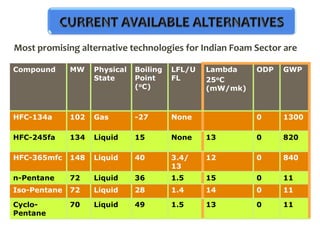

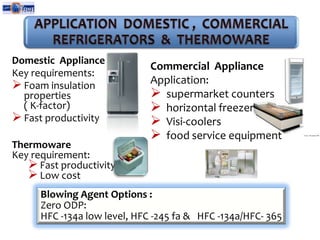

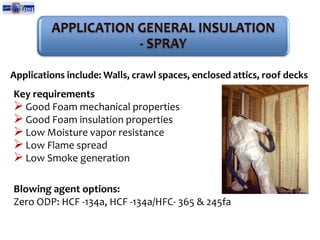

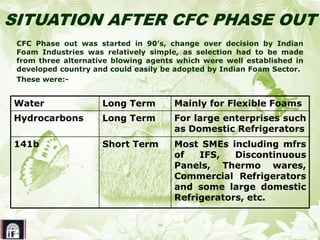

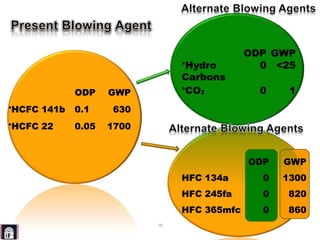

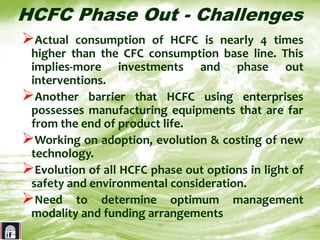

This document summarizes the challenges facing the Indian foam sector in phasing out HCFCs. It notes that India has over 450 small and medium foam enterprises that currently use HCFCs as blowing agents. Transitioning to alternatives will be difficult as there are no proven low-GWP options available yet that can meet the needs of the SME sector. The document proposes a staged approach, including continuing to use reduced levels of HCFC-141b by mixing it with other agents. It emphasizes that the chosen alternatives must consider safety, energy efficiency, and be suitable for smaller companies.