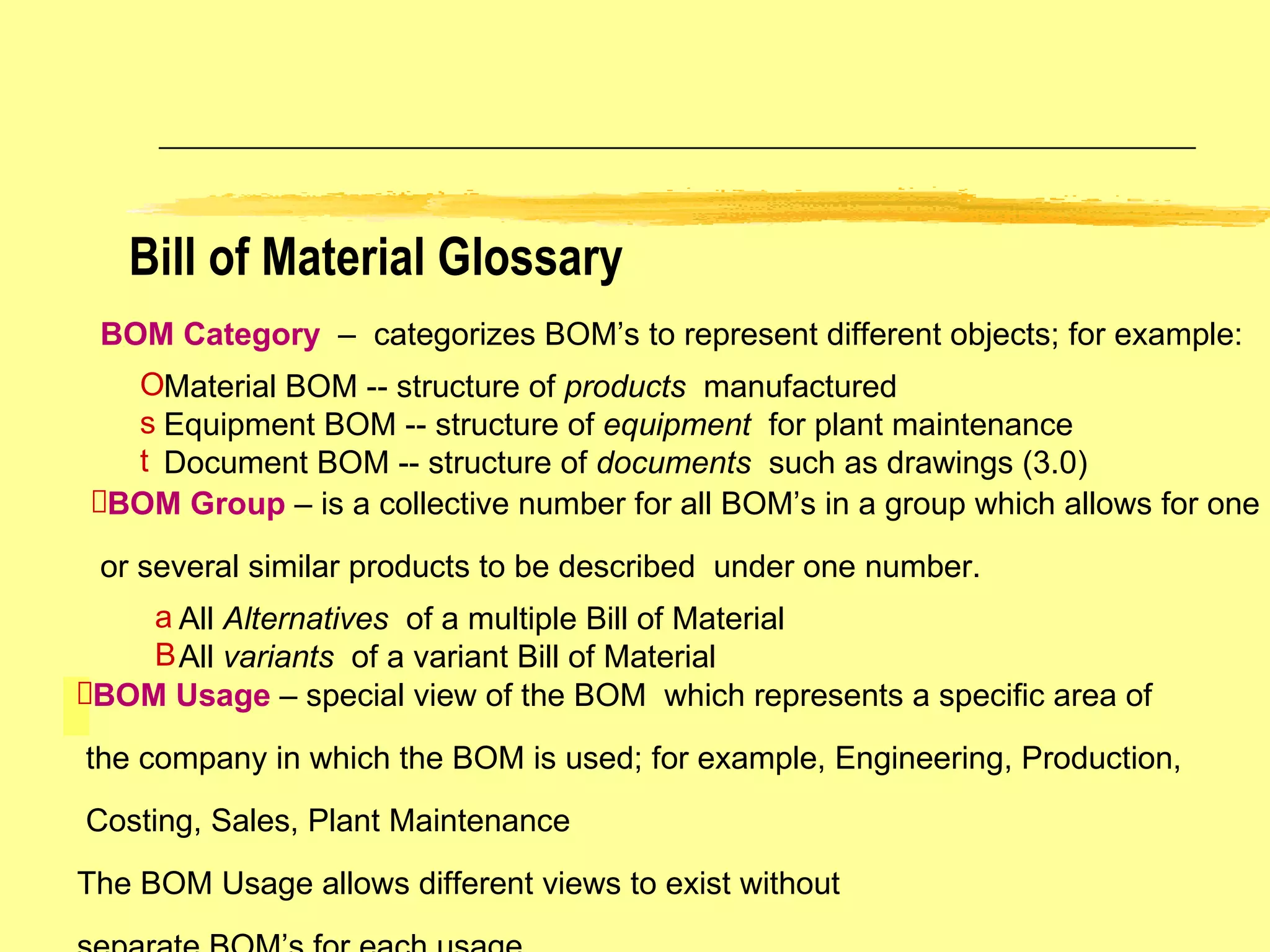

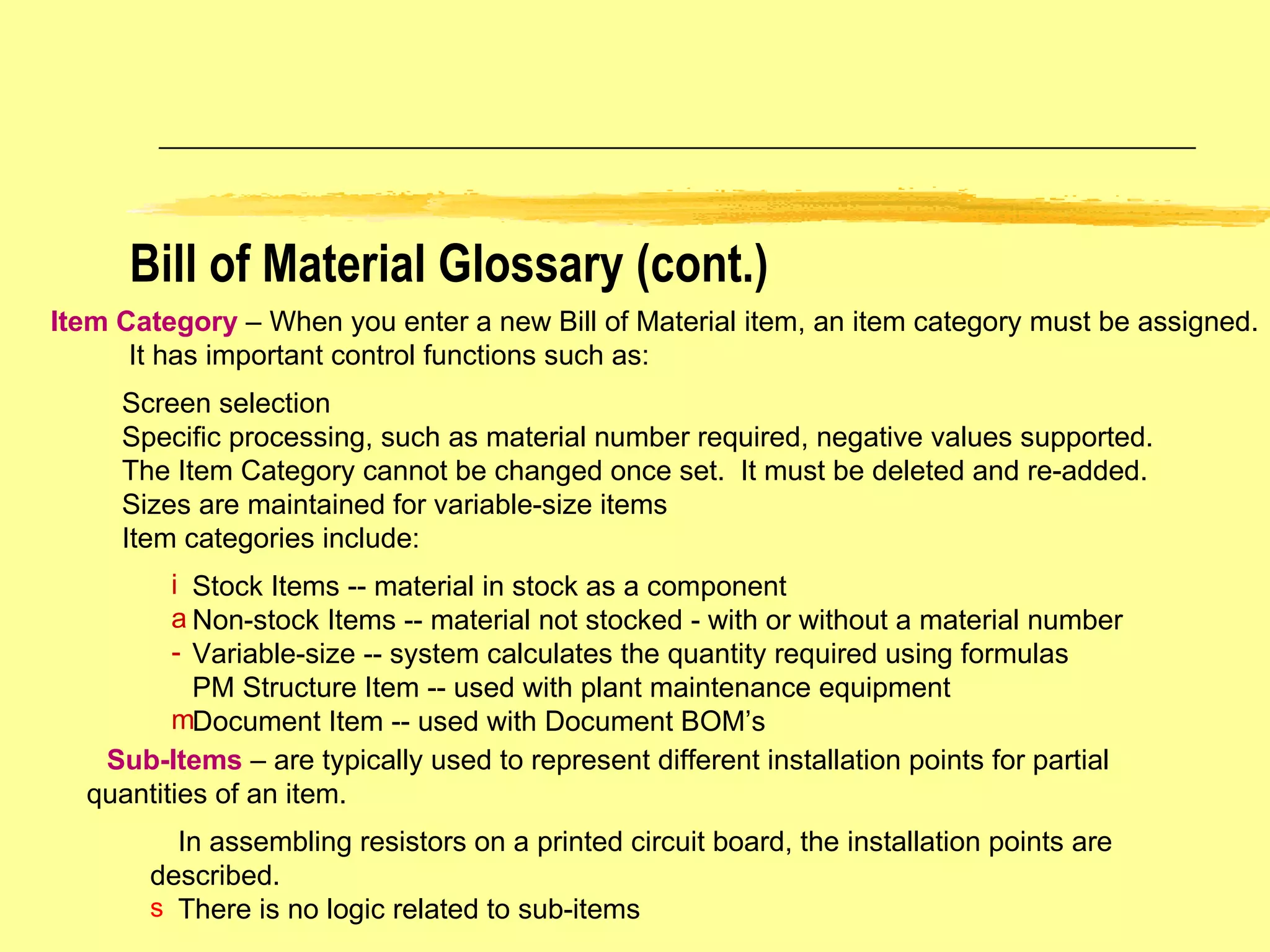

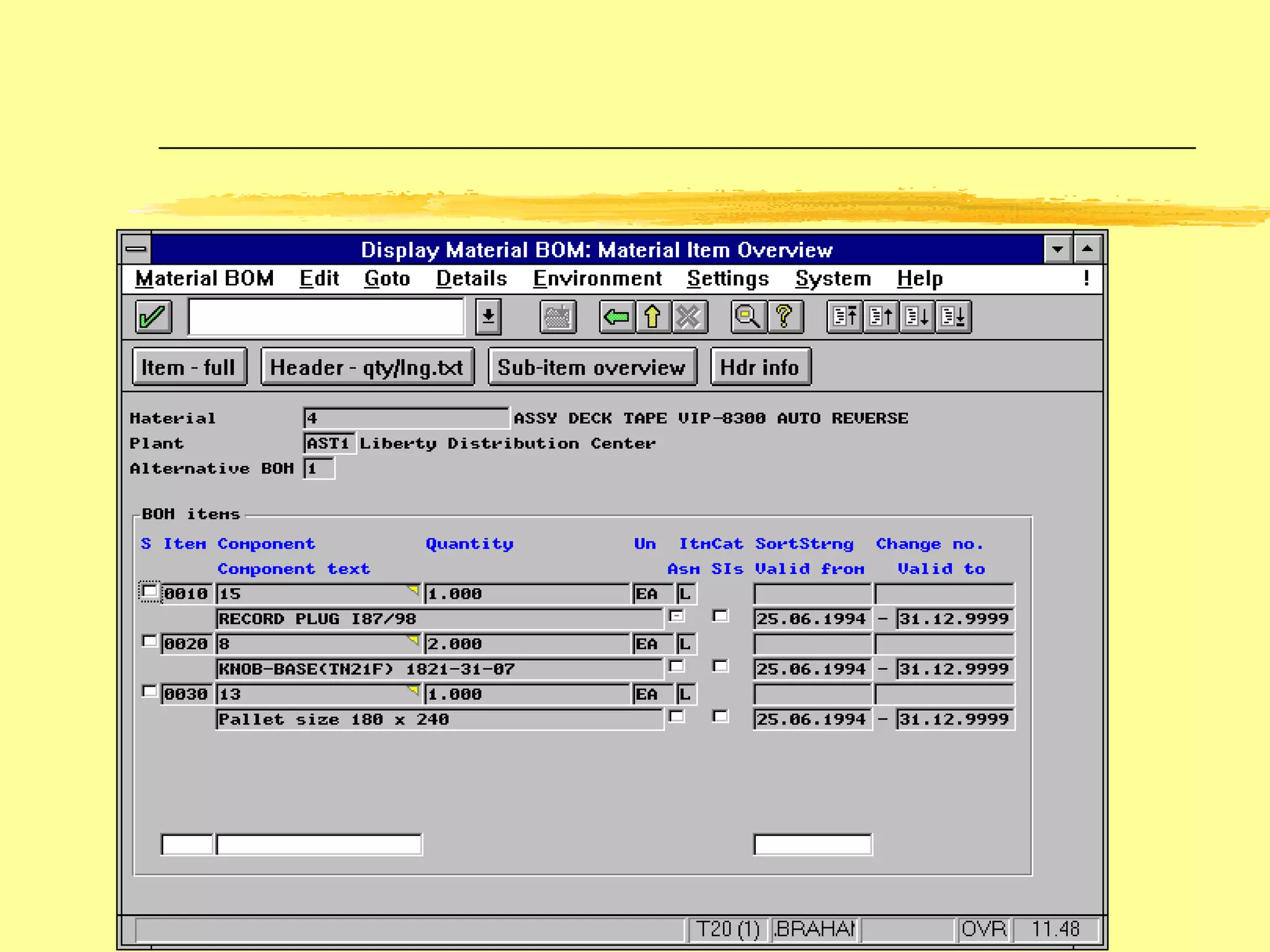

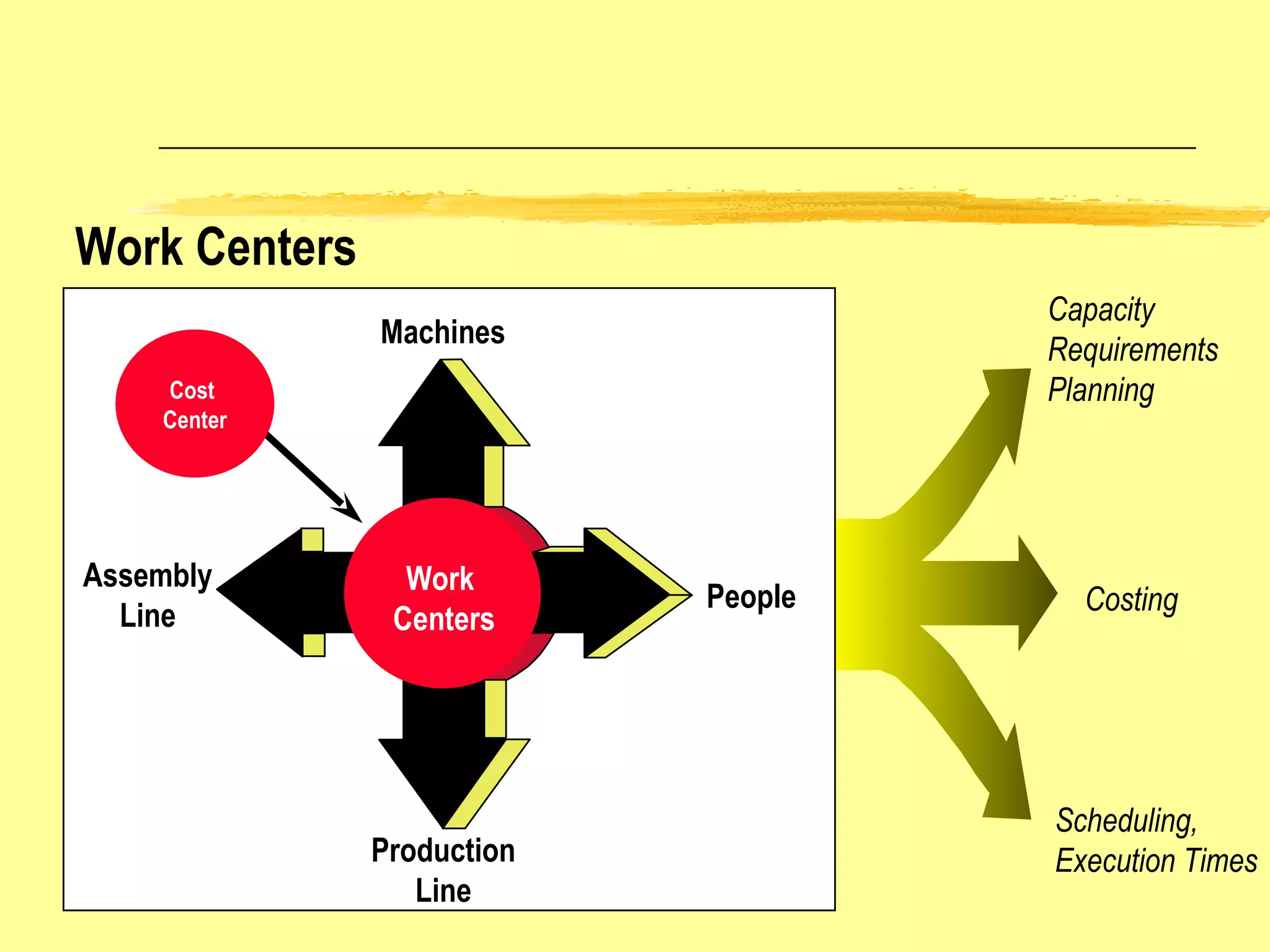

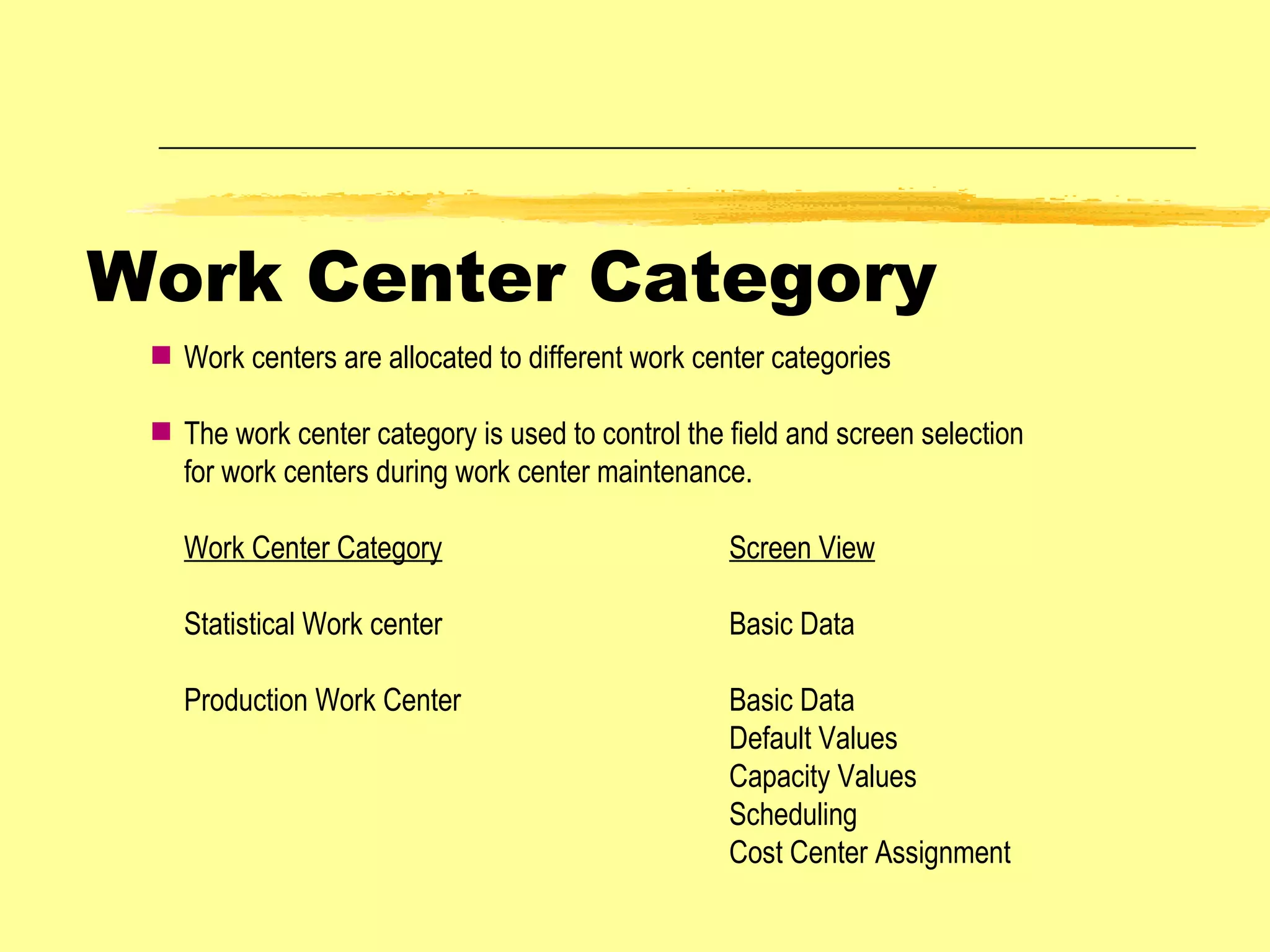

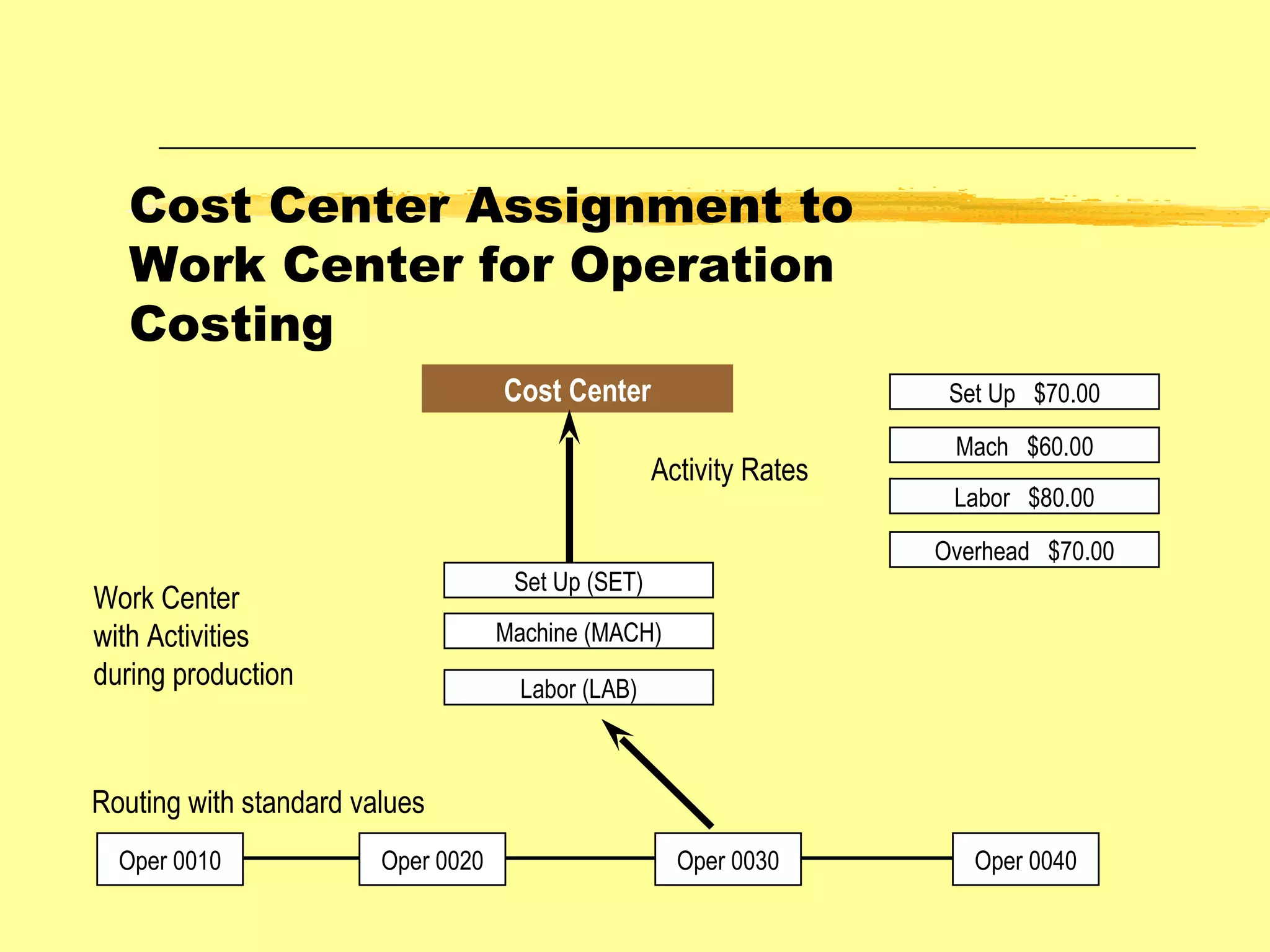

