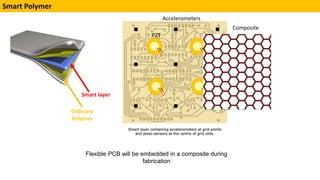

This document describes using both active and passive sensors for structural health monitoring. Passive accelerometers continuously collect data and trigger active piezo sensors when vibrations are detected. The piezo sensors then generate and receive guided waves to be analyzed for changes in travel time that could indicate damage. Both sensor types are embedded in a flexible PCB and smart polymer composite to monitor the structure. The goal is to detect potential failures by monitoring variations in wave travel times before damage occurs.