Report

Share

Download to read offline

Recommended

(http://www.professionaltechnicalservices.in) We are the leading service provider of Epoxy Flooring Service, Epoxy Coating Service, Epoxy Painting Service, Epoxy Coving Service etc.Industrial Coating & Flooring By Professional Technical Services Private Limited

Industrial Coating & Flooring By Professional Technical Services Private LimitedIndiaMART InterMESH Limited

EMSEAL expansion joints, precompressed sealants, and expansion joint covers have set the standard for durability and performance in structural expansion joint applications in the construction industry. Watertight, fire-rated, traffic durable, acoustic dampening, and high movement capable.Emseal expansion joint and precompressed sealant catalog for architecture and...

Emseal expansion joint and precompressed sealant catalog for architecture and...EMSEAL Joint Systems, Ltd.

Recommended

(http://www.professionaltechnicalservices.in) We are the leading service provider of Epoxy Flooring Service, Epoxy Coating Service, Epoxy Painting Service, Epoxy Coving Service etc.Industrial Coating & Flooring By Professional Technical Services Private Limited

Industrial Coating & Flooring By Professional Technical Services Private LimitedIndiaMART InterMESH Limited

EMSEAL expansion joints, precompressed sealants, and expansion joint covers have set the standard for durability and performance in structural expansion joint applications in the construction industry. Watertight, fire-rated, traffic durable, acoustic dampening, and high movement capable.Emseal expansion joint and precompressed sealant catalog for architecture and...

Emseal expansion joint and precompressed sealant catalog for architecture and...EMSEAL Joint Systems, Ltd.

More Related Content

What's hot

What's hot (20)

Proteck Anti - Corrosives, Vadodara, Acid Resistance Lining

Proteck Anti - Corrosives, Vadodara, Acid Resistance Lining

Latest aluminium innovations to meet passenger vehicle lightweight needs

Latest aluminium innovations to meet passenger vehicle lightweight needs

Aluminum in Body-in-White Design - Light Metal Age article, October 2015

Aluminum in Body-in-White Design - Light Metal Age article, October 2015

Viewers also liked

Viewers also liked (20)

Sarus Exchange Program 2011 - Seminar 2 In Cambodia

Sarus Exchange Program 2011 - Seminar 2 In Cambodia

How a library_visit_differentiates_your_brand_sxsw2105_jenessacarder_sapeient

How a library_visit_differentiates_your_brand_sxsw2105_jenessacarder_sapeient

Similar to Industrial flooring

Similar to Industrial flooring (20)

Gubbi Civil Engineers, Leading Structural Repairs Company in Dubai.pdf

Gubbi Civil Engineers, Leading Structural Repairs Company in Dubai.pdf

Colorex SD - EC Kondaktif PVC Zemin Kaplama - Anıl Zemin Market

Colorex SD - EC Kondaktif PVC Zemin Kaplama - Anıl Zemin Market

Aerocon Panels: An Alternative Building Walling Solution for the Modern Age

Aerocon Panels: An Alternative Building Walling Solution for the Modern Age

Aerocon Panels | Aerocon Blocks | Aadam Enterprises

Aerocon Panels | Aerocon Blocks | Aadam Enterprises

Bonding solutions for railway industry - Market brochure

Bonding solutions for railway industry - Market brochure

More from Rana Imran

More from Rana Imran (17)

Recently uploaded

Falcon stands out as a top-tier P2P Invoice Discounting platform in India, bridging esteemed blue-chip companies and eager investors. Our goal is to transform the investment landscape in India by establishing a comprehensive destination for borrowers and investors with diverse profiles and needs, all while minimizing risk. What sets Falcon apart is the elimination of intermediaries such as commercial banks and depository institutions, allowing investors to enjoy higher yields.Falcon Invoice Discounting: The best investment platform in india for investors

Falcon Invoice Discounting: The best investment platform in india for investorsFalcon Invoice Discounting

Recently uploaded (20)

Call Girls Hebbal Just Call 👗 7737669865 👗 Top Class Call Girl Service Bangalore

Call Girls Hebbal Just Call 👗 7737669865 👗 Top Class Call Girl Service Bangalore

Call Girls In Panjim North Goa 9971646499 Genuine Service

Call Girls In Panjim North Goa 9971646499 Genuine Service

Call Girls Electronic City Just Call 👗 7737669865 👗 Top Class Call Girl Servi...

Call Girls Electronic City Just Call 👗 7737669865 👗 Top Class Call Girl Servi...

Insurers' journeys to build a mastery in the IoT usage

Insurers' journeys to build a mastery in the IoT usage

How to Get Started in Social Media for Art League City

How to Get Started in Social Media for Art League City

Value Proposition canvas- Customer needs and pains

Value Proposition canvas- Customer needs and pains

Call Girls Jp Nagar Just Call 👗 7737669865 👗 Top Class Call Girl Service Bang...

Call Girls Jp Nagar Just Call 👗 7737669865 👗 Top Class Call Girl Service Bang...

Mysore Call Girls 8617370543 WhatsApp Number 24x7 Best Services

Mysore Call Girls 8617370543 WhatsApp Number 24x7 Best Services

Chandigarh Escorts Service 📞8868886958📞 Just📲 Call Nihal Chandigarh Call Girl...

Chandigarh Escorts Service 📞8868886958📞 Just📲 Call Nihal Chandigarh Call Girl...

Call Girls Kengeri Satellite Town Just Call 👗 7737669865 👗 Top Class Call Gir...

Call Girls Kengeri Satellite Town Just Call 👗 7737669865 👗 Top Class Call Gir...