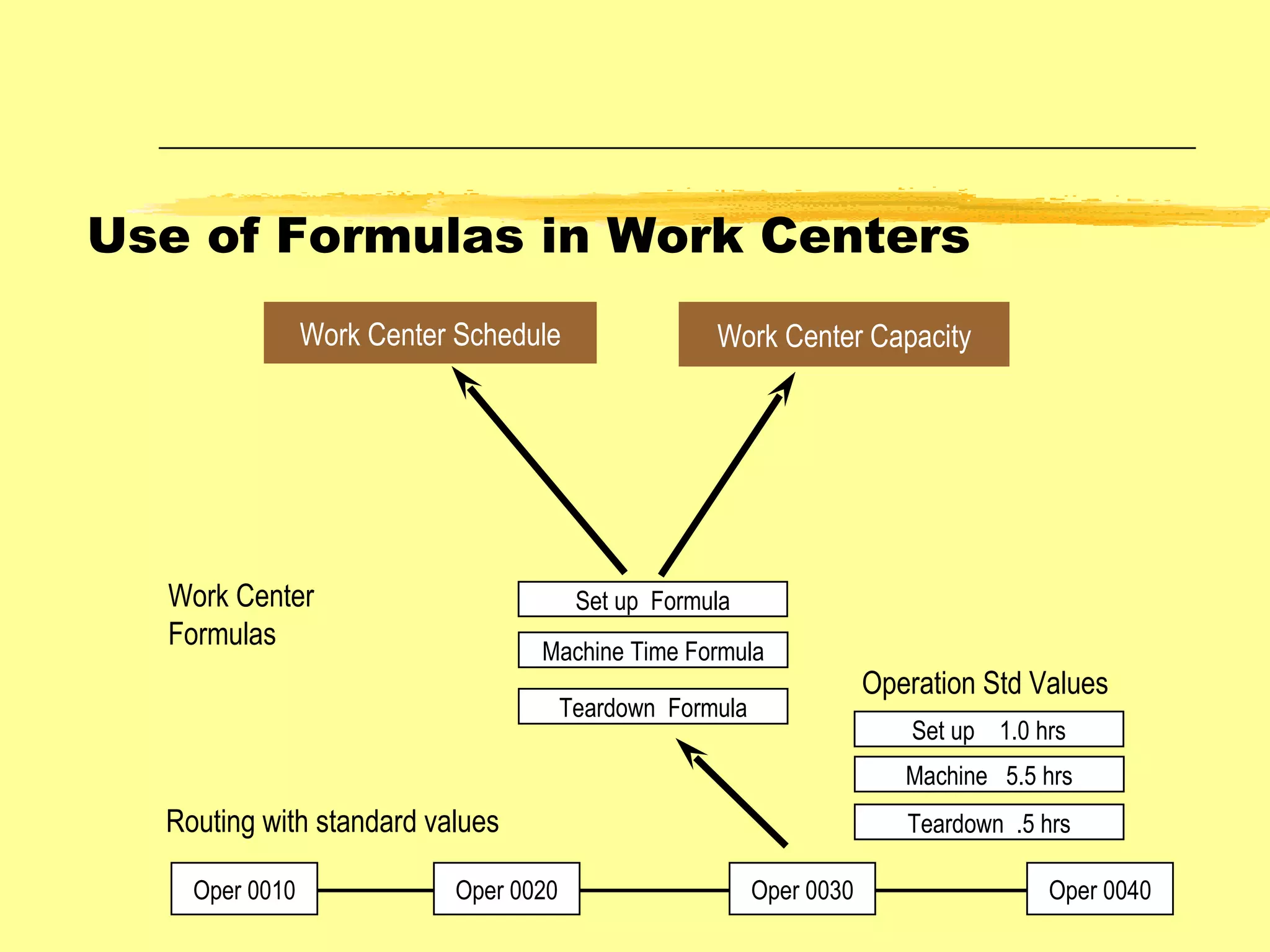

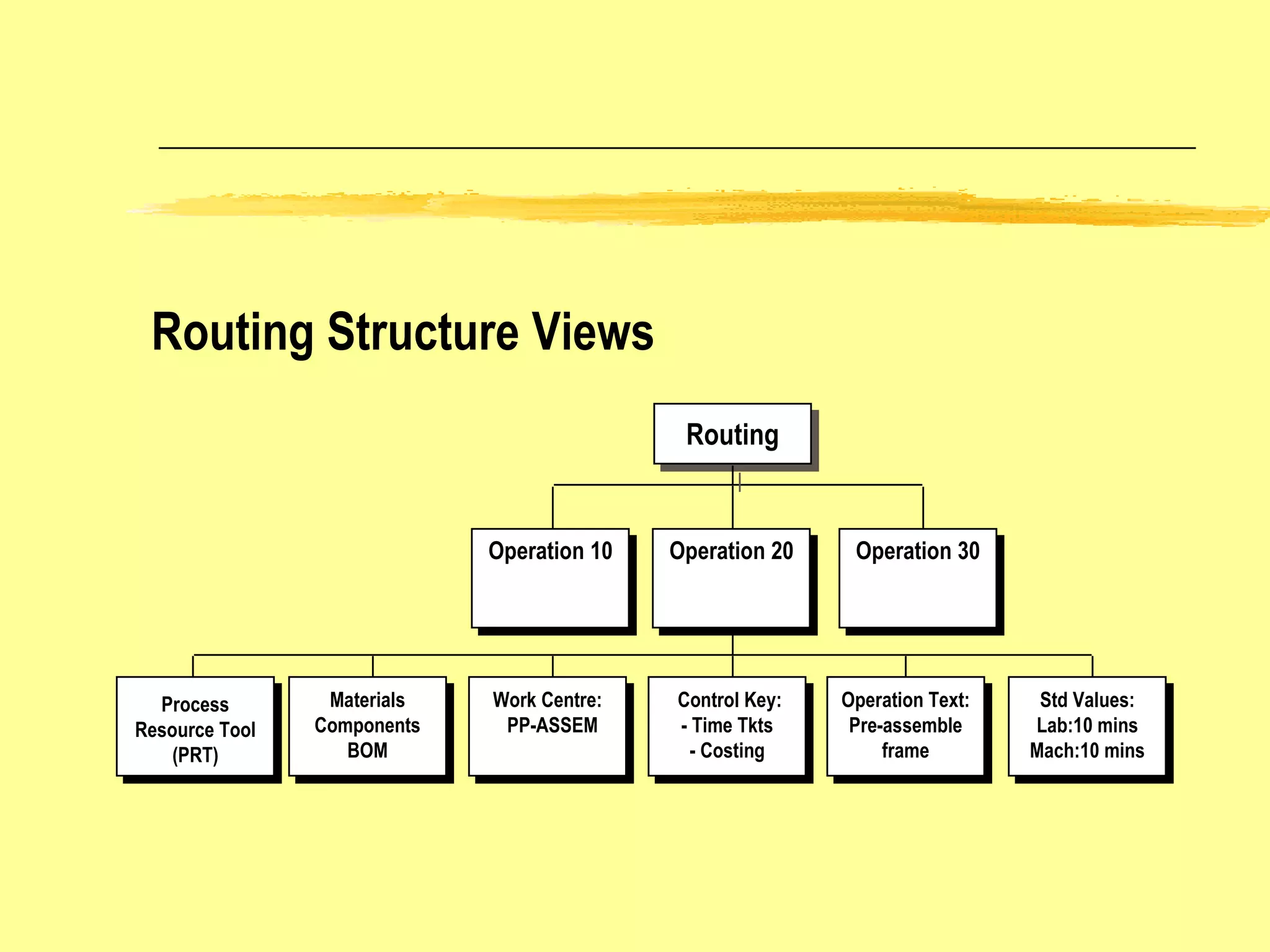

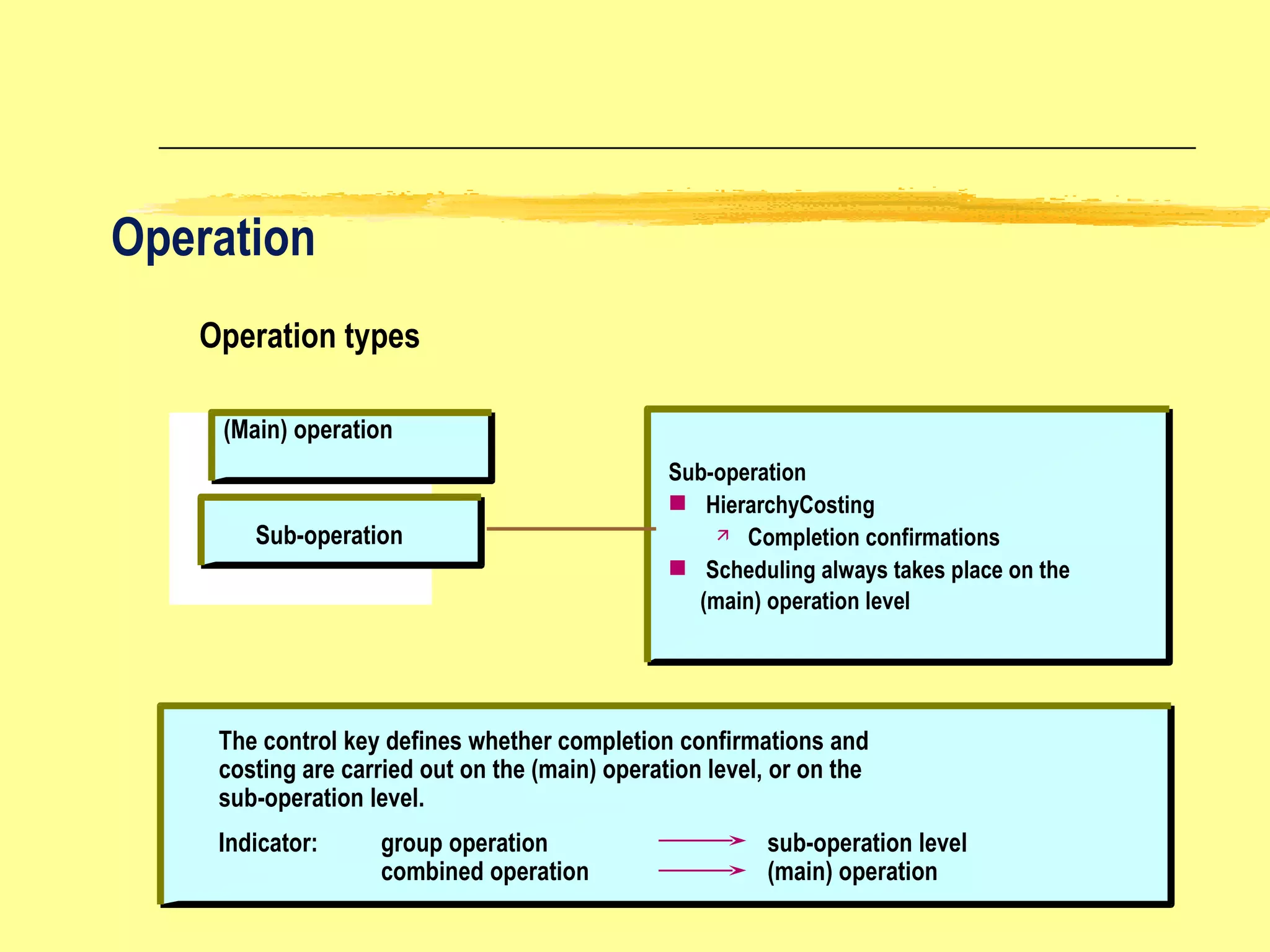

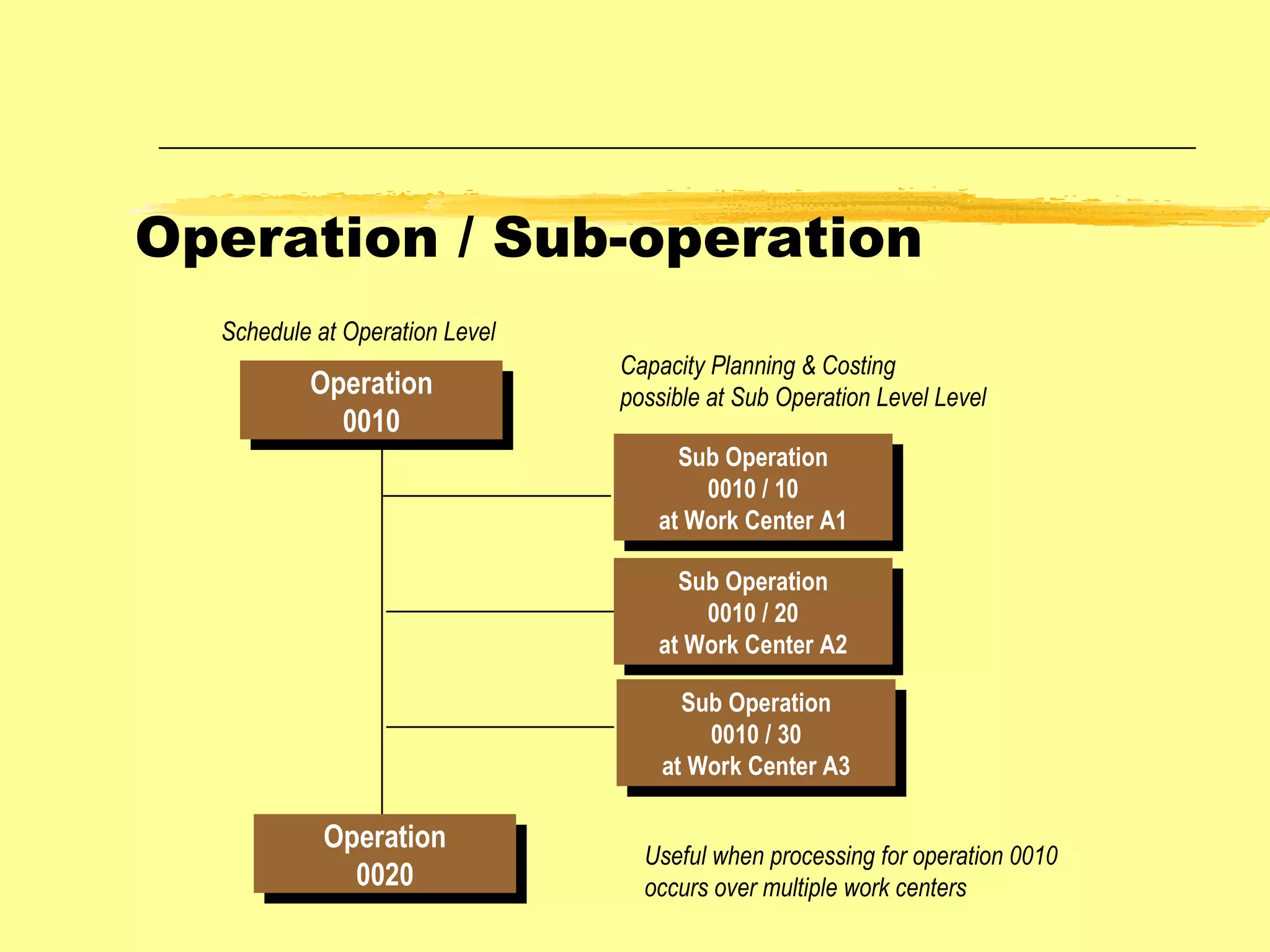

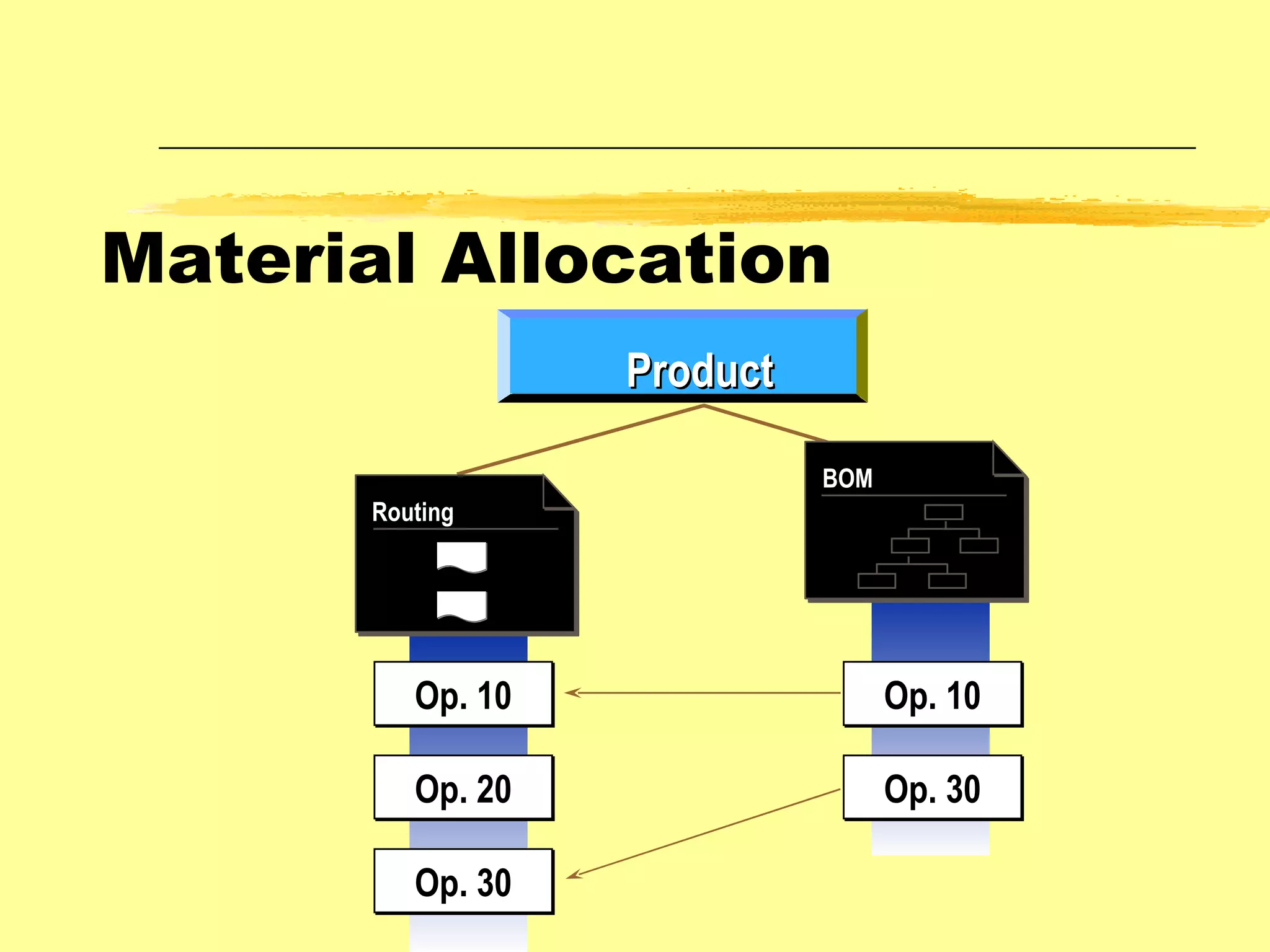

