sheet-metal.ppt

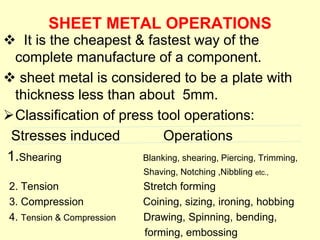

- 1. SHEET METAL OPERATIONS It is the cheapest & fastest way of the complete manufacture of a component. sheet metal is considered to be a plate with thickness less than about 5mm. Classification of press tool operations: Stresses induced Operations 1.Shearing Blanking, shearing, Piercing, Trimming, Shaving, Notching ,Nibbling etc., 2. Tension Stretch forming 3. Compression Coining, sizing, ironing, hobbing 4. Tension & Compression Drawing, Spinning, bending, forming, embossing

- 2. SHEET METAL WORKING • In this simply metal formed into thin and flat pieces. • It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. • Countless everyday objects are constructed of the material • Low cost parts with very high rates at faster rates. • Thicknesses can vary significantly, although extremely thin thicknesses are considered foil or leaf, and pieces thicker than 5 mm (0.25 in) are considered.

- 4. • Sheet metal is available in flat pieces or as a coiled strip. • The coils are formed by running a continuous sheet of metal through a roll slitter. • The thickness of the sheet metal is called its gauge. • The gauge of sheet metal ranges from 30 gauge to about 8 gauge. • Different metals that can be made into sheet metal, such as aluminum, brass, copper, steel, tin, nickel and titani um.

- 5. • For decorative uses, important sheet metals include silver, gold, and platinum • Sheet metal has applications in car bodies, airplane wings, medical tables, roofs for buildings and many other things.

- 6. Sheet Metal Forming processes • Shearing processes -- processes which apply shearing forces to cut, fracture, or separate the material. • Forming processes -- processes which cause the metal to undergo desired shape changes without failure, excessive thinning, or cracking. This includes bending and stretching. • Finishing processes -- processes which are used to improve the final surface characteristics.

- 7. SHEARING • It is a cutting operation used to remove a blank of required dimensions from a large sheet. To understand the shearing mechanism, consider a metal being sheared between a punch and a die, Fig.

- 9. • Shearing starts as the punch presses against the sheet metal. • At first, cracks form in the sheet on both the top and bottom edges (marked T and T', in the figure). • As the punch descends further, these cracks grow and eventually meet each other and the slug separates from the sheet. • A close look at the fractured surfaces will reveal that these are quite rough and shiny.

- 10. • Major processing parameters in shearing are shape and materials for punch and die, speed of punching, lubrication, clearance between punch and die . • The clearance between the punch and the die plays an important role in the determination of the shape and quality of the sheared edge. • There is an optimum range for the clearance, which is 2 to 10% of the sheet thickness, for the best results.

- 11. Cutting (Shearing) Operations • In this operation, the work piece is stressed beyond its ultimate strength. • The stresses caused in the metal by the applied forces will be shearing stresses. The cutting operations include: Punching (Piercing) Blanking Notching Perforating Parting Lancing Slitting Shaving Trimming Fine blanking

- 12. PUNCHING & BLANKING • It is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal. • If the small removed piece is discarded, the operation is called punching(or Piercing), whereas if the small removed piece is the useful part and the rest is scrap, the operation is called blanking.

- 13. Metal around the part is removed. Metal inside the part is removed

- 15. NOTCHING: • This is cutting operation by which metal pieces are cut from the edge of a sheet, strip or blank. PERFORATING: • This is a process by which multiple holes which are very small and close together are cut in flat work material. PARTING: • Parting involves cutting a sheet metal strip by a punch with two cutting edges that match the opposite sides of the blank. or shearing sheet in to 2/ more pieces.

- 17. LANCING: • This is a cutting operation in which a hole is partially cut and then one side is bent down to form a sort of tab. • Since no metal is actually removed, there will be no scrap SHAVING: • The edge of blanked parts is generally rough, uneven and unsquare. • Accurate dimensions of the part are obtained by removing a thin strip of metal along the edges. • For close tolerance work, the blanking or piercing is followed by shaving which removes the burr left on the product.

- 19. TRIMMING: • This operation consists of cutting unwanted excess material from the periphery of previously formed components. • The flash has to be trimmed before the casting or forging is to be used. (In operations such as drop forging & die casting, a small amount of extra metal gets spread out near the parting plane,which is termed as flash

- 20. Nibbling: • It is a method to cut a specified small portion of metal towards the edge of the stock.

- 21. SPINNING BENDING STRETCH FORMING EMBOSSING & COINING

- 22. Shaping Operations In shaping operations the metal is deformed into required shapes by punch & die. In forming, the metal is deformed or bent along a curved axis. Various forming operations are: 1. Embossing 2. Coining 3. Spinning 4. Swaging 1. EMBOSSING: It is a shallow forming operation which uses a matched punch & die. The thickness of work piece is uniform, and is intended for duplicating of the pattern on either sides of the sheet metal. It is used for decorative sheet work and to obtain the impressions of desired form.

- 23. 2. COINING: Coining is squeezing operation in which the metal flows into the cavity between the punch & die. It is employed for making coins, medals and similar articles.

- 24. 3. SPINNING: It is the process of shaping thin sheet of metal(blank) by pressing against a rotating former. The blank is held between former and adopter. The blank rotates with former. A specially shaped tool is then pressed against the blank and slowly moved to cover the former. Deformation of the metal during spinning is due to combined effect of bending & stretching, and the process is suitable for shaping ductile metals and alloys such as aluminum, copper, brass and mild steel. This process is extensively adopted to produce lamp reflectors, cooking utensils, funnels and containers used in chemical plants. For thick sheets, spinning is carried out at forging temperature and is referred as ‘Hot spinning’

- 26. Fig. (a) Schematic illustration of the conventional spinning process (b) Types of parts conventionally spun. All parts are antisymmetric

- 27. Stretch forming Sheet metal clamped along its edges and stretched over a die or form block in required directions. Loading Pre-Stretching Wrapping Release

- 28. Stretch forming Stretch forming or stretch draw forming is the process of producing contoured parts. In stretch forming, the sheet metal is clamped between jaws and stretched beyond the elastic limit. Then the die is forced against the sheet metal that is firmly held by the clamps. In another method , the die is stationary and sheet metal is stretched(pulled) over the die. 1. It is not suitable for complicated shapes. 2. It uses single die and is simple and inexpensive. 3. The properties of metals are generally improved by stretch forming. 4. This process used to produce aircraft parts and contour panels for bus bodies.