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Eluru Call Girls Service ☎ ️93326-06886 ❤️🔥 Enjoy 24/7 Escort Service

Eluru Call Girls Service ☎ ️93326-06886 ❤️🔥 Enjoy 24/7 Escort Service

The Path to Product Excellence: Avoiding Common Pitfalls and Enhancing Commun...

The Path to Product Excellence: Avoiding Common Pitfalls and Enhancing Commun...

Call Girls From Pari Chowk Greater Noida ❤️8448577510 ⊹Best Escorts Service I...

Call Girls From Pari Chowk Greater Noida ❤️8448577510 ⊹Best Escorts Service I...

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

B.COM Unit – 4 ( CORPORATE SOCIAL RESPONSIBILITY ( CSR ).pptx

Russian Call Girls In Gurgaon ❤️8448577510 ⊹Best Escorts Service In 24/7 Delh...

Russian Call Girls In Gurgaon ❤️8448577510 ⊹Best Escorts Service In 24/7 Delh...

Falcon Invoice Discounting: The best investment platform in india for investors

Falcon Invoice Discounting: The best investment platform in india for investors

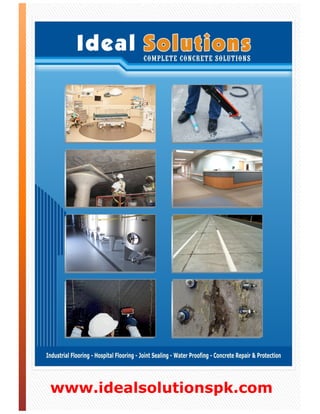

Industrial flooring

- 2. “INDUSTRIAL FLOORING” Floors in industry and commerce are not just parts of a structure. Industrial floors are heavily exposed to stress. Many production processes and procedures take place on these floors. They are also exposed to industrial chemicals. On top of this, industrial floors also have to meet a variety of operational requirements. Slip resistance, crack bridging, non-flammability, conductivity, aesthetics, ease of maintenance, and, last but not least, long life – these are just a few examples of the expectations for functional industrial floors. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING IDEAL SOLUTIONS

- 3. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING IDEAL SOLUTIONS

- 4. CONCEPT Every industrial floor consist of two elements; Element 1, the base course, which always consists of the structural reinforced concrete slab. The purpose of this “load-bearing” course is to absorb or distribute static and dynamic loads. Element 2, the wearing course is the dominant part. The wearing course protects the floor from physical and/or chemical attack. The wearing course also has to meet the individual operational demands. Each element has its function, which is precisely defined. An industrial Floor can not be high – quality unless both the base course and the wearing course meet all of the requirements. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING IDEAL SOLUTIONS

- 5. Two factors are particularly important in the construction or design of a high quality yet economic industrial floor: - The Operational Requirements - The Selection, Analysis And Preparation Of A Suitable Substrate. To select the right coating system, both must be examined in detail and coordinated. This is the only way to ensure that the industrial flooring meets the requirements of the project – cost effective and just right for the application. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING IDEAL SOLUTIONS

- 6. OPERATIONAL REQUIREMENTS The application and the severity of the operational requirements can vary widely. Below are a few examples of typical exposures; 1.Mechanical Exposure From: Pedestrian and/or vehicular traffic, Low and light lift trucks, Transport containers, such as pallets, steel mesh boxes, containers, drums, reel holders etc., Weight of tools / products /machines, Abrasion, shock and impact (broken glass etc.) CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING IDEAL SOLUTIONS

- 7. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING 2. Chemical Attack From: Oil, greases, Soluble salts, Alkalis, acids, Fuels, solvent, Cleaning agents etc 3. Thermal Stress From: -Heat: Short term by steam cleaning etc, Long term in specific production areas. - Cold: Short term by shock, open doors, etc, Long term in specific production areas, cold storage etc. 4.Weathering, Mainly On External Sunlight, UV, Frost, thermal shock, Rain 5.Aesthetics Colour, design/coding, Coloured chips, Gloss/ Matt IDEAL SOLUTIONS

- 8. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING 6.SurfaceTexture - Smooth, Textured 7. Safety Slip resistant, Electrically insulating, conductive, Crack- bridging, Waterproof, Non- flammable, Decontaminable, Colour stable, Low – odour, environmentally friendly, solvent free 8. Care And Maintenance: Easy to clean, Easy to repair, Overcoat able 9. Comfort Insulating effect (warm), Dampening effect, Sound deadening IDEAL SOLUTIONS

- 9. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING IDEAL SOLUTIONS

- 10. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING Selection, Analysis And Preparation Of A Suitable Substrate The second and equally important factor in selection of a suitable wearing course is the type of substrate and its condition. Any wearing course can only be as good as its base. If the load- bearing course or substrate is defective even the best and most expensive wearing course cannot improve it. IDEAL SOLUTIONS

- 11. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING 1.Base Courses/ Substrates - Concrete - Cement/granolithic screed/overlay - anhydrite screed - Magnesite screed - poured asphalt - old coatings - Ceramic tiles - Timber boards - Steel 2.Location Of The Substrate - Internal areas - External exposed - On garde /no d.p.m - Risk of rising damp - without insulation IDEAL SOLUTIONS

- 12. CONCRETE REPAIR EPOXY FLOORING WATERPROOFING JOINT SEALING 3. Substrate Condition - Age (new or old), Moisture content, - surface profile - Density - Porosity - Brittle - Dehydrated - Physical strength - Compressive - Pull-off - surface harness 4. Contamination - Dust, laitance - Oils, greases - Acids, alkalis - Paints, plastics - Fuels, solvents 5. Damages - Shrinkage, isolation or settlement cracks - Sapling, voids - Roughness, erosion - Joint damage, broken arises IDEAL SOLUTIONS