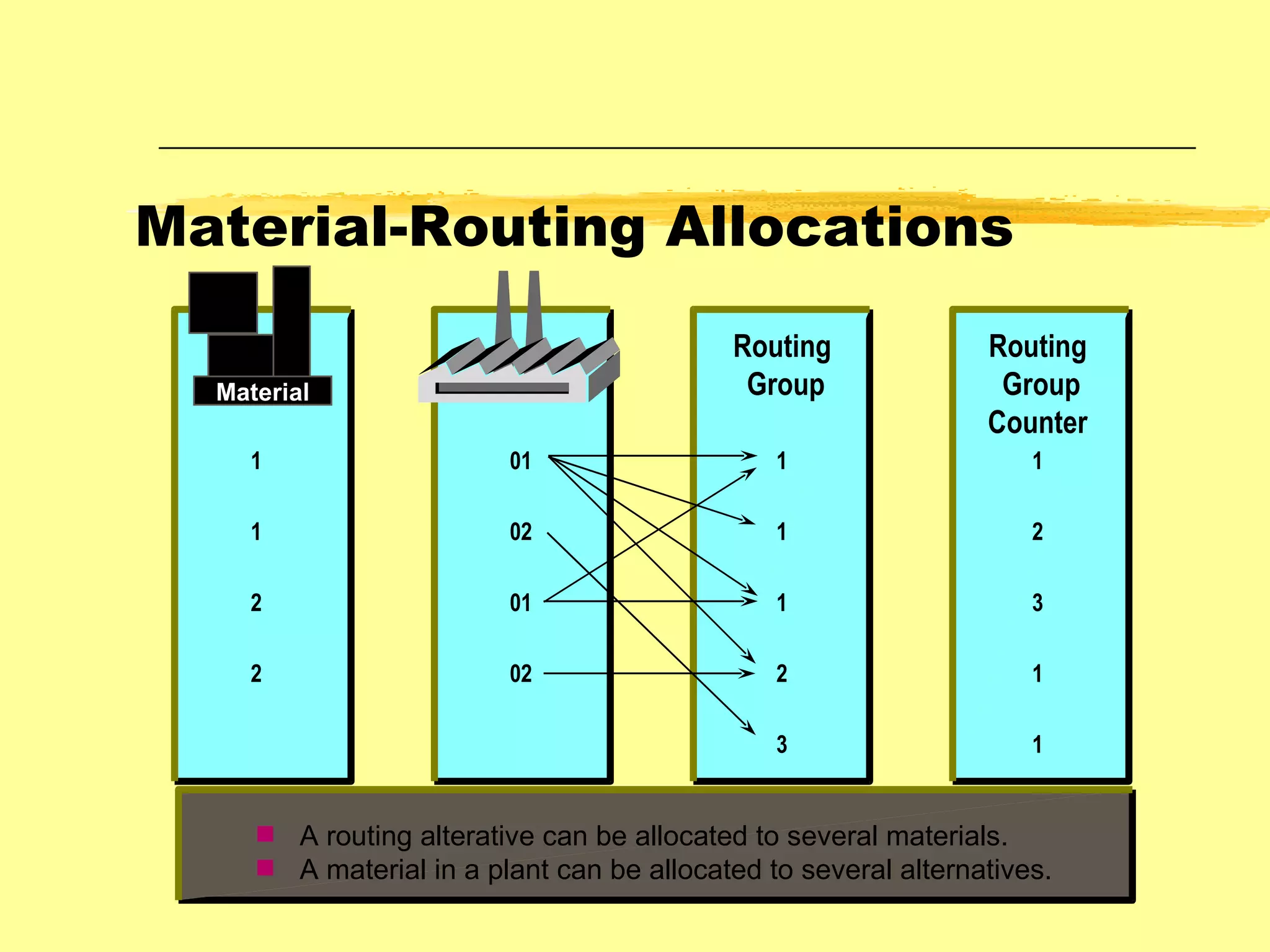

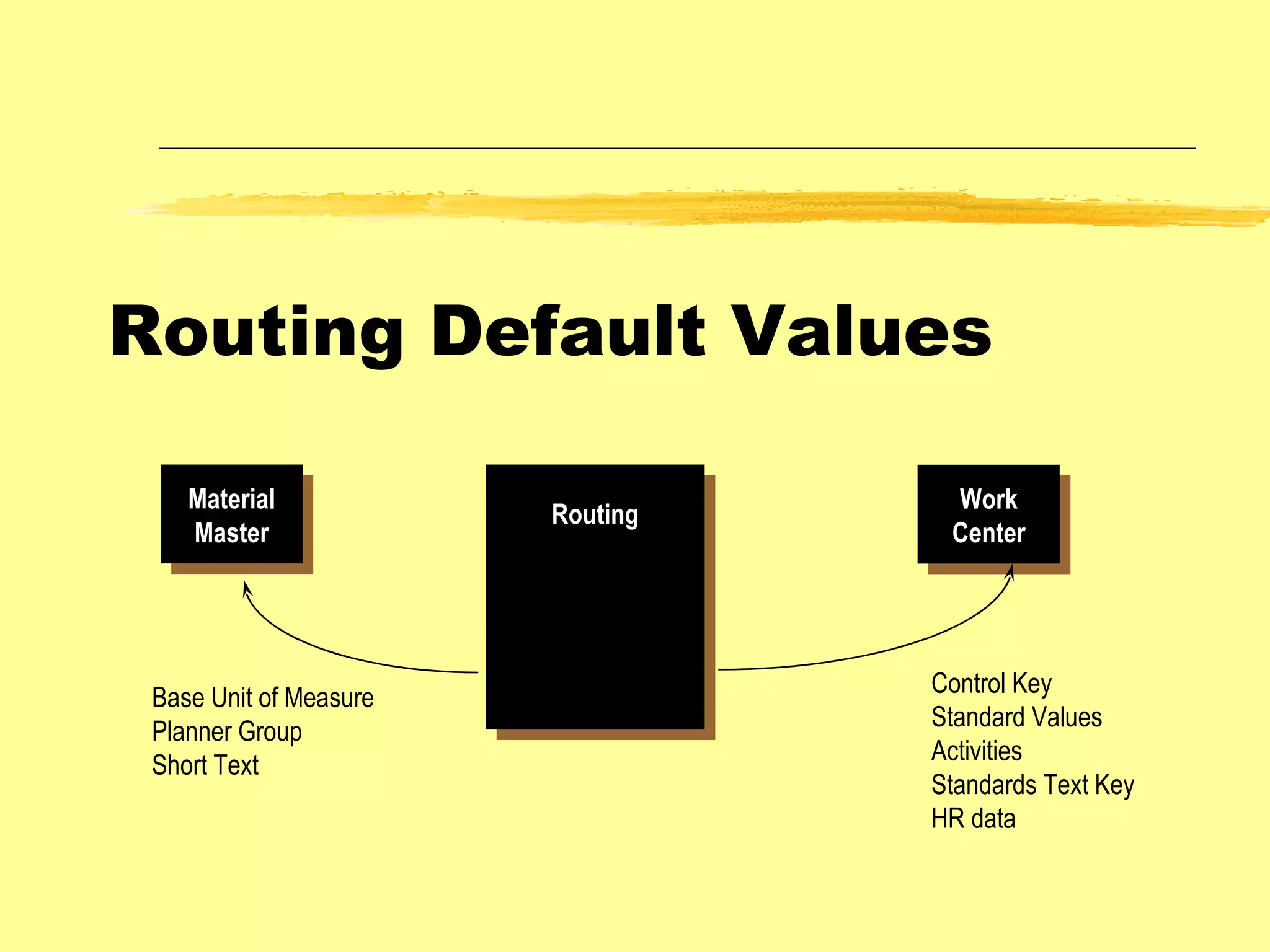

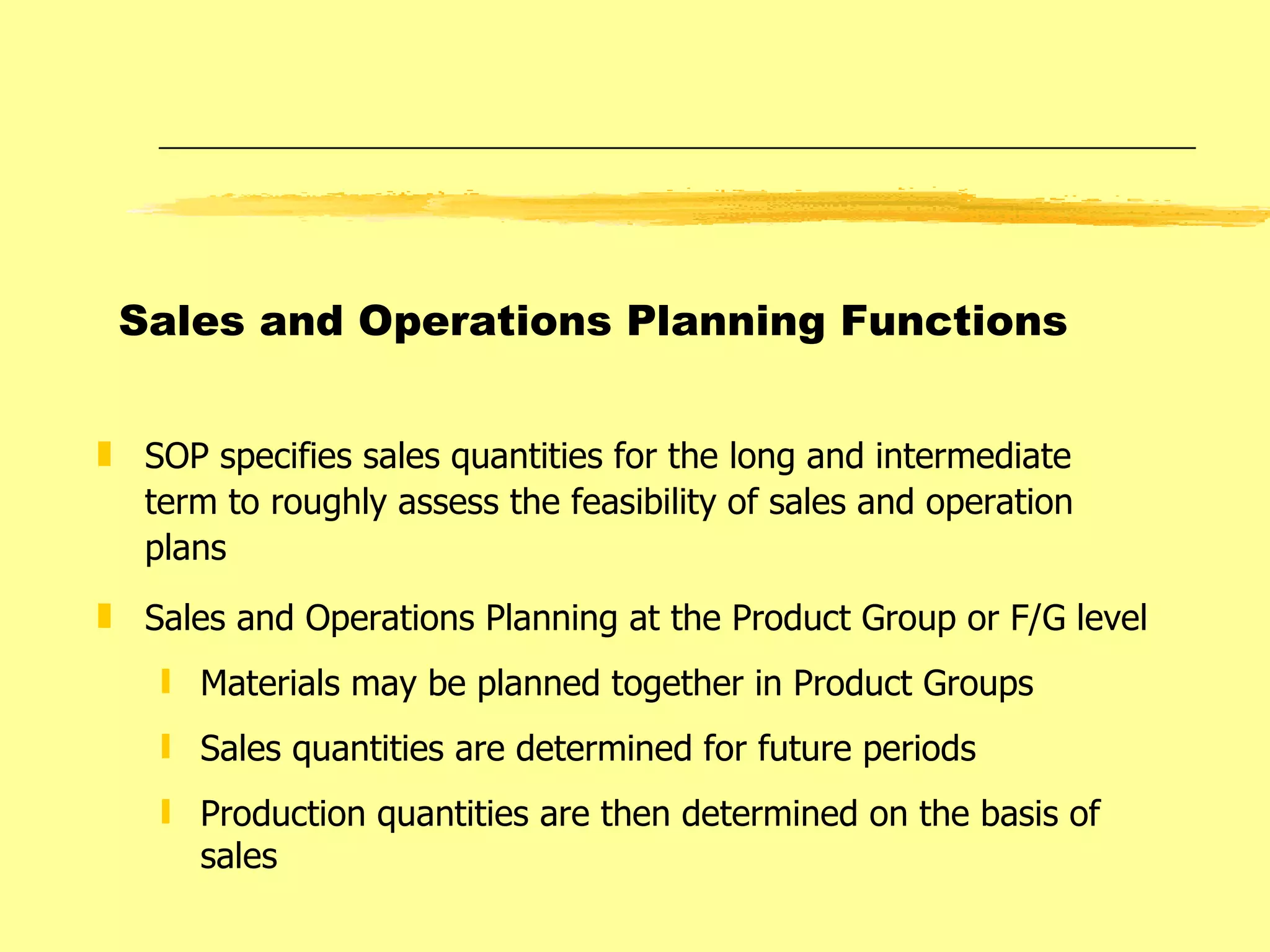

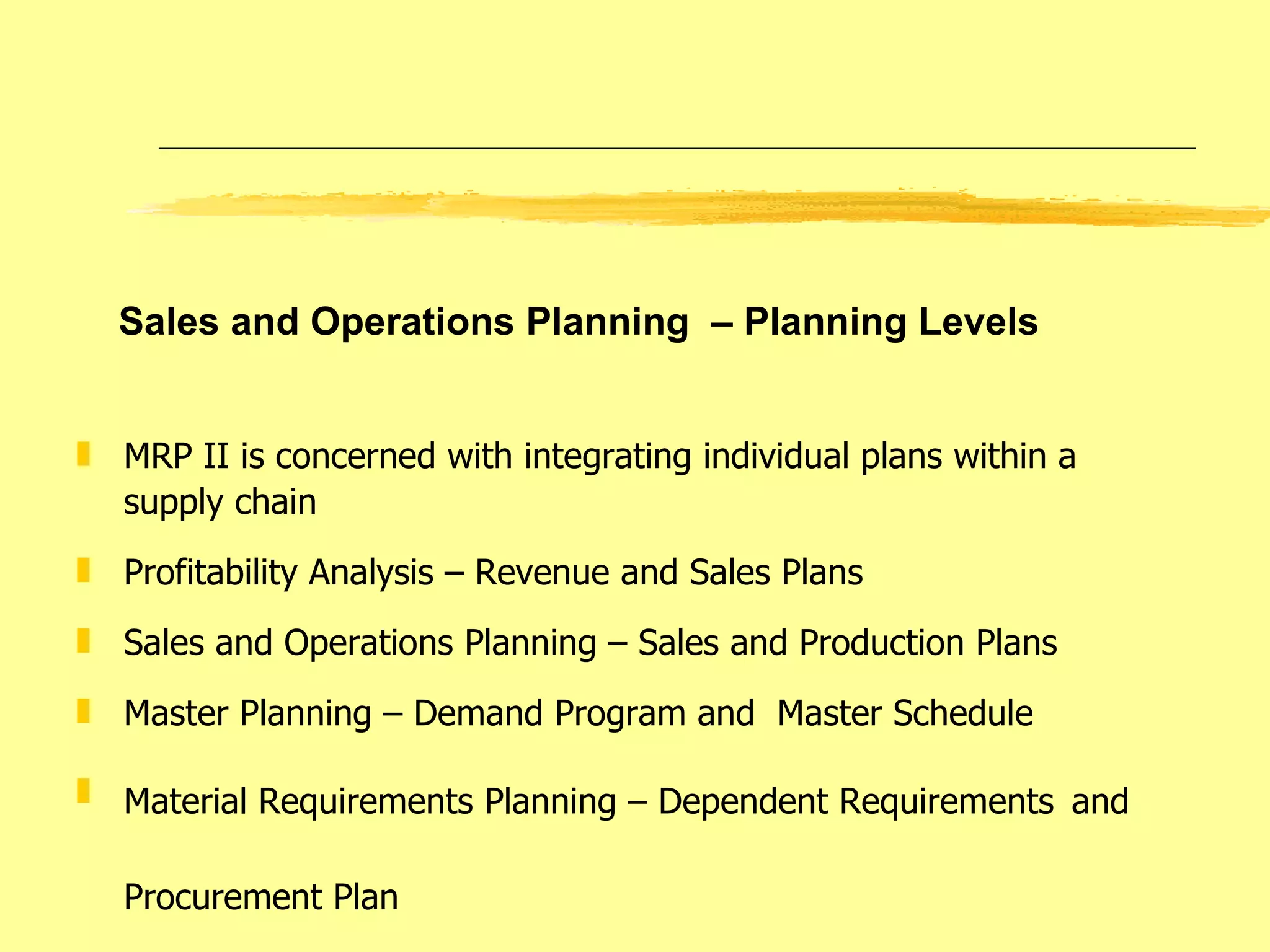

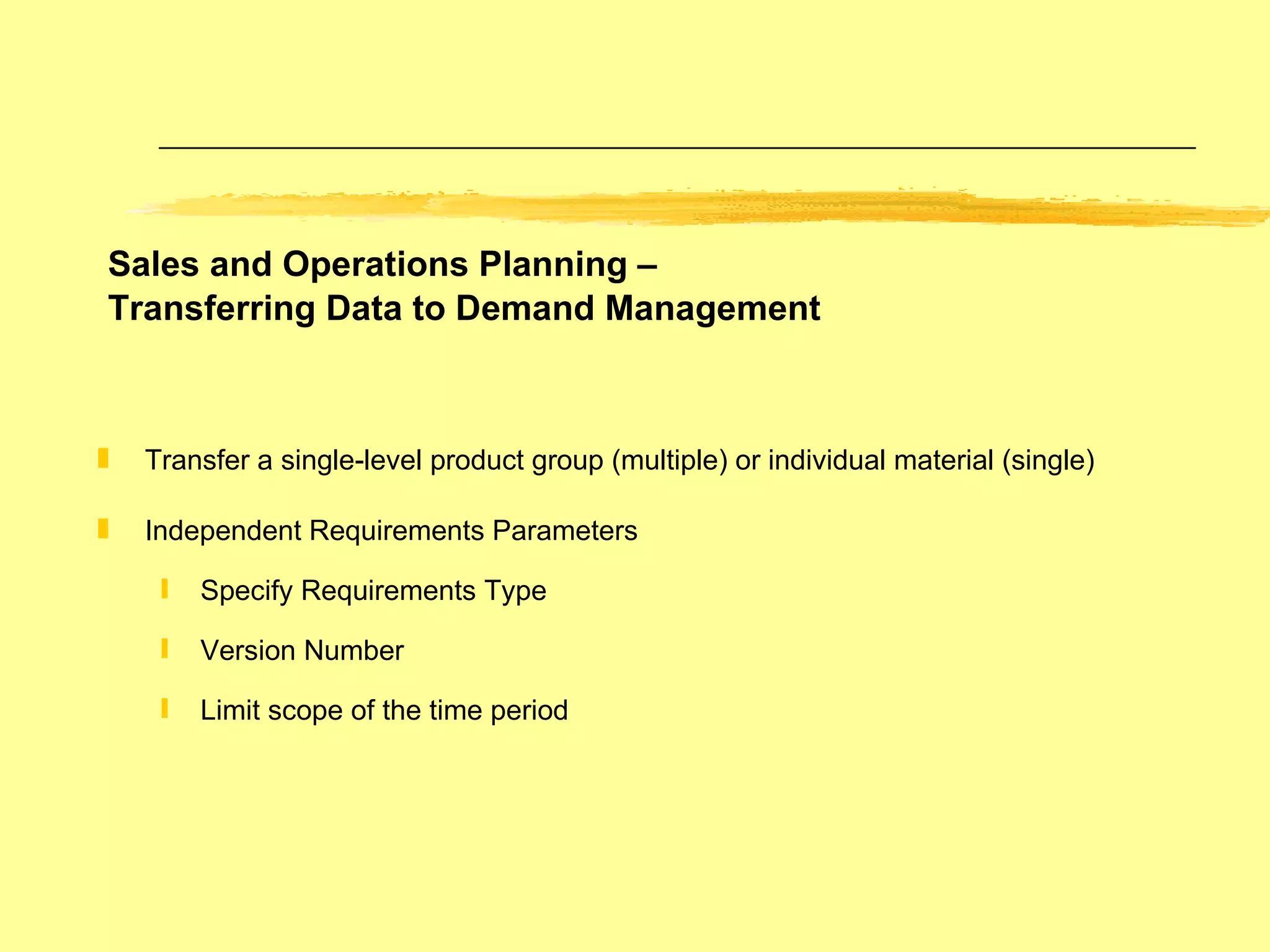

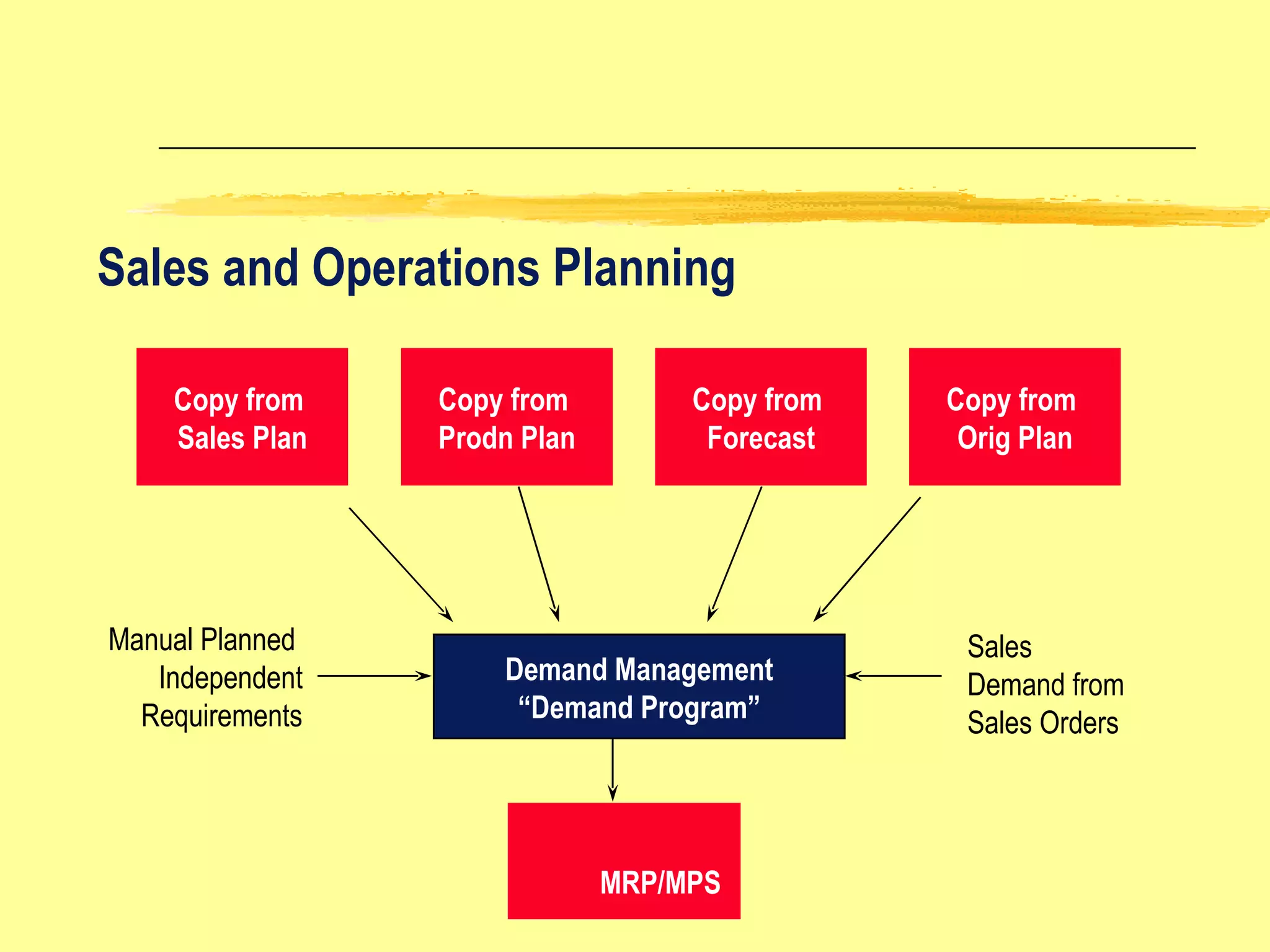

