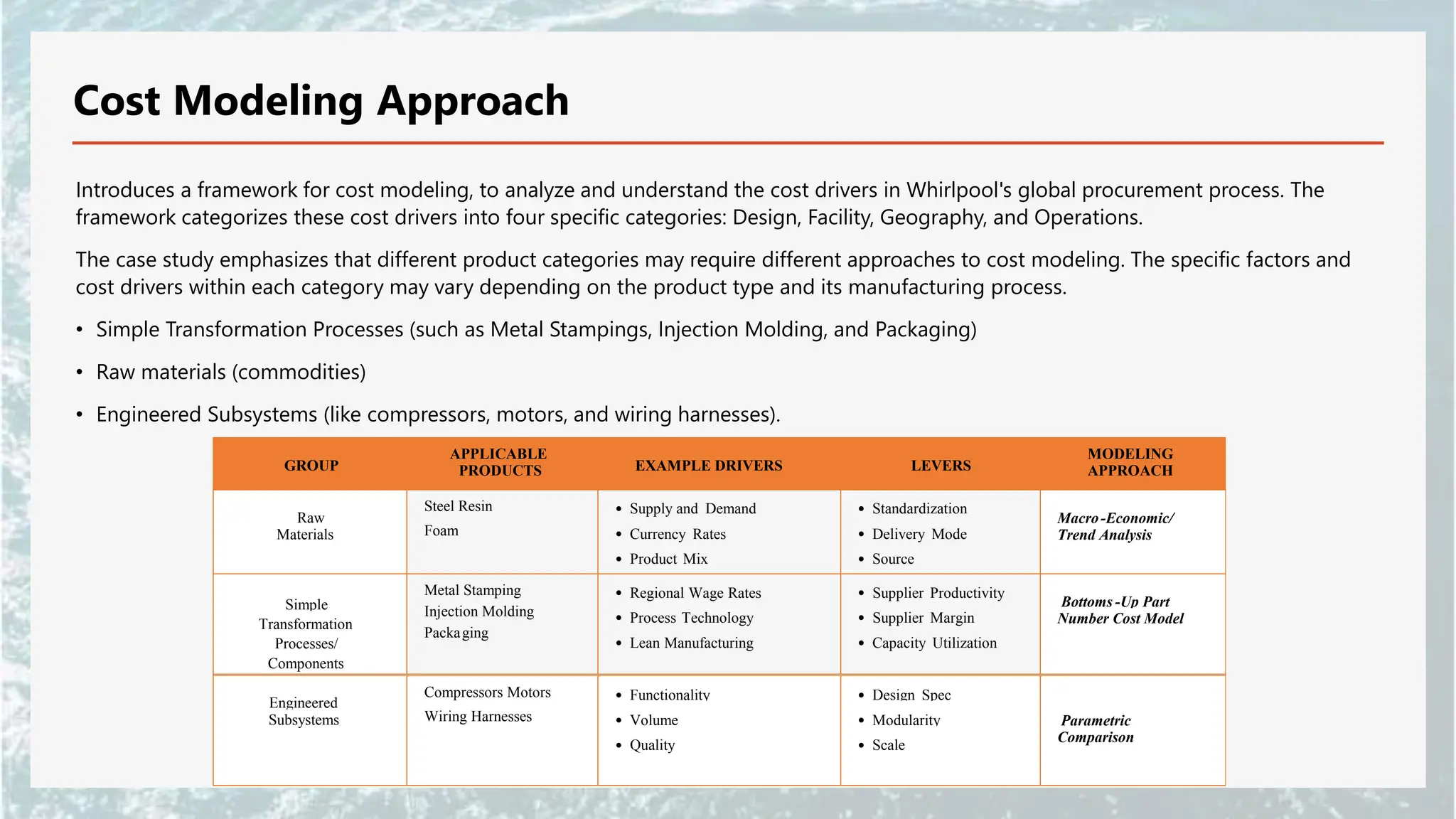

The document discusses cost modeling approaches for analyzing cost drivers in Whirlpool Corporation's global procurement process. It introduces a framework that categorizes cost drivers into design, facility, geography, and operations. These categories and their factors may vary depending on the product type and manufacturing process. The case study emphasizes selecting the appropriate cost modeling technique based on the product, such as bottom-up modeling for simple components or parametric comparison for complex subsystems. It also provides examples of analyzing injection molded plastic parts and compressors to identify regional cost differences.