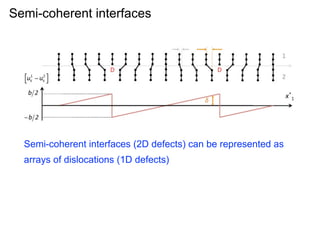

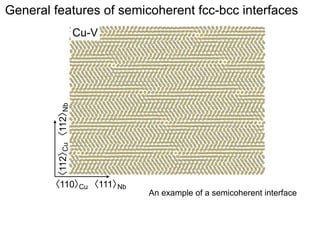

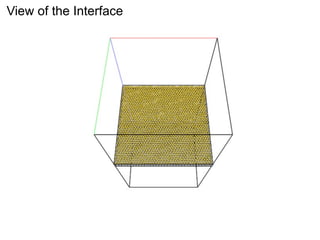

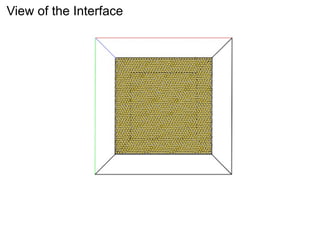

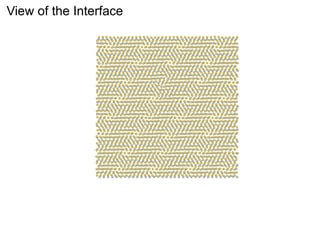

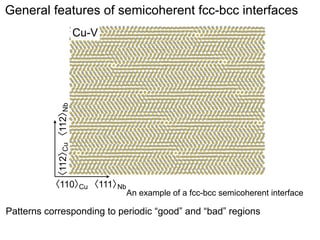

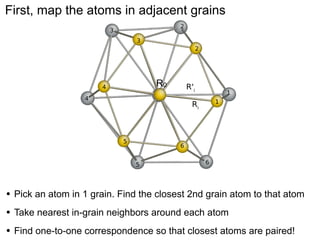

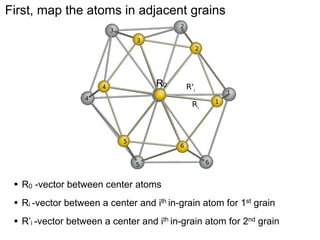

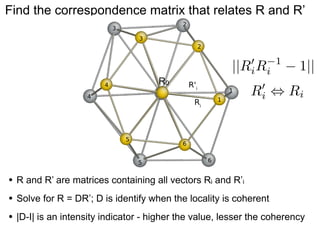

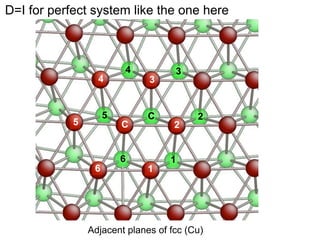

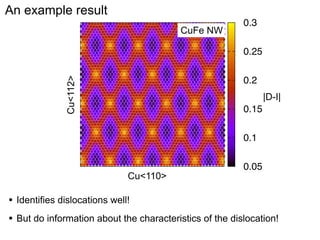

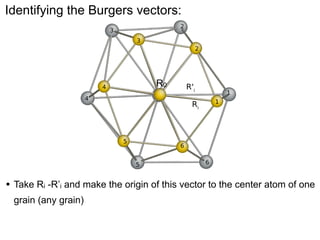

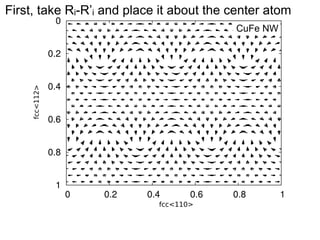

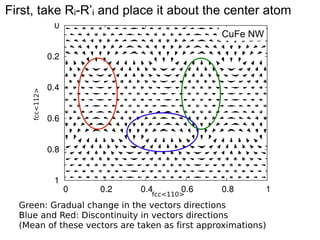

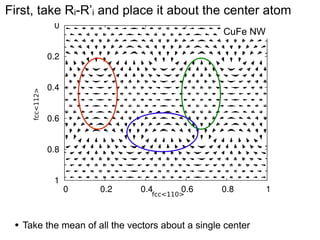

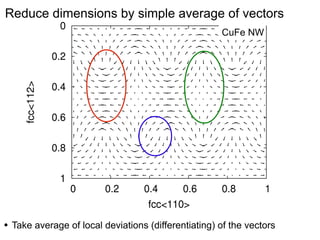

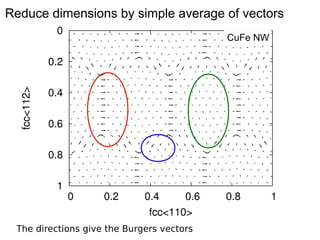

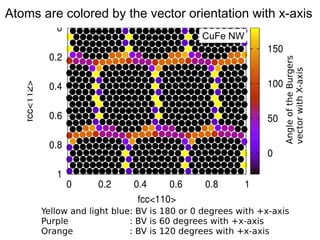

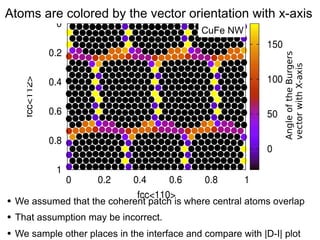

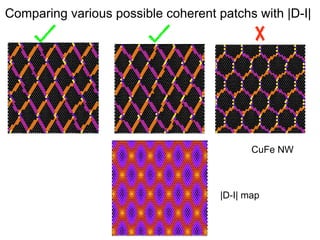

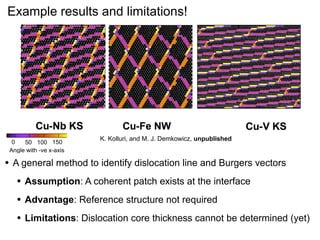

This document presents a new method for characterizing misfit dislocations at interfaces without requiring a reference structure. The method maps atoms in adjacent grains and computes vectors between closest atom pairs to identify coherent and incoherent regions. Taking the difference between these vectors approximates Burgers vectors of misfit dislocations. The method was demonstrated on a Cu-Fe nanowire interface, identifying multiple dislocation Burgers vectors that agreed with prior characterization. However, limitations include inability to determine dislocation core thickness.