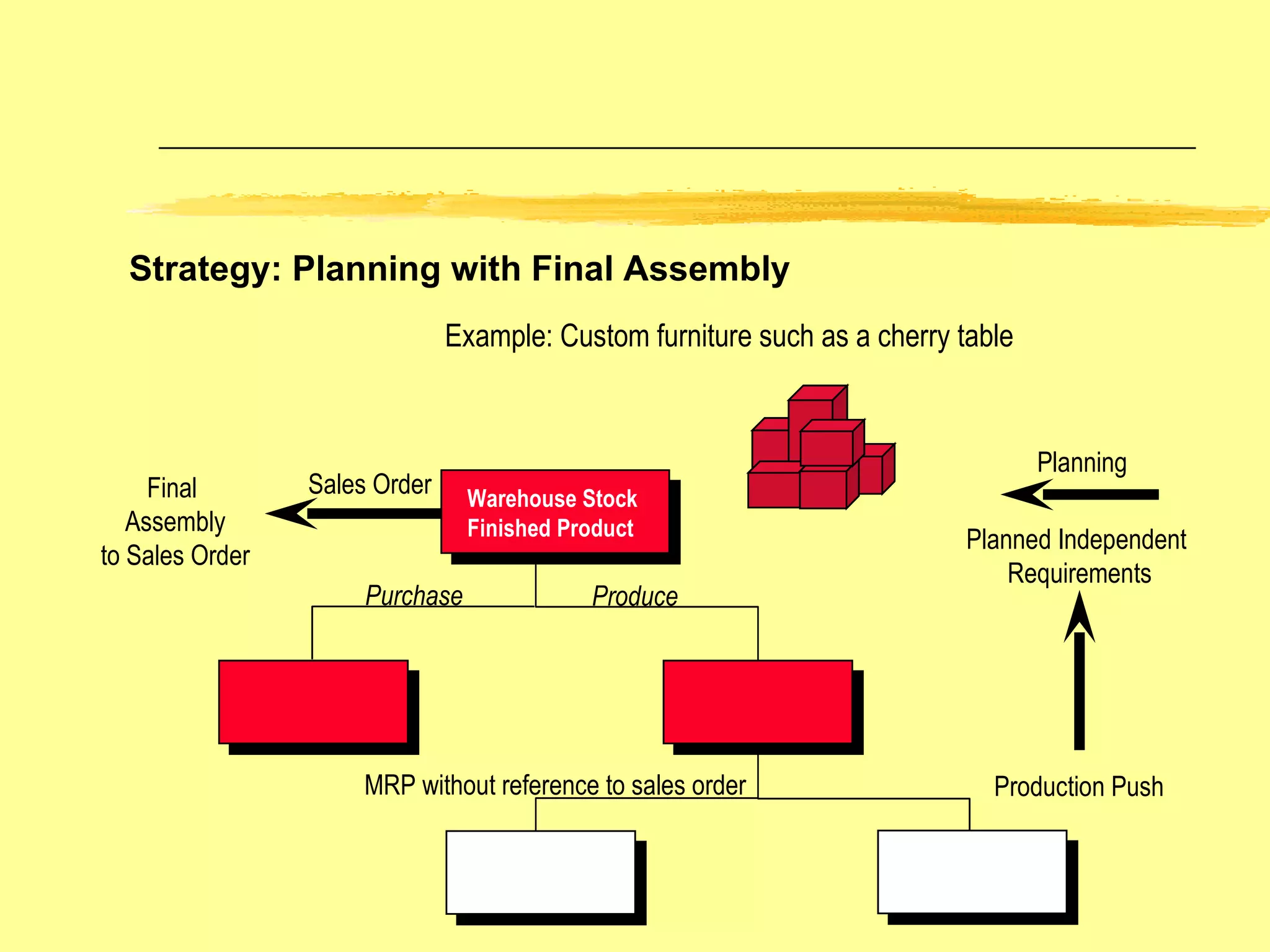

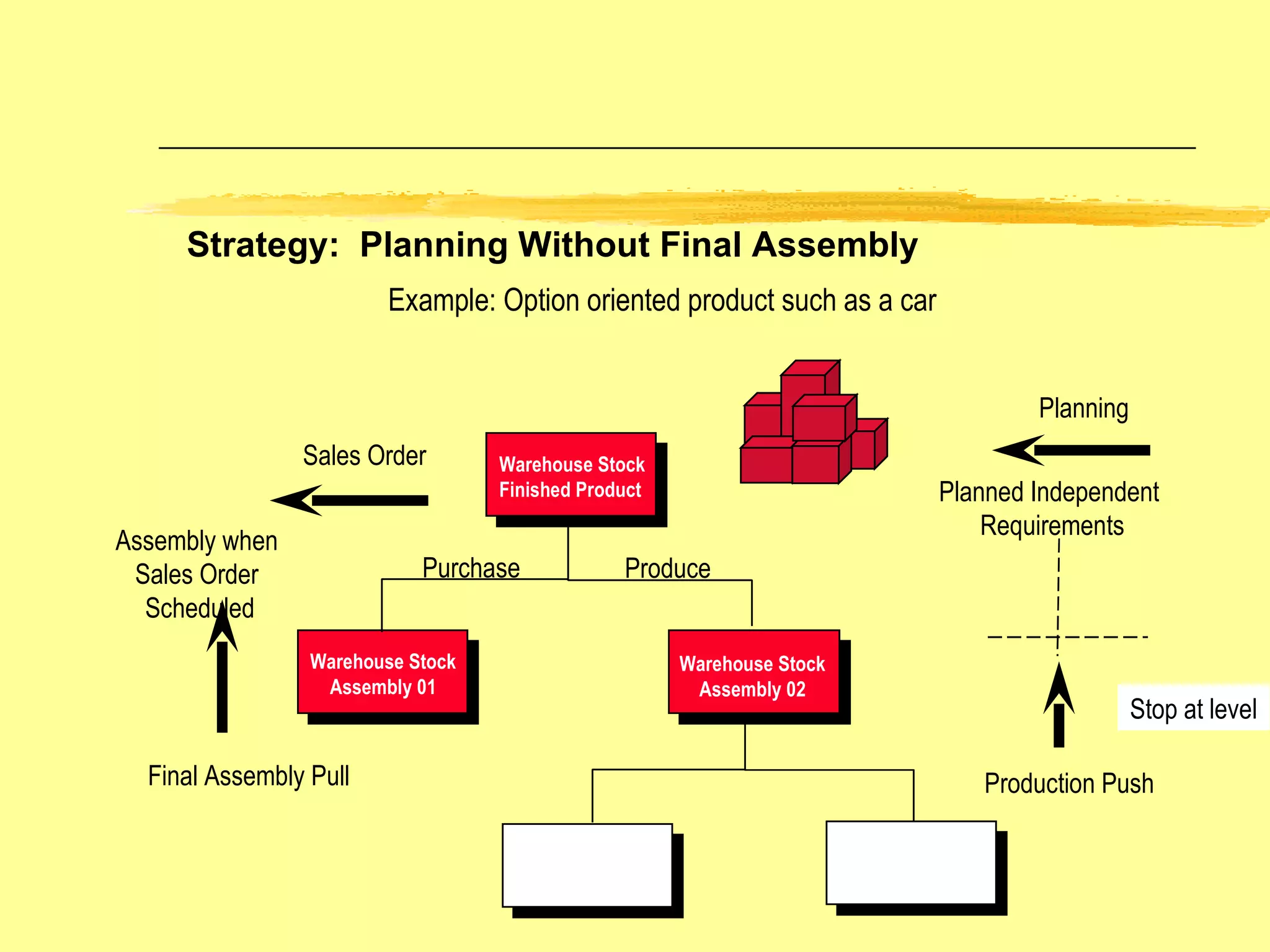

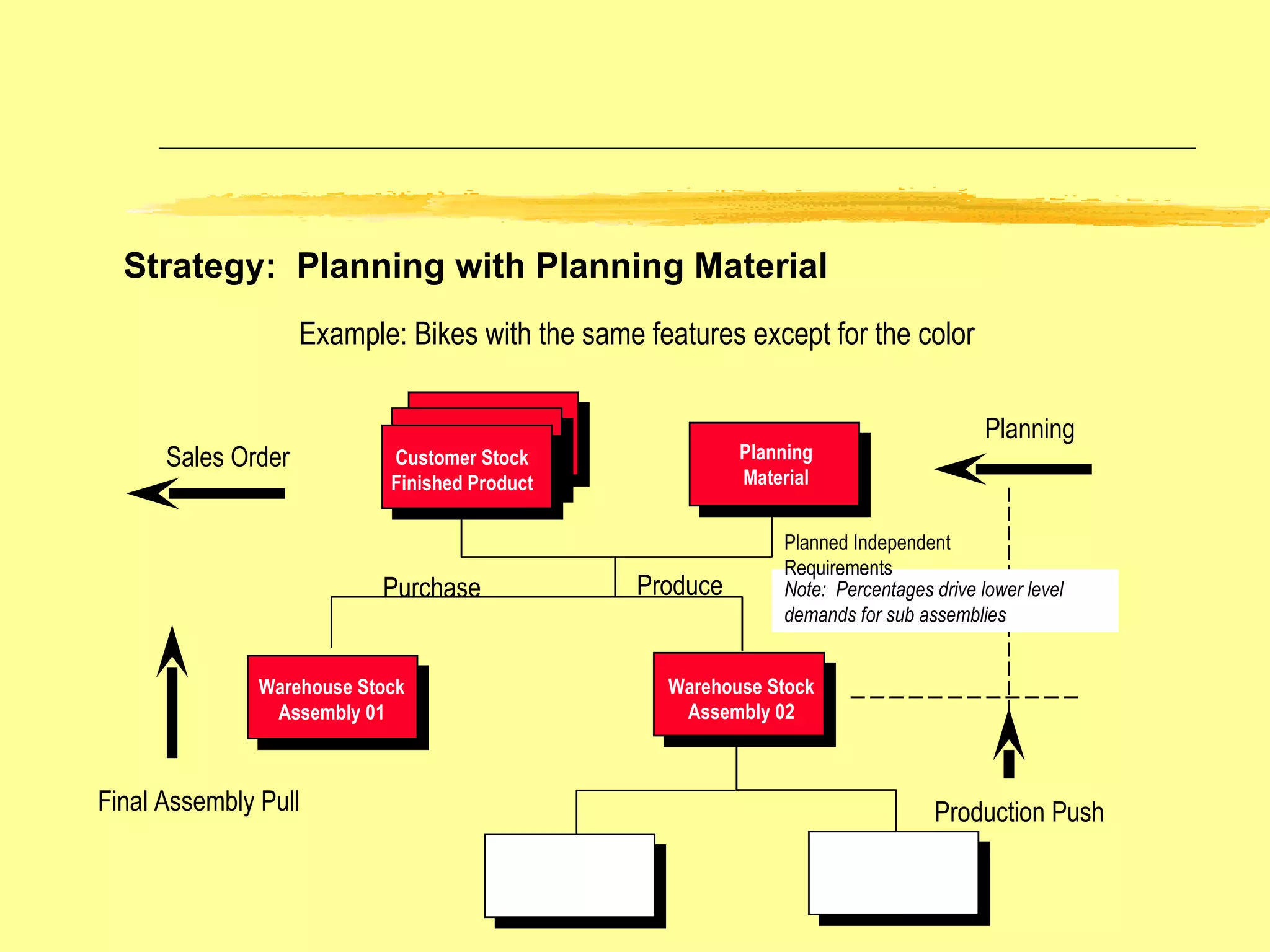

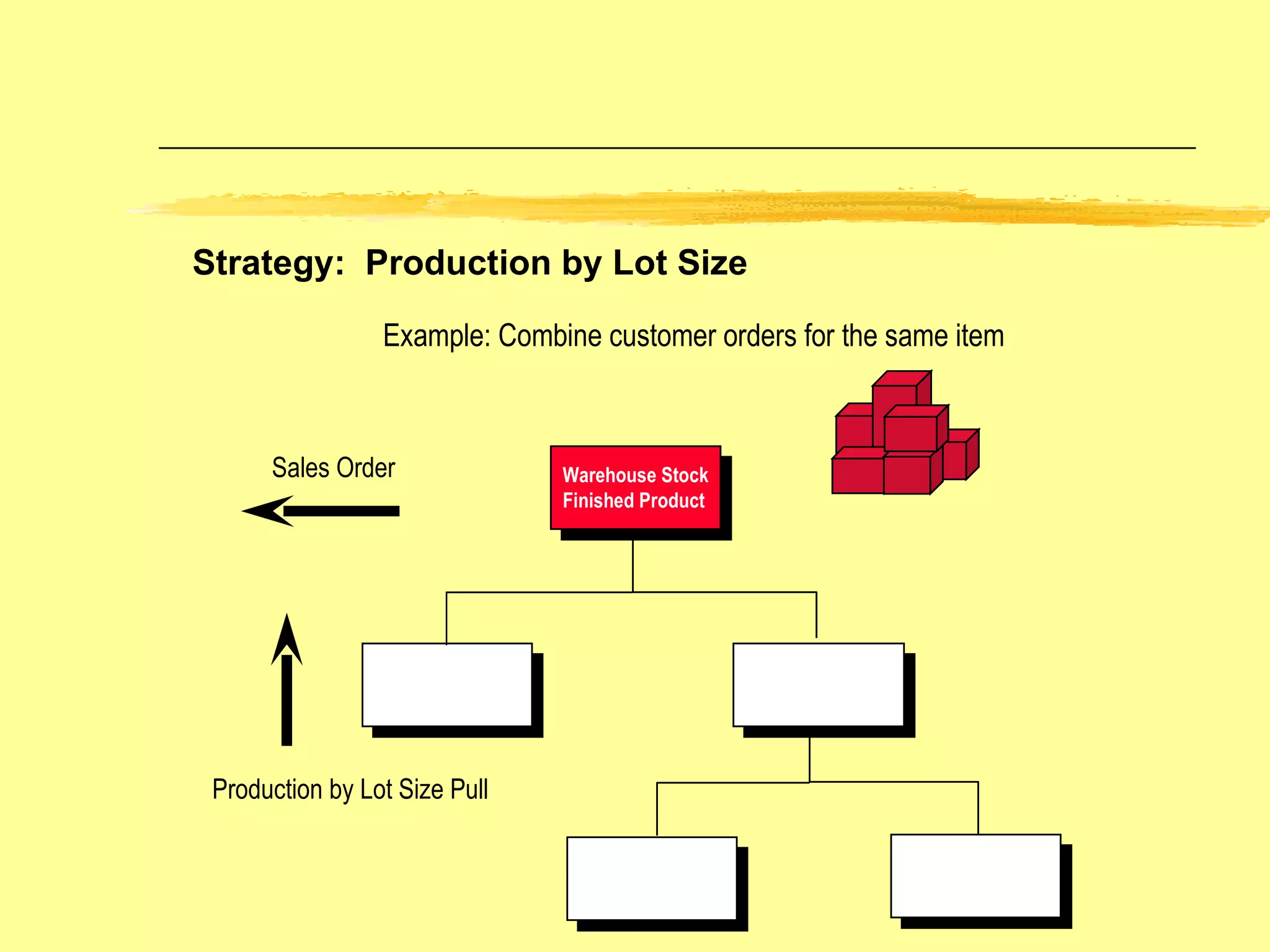

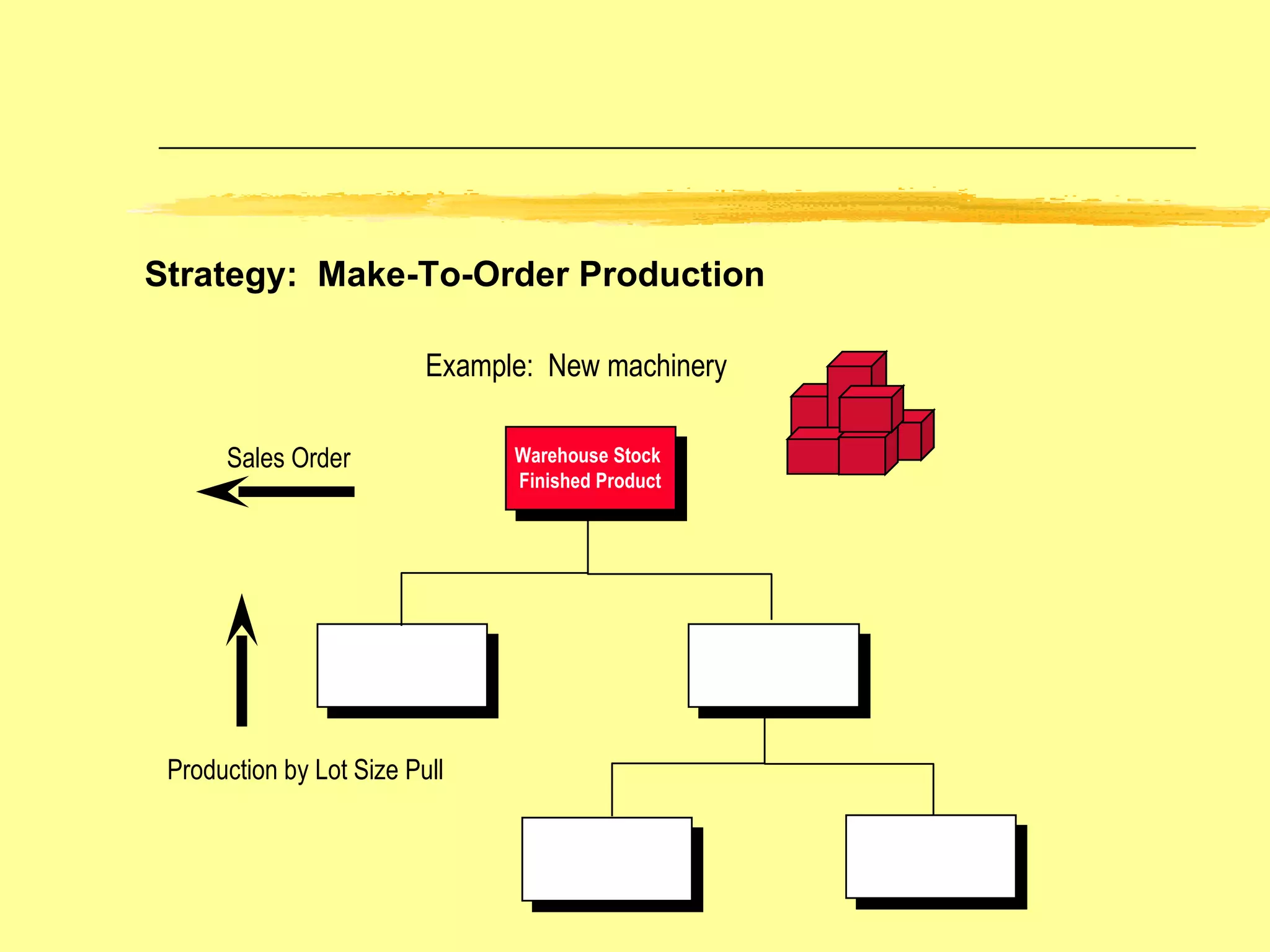

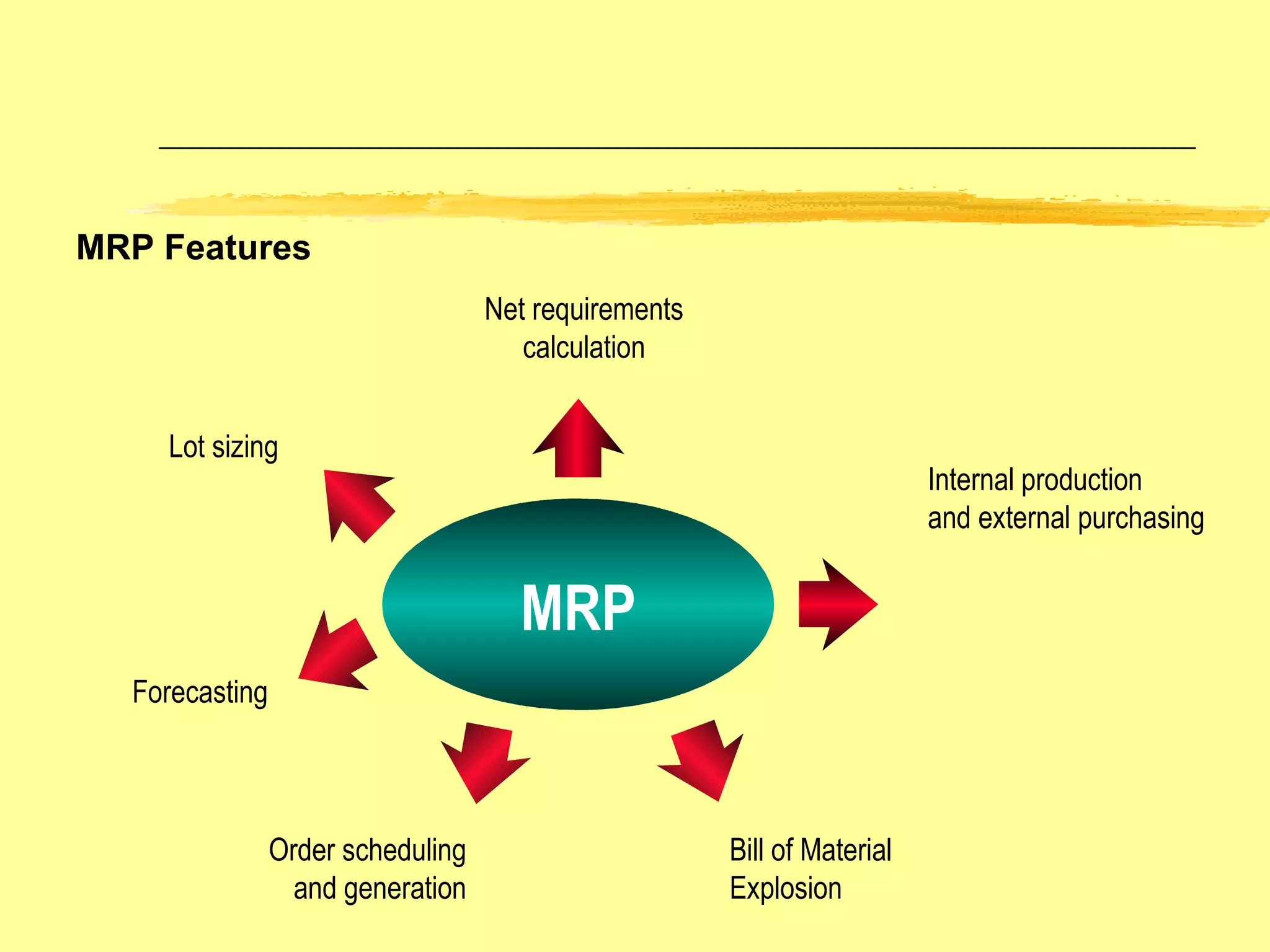

