Ultrasonic Machining (USM)

•Download as PPT, PDF•

34 likes•9,768 views

Ultrasonic machining uses a vibrating tool at ultrasonic frequencies to machine hard, brittle materials with little heat generation. It works by using an abrasive slurry between the tool and workpiece. The process allows machining of non-conductive materials that cannot be cut via other methods. It produces burr-free surfaces but has low material removal rates and high tool wear. Applications include machining ceramics, semiconductors, glass, and other hard materials, as well as drilling small, deep holes without damaging surrounding structures.

Report

Share

Report

Share

Recommended

More Related Content

What's hot

What's hot (20)

CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESS

CHEMICAL AND ELECTRO-CHEMICAL ENERGY BASED PROCESS

Similar to Ultrasonic Machining (USM)

Similar to Ultrasonic Machining (USM) (20)

Advantages and disadvantages of Ultrasonic Machining by Himanshu Vaid

Advantages and disadvantages of Ultrasonic Machining by Himanshu Vaid

Recently uploaded

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Welcome to the April edition of WIPAC Monthly, the magazine brought to you by Water Industry Process Automation & Control.

In this month's edition, along with the latest news from the industry we have articles on:

The use of artificial intelligence and self-service platforms to improve water sustainability

A feature article on measuring wastewater spills

An article on the National Underground Asset Register

Have a good month,

OliverWater Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024Water Industry Process Automation & Control

Recently uploaded (20)

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

Roadmap to Membership of RICS - Pathways and Routes

Roadmap to Membership of RICS - Pathways and Routes

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

Ultrasonic Machining (USM)

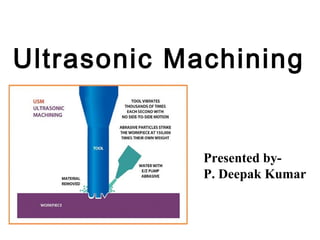

- 1. Ultrasonic Machining Presented by- P. Deepak Kumar

- 2. Contents Introduction Ultrasonic Machine Parts Working Advantages Disadvantages Applications

- 3. Introduction Also Known as Ultrasonic Impact Grinding. Vibrating tool at ultrasonic frequency. Use of abrasive slurry. Very little heat generated.

- 5. Working

- 7. Advantages It can be used machine hard, brittle, fragile and non conductive material. No heat is generated in work, therefore no significant changes in physical structure of work material.

- 8. Non-metal (because of the poor electrical conductivity) that cannot be machined by EDM and ECM can very well be machined by USM. It is burr less and distortion less processes. It can be adopted in conjunction with other new technologies like EDM,ECG,ECM.

- 9. Disadvantages Low Metal removal rate. It is difficult to drill deep holes, as slurry movement is restricted.

- 10. Tool wear rate is high due to abrasive particles. Tools made from brass, tungsten carbide, MS or tool steel will wear from the action of abrasive grit with a ratio that ranges from 1:1 to 200:1. USM can be used only when the hardness of work is more than 45 HRC.

- 11. Applications Machining of cavities in electrically non- conductive ceramics Used to machine fragile components in which otherwise the scrap rate is high Used for multistep processing for fabricating silicon nitride (Si3N4) turbine blades

- 12. Used for machining hard, brittle metallic alloys, semiconductors, glass, ceramics, carbides etc. Used for machining round, square, irregular shaped holes and surface impressions. Used in machining of dies for wire drawing, punching and blanking operations

- 13. USM has been used for piercing of dies and for parting off and blanking operations. USM enables a dentist to drill a hole of any shape on teeth without any pain. Ferrites and steel parts , precision mineral stones can be machined using USM

- 14. USM can be used to cut industrial diamonds USM is used for grinding Quartz, Glass, ceramics Cutting holes with curved or spiral centre lines and cutting threads in glass and mineral or metallo-ceramics

- 15. USM can perform machining operations like drilling, grinding and milling operations on all materials which can be treated suitably with abrasives. Large number of holes of small diameter. 930 holes with 0.32mm has been reported (Benedict, 1973) using hypodermic needles.

- 16. Thank you

Editor's Notes

- Ultrasonic machining, also known as ultrasonic impact grinding, is a machining operation in which a vibrating tool oscillating at ultrasonic frequencies is used to remove material from the workpiece, aided by an abrasive slurry that flows freely between the workpiece and the tool. It differs from most other machining operations because very little heat is produced. The tool never contacts the workpiece and as a result the grinding pressure is rarely more than 2 pounds,which makes this operation perfect for machining extremely hard and brittle materials, such as glass, sapphire, ruby, diamond, and ceramics.

- In ultrasonic machining, tool of desired shape vibrates at ultrasonic frequency ( 19 to 25 kHz. ) with an amplitude of 15-50 Microns over work piece. Generally tool is pressed down with a feed force F. Between the tool and work, machining zone is flooded with hard abrasive particles generally in the form of water based slurry. As the tool vibrates over the work piece, abrasive particles acts as indenter and indent both work and tool material . Abrasive particles , as they indent , the work material would remove the material from both tool and work piece. In Ultrasonic machining material removal is due to crack initiation, propagation and brittle fracture of material. USM is used for machining hard and brittle materials, which are poor conductors of electricity and thus cannot be processed by Electrochemical machining ( ECM) or Electro discharge machining (EDM). The tool in USM is made to vibrate with high frequency on to the work surface in the midst of the flowing slurry. The main reason for using ultrasonic frequency is to provide better performance. Audible frequencies of required intensities would be heard as extremely loud sound and would cause fatigue and even permanent damage to the auditory apparatus.