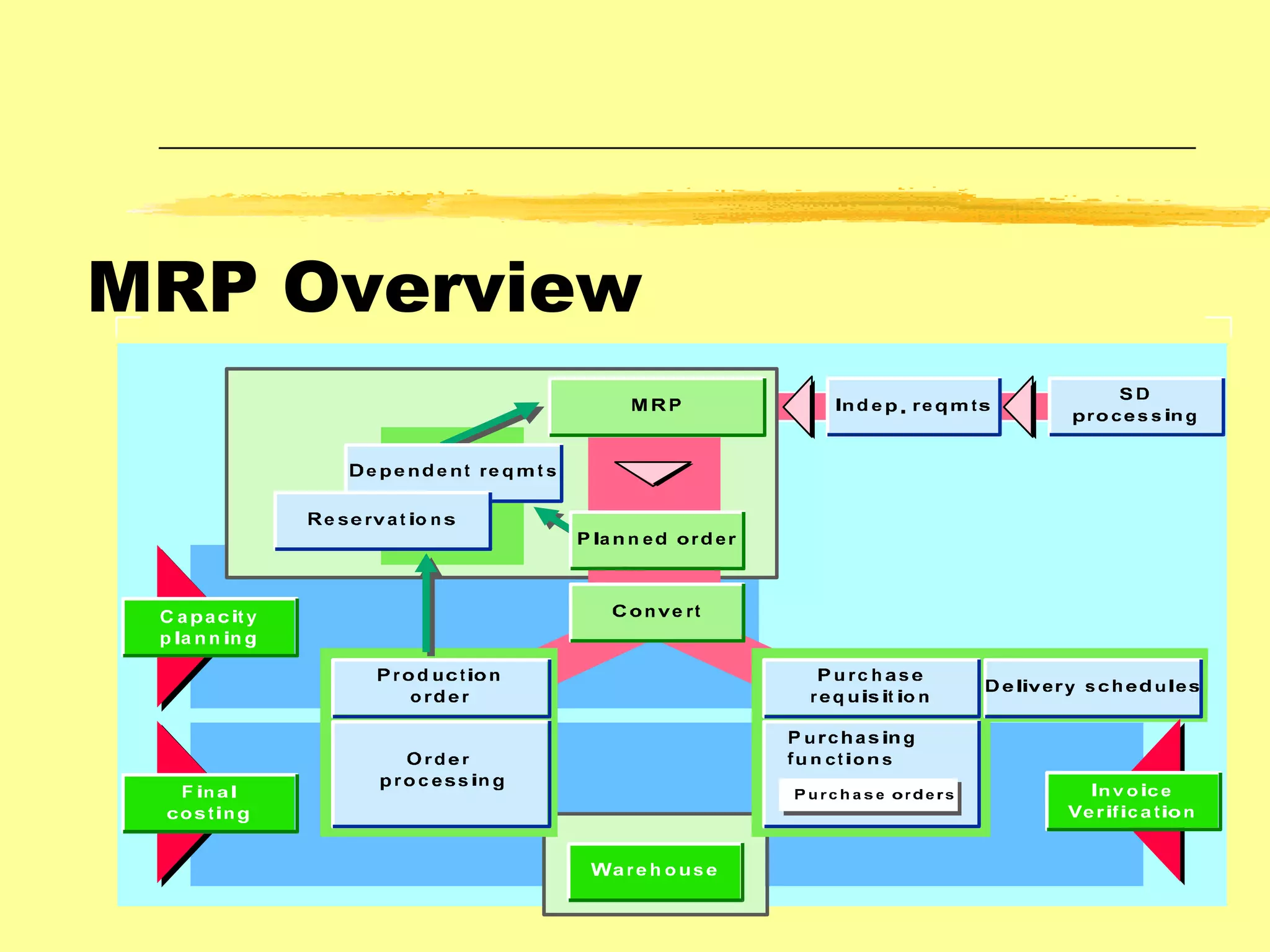

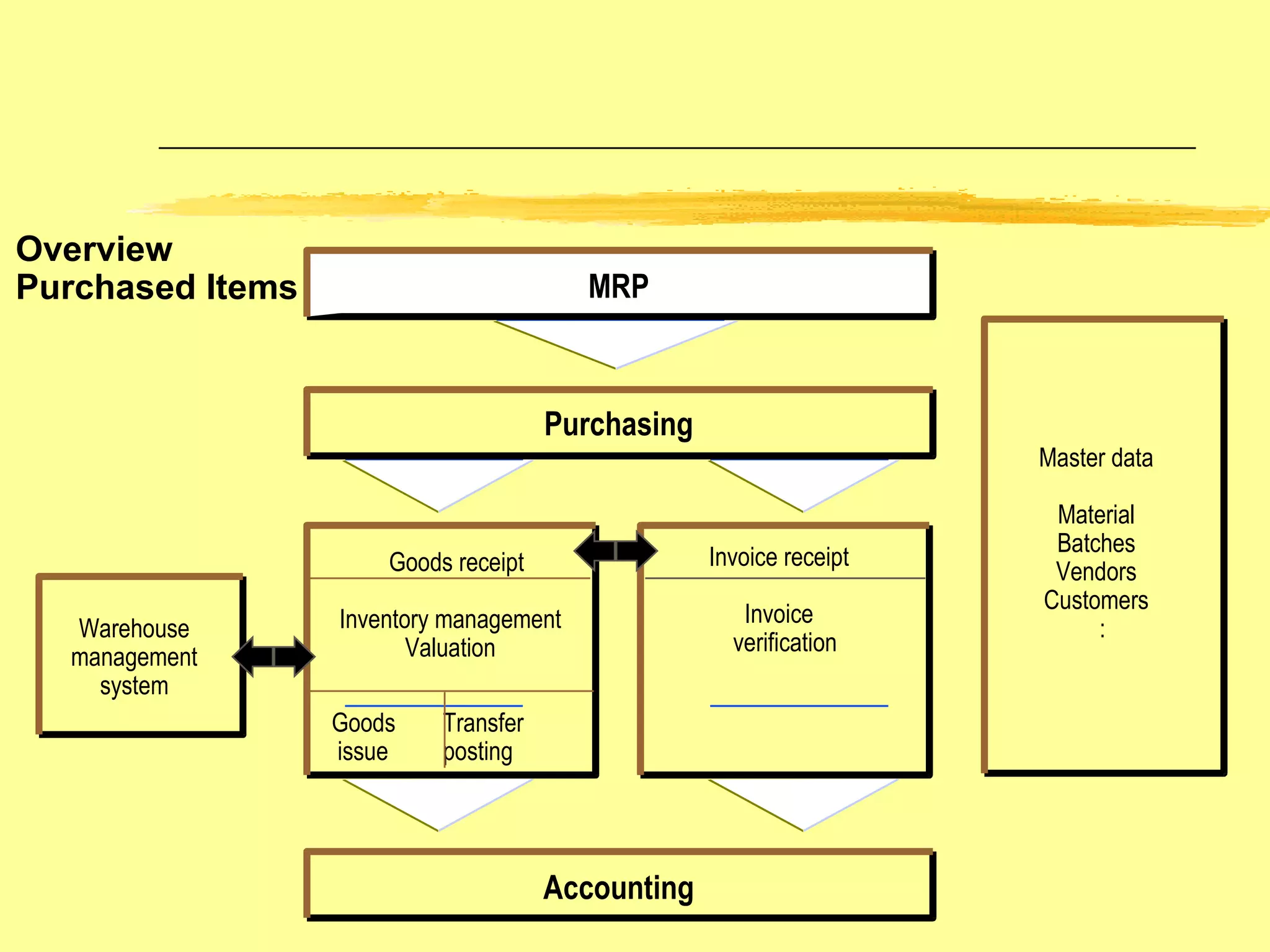

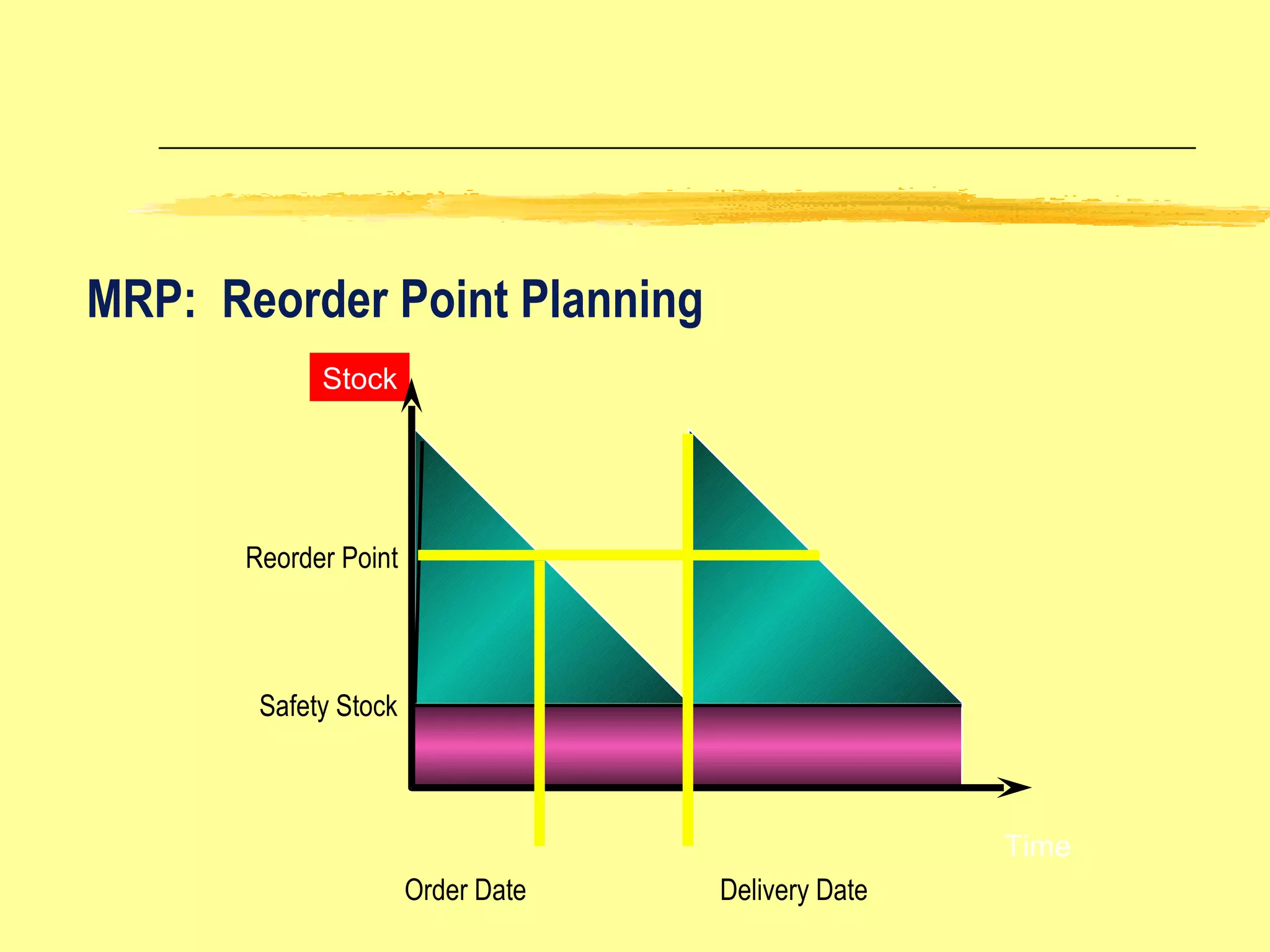

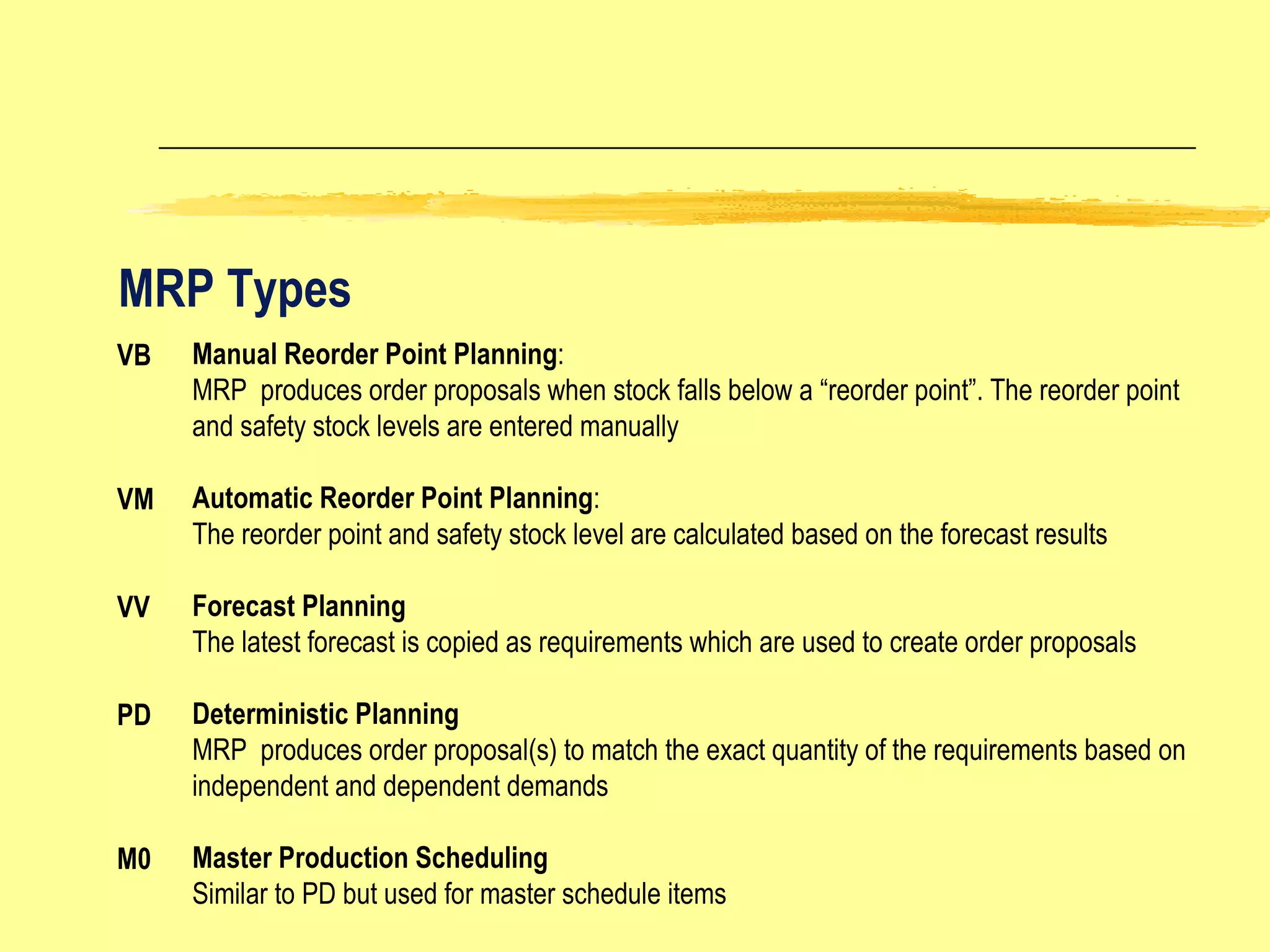

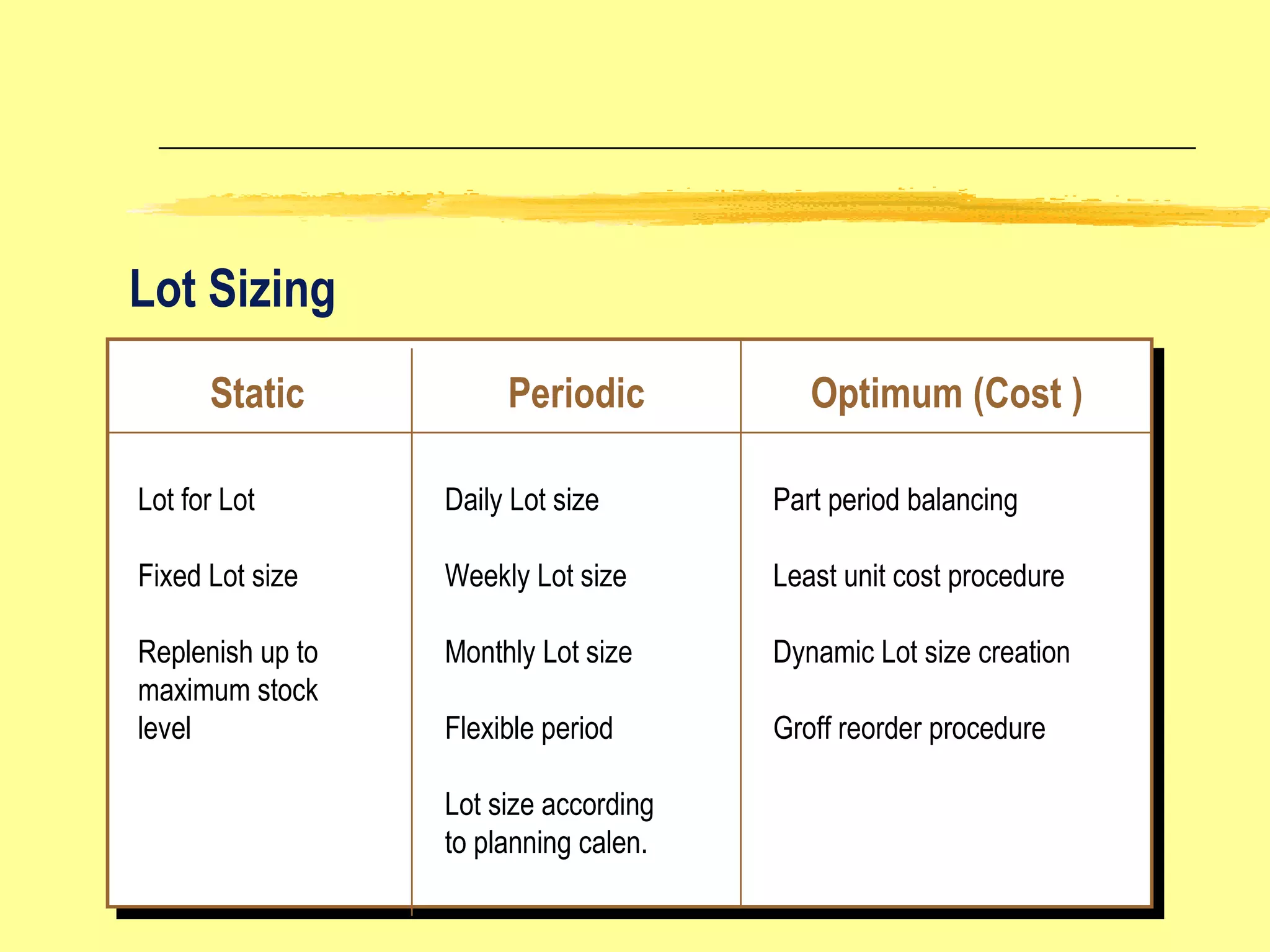

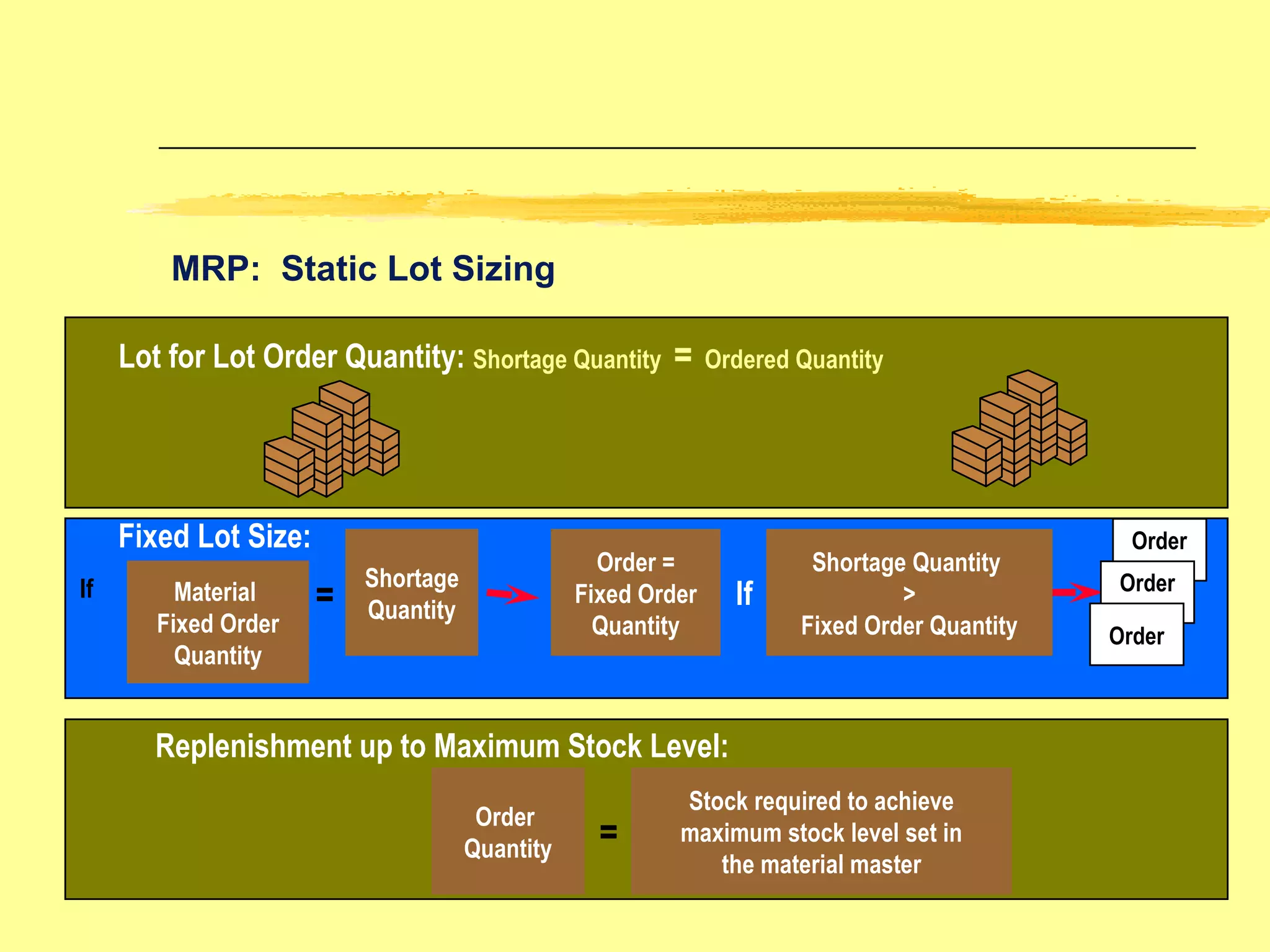

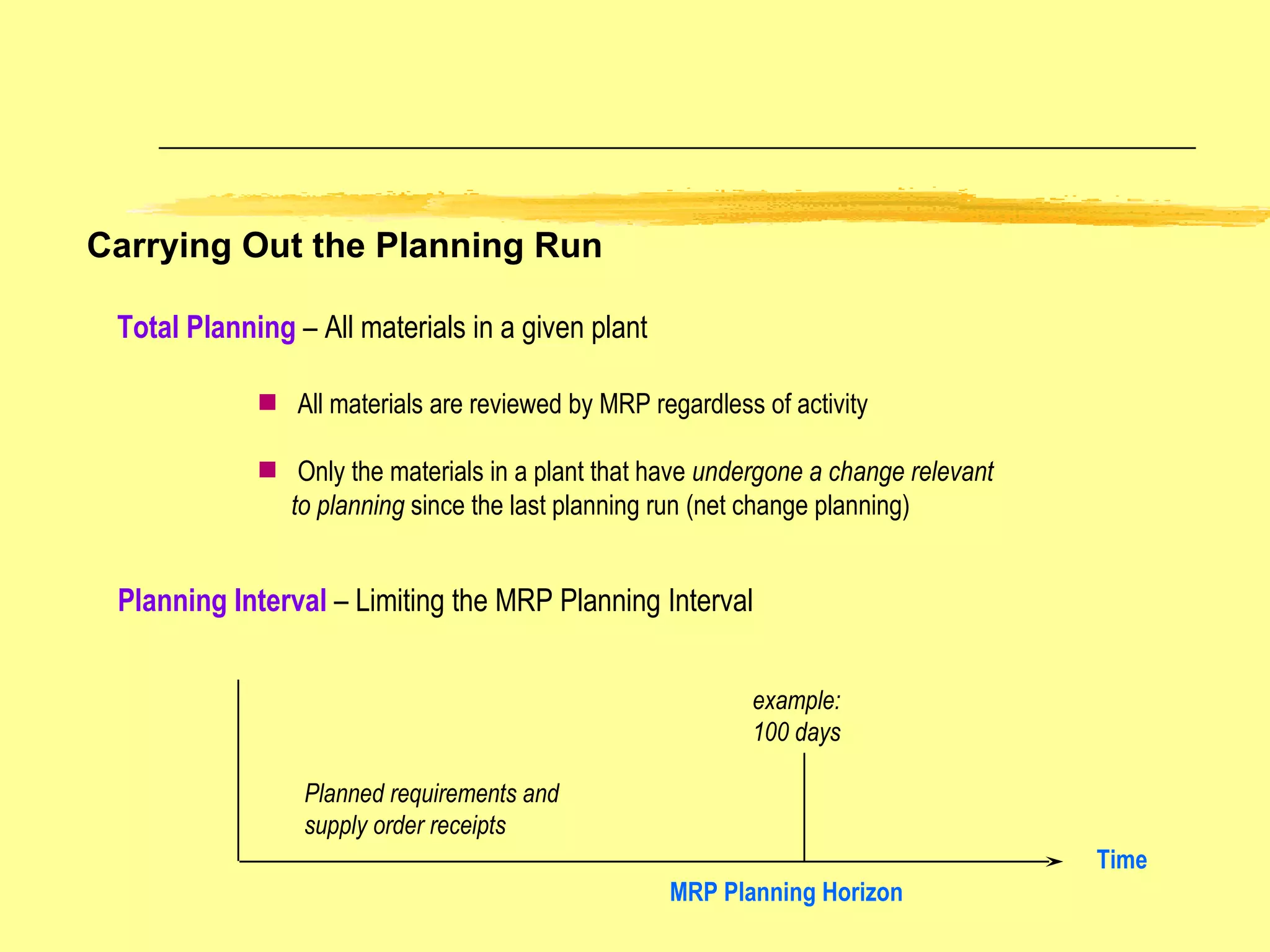

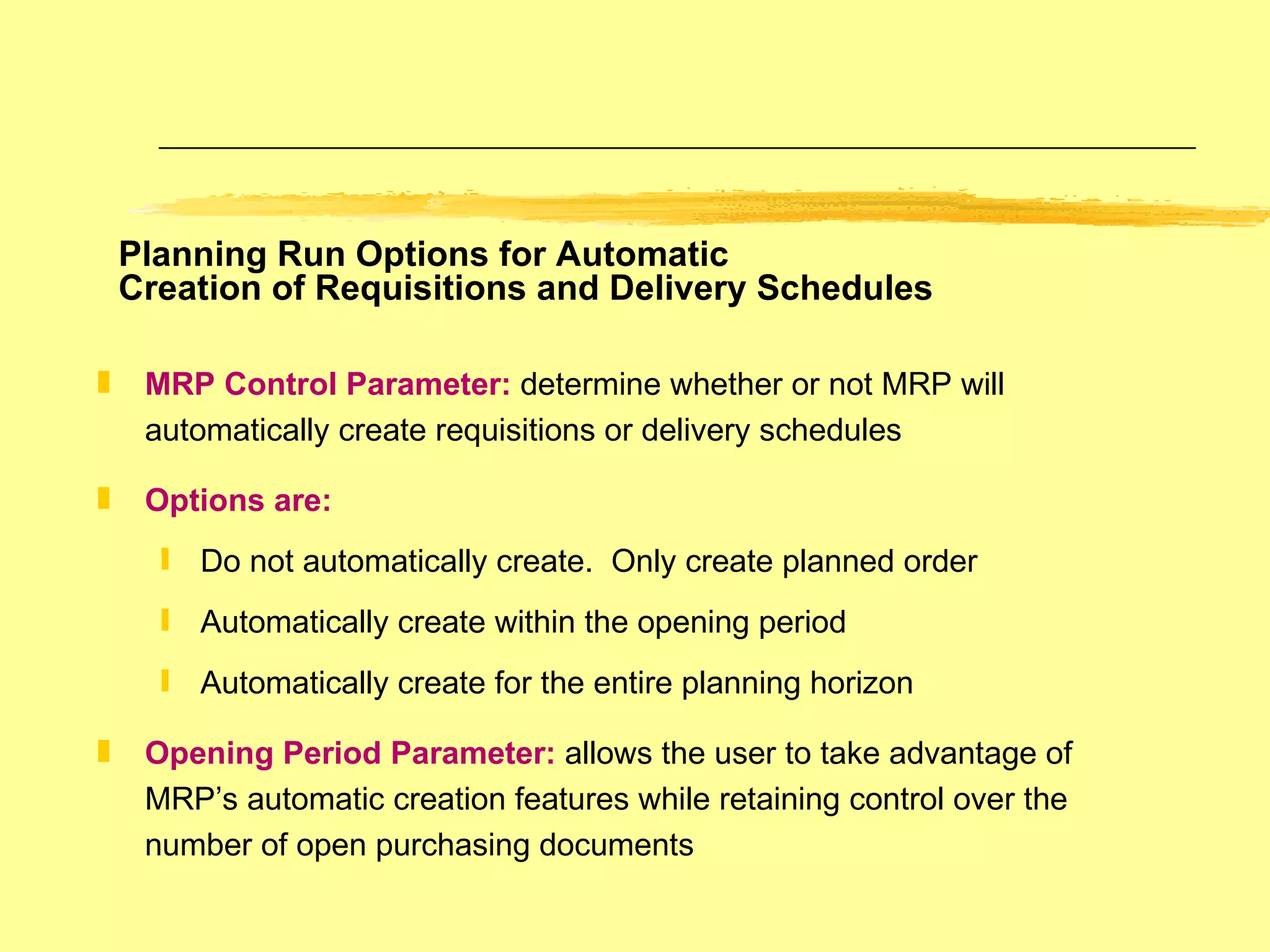

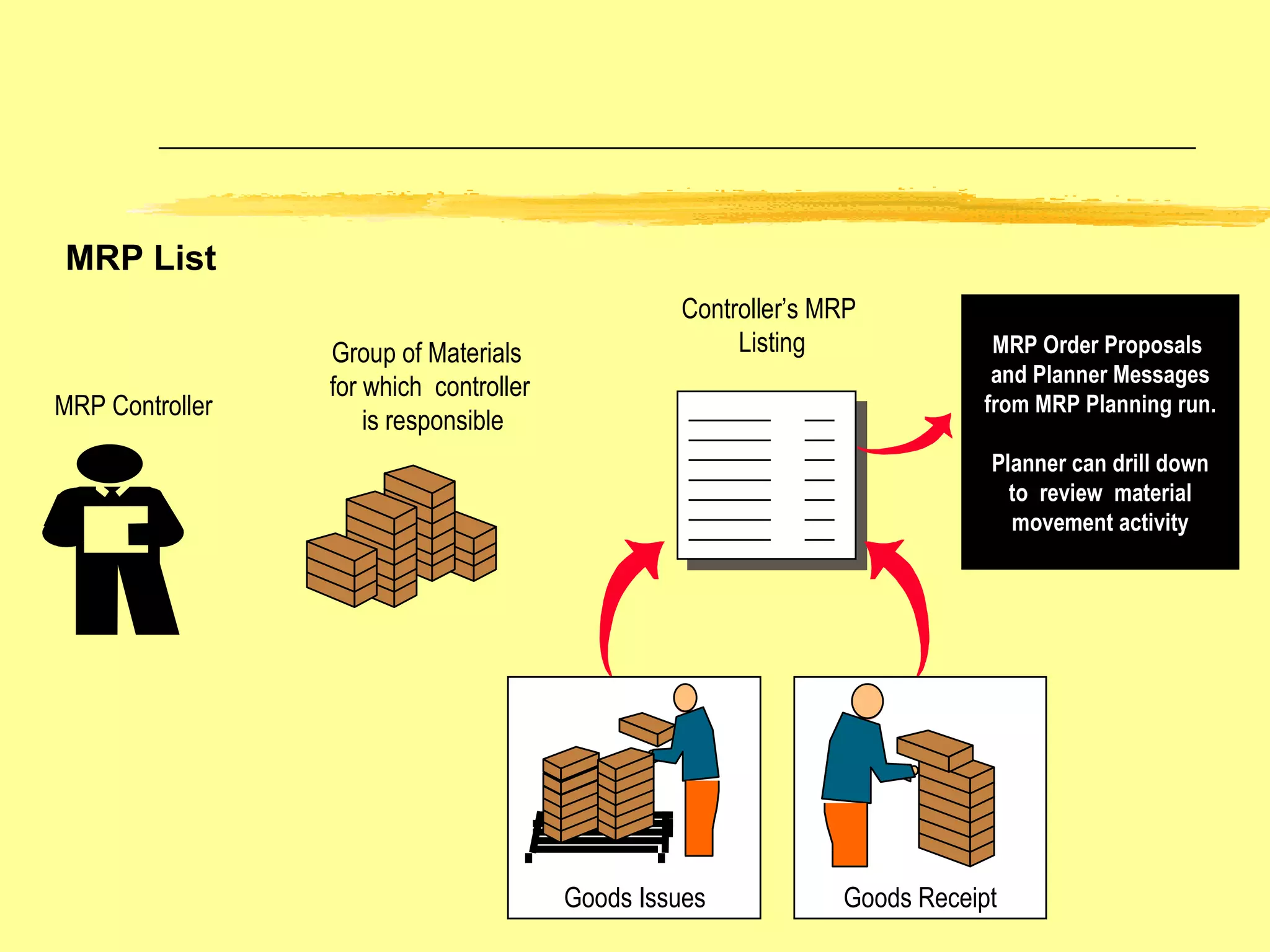

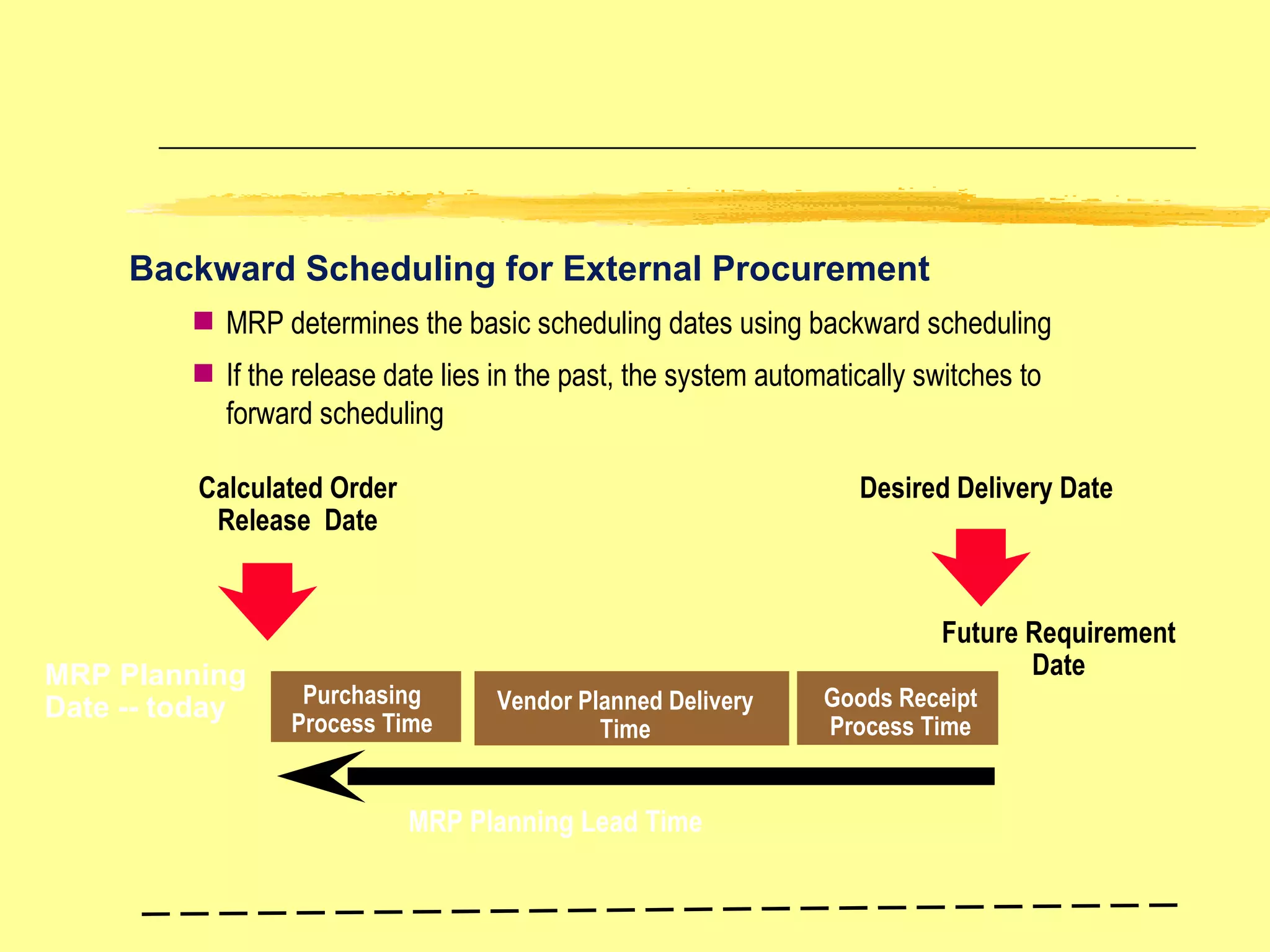

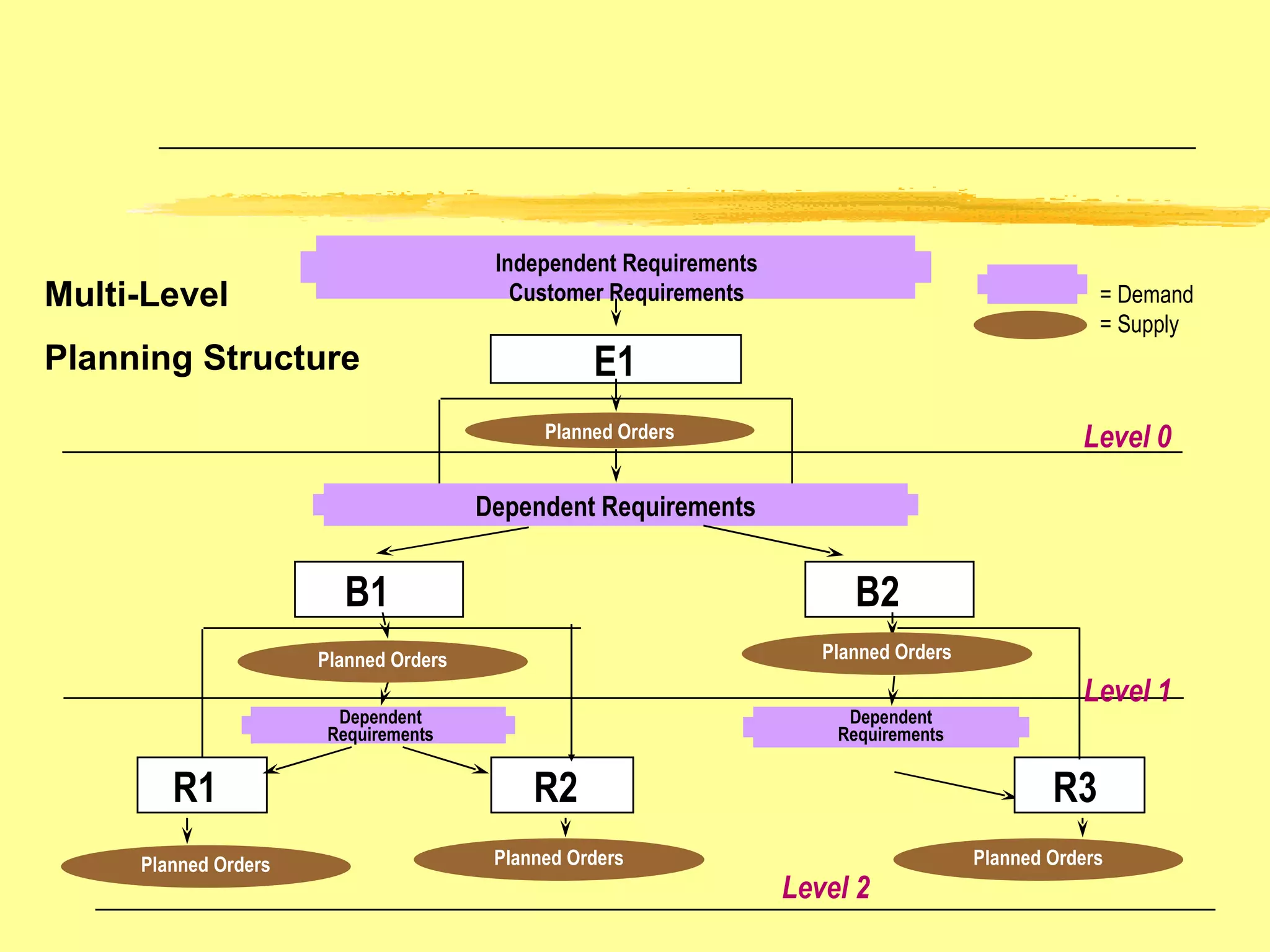

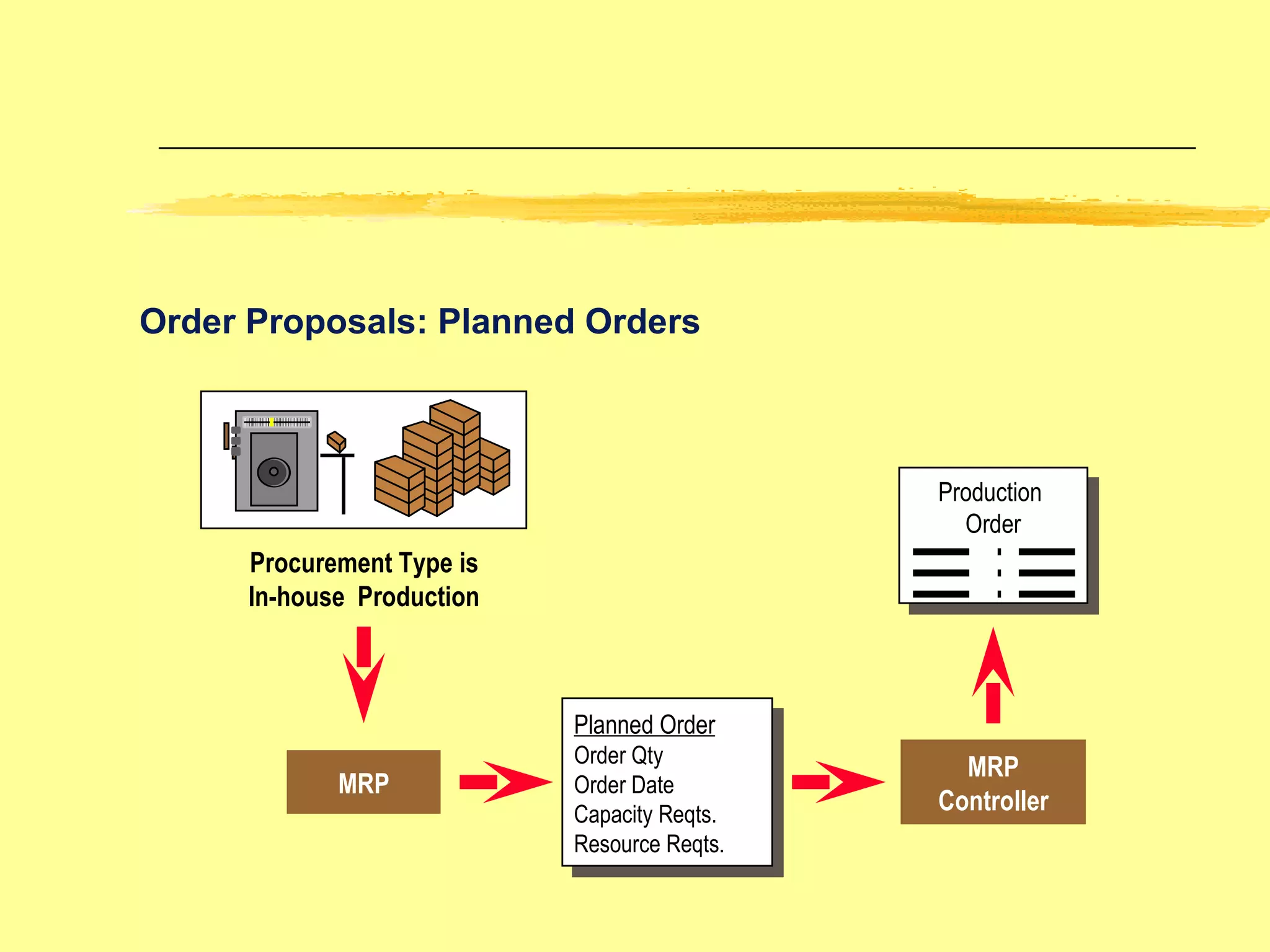

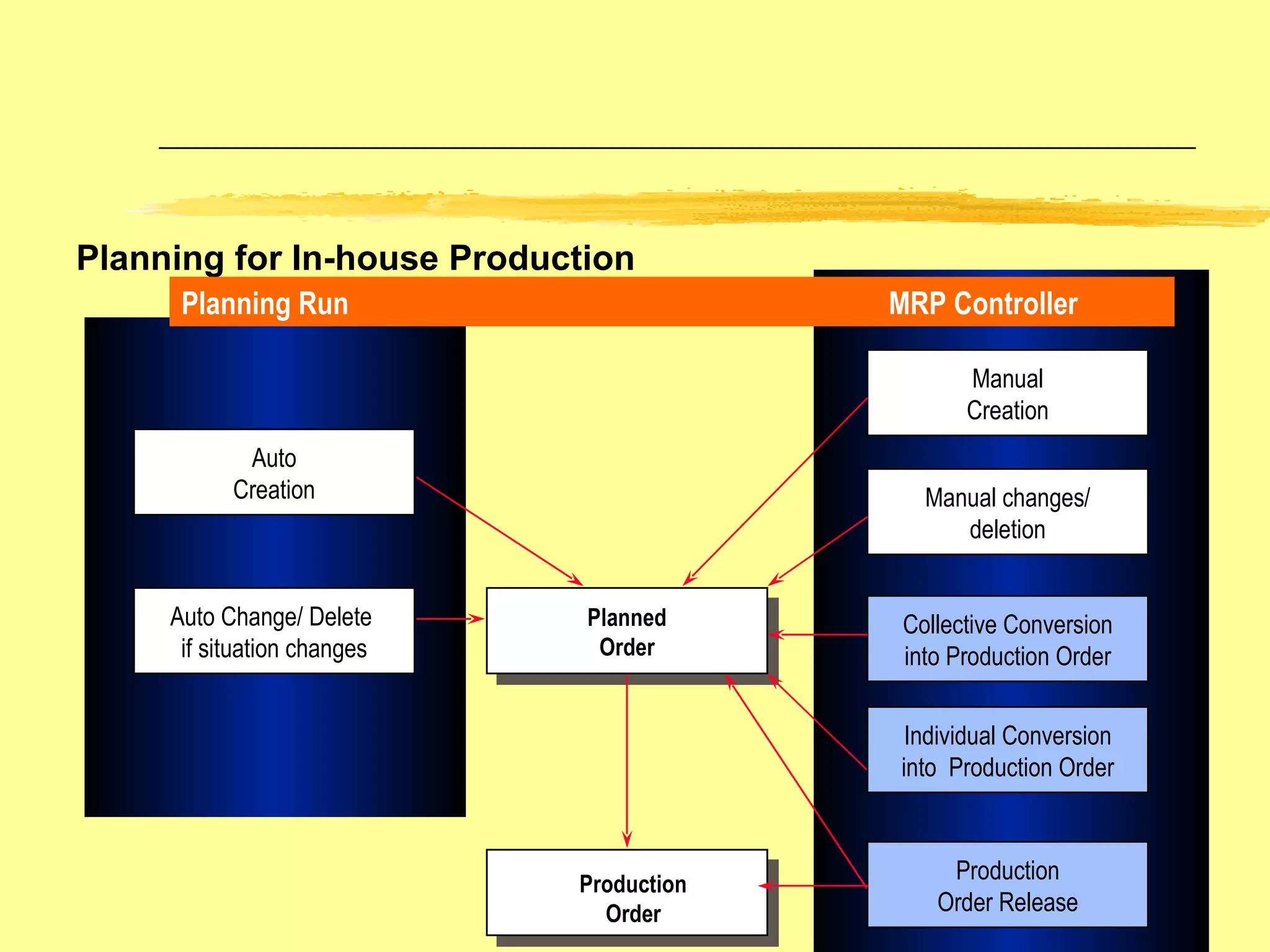

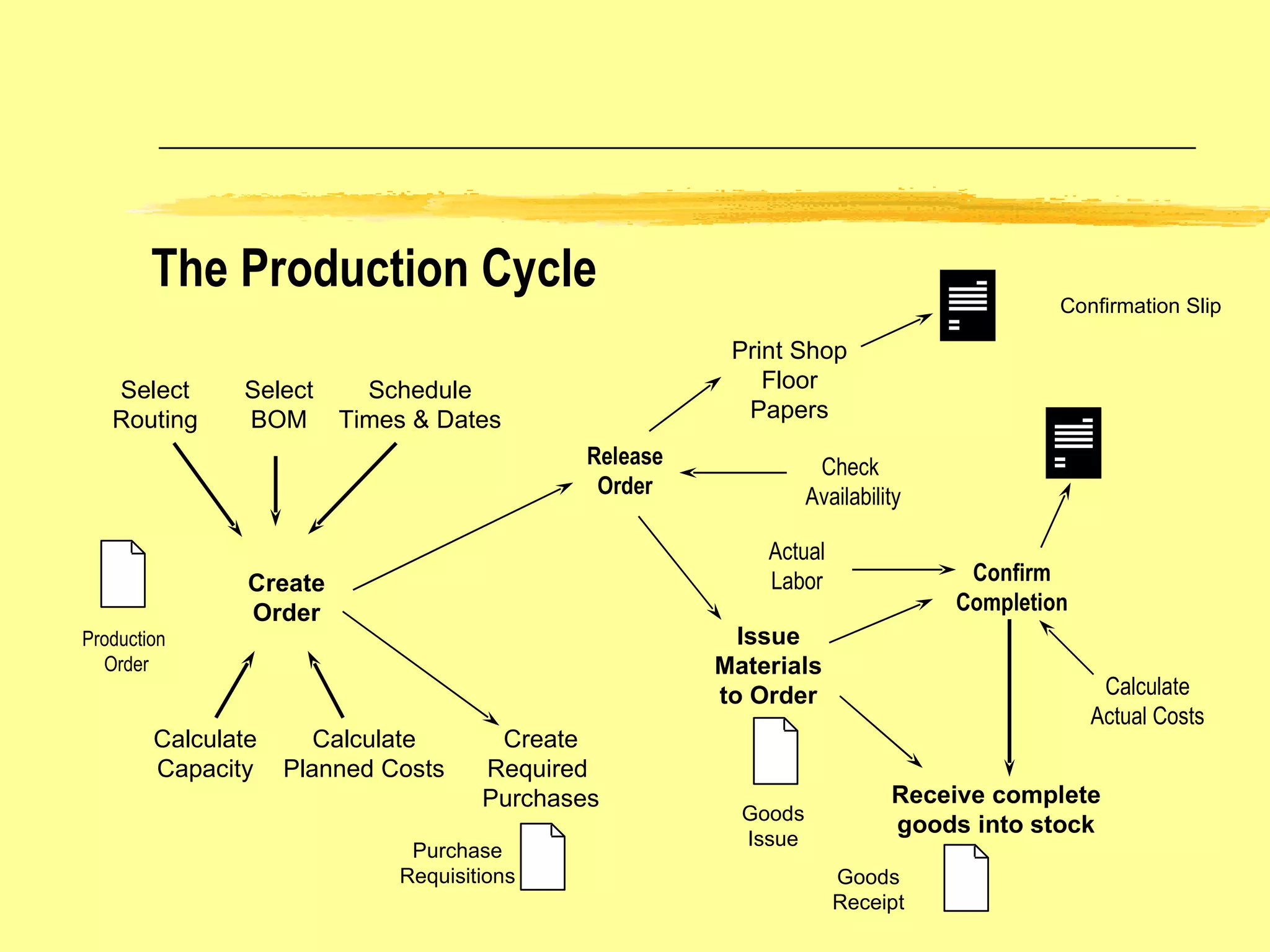

The document discusses production planning in SAP. It covers key modules like sales and operations planning, master production scheduling, material requirements planning, bills of material, work centers, routings and operation costing. The goal of production planning is to integrate sales forecasts with manufacturing capabilities to generate production and procurement plans.